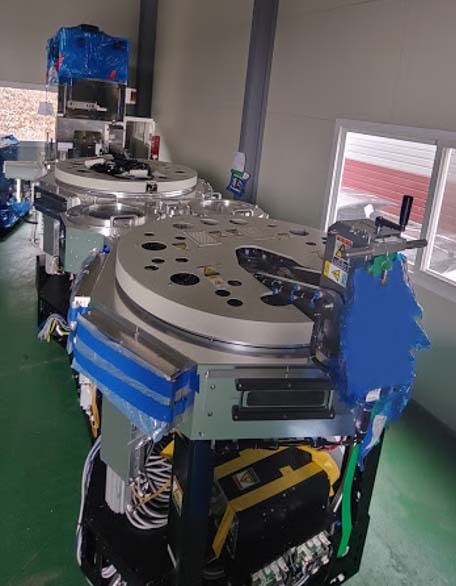

Used ULVAC Entron EX W300 #9381852 for sale

URL successfully copied!

Tap to zoom

ID: 9381852

Wafer Size: 12"

Vintage: 2007

PVD Sputtering system, 12"

AC Rack

Pump rack

DC Power supply rack

Heater rack

Does not include Hard Disk Drive (HDD)

Transfer module: (2) Robot arms

(8) Chambers with pump

Multi-chamber process:

Metal

ITO

Furnace

Load module:

Load port

Robot arm

2007 vintage.

ULVAC Entron EX W300 is a sputtering equipment used for the production of thin films through physical vapor deposition. ULVAC ENTRON-EX W300 is a compact desktop sputter system capable of depositing a wide variety of materials for dielectric, metal and resistive layer structures, designed for use in both semiconductor and thin film deposition applications. The sputter unit can sputter target materials including, but not limited to, aluminum, gold, tantalum, platinum, aluminum oxide, and silicon dioxide. ENTRON EX W 300 is designed to easily integrate into manual or automated production lines, featuring a small footprint and a low center of gravity. Moreover, its optically clear quartz view port provides a clear view of the target material and substrate without the need for a moving door. It utilizes a unique patented magnet-free single-axis DC sputter to minimize maintenance and gas consumption, as well as a patented quick-change sputter insert to allow for rapid switchover of target materials. The machine's vacuum chamber features a low-pressure diagram and a front-loading magnetic filter to reduce dust levels. The tool is capable of producing layers of uniform thickness and composition due to a patented safety shutter and a wide range of Auto Shut Asset control options. The Auto Shut Model allows for user-defined target power, target position, and cooling time when depositing layers of various thicknesses. ULVAC ENTRON EX W300 features the latest in PECVD (Plasma Enhanced Chemical vapor deposition) technology, providing high-density, pin-point deposition. Finally, Entron EX W300 offers the latest in software monitoring and diagnostics monitoring to ensure smooth operation, as well as the highest quality of thin film deposition.

There are no reviews yet