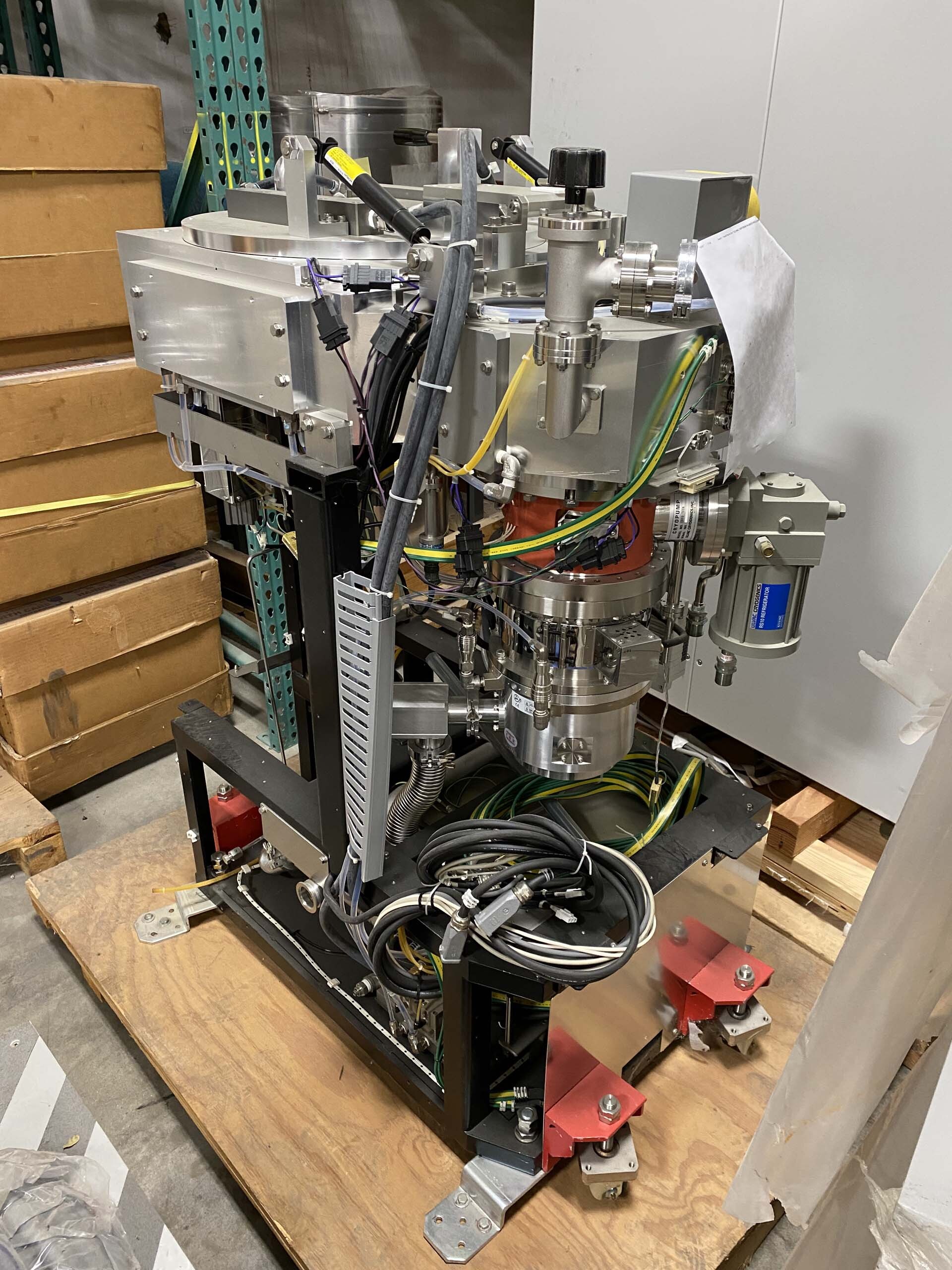

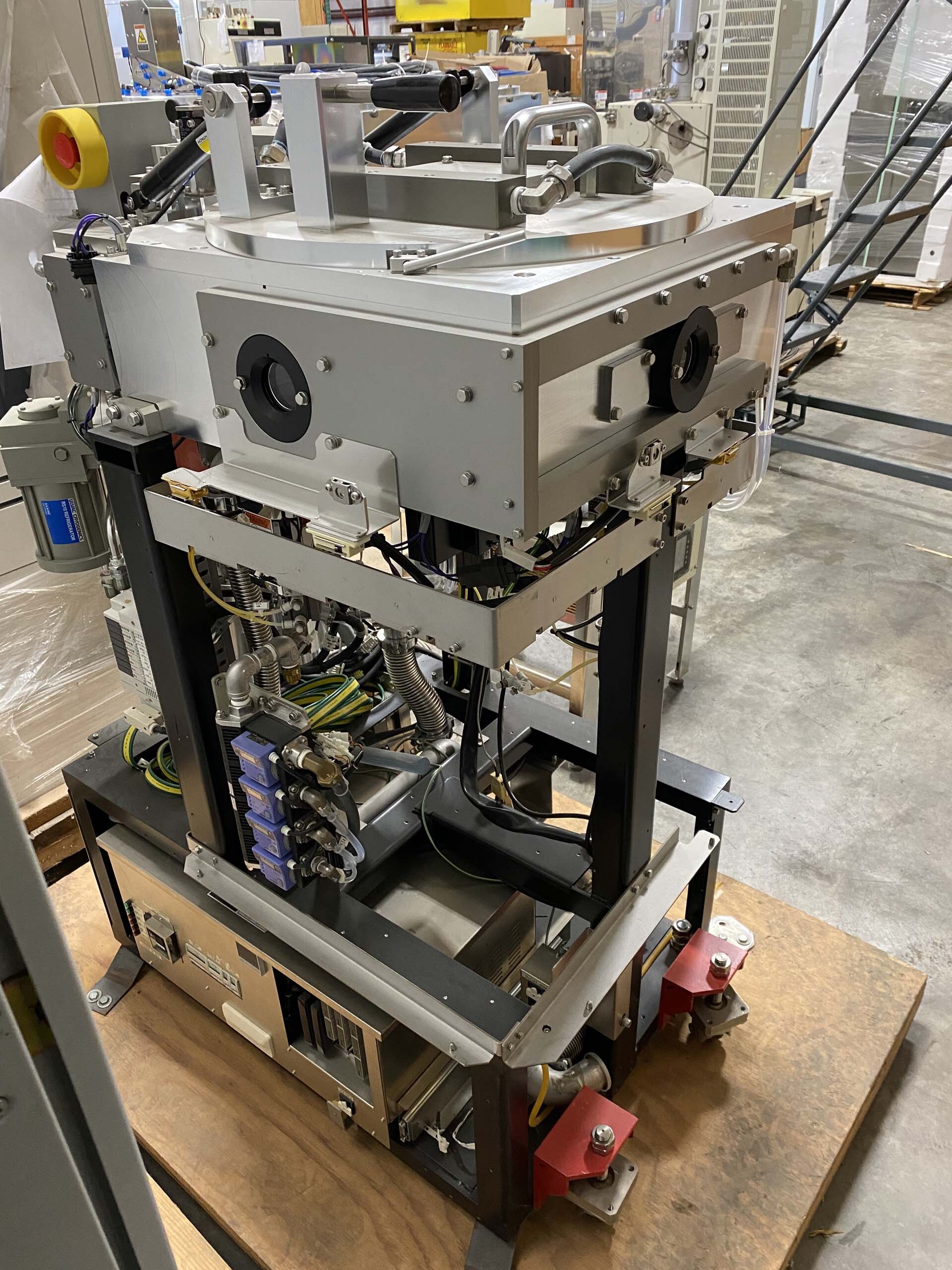

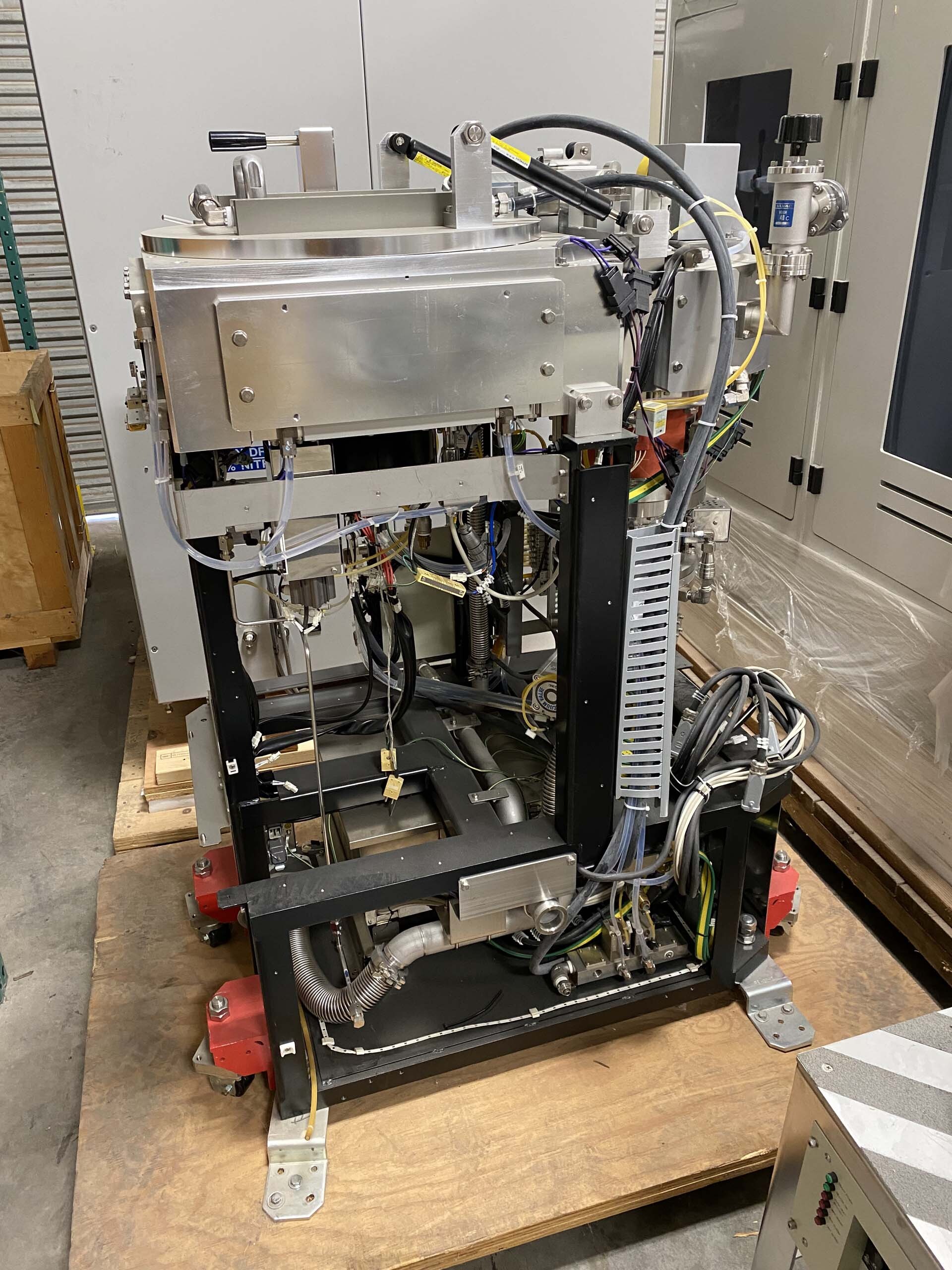

