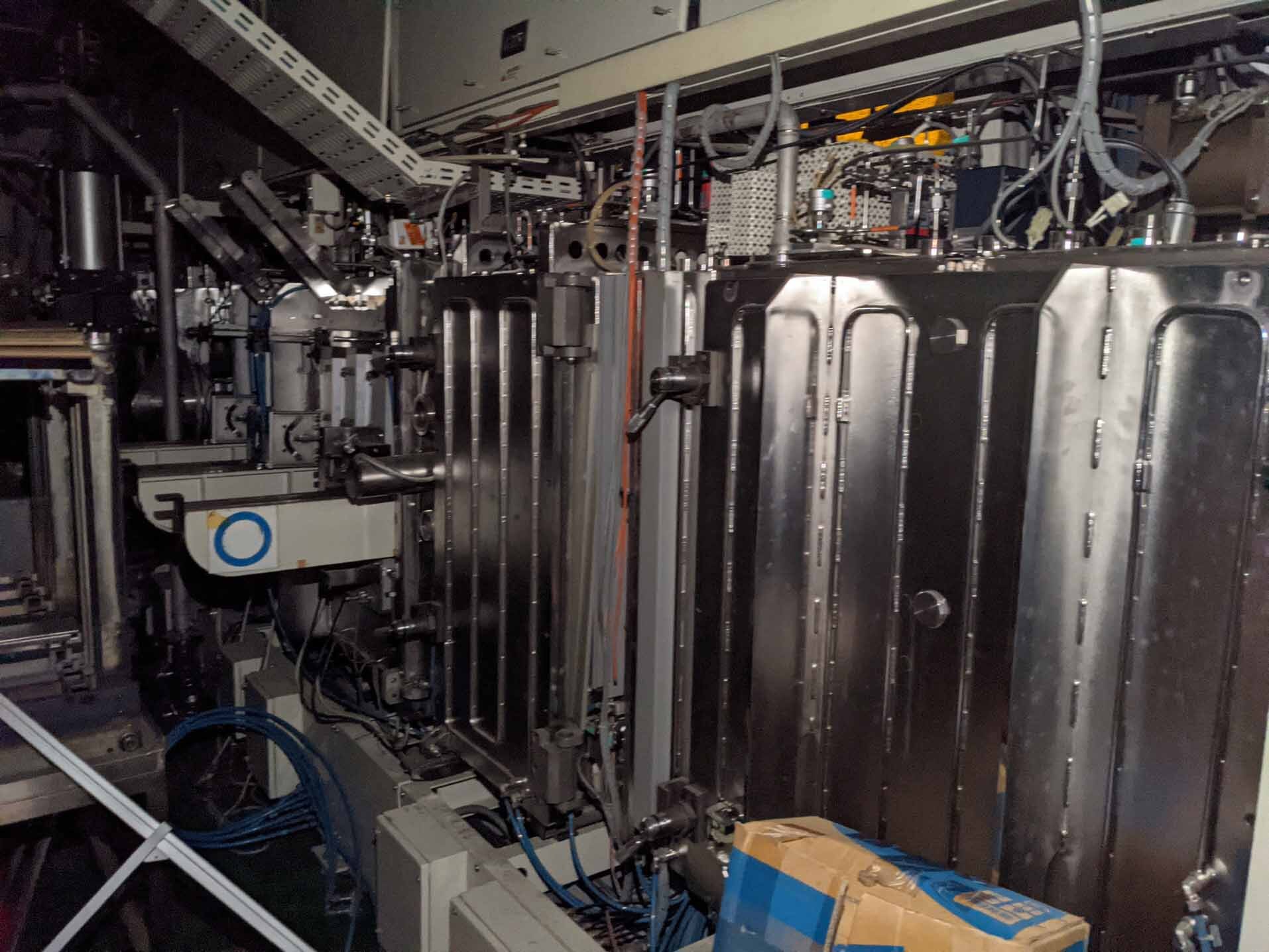

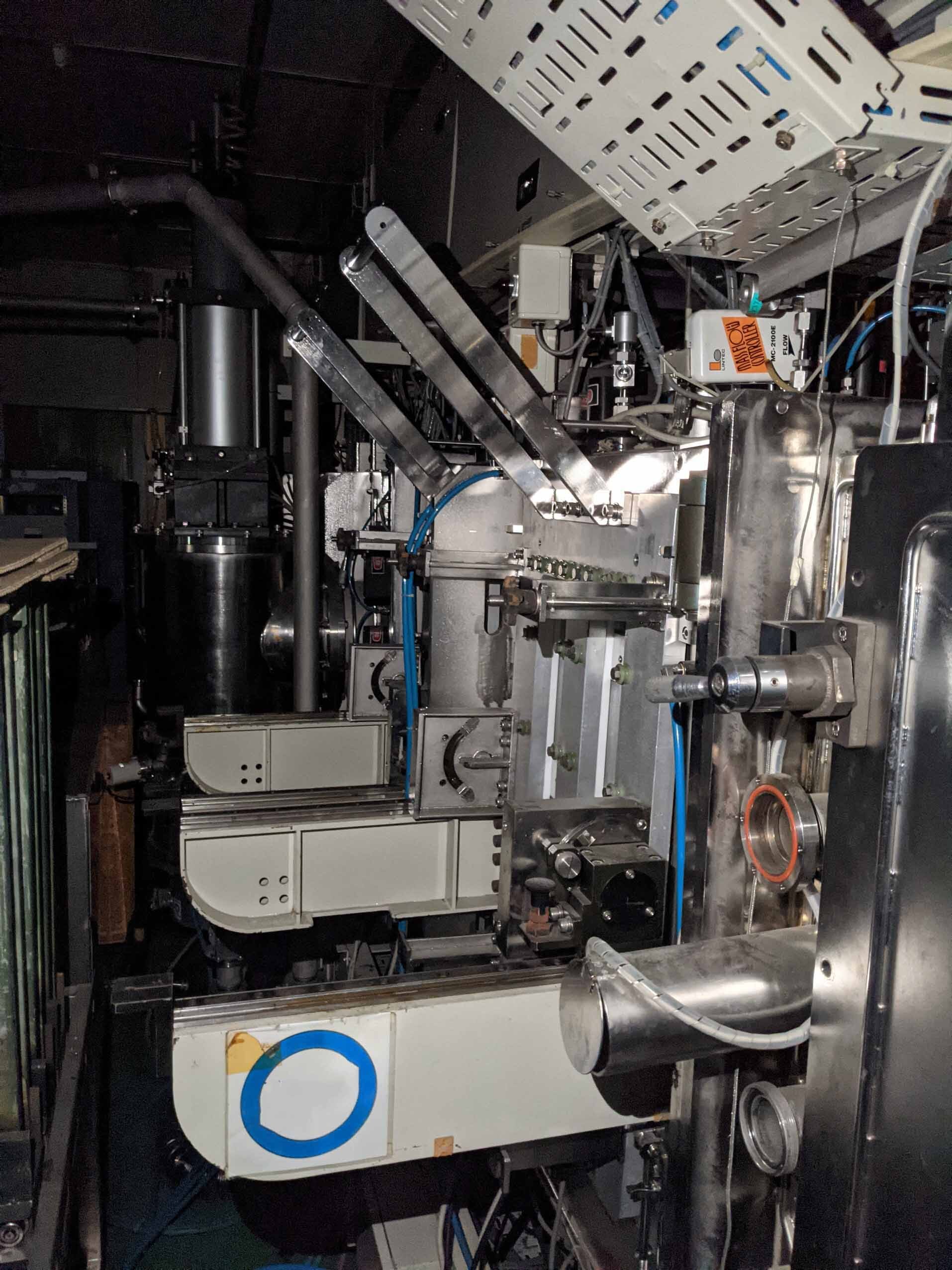

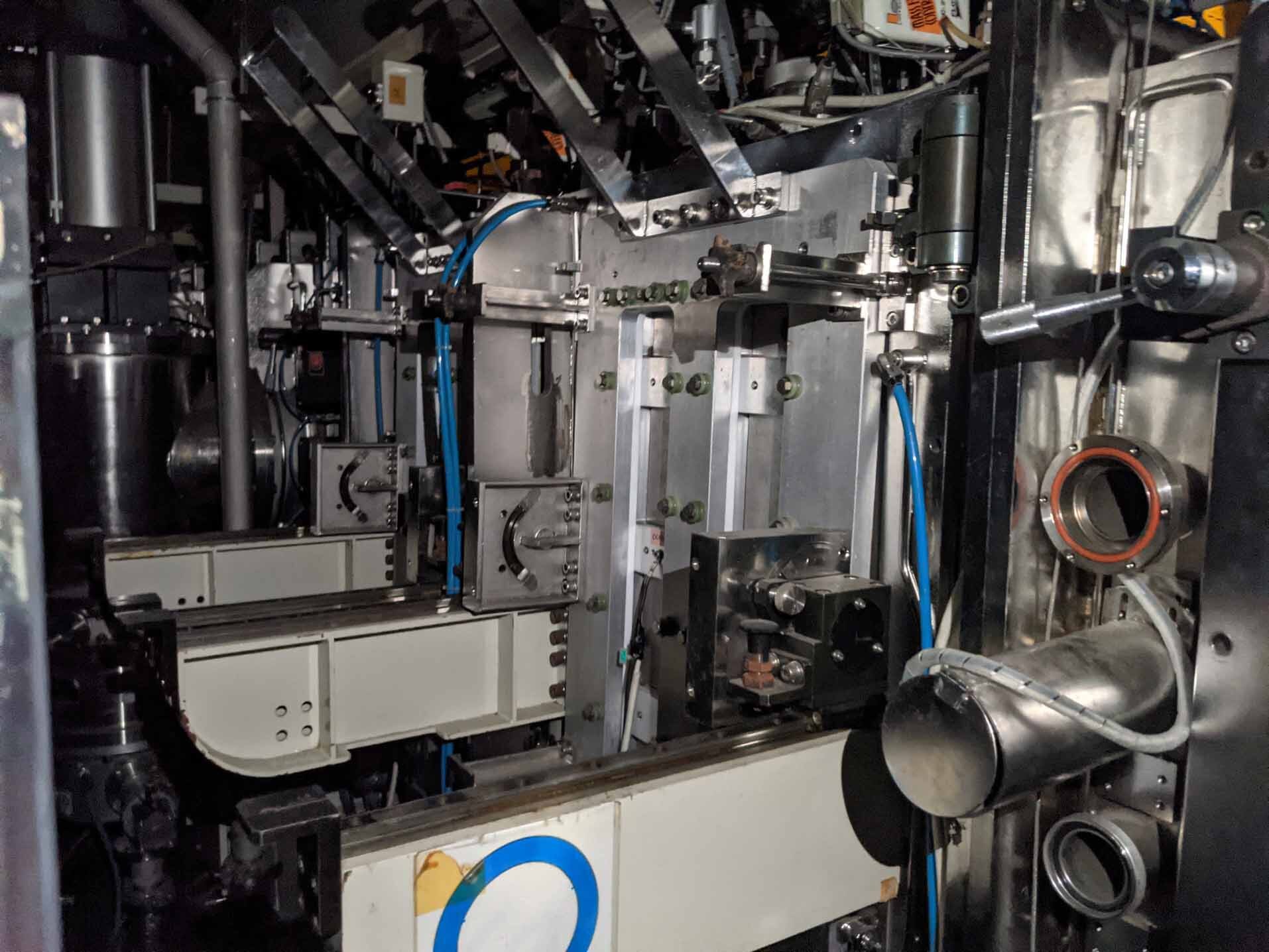

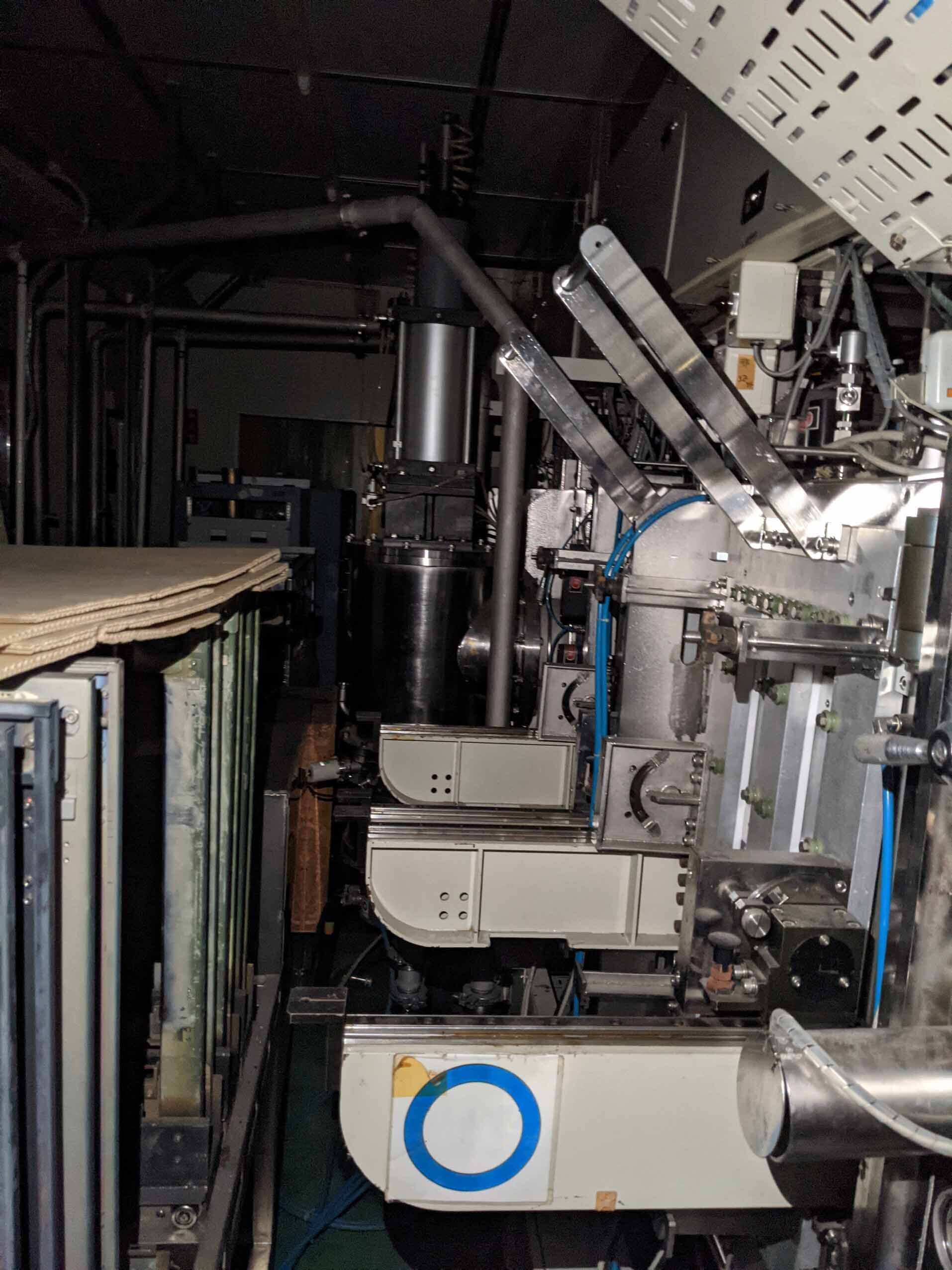

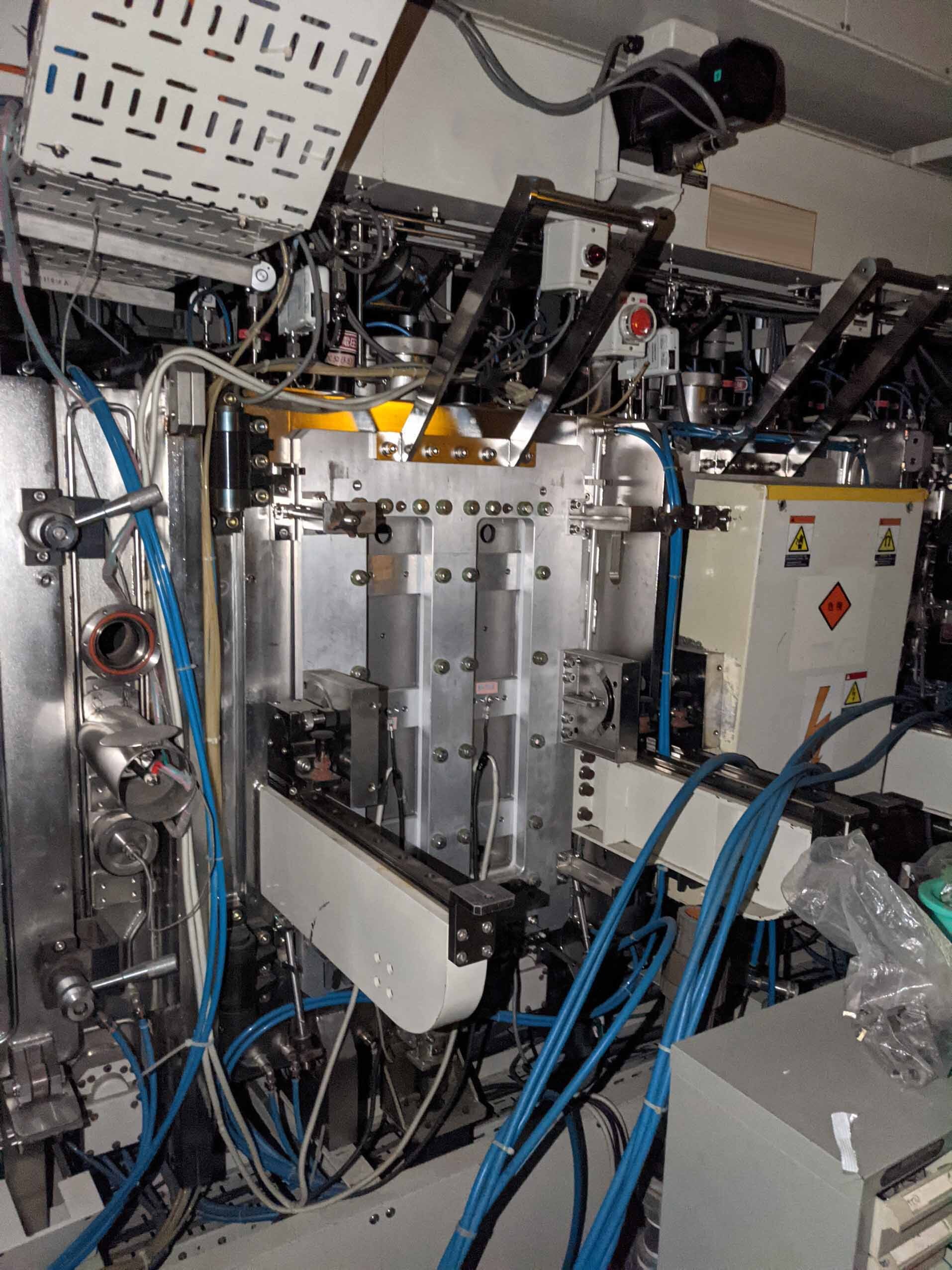

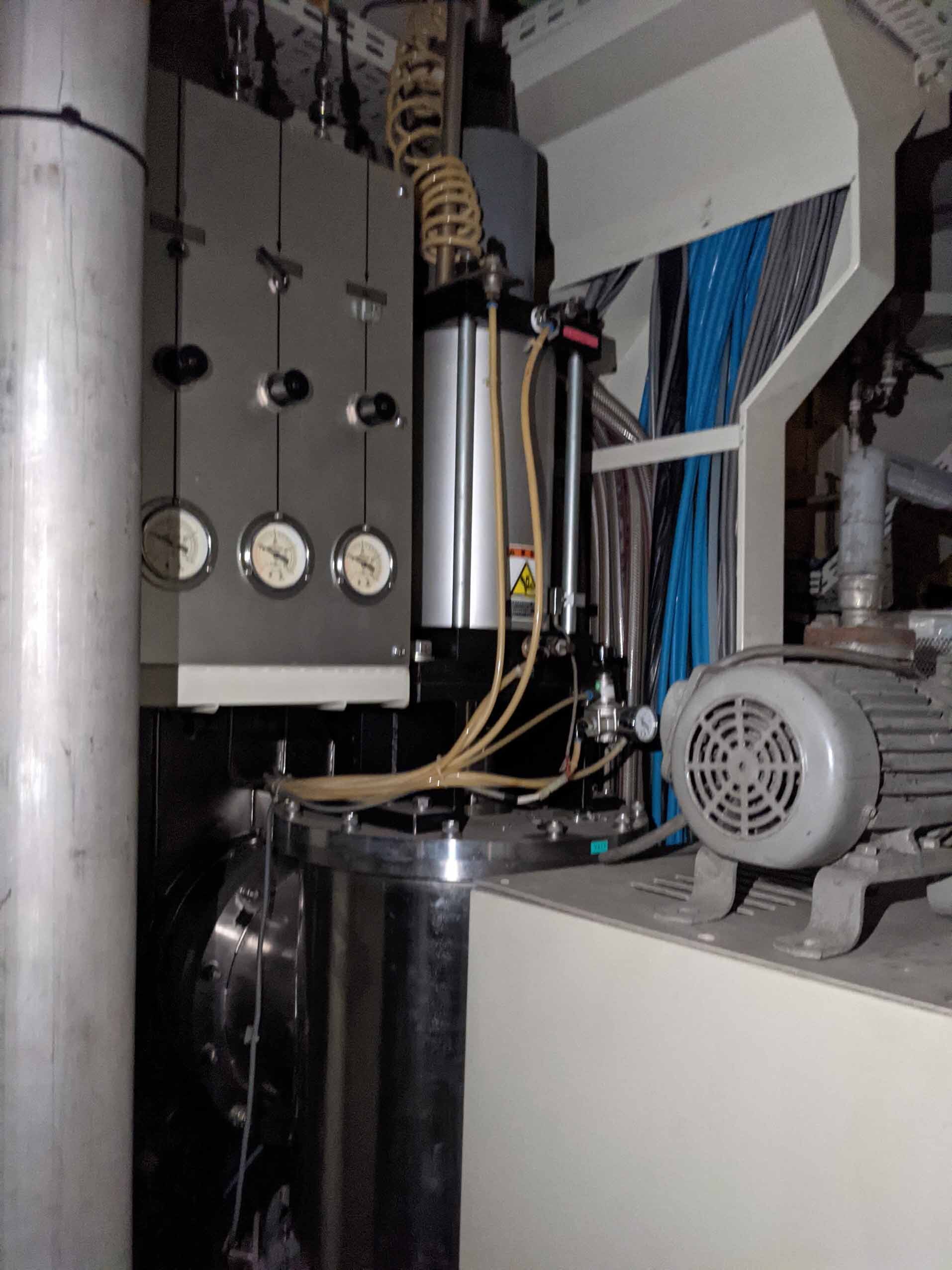

Used ULVAC SDP-550 #9411768 for sale

URL successfully copied!

Tap to zoom

ULVAC SDP-550 is a sputtering equipment that is designed to deposit thin layers of materials onto substrates. It