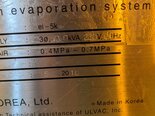

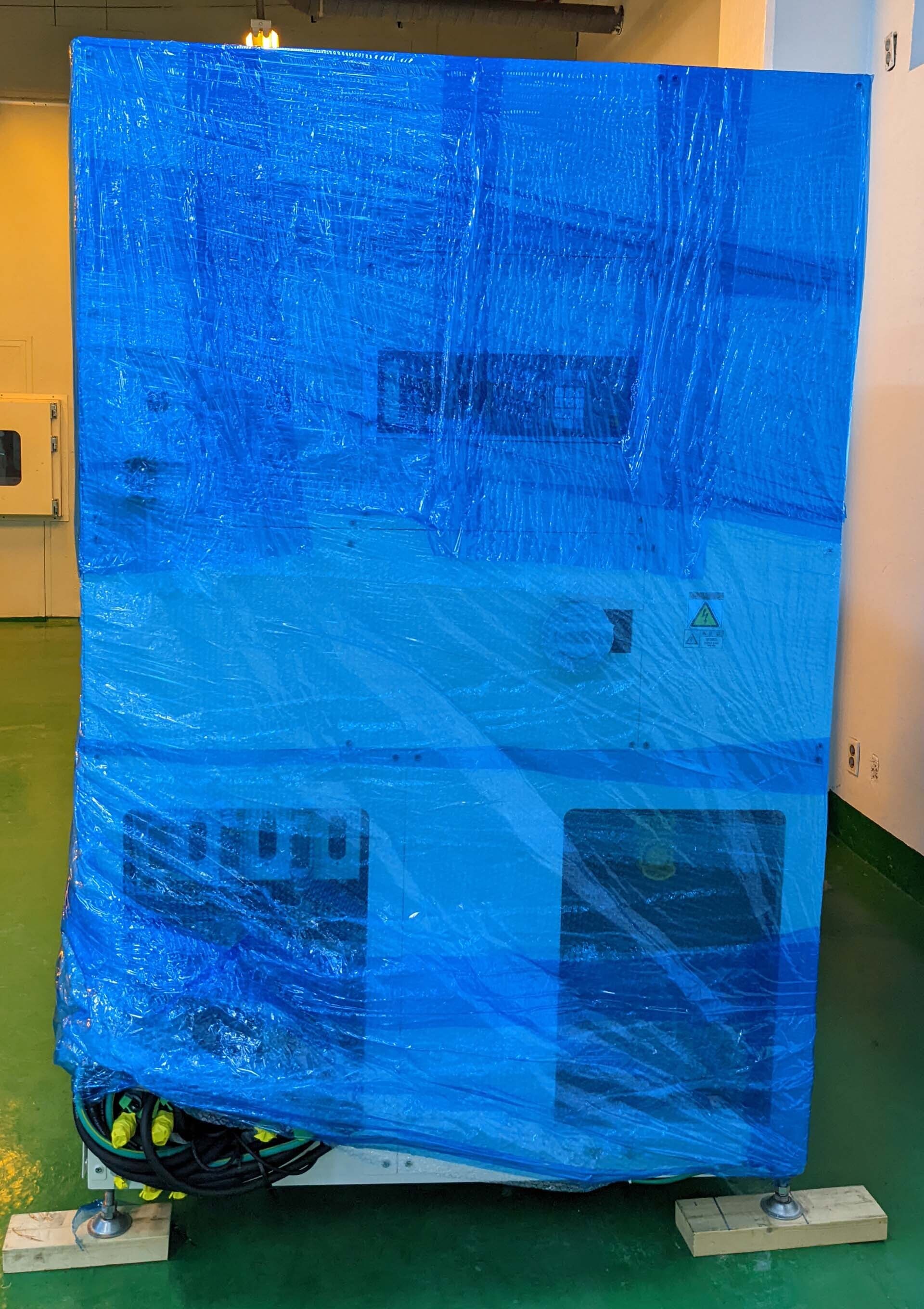

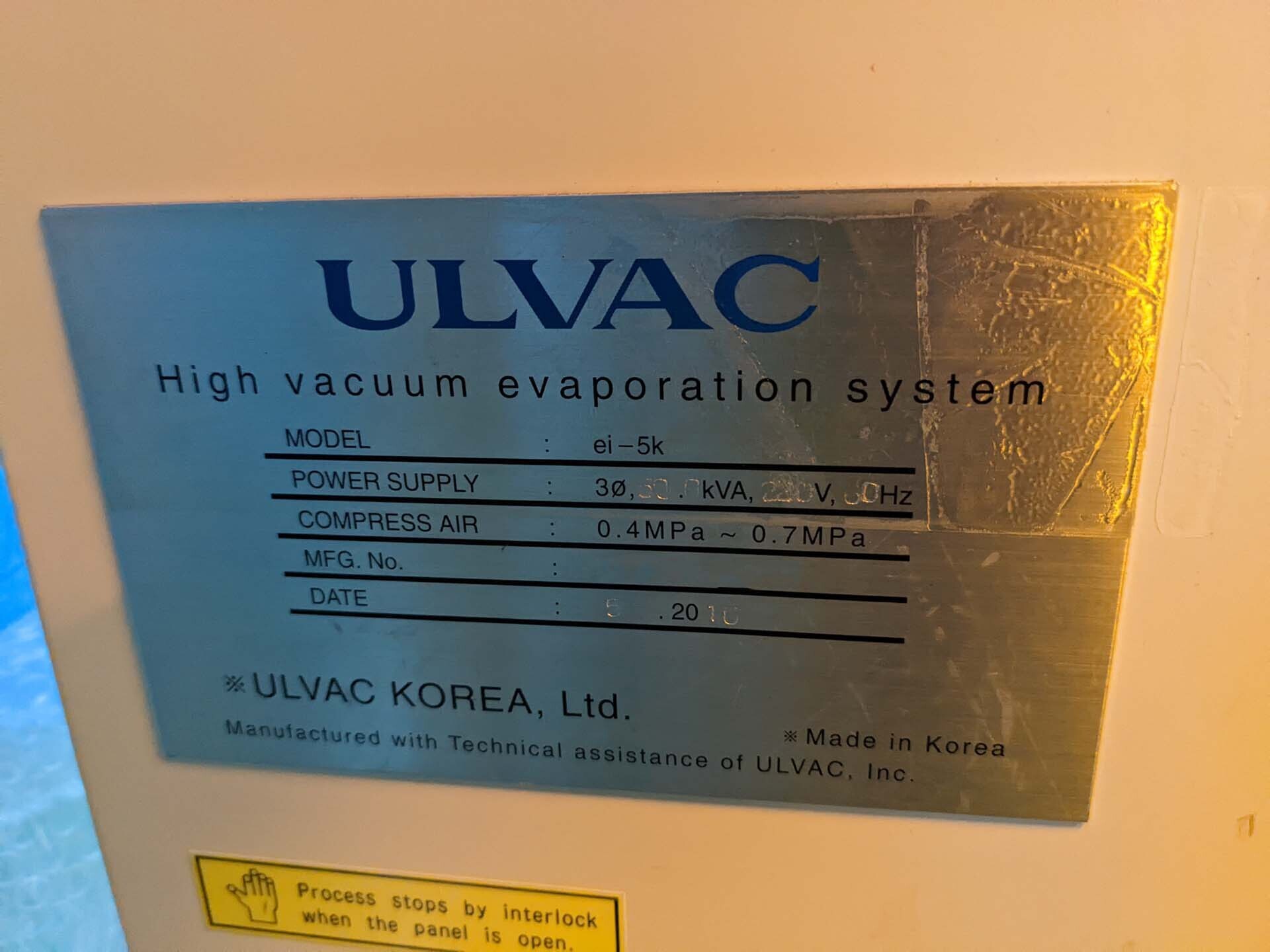

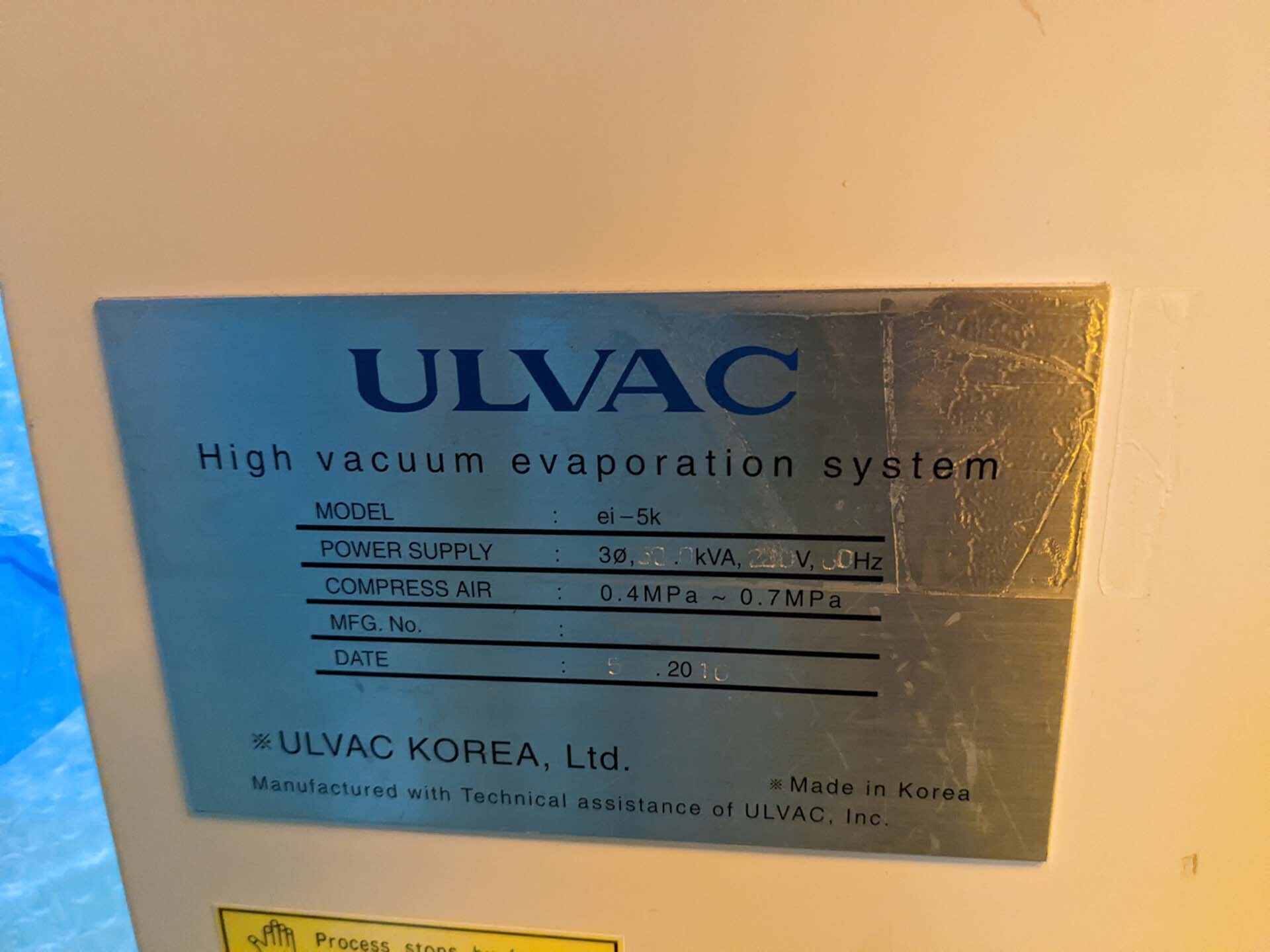

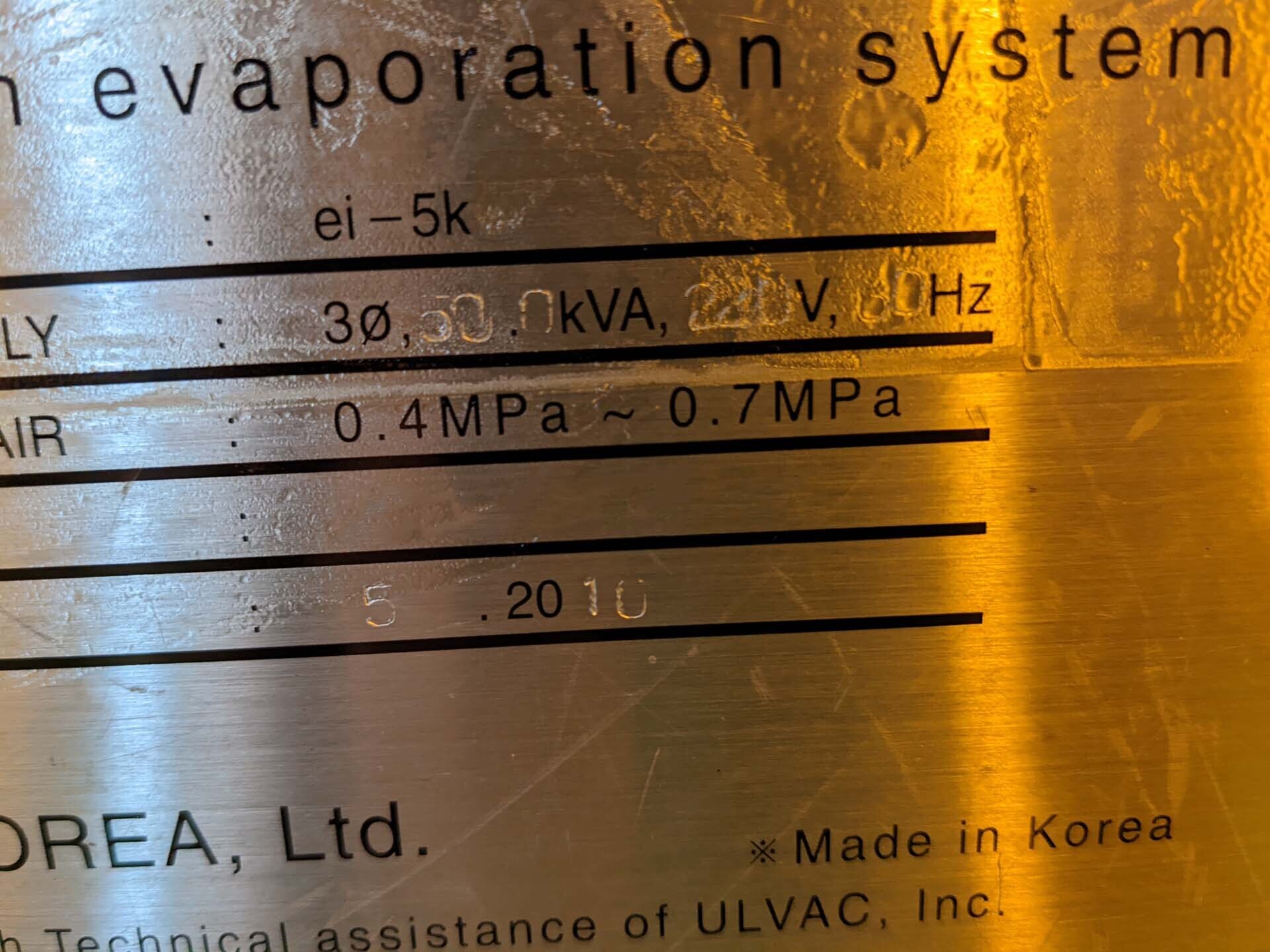

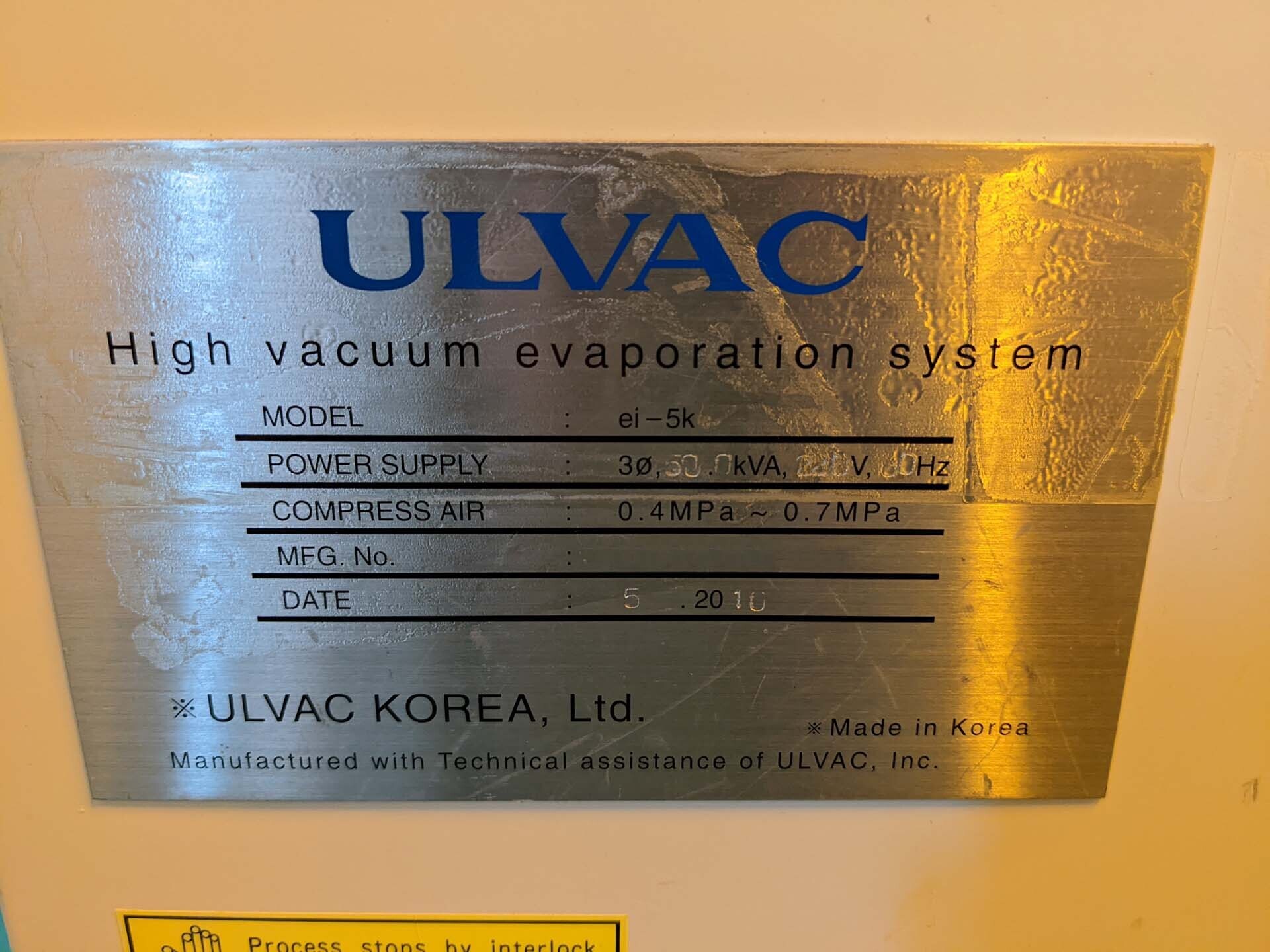

Used ULVAC Ei-5K #293603133 for sale

URL successfully copied!