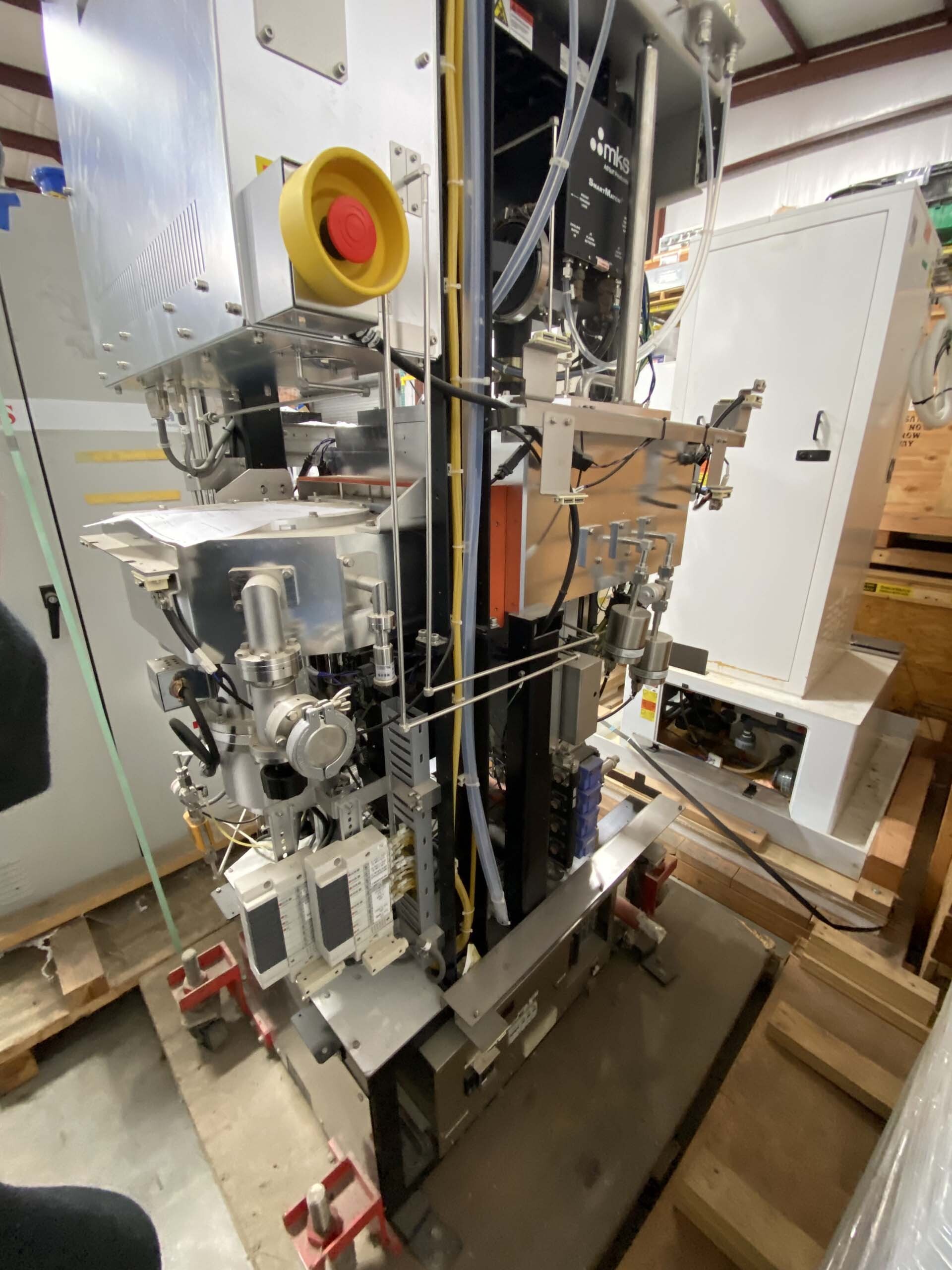

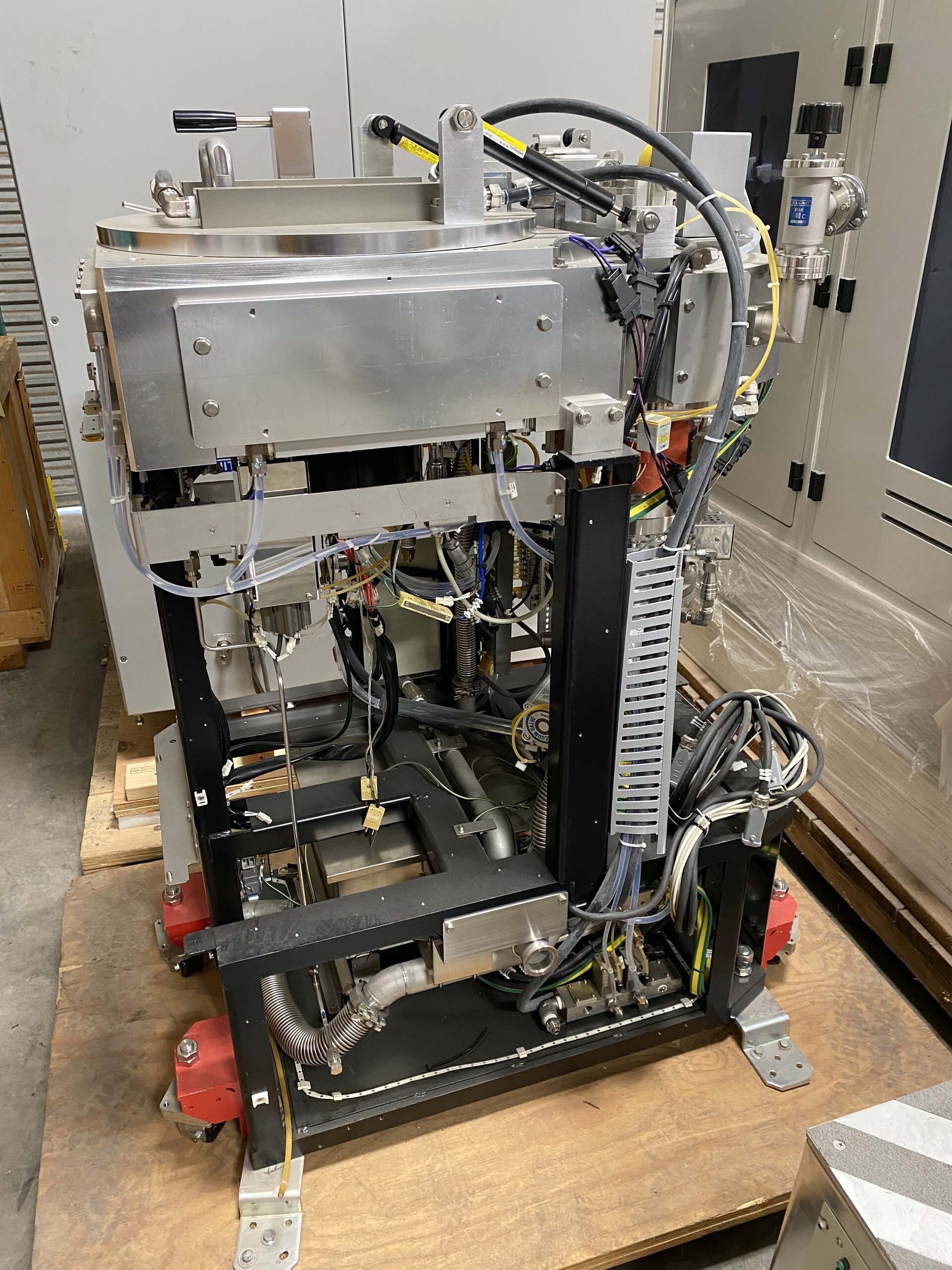

