Used ULVAC SCH-135 #9411089 for sale

URL successfully copied!

Tap to zoom

ID: 9411089

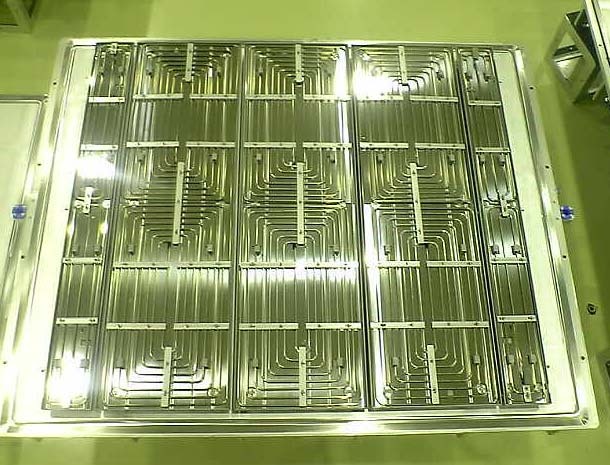

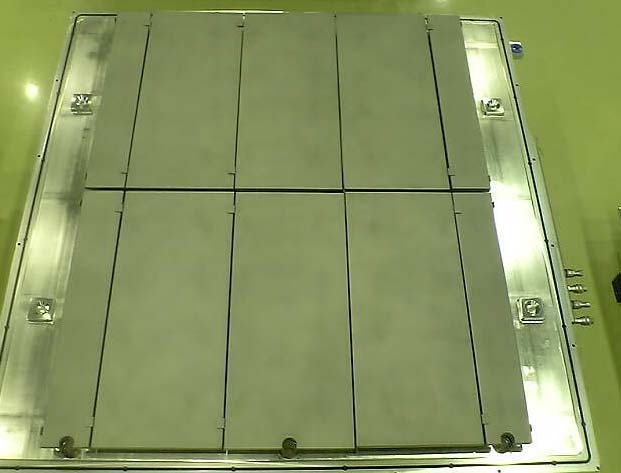

Horizontal inline sputtering system

Electrode deposition 90 sec tact

Chamber:

Loading

Heating

Isolation

Unloading

Assembly:

Vacuum

Transfer

Internal jig

Heating

Sputtering cathode

Power supply

Frame and conveyor

System:

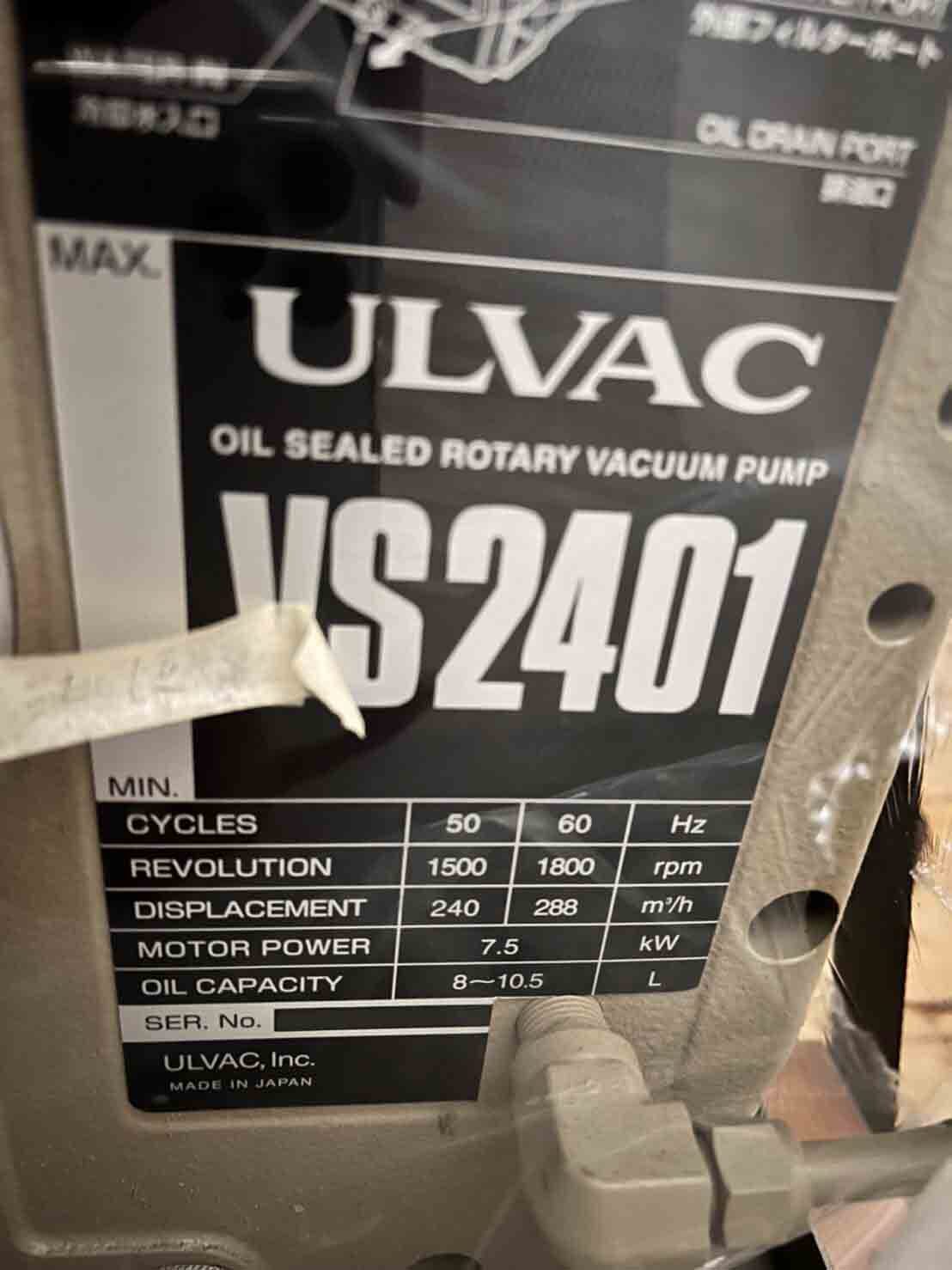

Pumping

Operation

Measurement

Gas inlet

Compressed air

Cooling water

Spare parts.

ULVAC SCH-135 is a high-precision sputtering equipment designed for optimal thin-film deposition. This system is ideal for forming thin metal, oxide, and nitride layers with precise control and uniformity over large areas. SCH-135 is an advanced, single-ended magnetron sputtering unit composed of a high-accuracy substrate positioner, a sophisticated controller, and a cluster of variously-sized magnetic sputtering targets. ULVAC SCH-135 allows for depositions to take place at higher pressures than other conventional systems and has become a leading tool for industrial thin-film applications. SCH-135 offers one-dimensional uni-directional sputtering that can operate at a wide range of pressures, from high-vacuum (1x10-7 Pa) to ultra-high-vacuum (1x10-9 Pa). Electrons from the cathode are accelerated towards the anode, and when they impact the target, they cause detachment of target atoms which are then deposited onto substrates. This sputtering process is highly repeatable and reliable, and provides excellent control over thin-film properties such as thickness, composition, shape, and reflectivity. The controller interface of ULVAC SCH-135 is extremely user-friendly and allows for easy setup, control, and monitoring of thin-film multi-layered deposition processes. It has a large database of pre-defined recipes for sputter deposition processes, allowing for easy programmatic control of the machine. Additionally, the innovative graphical user interface (GUI) allows operators to easily visualize the deposition process, which sets SCH-135 apart from other sputter systems. ULVAC SCH-135 is the go-to tool for large-area thin-film deposition applications in industrial and scientific fields. It is widely used to produce thin-film transistors, optical coatings such as AR coatings, dielectric mirrors, energy storage and harvesting devices, as well as thin-film encapsulation/passivation layers. Moreover, its ability to produce thin-film layers with high precision and uniformity makes it ideal for a wide range of scientific research applications, such as the study of physical, chemical, and optical properties of thin-film materials. In short, SCH-135 sputtering tool is an advanced thin-film deposition asset capable of depositing high-precision, uniform thin-film layers onto large areas with highly repeatable, reliable results. It has a sophisticated controller interface and graphical user interface (GUI) that make setup, control, and monitoring of thin-film deposition processes extremely user-friendly and efficient. With ULVAC SCH-135, thin-film applications in industrial and scientific field have gained significant momentum and it is one of the most widely used sputtering systems for thin-film deposition.

There are no reviews yet