Tap to zoom

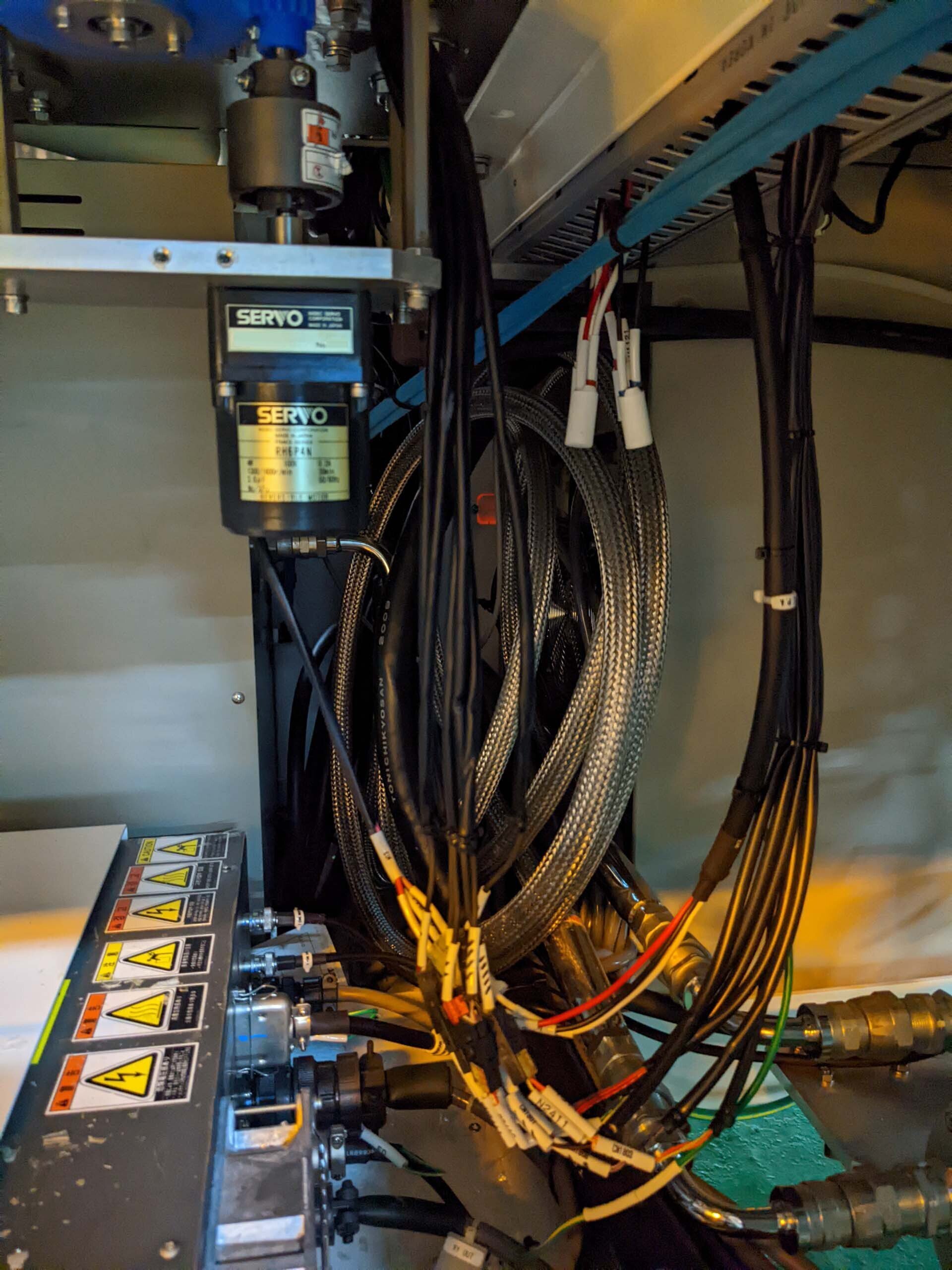

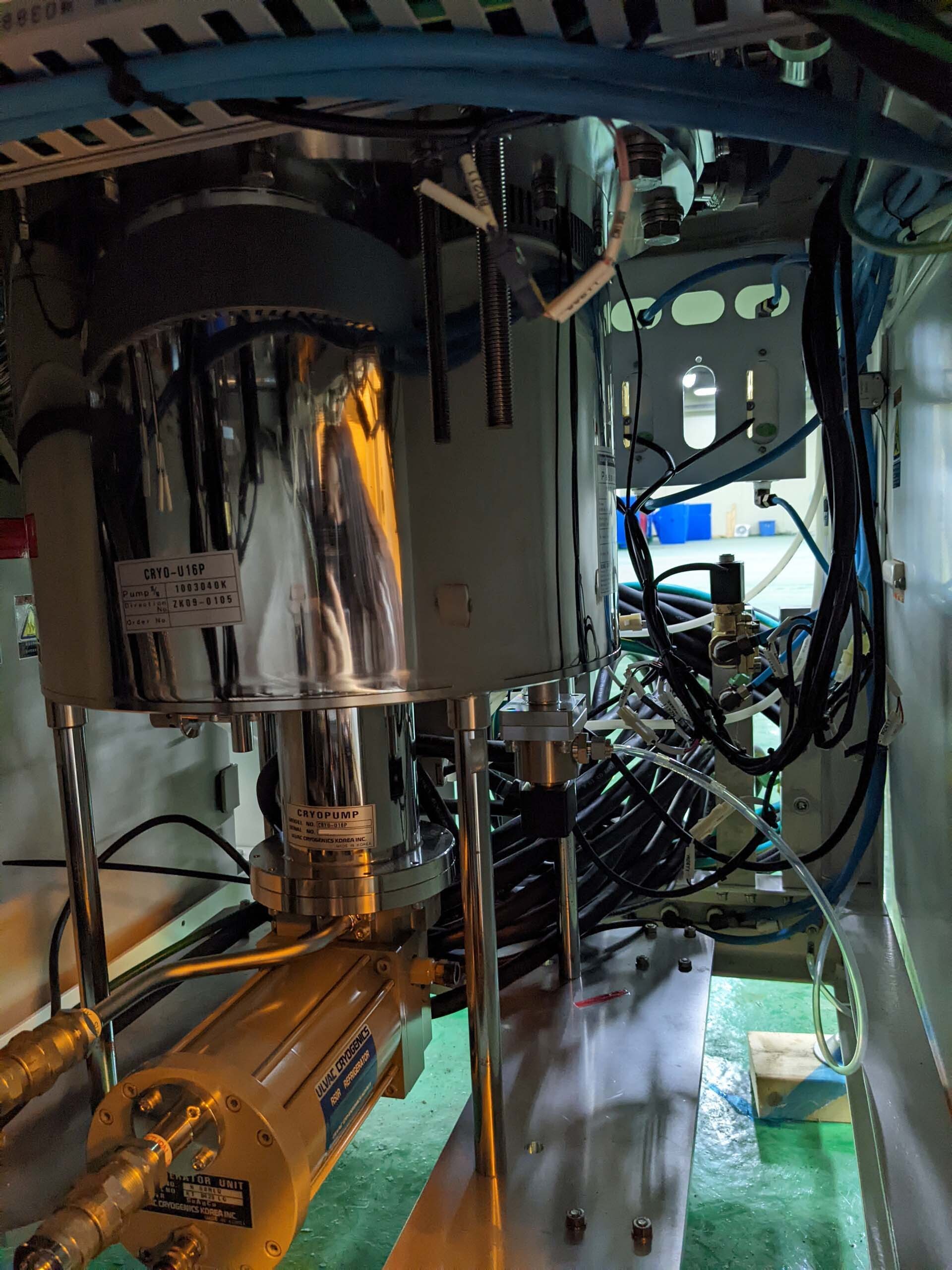

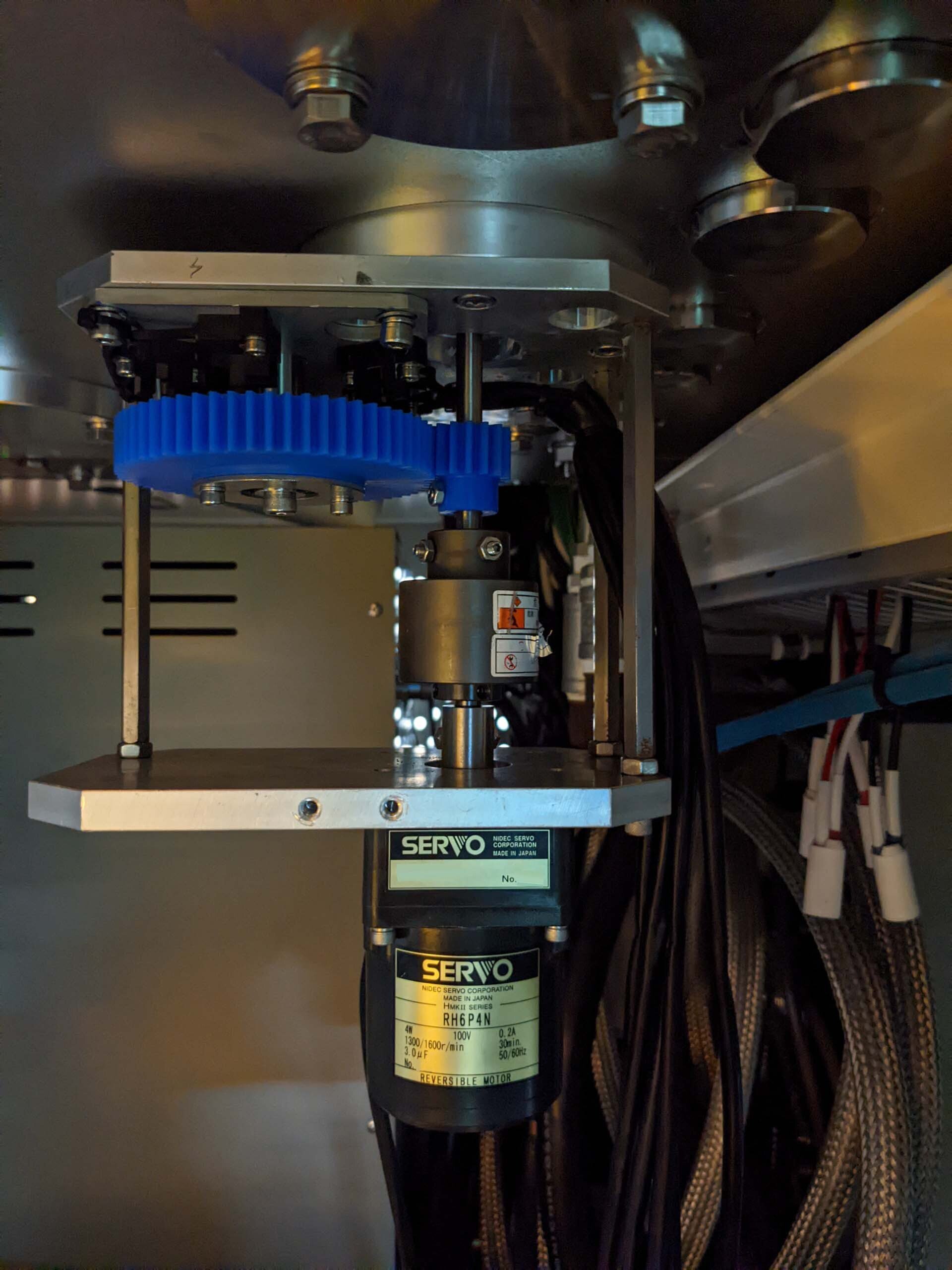

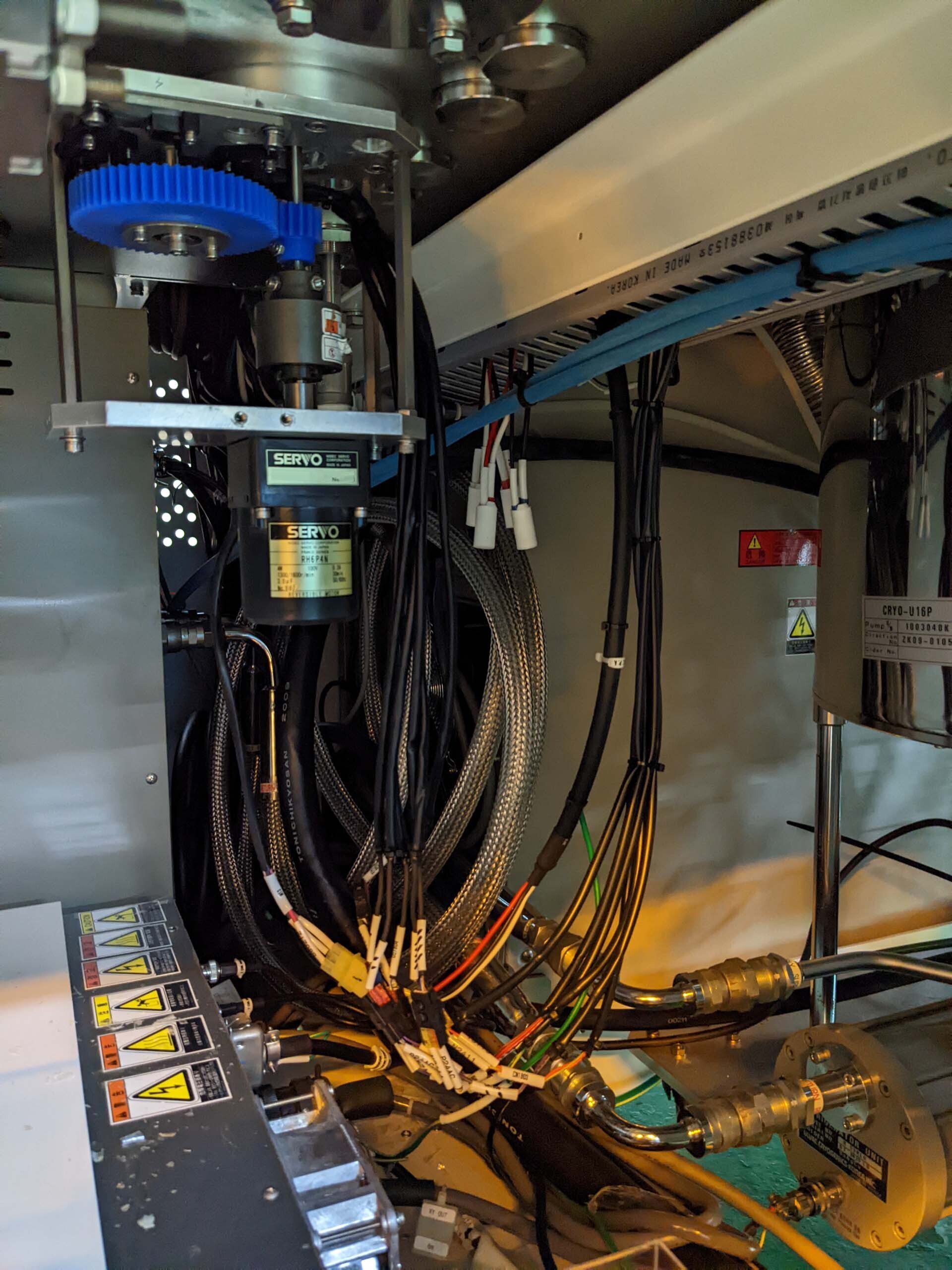

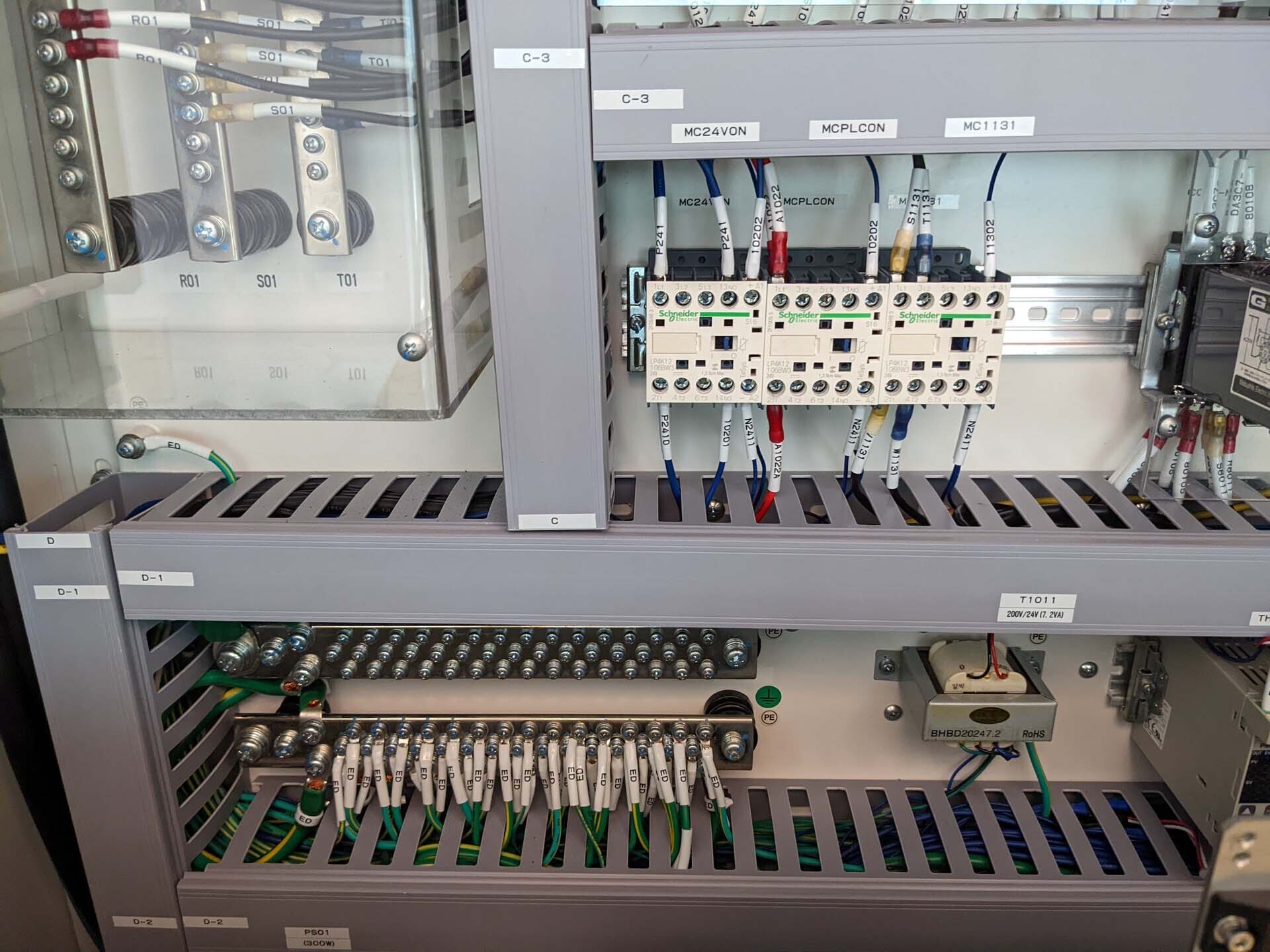

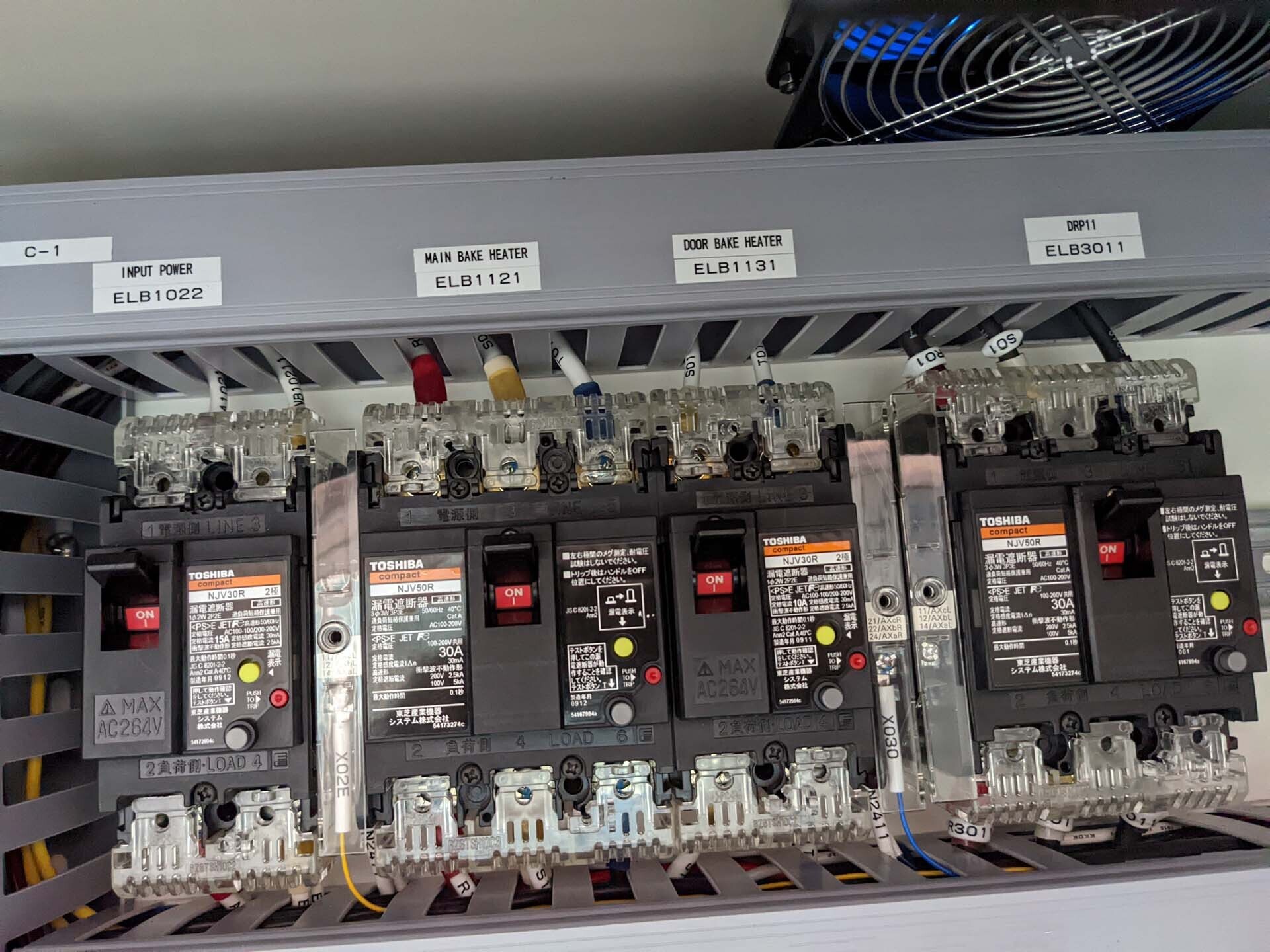

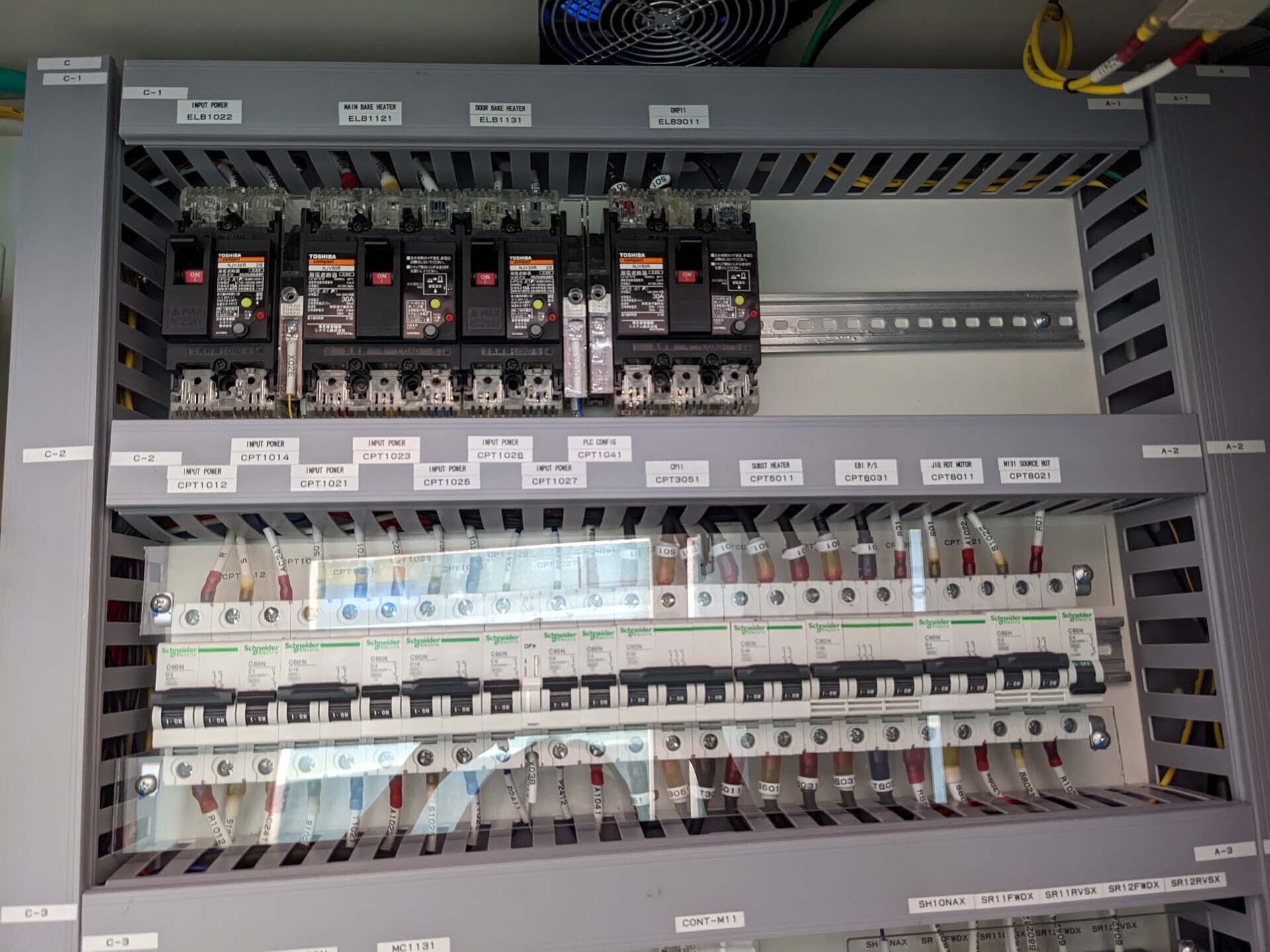

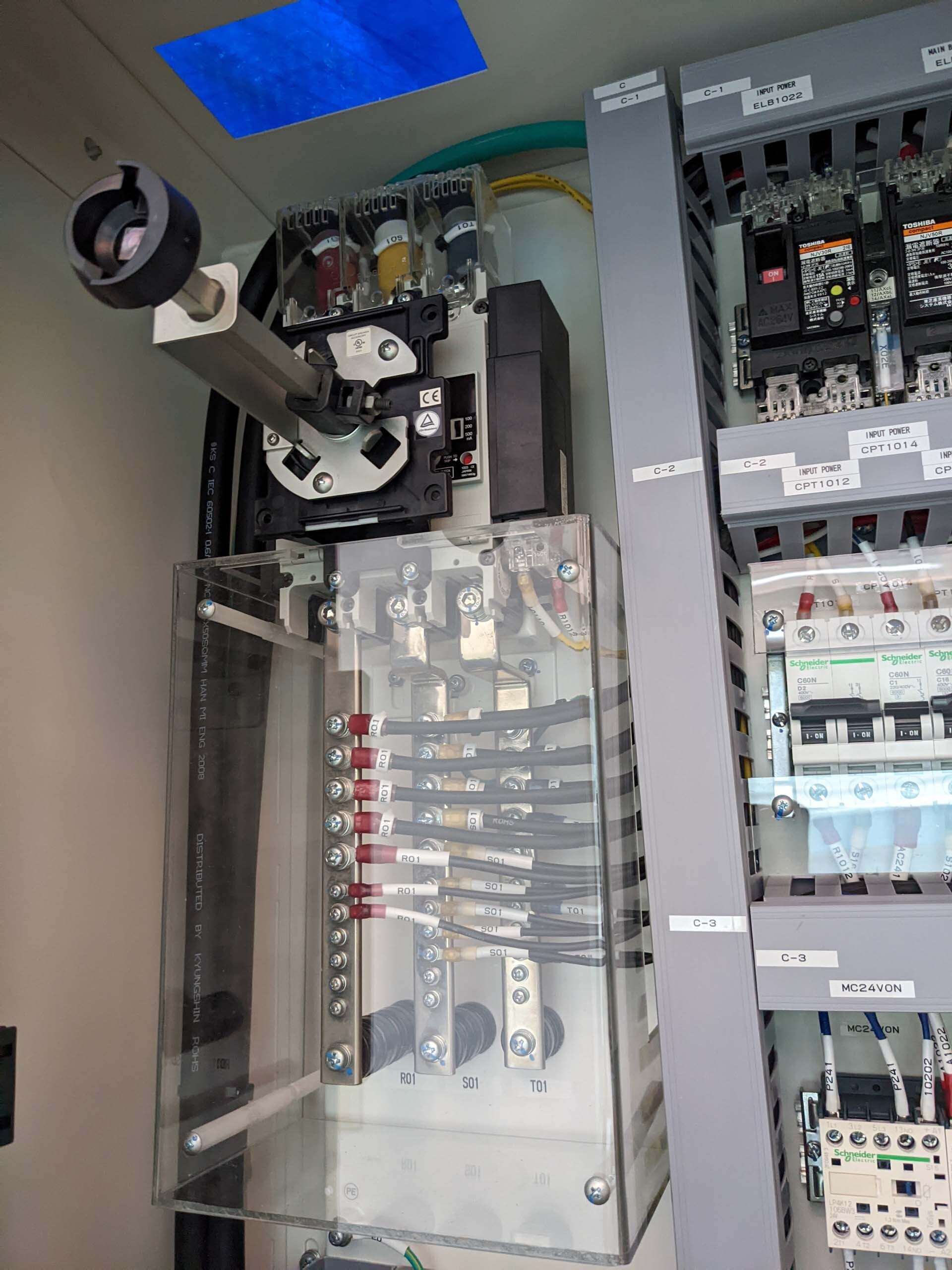

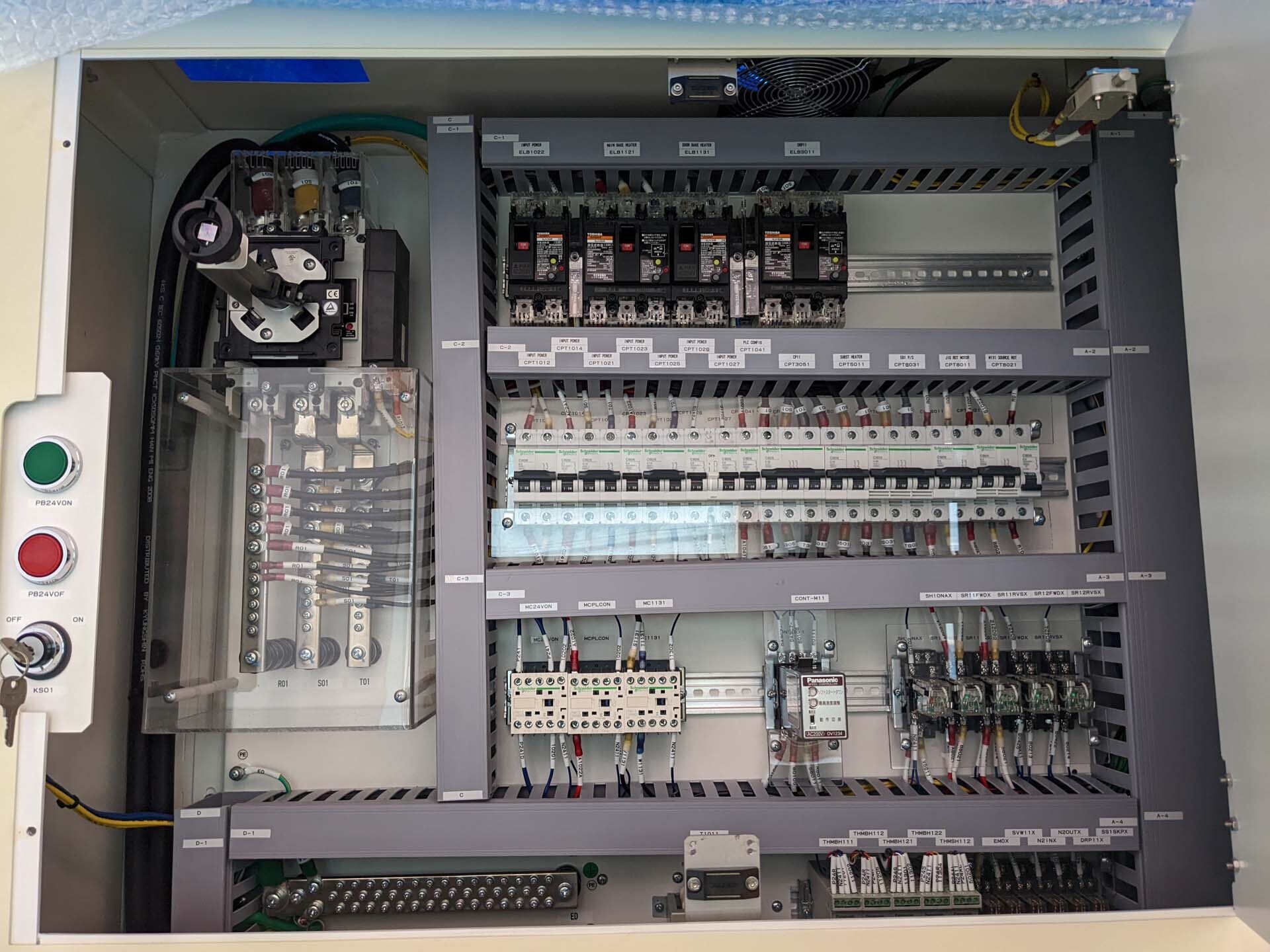

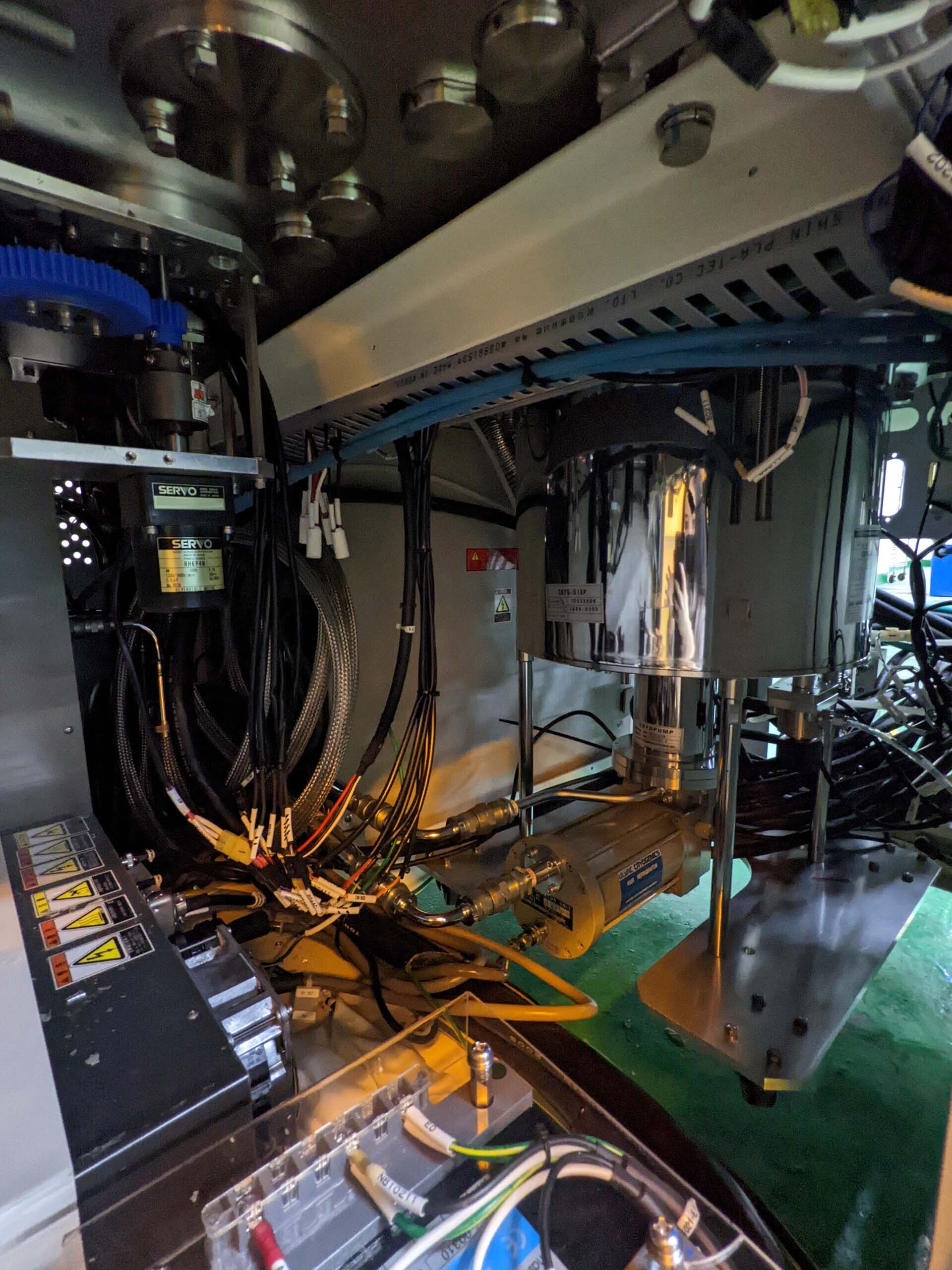

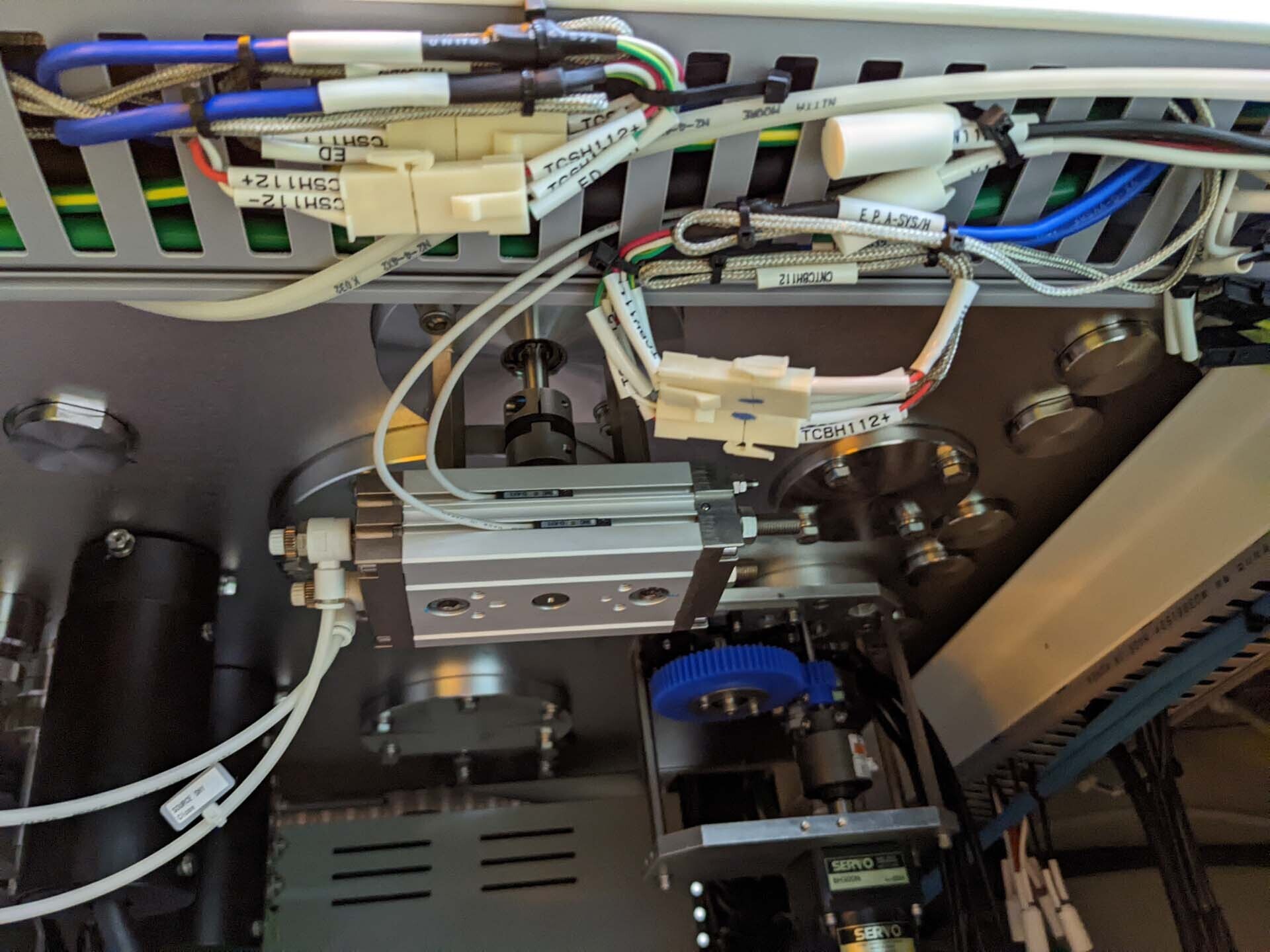

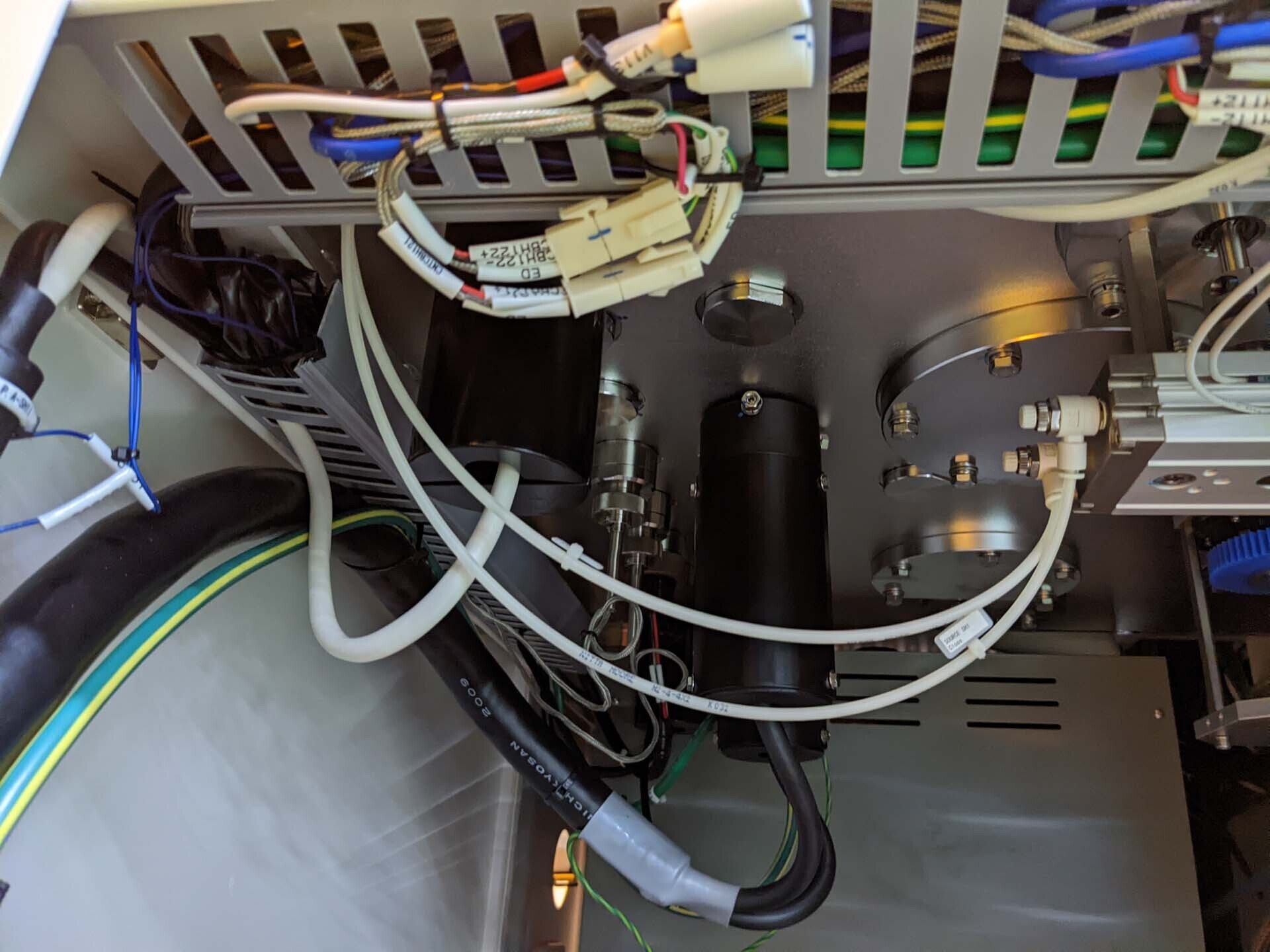