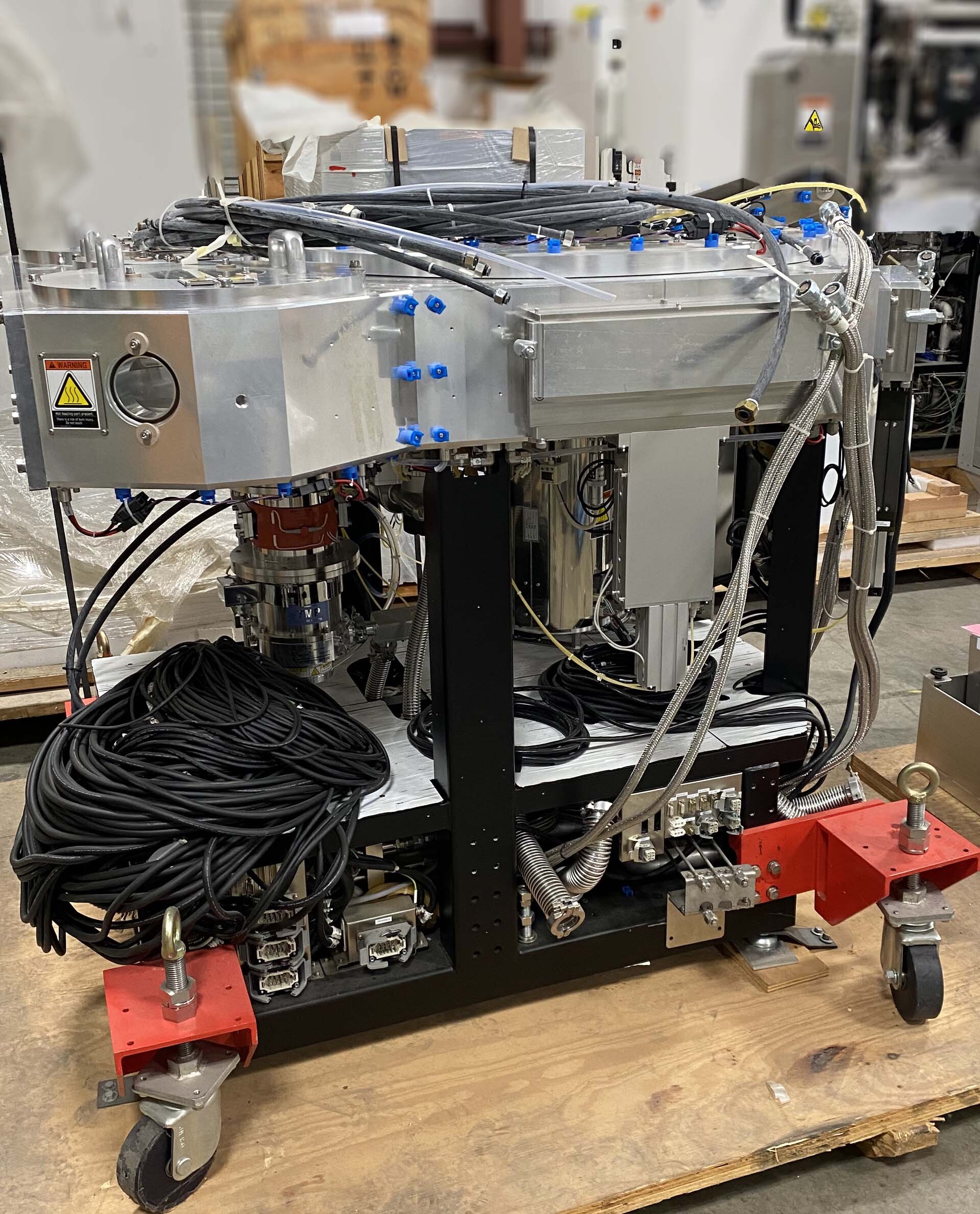

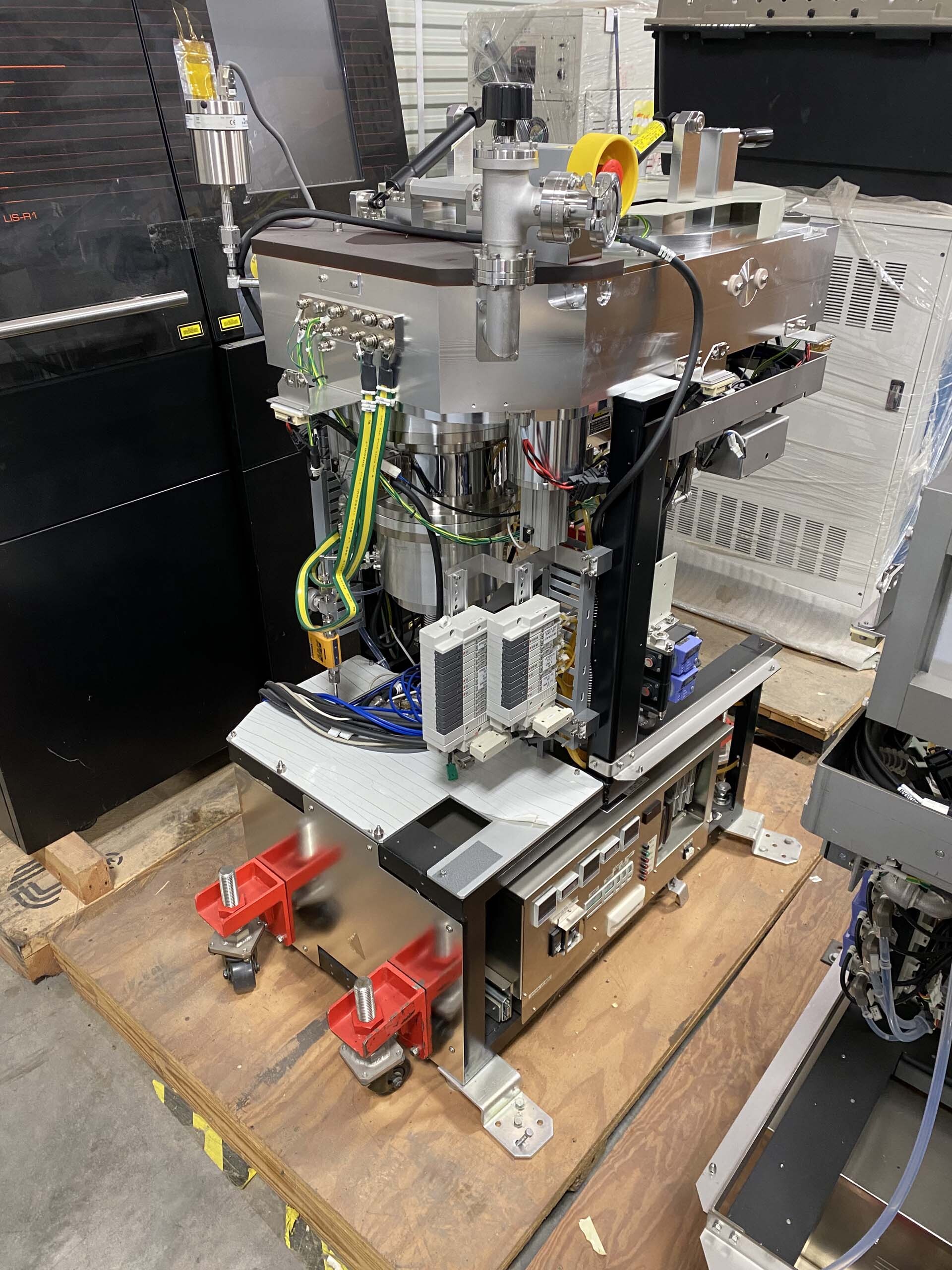

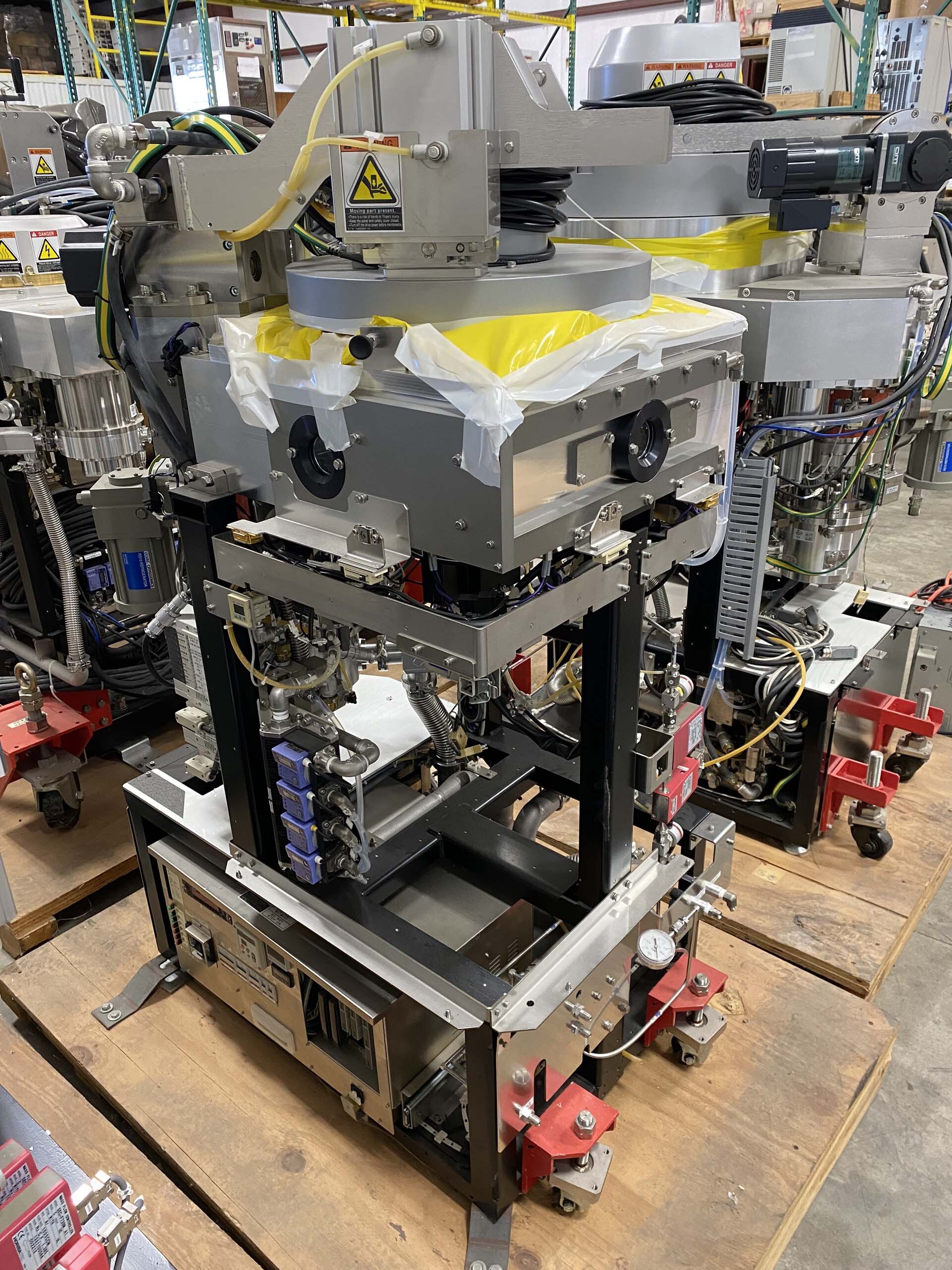