combines a powerful DC/RF magnetron sputtering chamber with an efficient rotatable sample holder. SDP-550 offers high uniformity of deposition and reliable sample transport, while its automated sputtering setup enables swift material selection and parameter selection. The sputtering chamber of ULVAC SDP-550 accommodates two or three targets, which are mounted on a rotatable stub or slide. All of the chamber components are made of stainless steel, and the chamber is designed to minimize the accumulation of deposited materials. An evaporation chamber is also available for sample-dedicated evaporation. This can be used for the deposition of high-purity metal layers and coating materials. SDP-550 offers a wide range of deposition sources. These include DC magnetron sputtering, RF magnetron sputtering, electron beam evaporation, multipole DC magnetron sputtering, directional DC magnetron sputtering, reactive DC magnetron sputtering, ion beam sputtering, suspended target sputtering, and laser induced deposition. All deposition sources can be easily installed and configured for complete sample coverage. In order to ensure uniformity of deposition across the substrate, ULVAC SDP-550 can be equipped with a special sample holder. This is designed to minimise target shadowing, enabling uniform deposition over the entire sample surface. The system also includes a two-stage chuck that provides excellent electrical connectivity and high sample rotation accuracy. SDP-550 is equipped with a number of safety features, such as a safety vacuum interlock, a cover opener, and pressure sensors. An automated sample handling unit is also available, enabling operators to use sample cassettes, enabling them to perform more efficient sample imaging and etching. ULVAC SDP-550 offers a wide range of deposition methods and high process uniformity. This makes it ideal for the deposition of a range of materials, such as ceramics, nano-coatings, metals, and metals alloys, onto any type of substrate. Its automated features and safety features, as well as its ability to provide uniform deposition across the entire substrate, makes it a great choice for anyone looking for a reliable sputtering machine.

There are no reviews yet