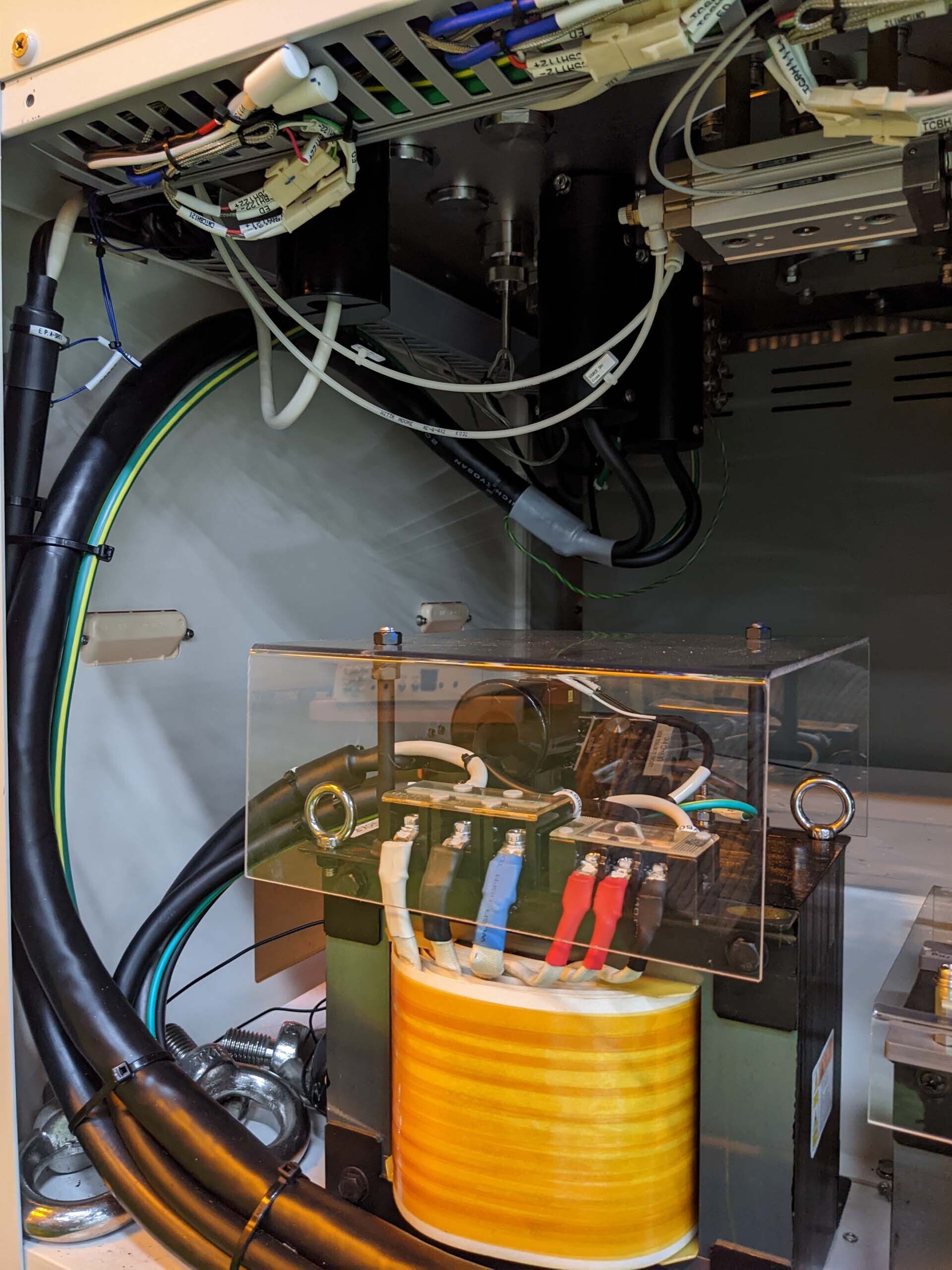

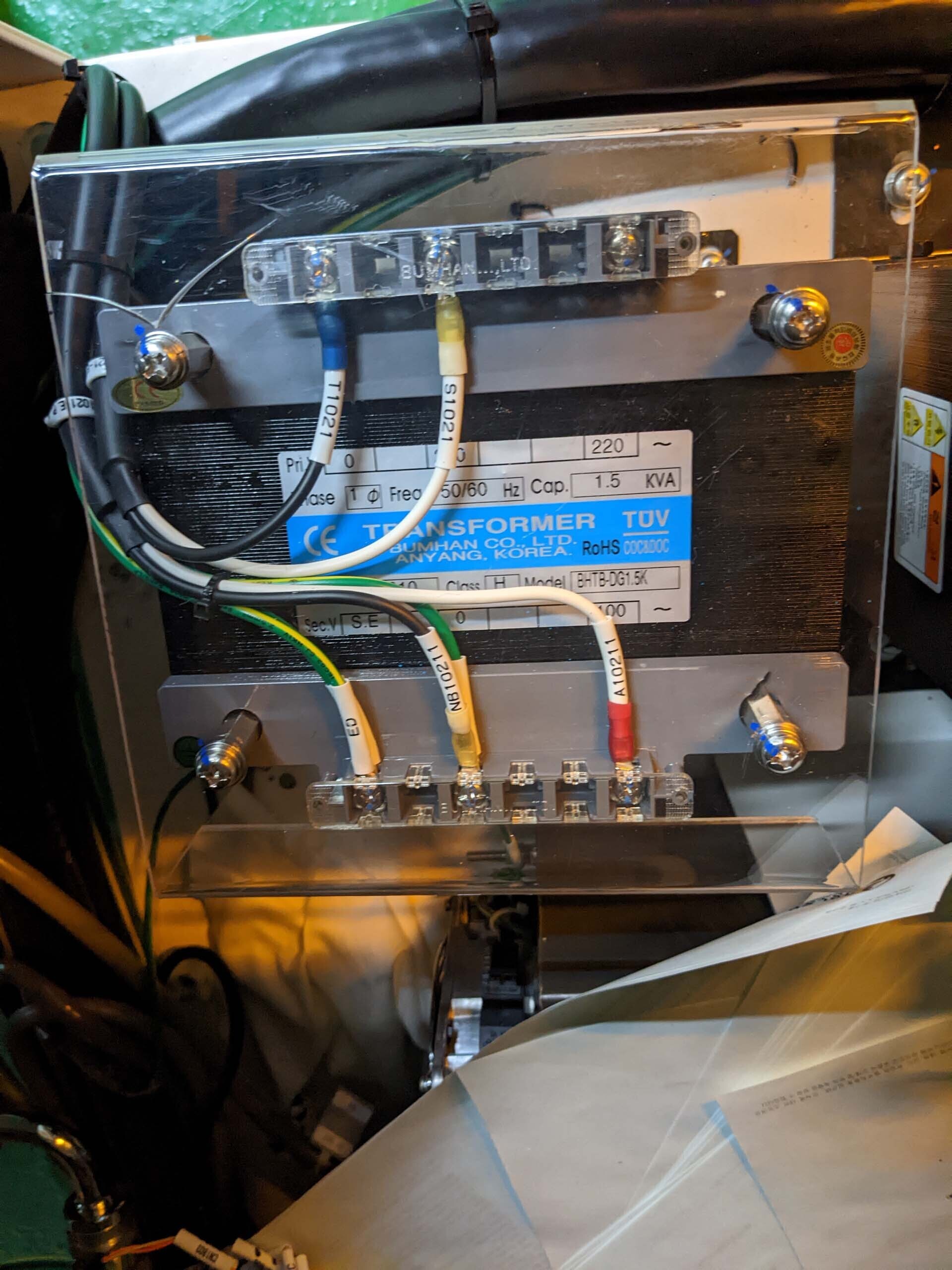

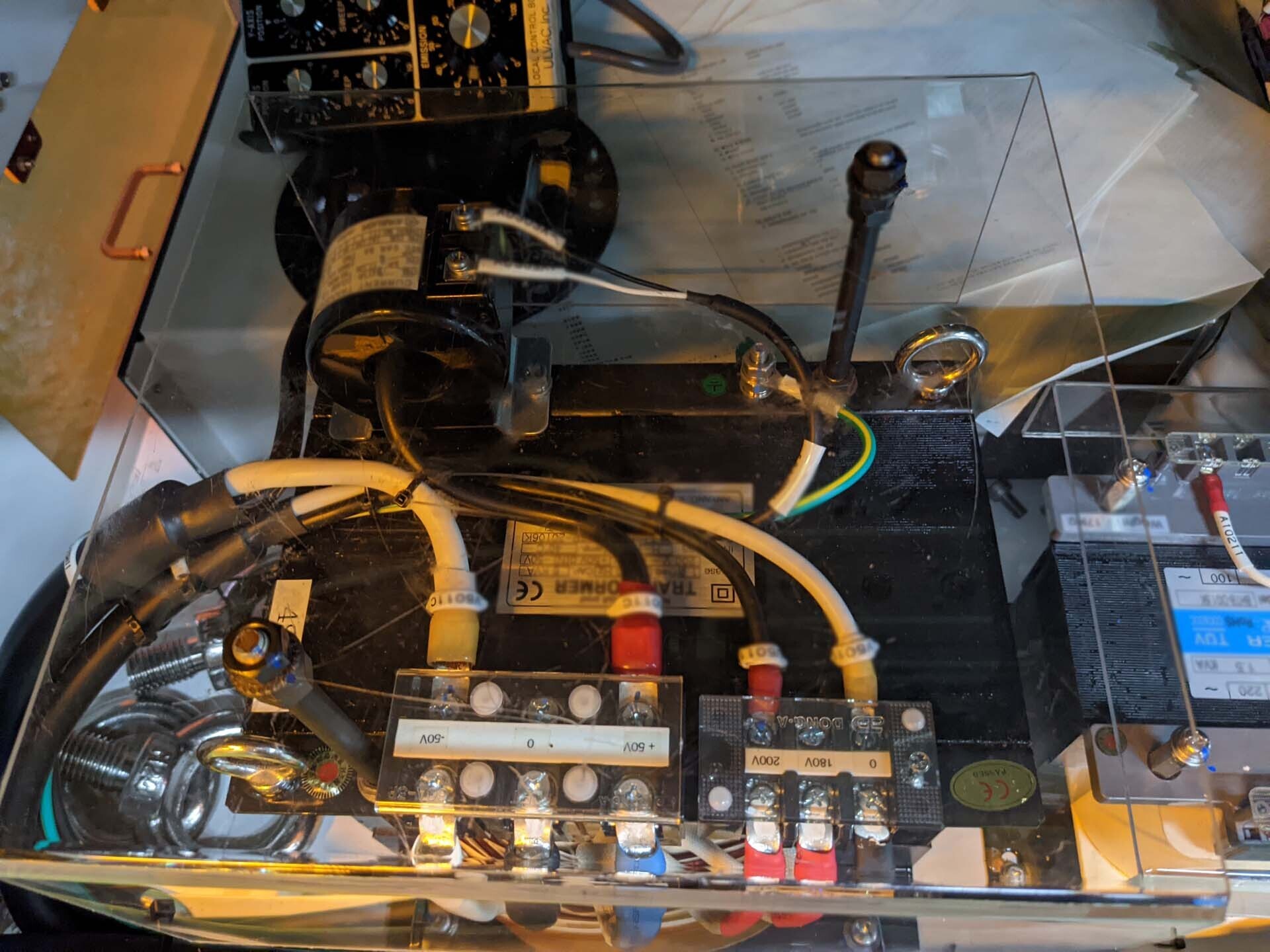

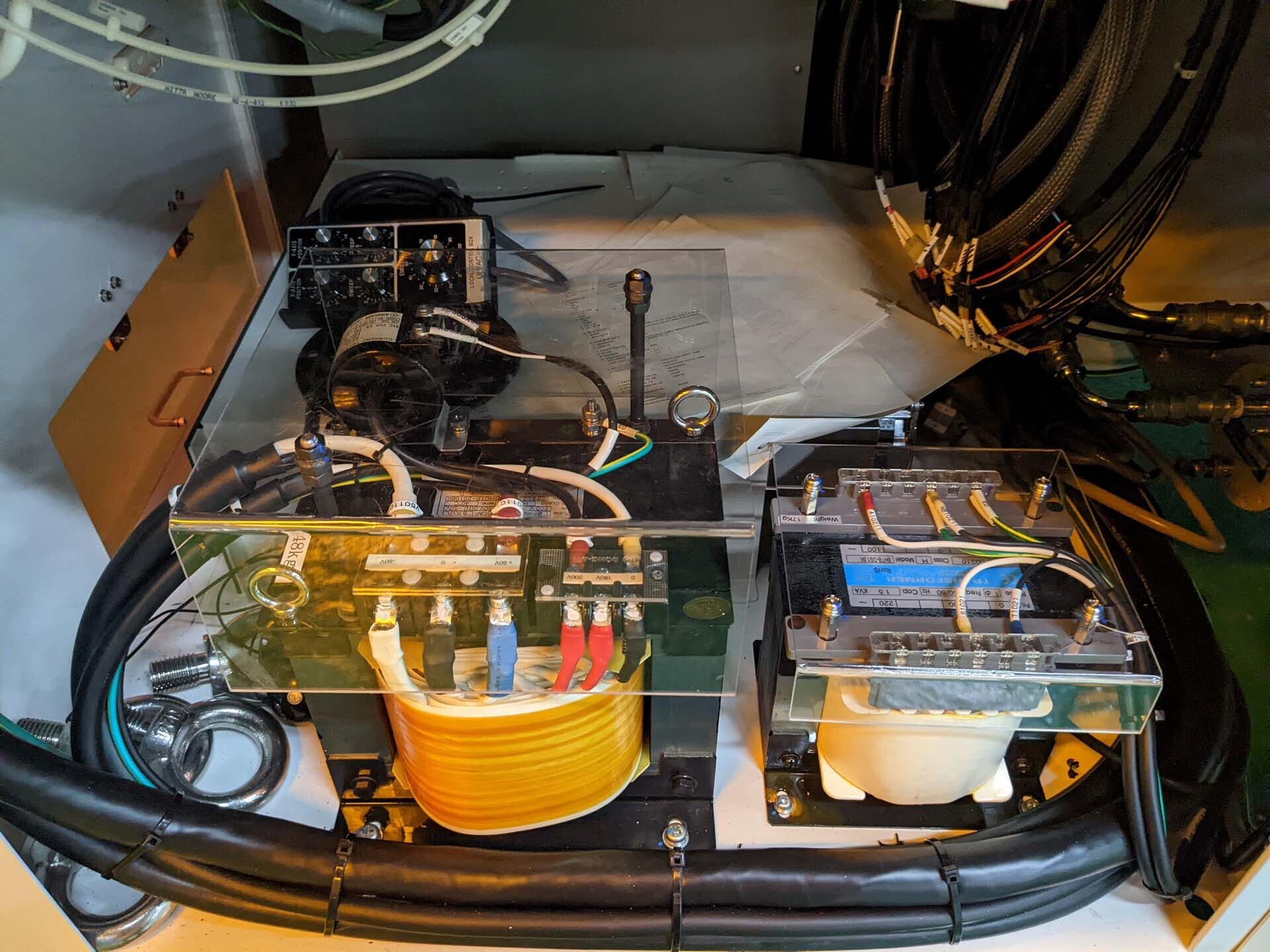

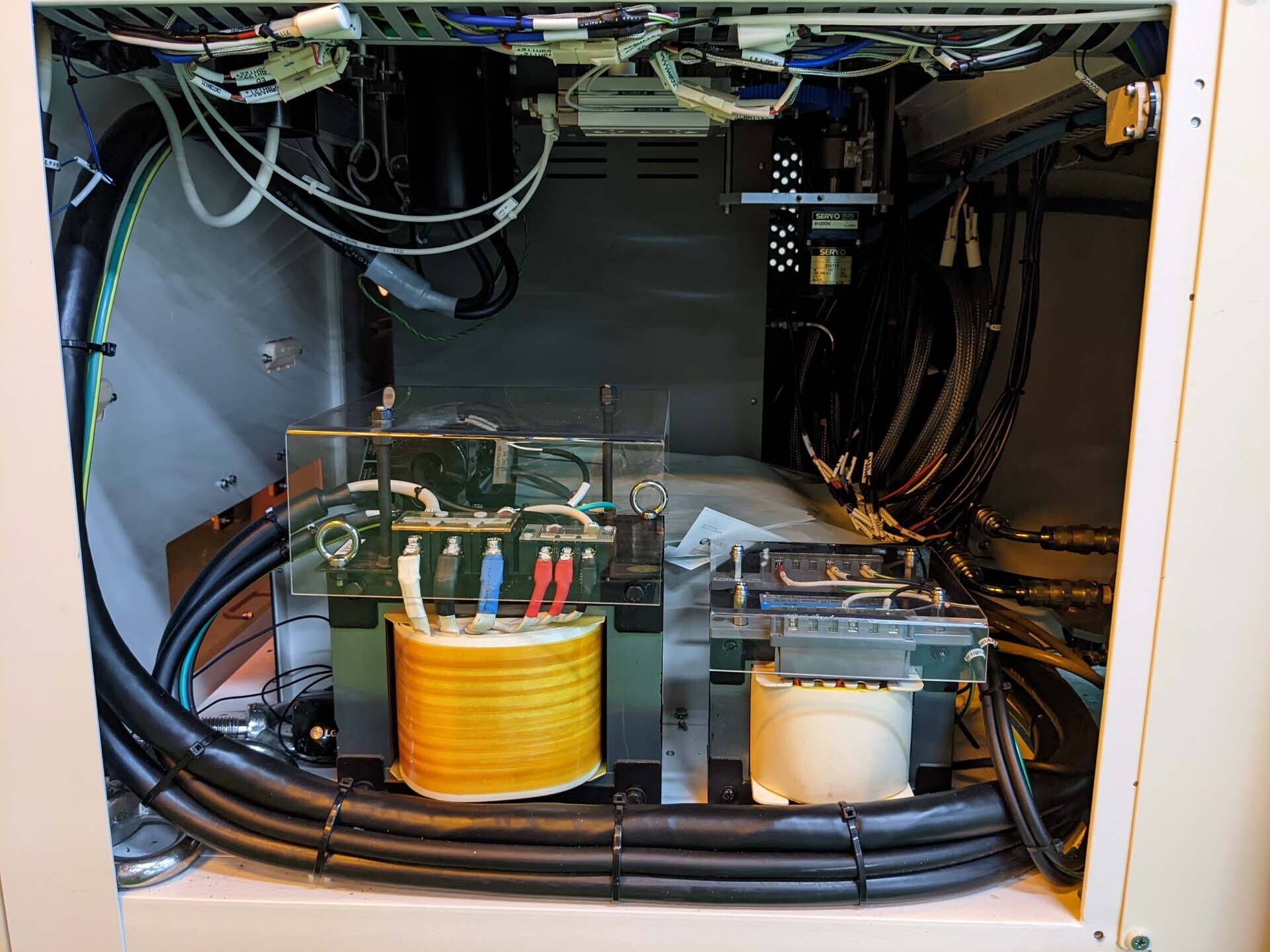

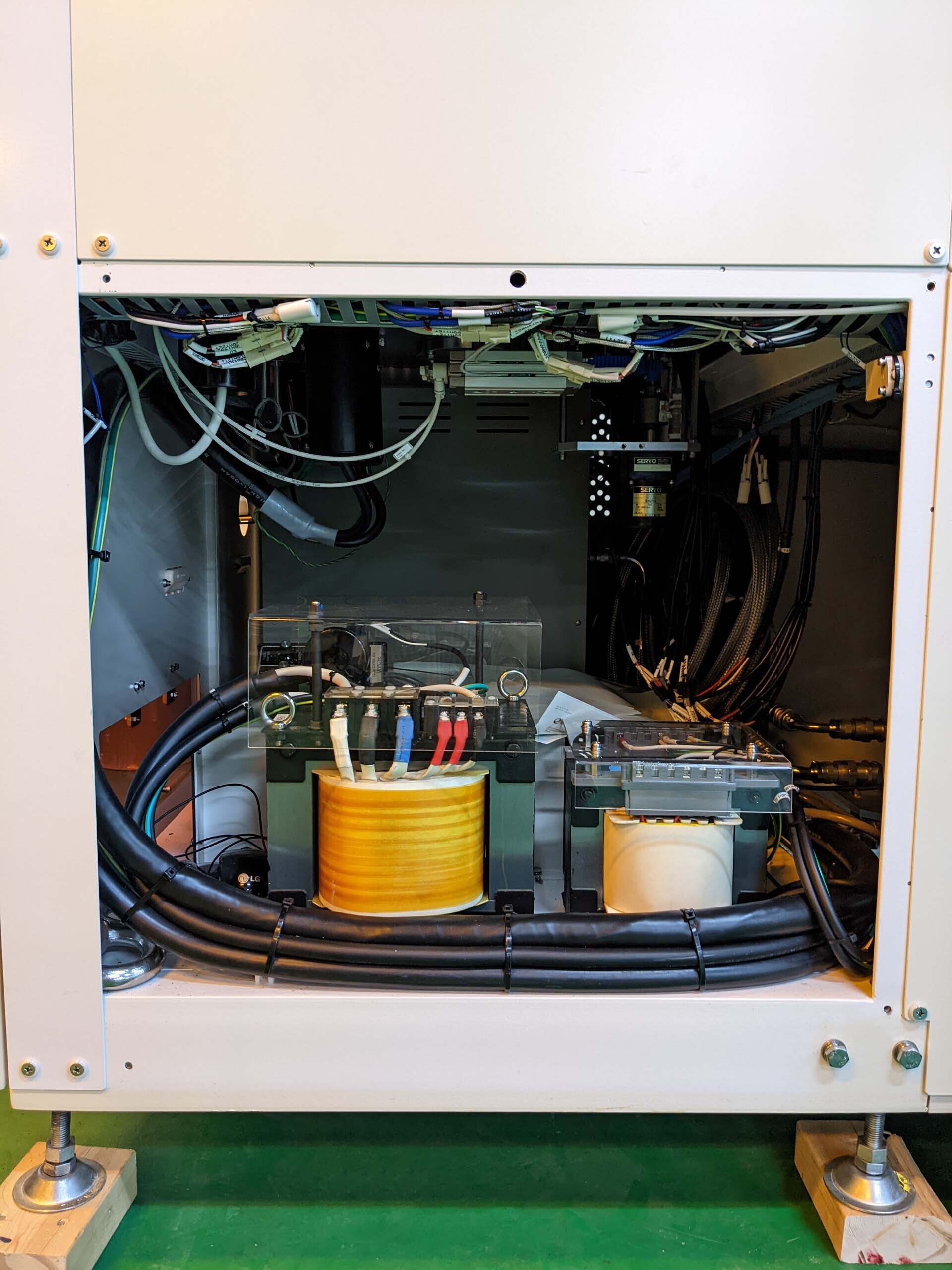

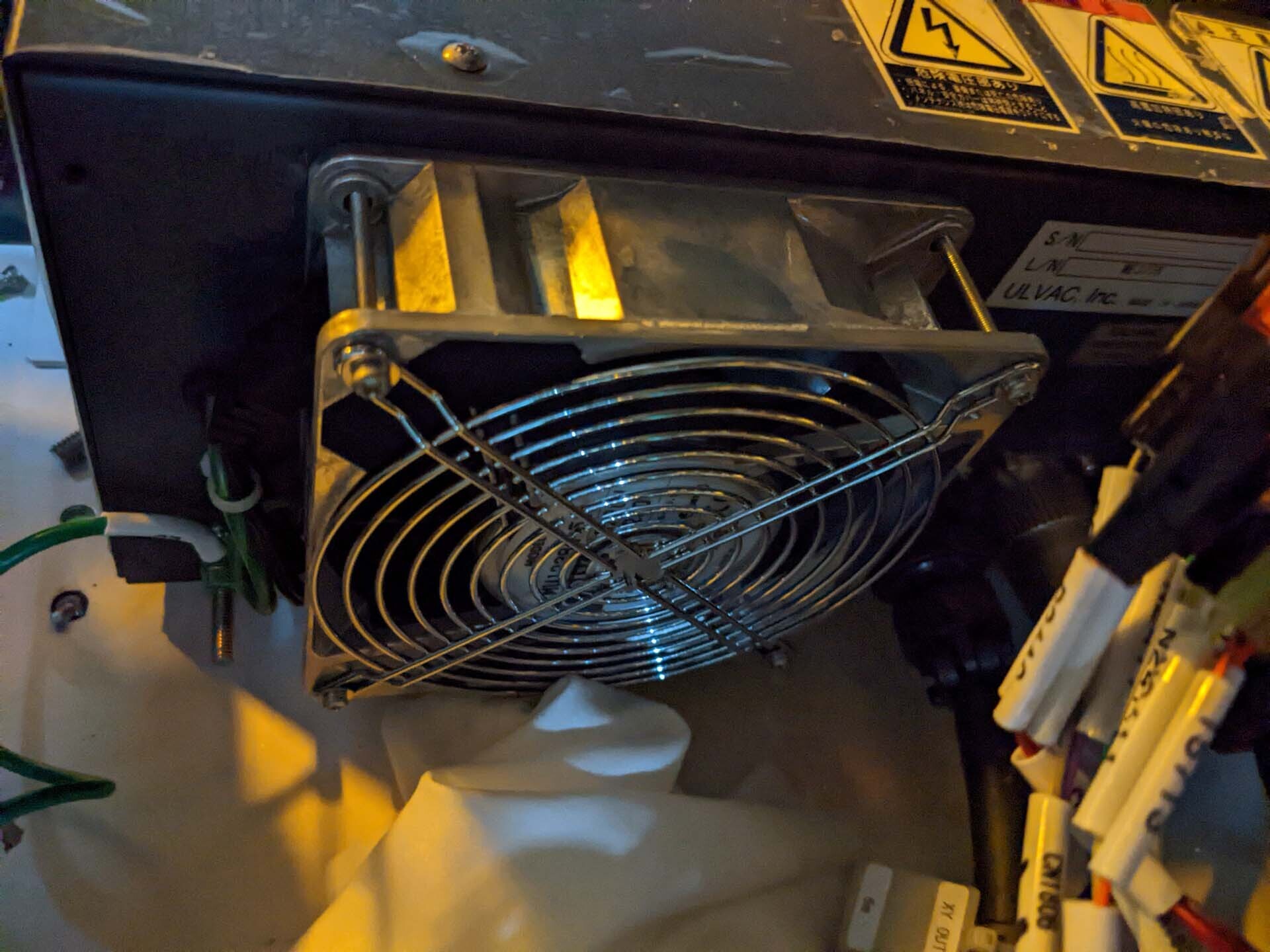

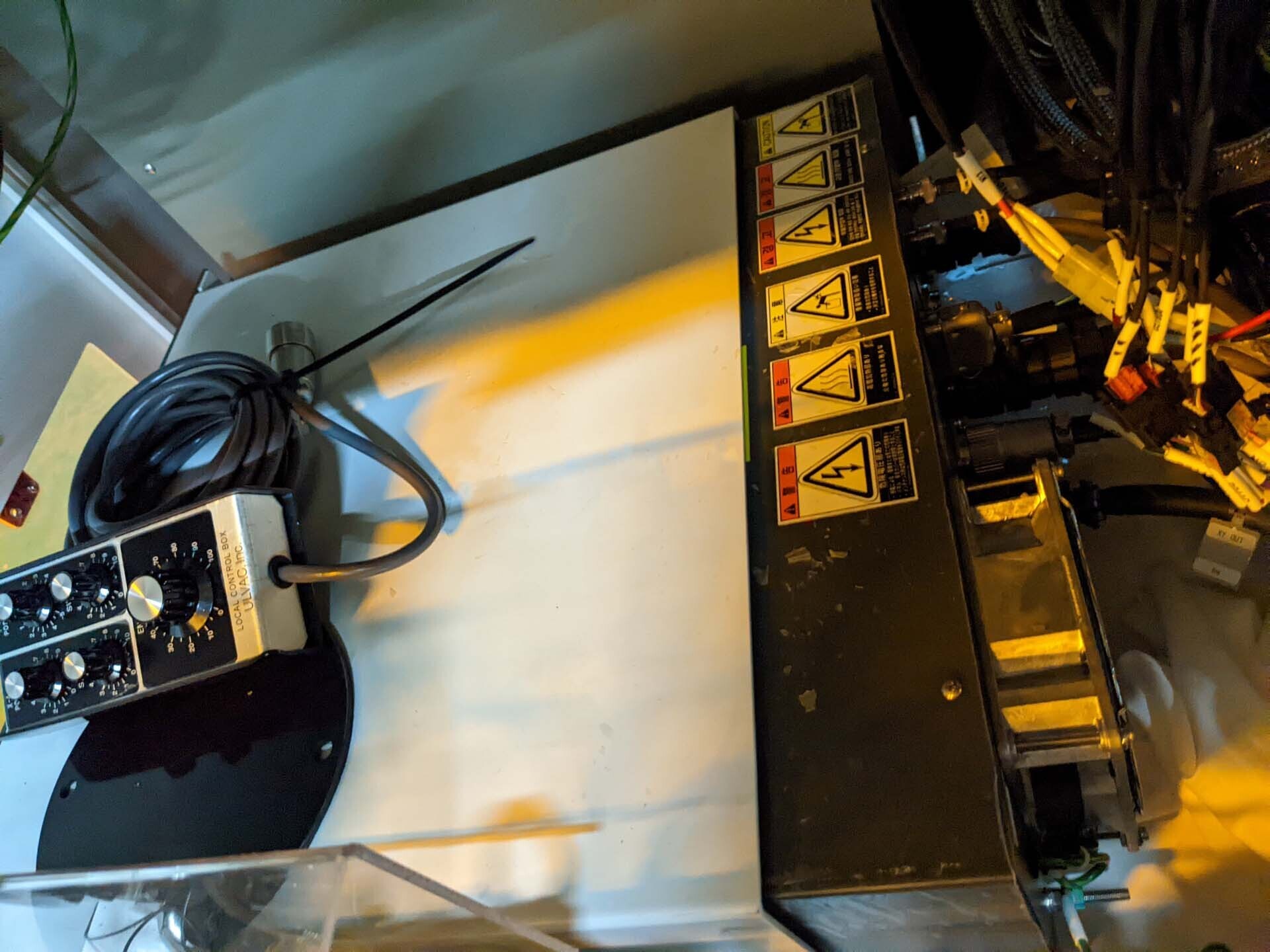

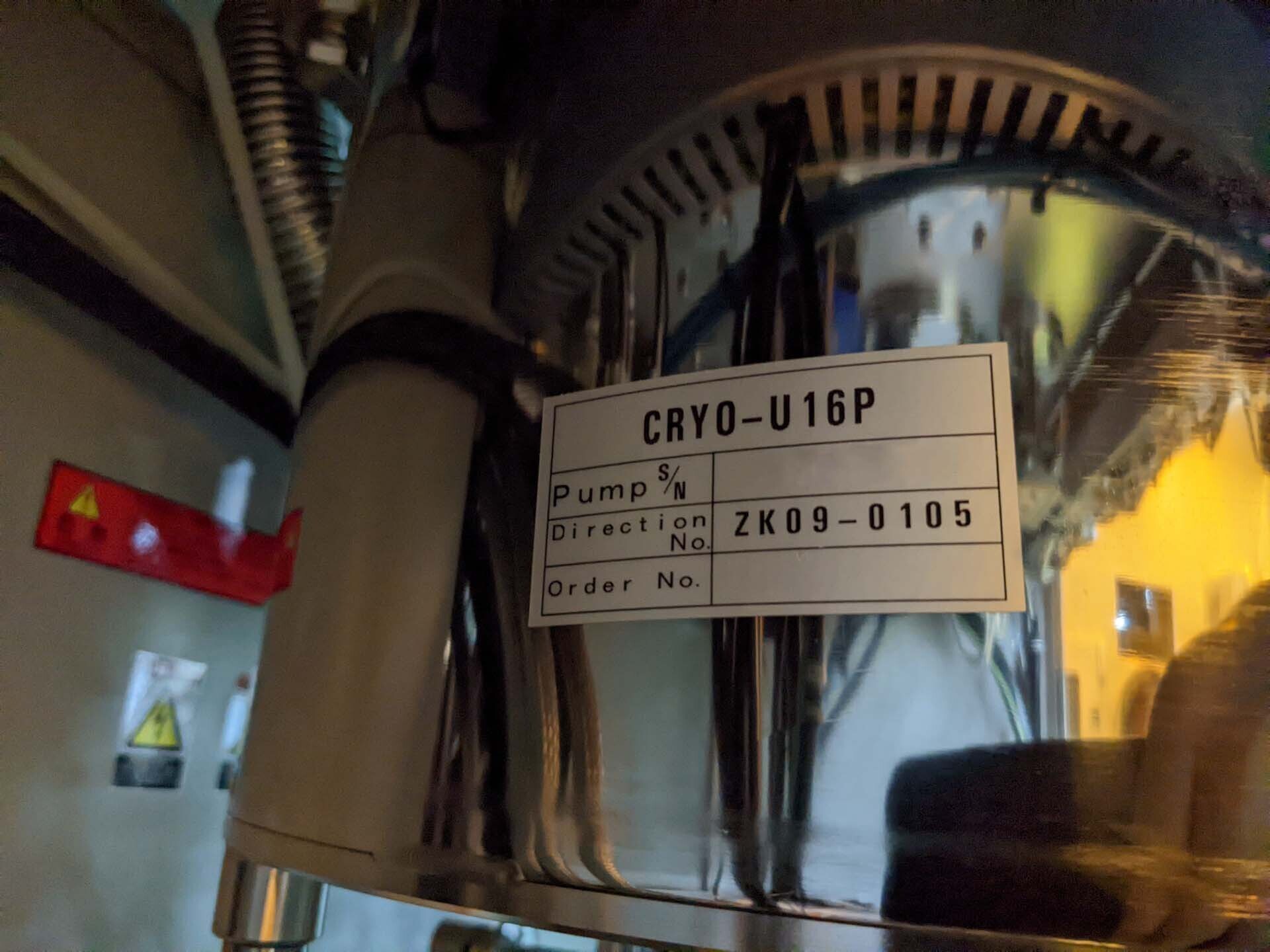

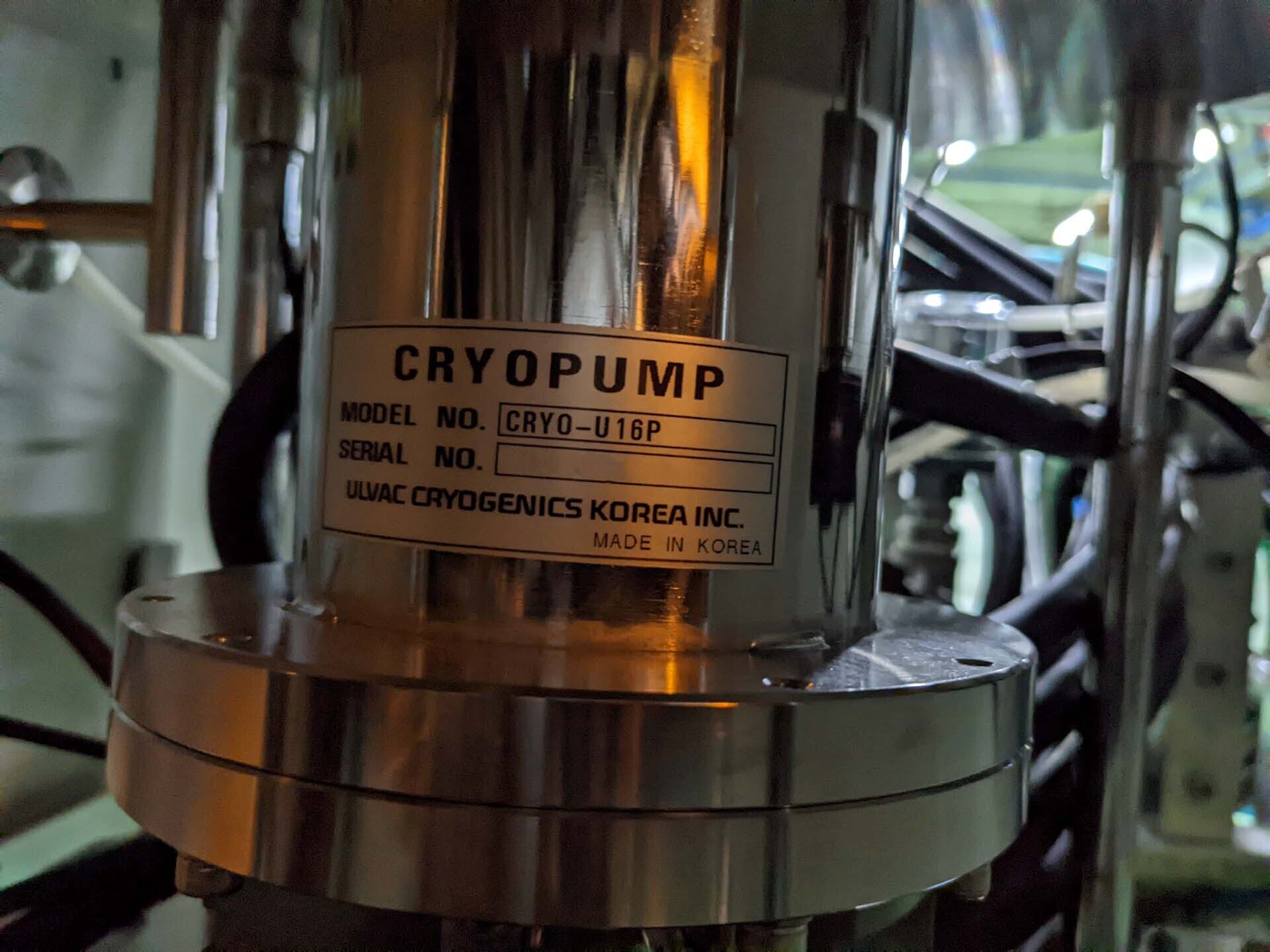

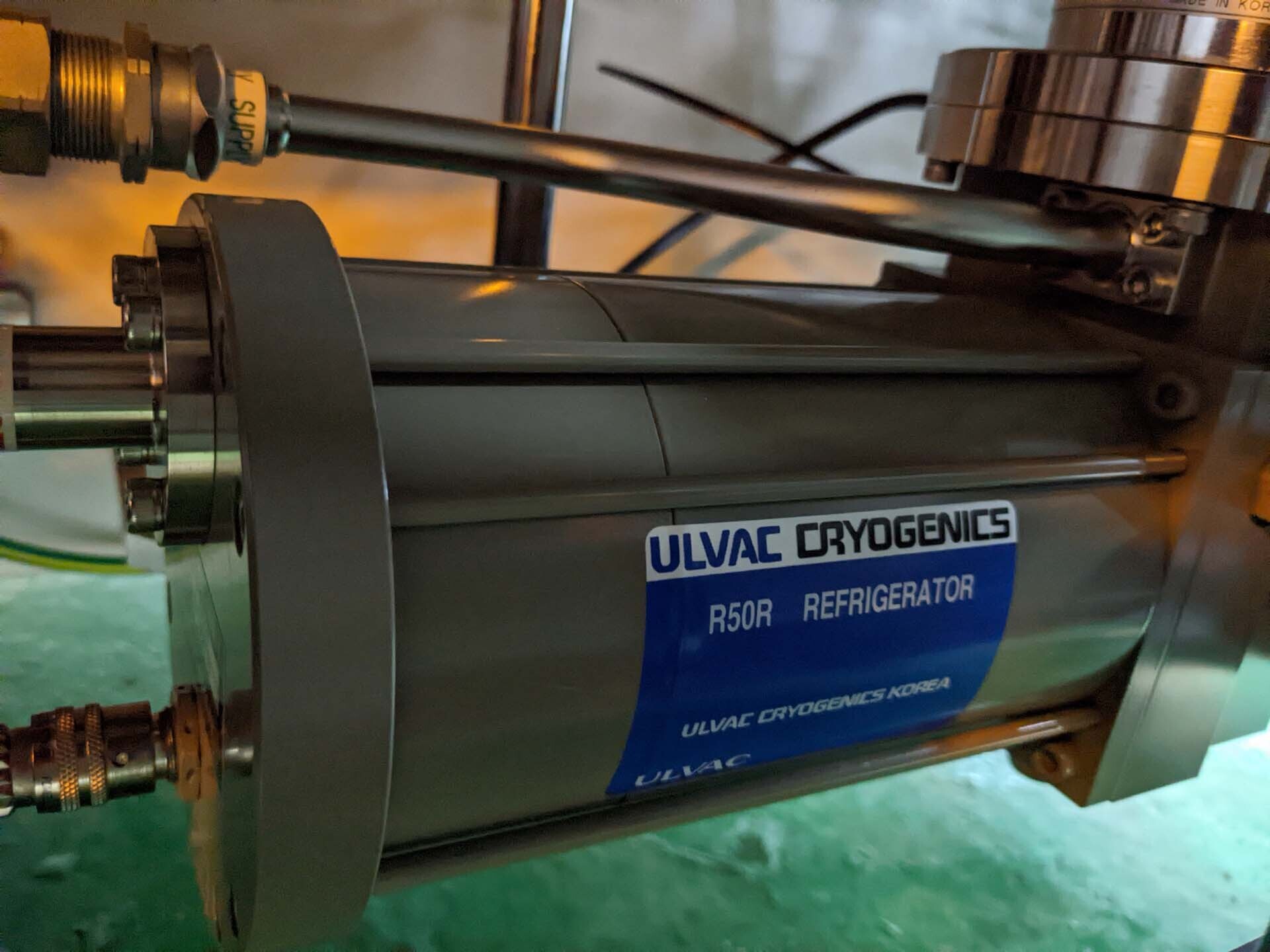