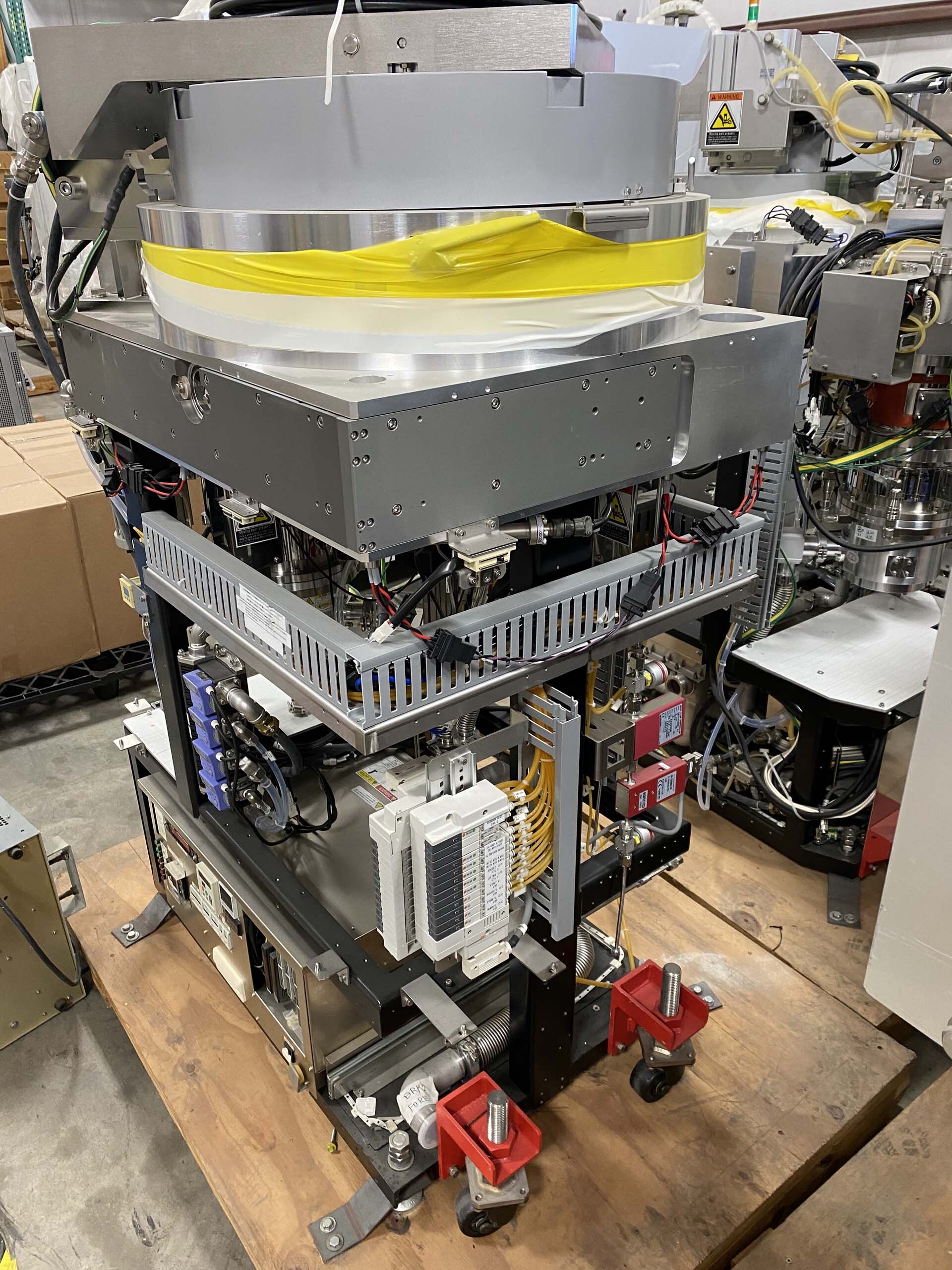

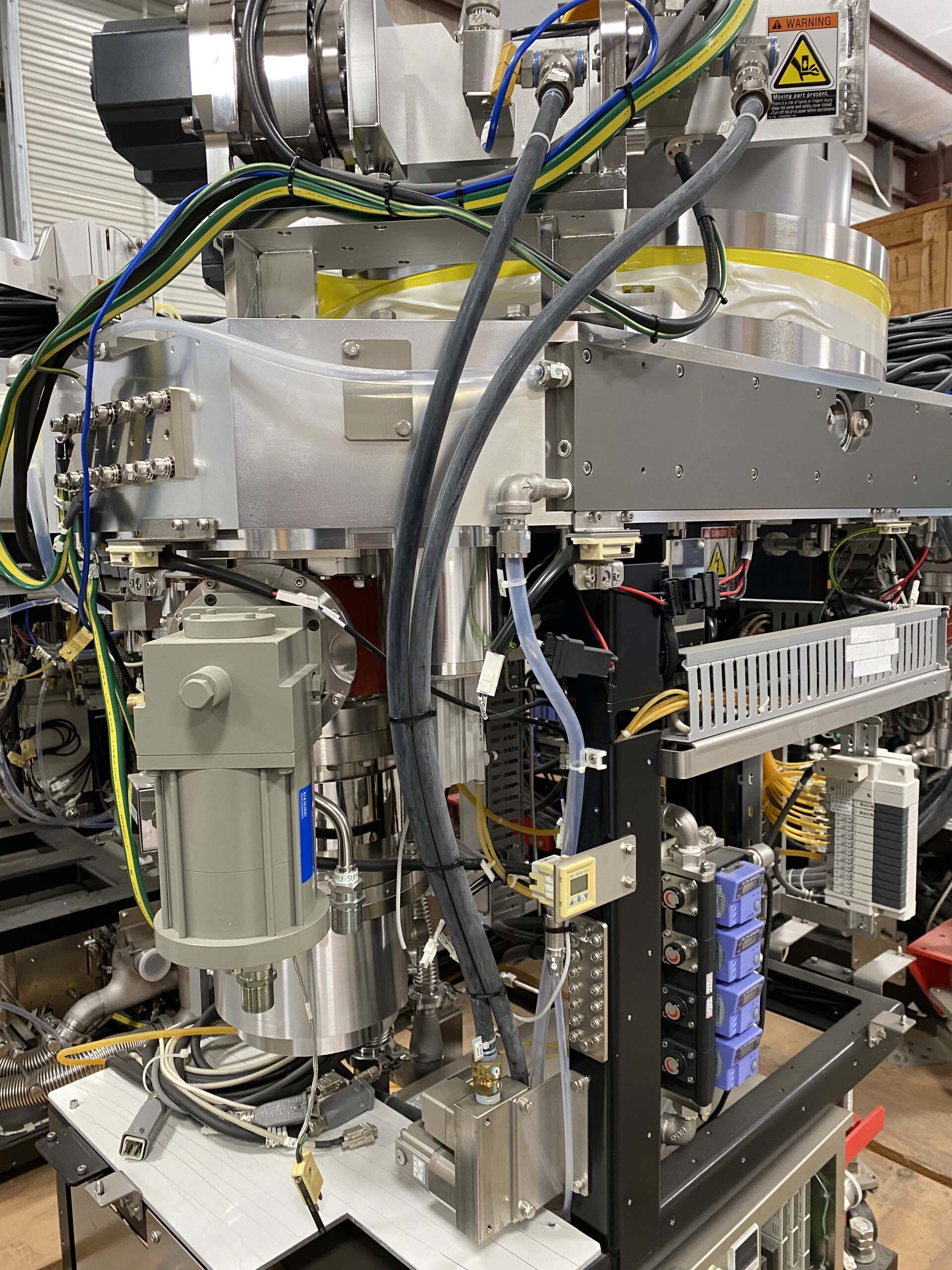

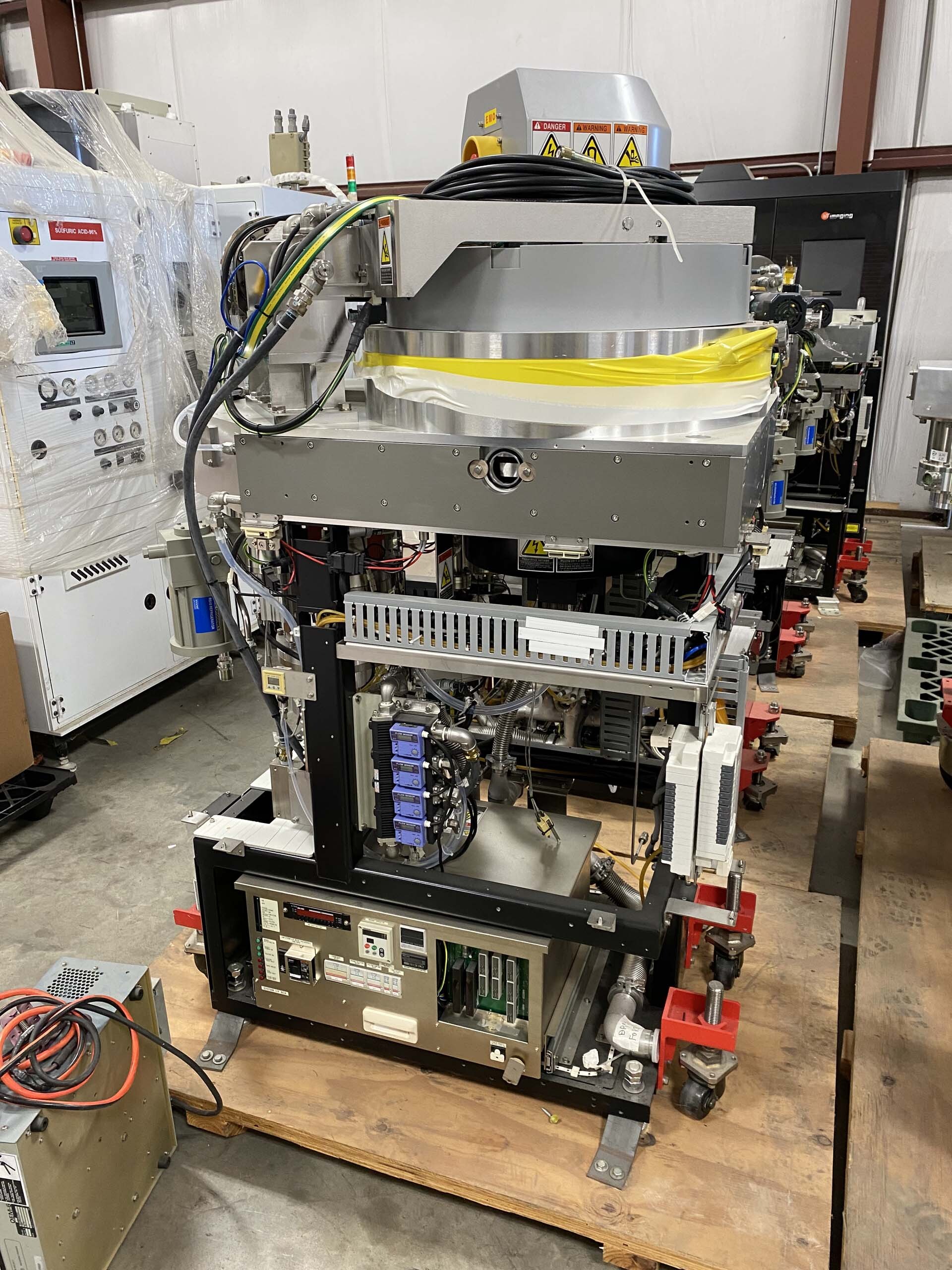

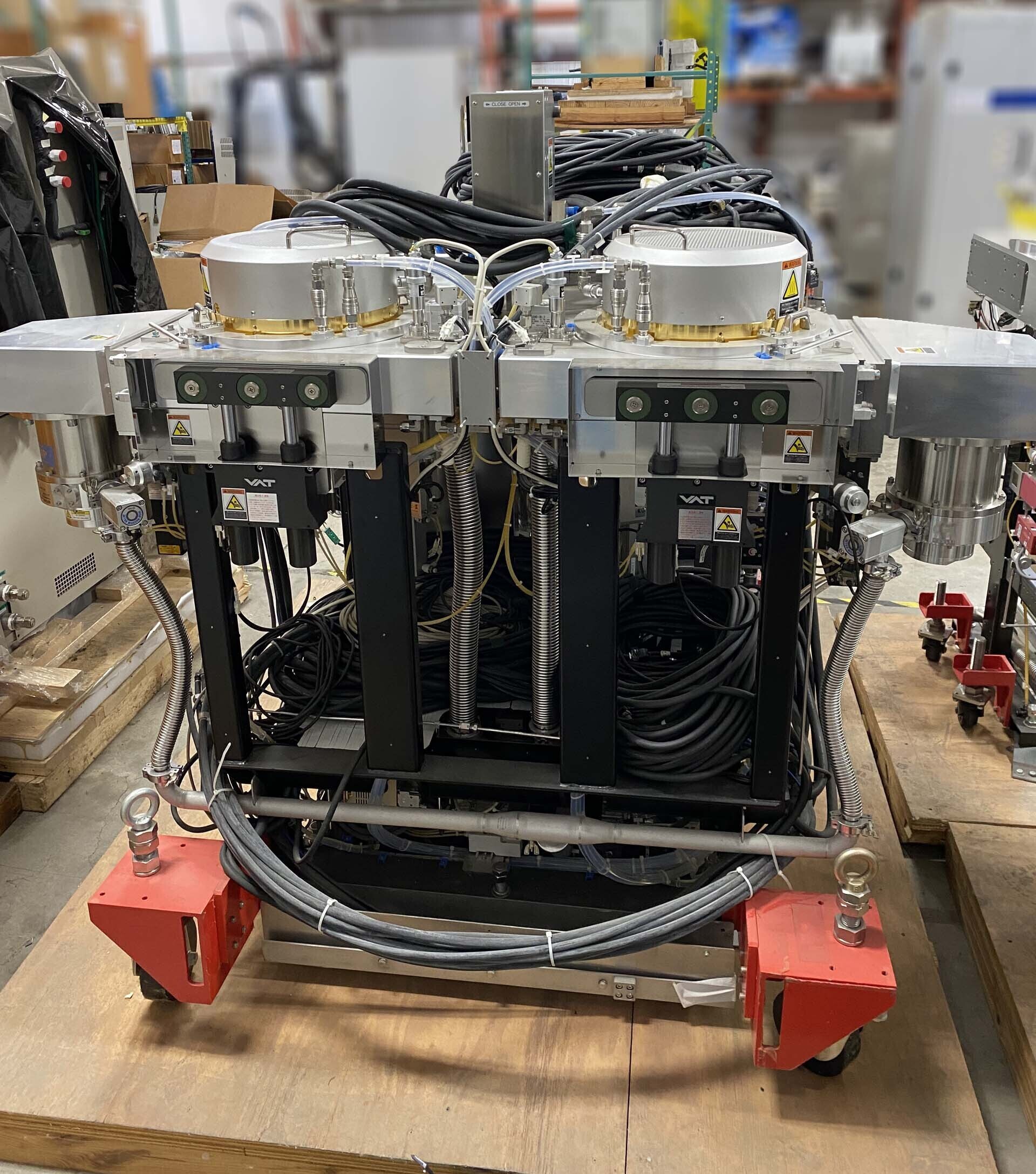

Used ULVAC Entron W 200T6 #9289943 for sale