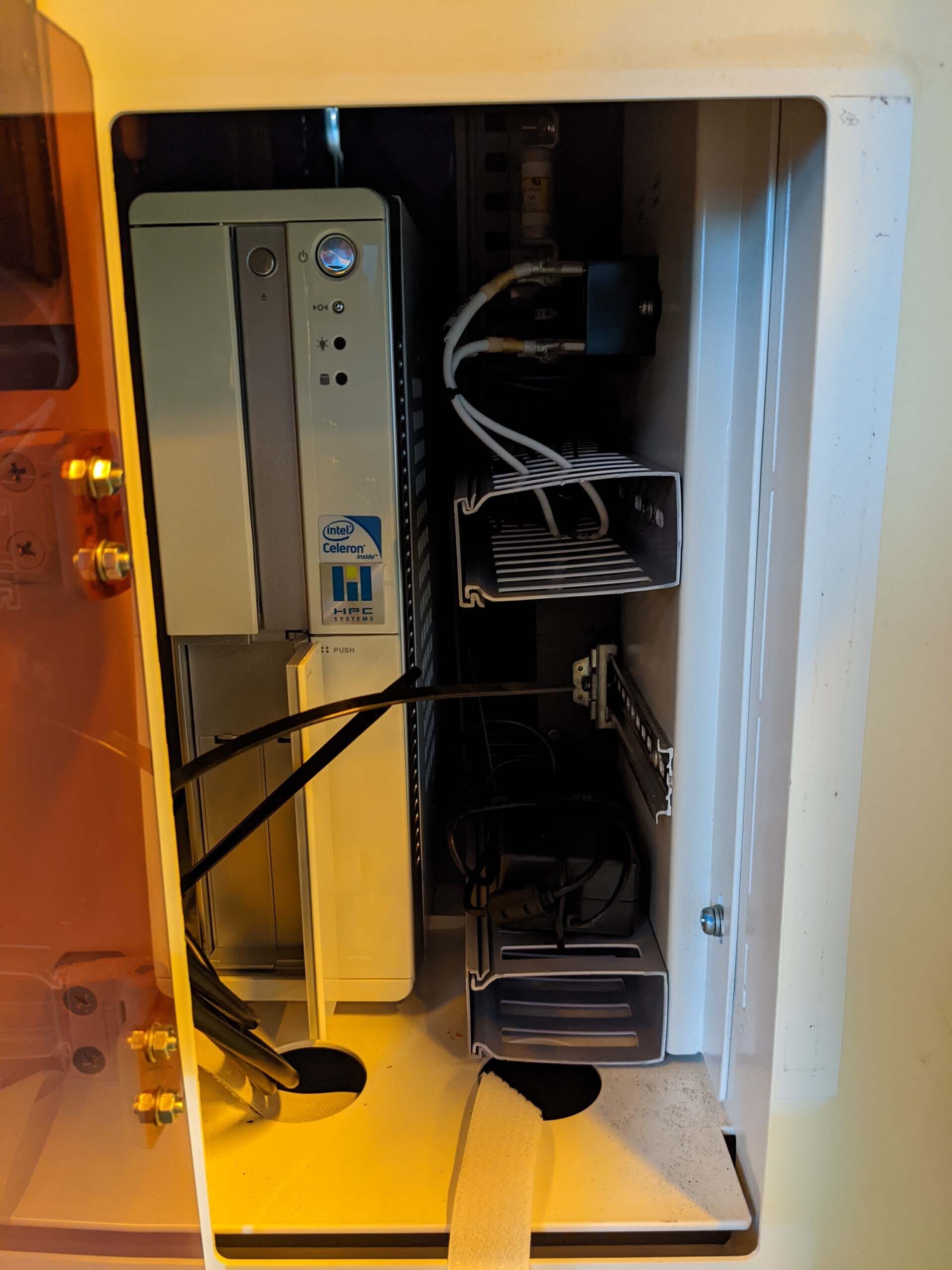

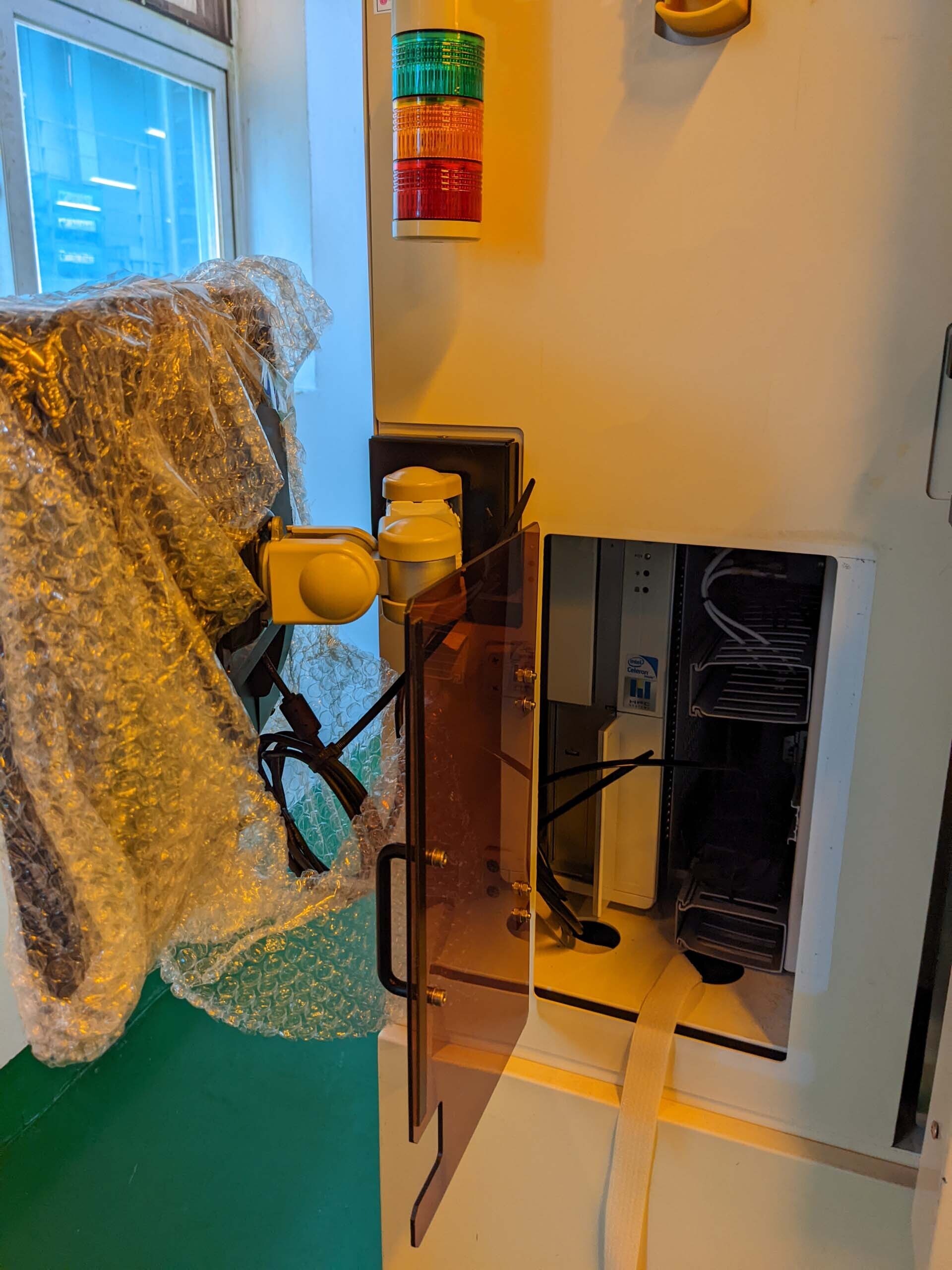

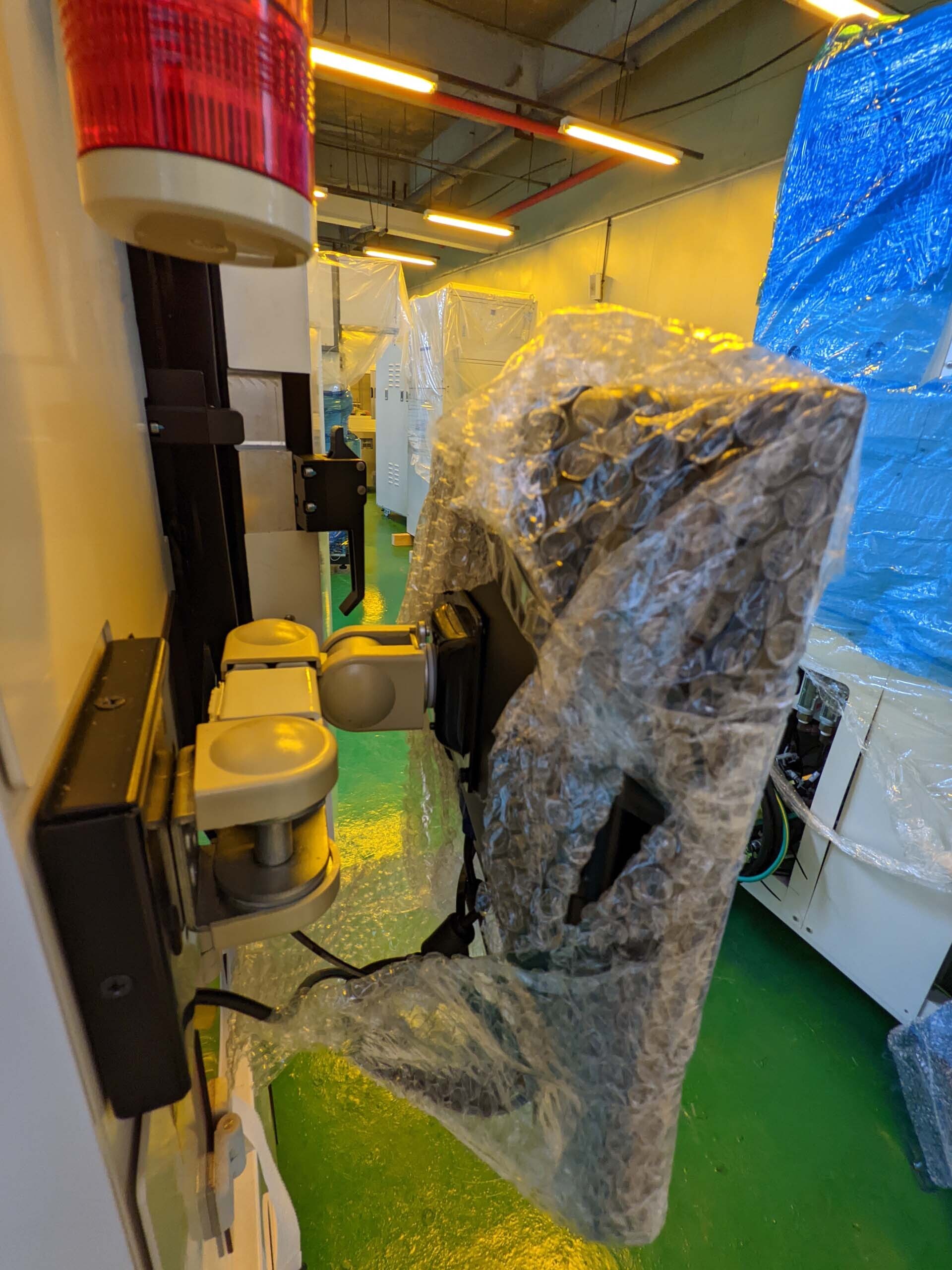

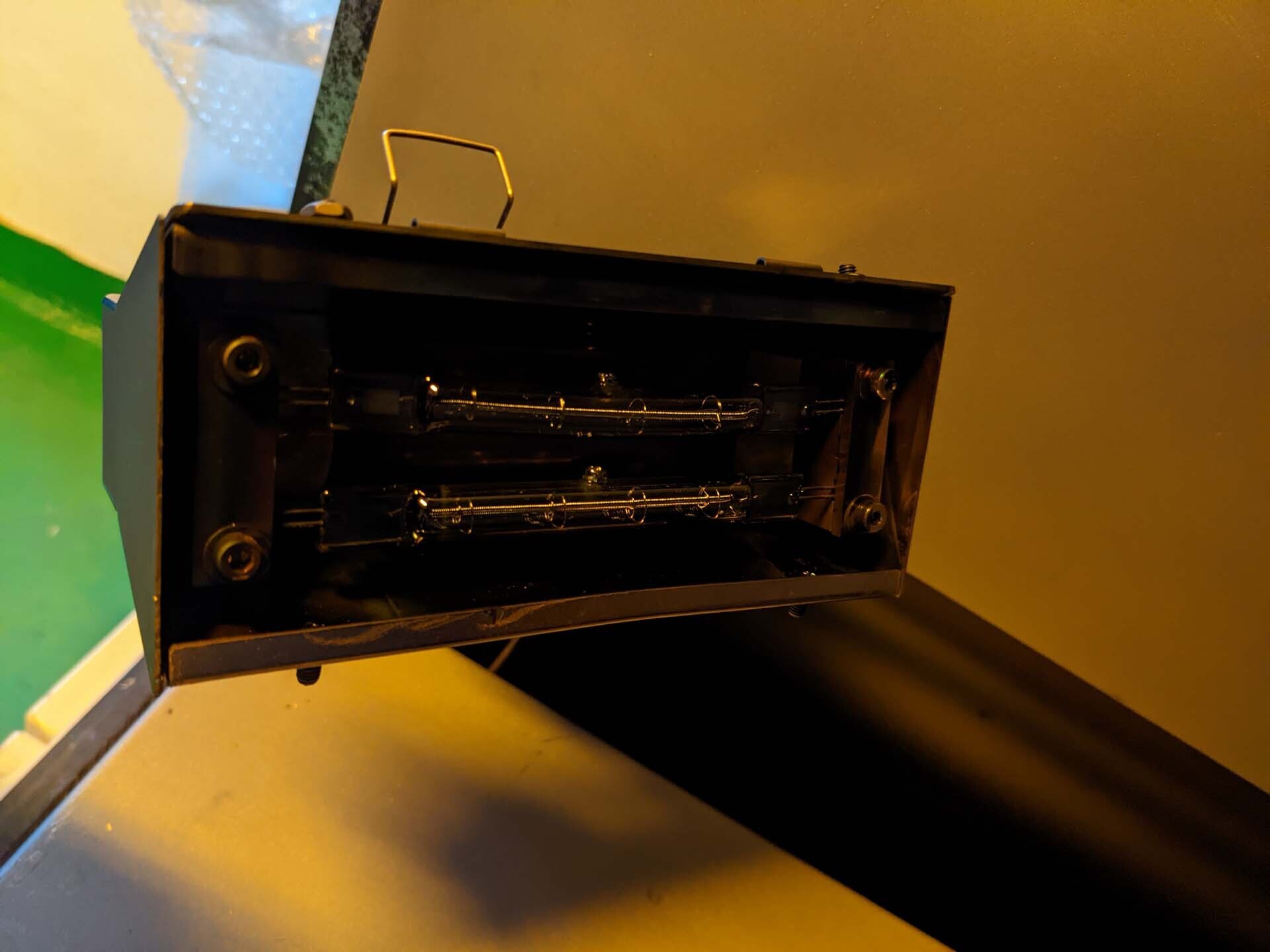

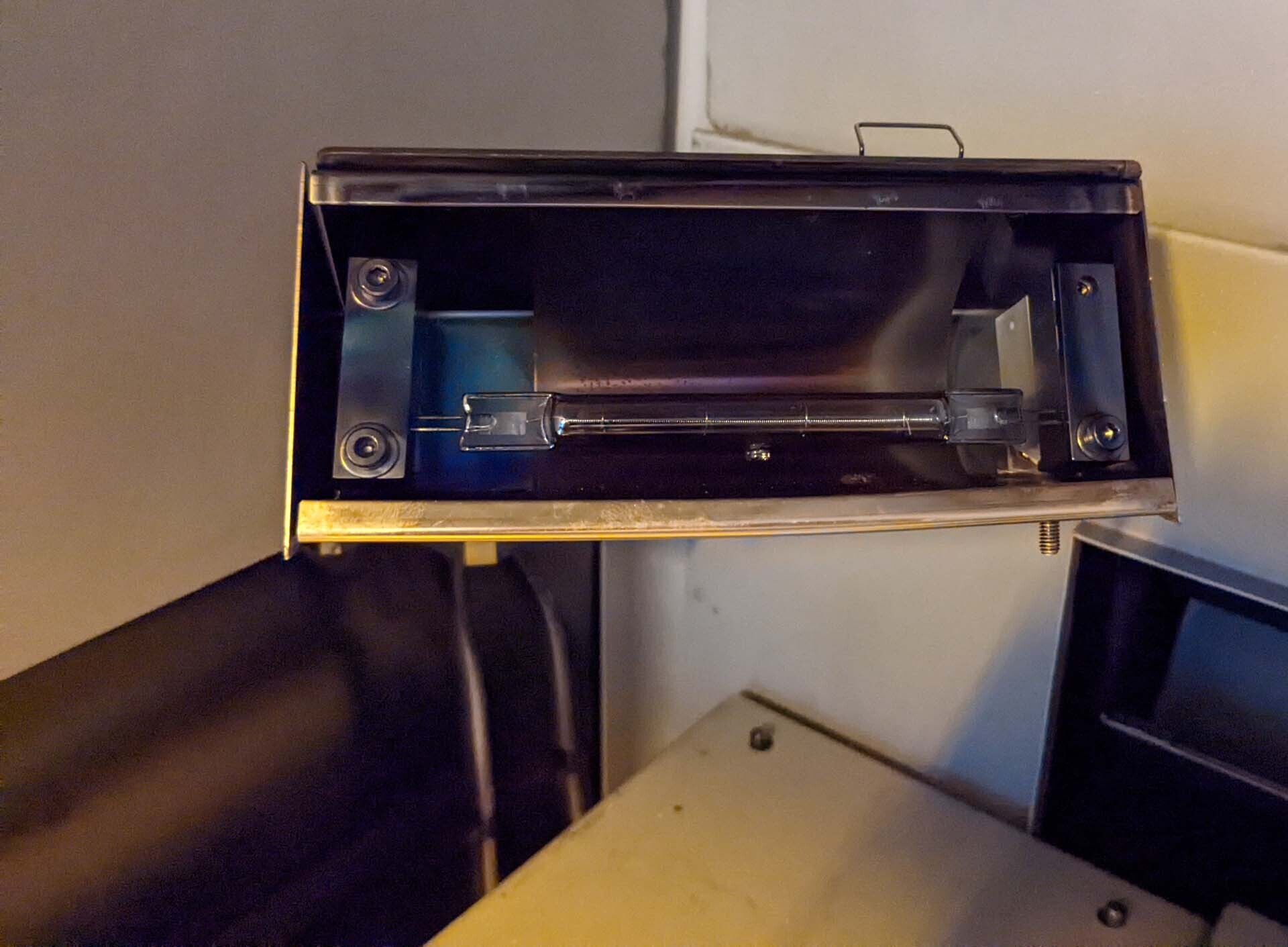

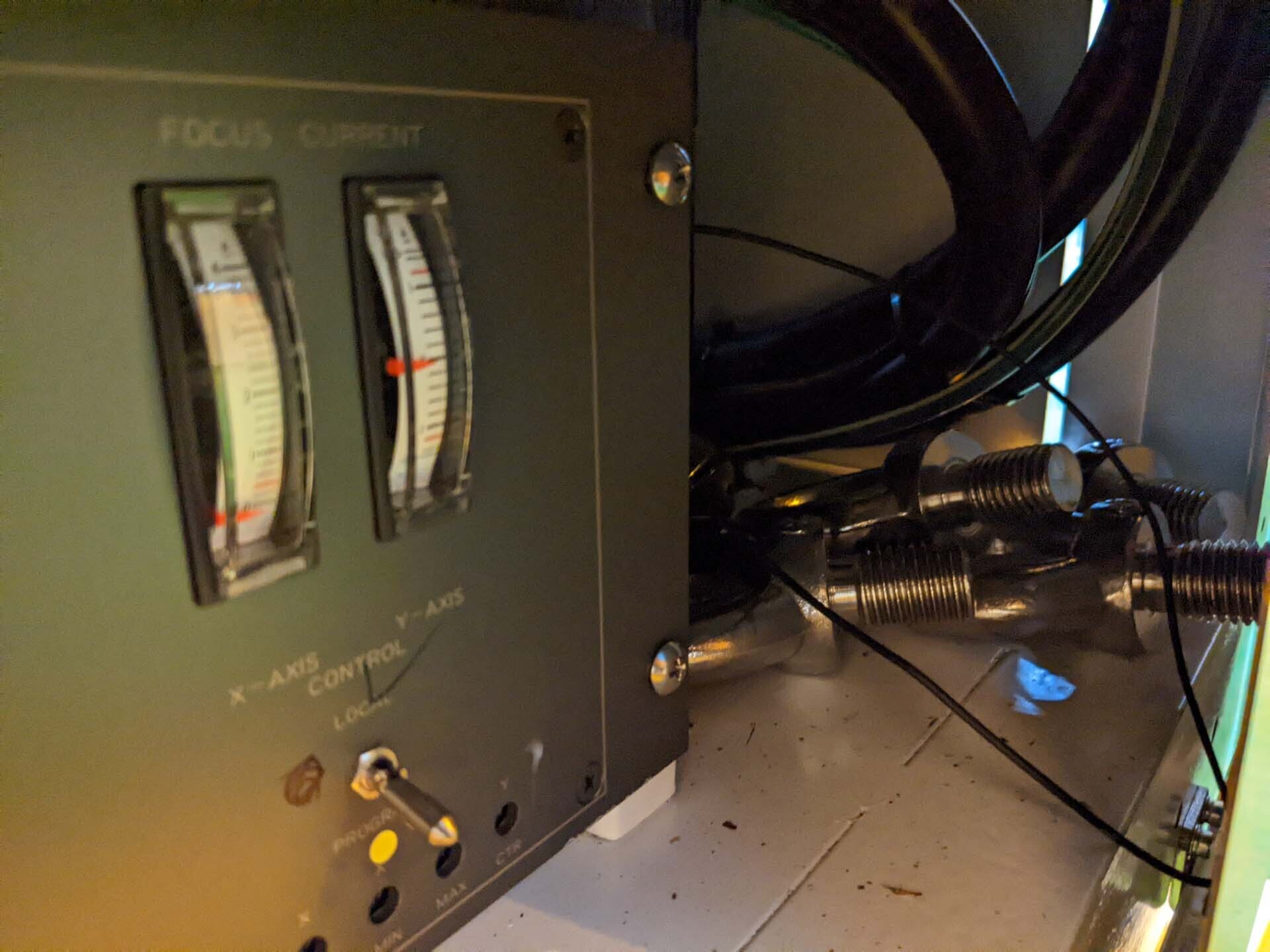

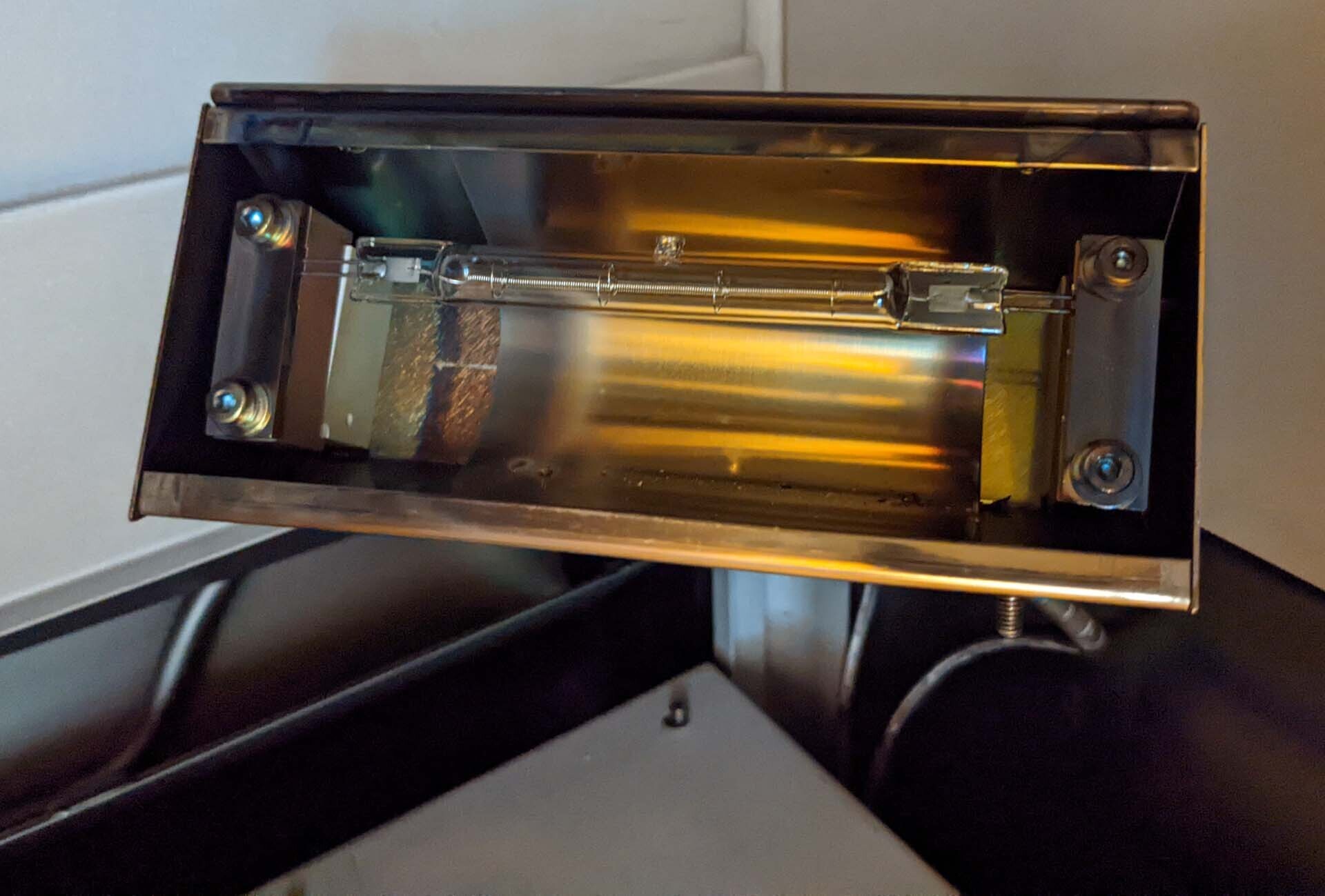

ULVAC Ei-5K is a sputtering equipment used for surface deposition in vacuum environments on metals, insulators, and semimetals. This system's power is adjustable and can be used to create a wide variety of deposition thicknesses and properties. Its maximum substrate size is 25cm by 20cm and the distance between the target surface and the substrate can be adjusted. ULVAC EI 5 K is a compact, compact model which allows it to easily fit in cleanrooms and labs. The sputtering process is based on using a voltage applied to the substrate to induce a process called sputtering. In this process, the targets can be bombarded by high-energy ions, thereby sputtering material from the target onto the substrate. This process can create thin and high-quality surface isolations. Ei-5K has a high plasma density which allows for higher deposition rates than other sputtering systems. This unit typically uses Argon gas as the sputtering medium, however, other gases such as Nitrogen and Oxygen can also be used. It also offers the user flexibility, as the machine can accommodate various material types, compounds, and concentrations. A key advantage of EI 5 K is its high ion yield. This is the rate at which ions are ejected from the target, increasing sputter yield and improving the deposition rate. Additionally, the tool offers a uniformity of deposition, allowing for uniform film thickness. ULVAC Ei-5K also has a unique substrate cleaning mode. The asset automatically cleans the substrate before the sputtering process begins. This improves the adhesion of the deposition material, eliminating contaminants. Furthermore, during the sputtering process, the model is able to maintain an optimized chamber pressure and temperature. This ensures that the sputtering process is not interrupted due to fluctuations or changes in the environment. ULVAC EI 5 K offers numerous benefits for users who work in the surface deposition field. Its adjustable power, uniform deposition, high ion yield, and substrate cleaning capabilities make it a great option for anyone looking for high-quality and reliable results. Furthermore, it is compact and requires minimal maintenance and upkeep.

There are no reviews yet