URL successfully copied!

Tap to zoom

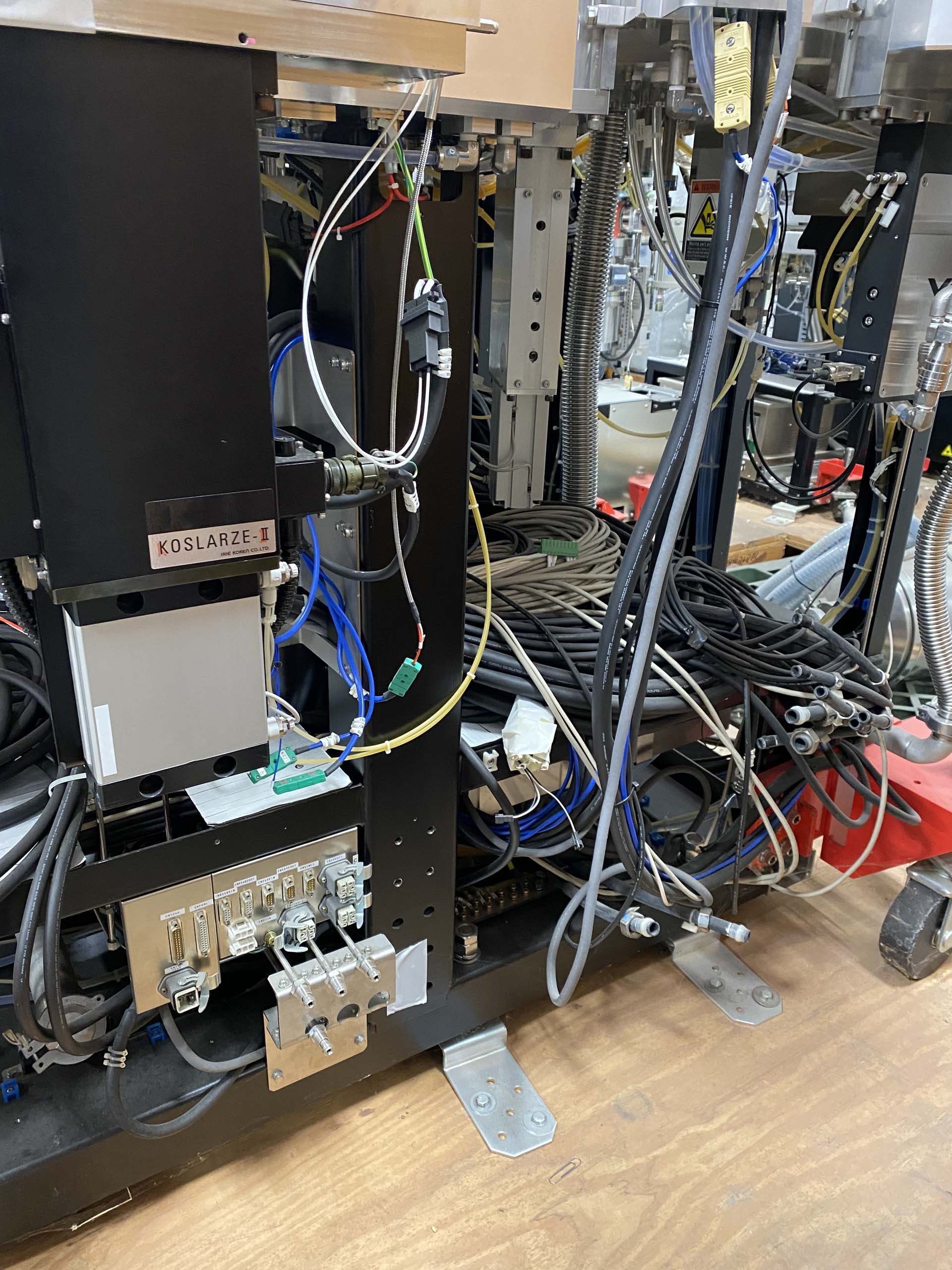

ID: 9289943

Wafer Size: 8"

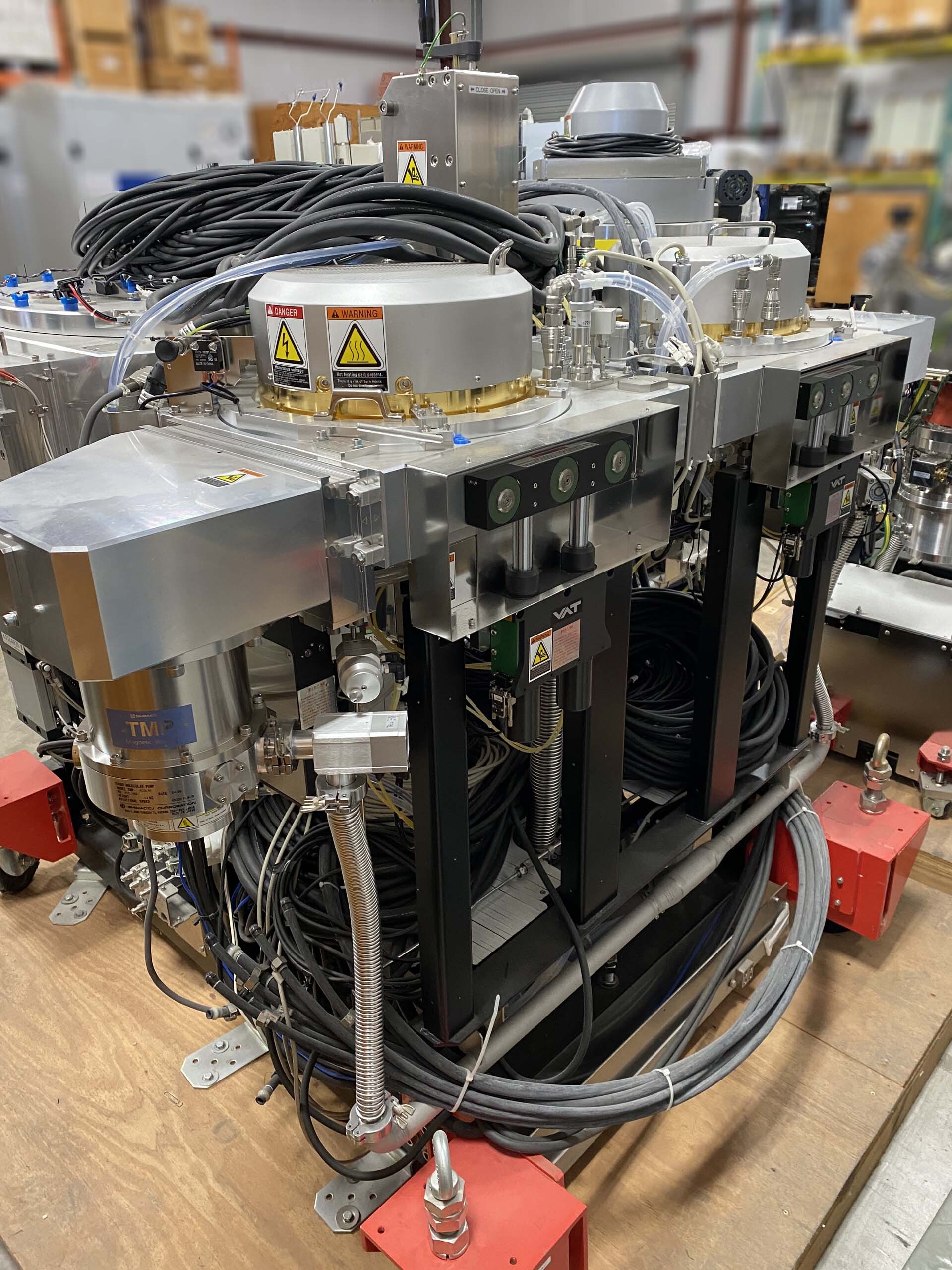

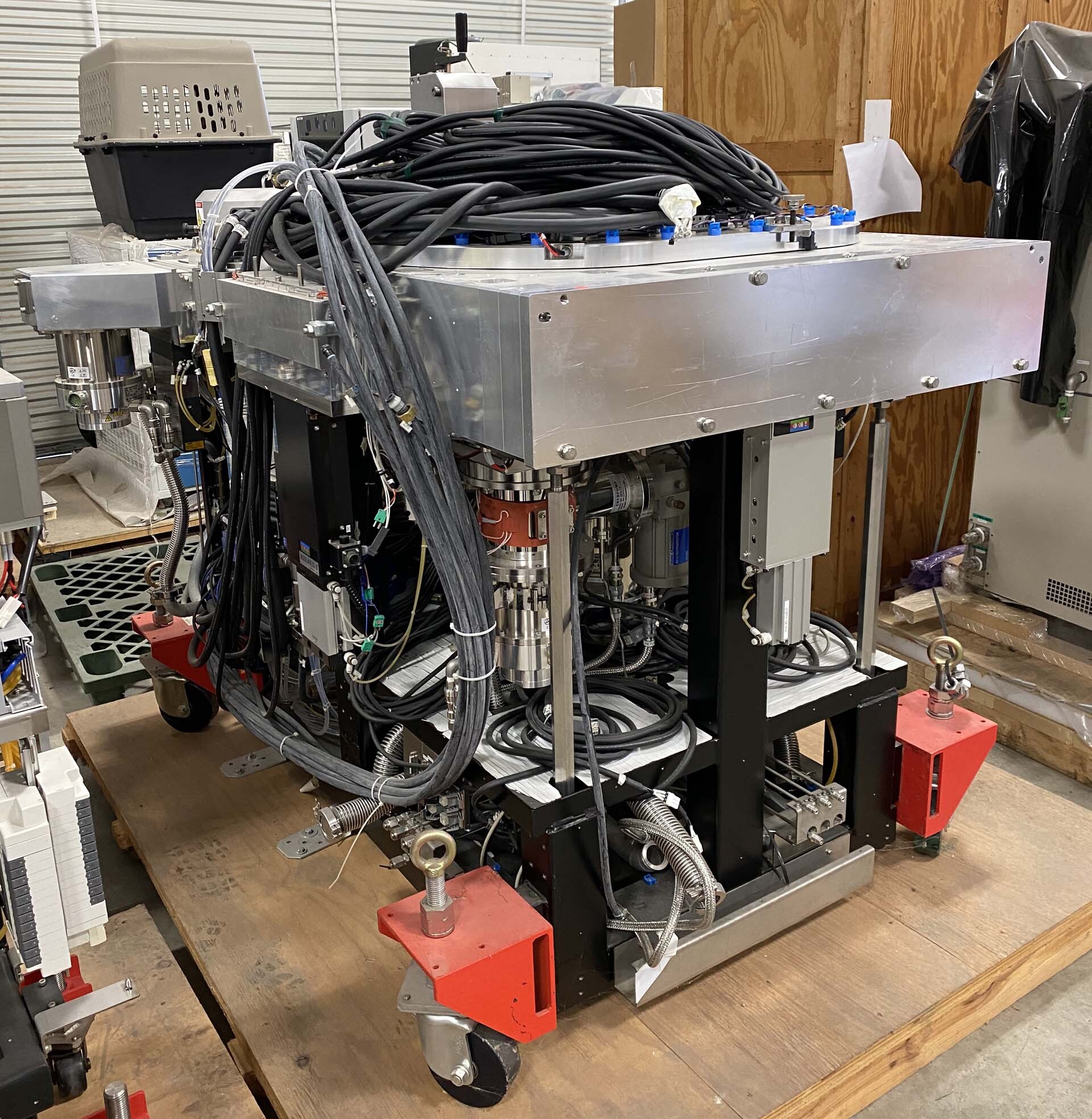

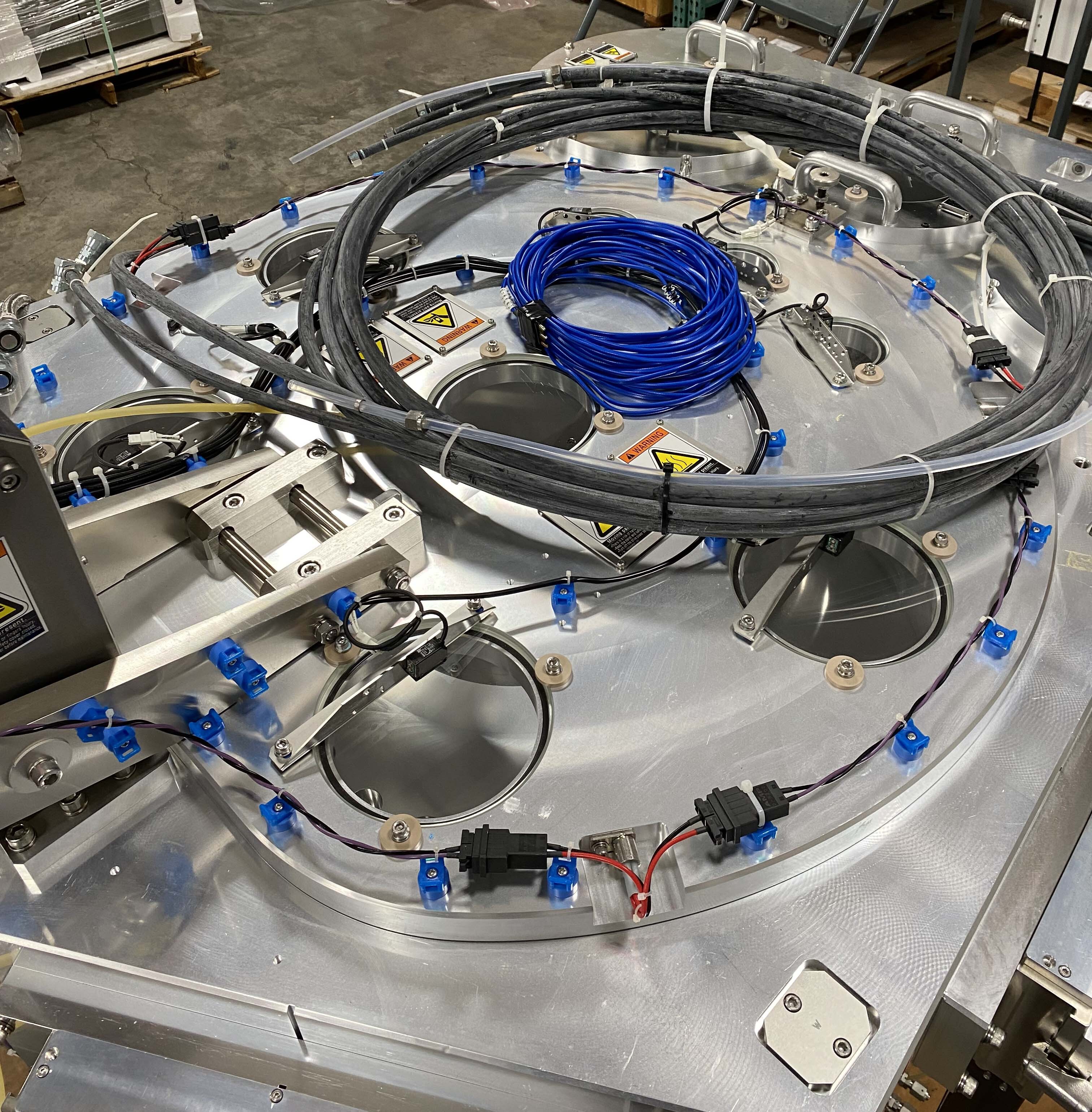

PVD Sputtering system, 8"

Chemical dry pre-clean chamber

Anneal chamber for chemical dry pre-clean chamber

Anneal chamber for post anneal

PVD-Ni Chamber

PVD-TiN

PVD Co Chamber

Front loader

(2) Transfer chambers

Main power rack

(6) Flow sensors:

(3) FS-10

(2) FS-3

FS-30

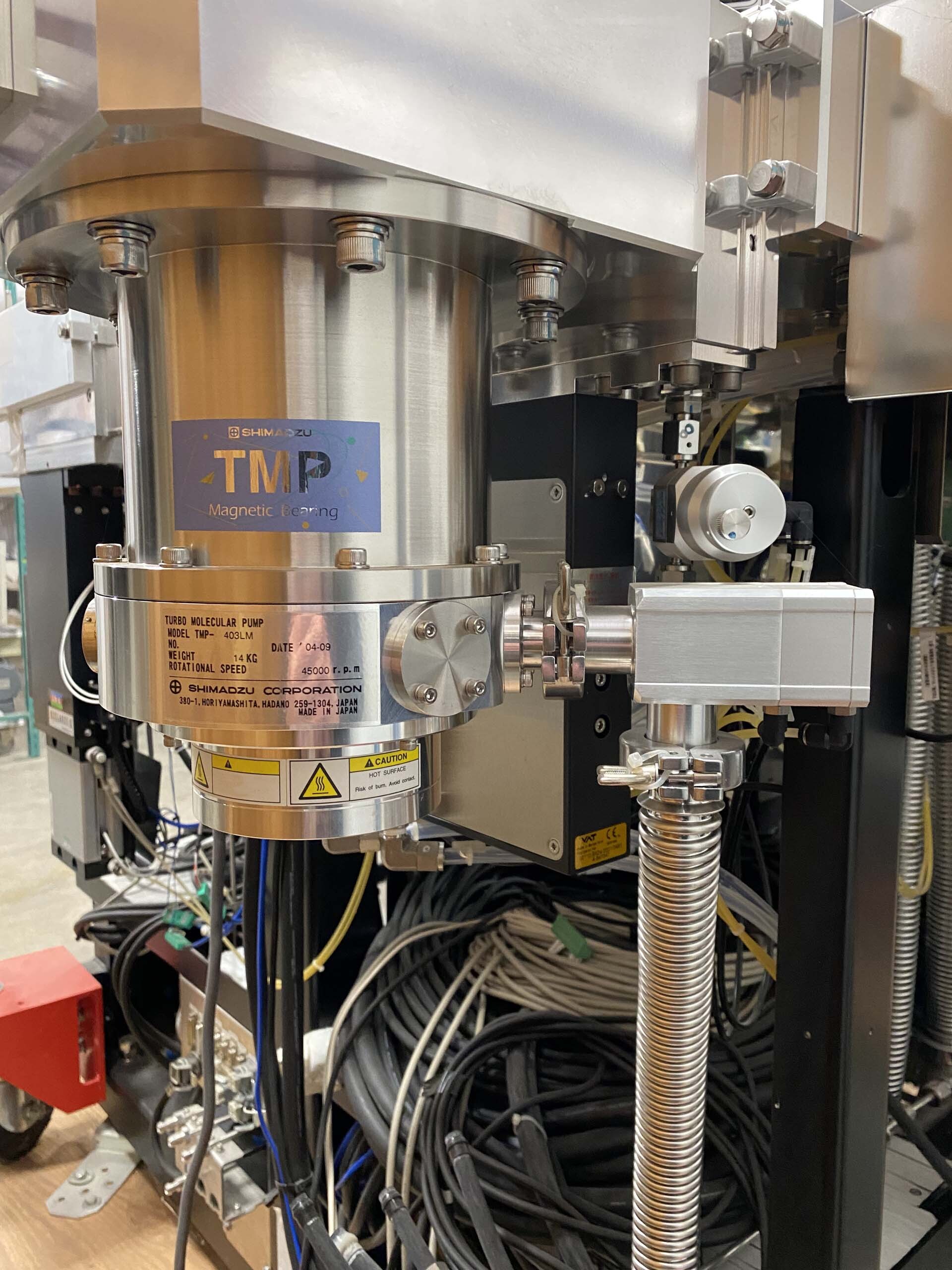

ULVAC CRYO-T8SN Cryo pump

HORIBA SEC-f730M A1 Mass Flow Controller (MFC)

Valve C

Gas used: Ar

Flow rate: 200 SCCM

Type: 02212

Cables and manuals included

Missing parts:

Controllers

Power supply.

ULVAC Entron W 200T6 sputtering equipment is a high-tech instrument designed for predominantly PVD (Physical Vapor Deposition) processes. It uses a wide range of target materials, including metals and dielectrics, to deposit thin films onto substrates. This system features a 200mm sputtering deposition chamber, with an integrated low- leak transfer lock-chamber that enables easy material exchange with an internal transfer robot. The multi-tier 6-slot platform and patented electrostatic chuck design provide unparalleled sample uniformity up to and across thermal-shocked* substrates. The unit comes equipped with ULVAC Technologies' proprietary charge neutralizer technology, which is ideal for deposition of ultra-thin films, especially for high-quality ITO. Additionally, ULVAC ENTRON W-200T6 is equipped with high-speed continuous motion positioner, allowing for "undo" operations as needed. For improved reactive sputtering process stability, Entron W 200T6 also integrates an ultra-stable, continuously adjustable mono-thermal plasma source. The machine also utilizes a multi-point mass-flow controller; providing an even balance of reactive gas across deposition chamber sections and zone temperatures. Patented temperature control and monitoring (TCMS) functions are further implemented to determine the substrate temperature, ensuring the best parameters to minimize film micro- defect formation. An advanced monitoring tool displays total monitor data and crystal monitor patterns. The optional advanced controller, ARM-5 Remote Interface, on the other hand, automates asset settings to meet desired recipes for routine operation. ENTRON W-200T6 sputtering model is a robust, reliable and easy to use tool that provides excellent reproducibility, making it an ideal platform for repeatable and reliable deposition processes. *Thermal-shocked substrates refer to a substrate that has just undergone an abrupt temperature change, such as a thermal shock annealing process.

There are no reviews yet