Used ULVAC SIH-4545 #9050844 for sale

URL successfully copied!

Tap to zoom

ID: 9050844

Vintage: 2005

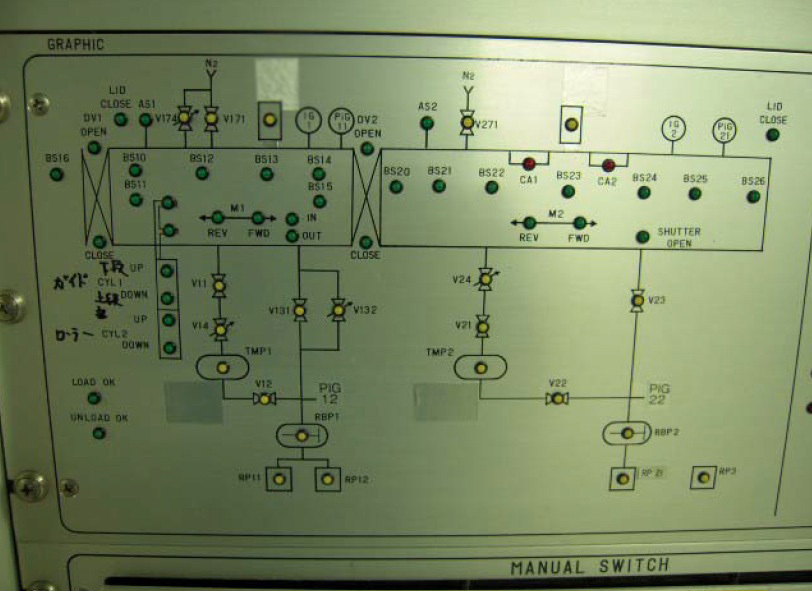

Horizontal inline sputtering system

Includes:

2-Chamber

Board try transport

Reverse sputtering mechanism (500 W)

Automatic film formation by exhaust operation

Automatic thickness meter

(16) pieces substrate holders: 460 mm x 470 mm (4 in/piece)

Exhaust system: TMP, RP, MBP

Up to high-rate magnetron cathode

Sputtering source: 5" x 15" x 1"

Power: DC (5 kW), RF (5 kW) switchable

Gas system: Ar (100 sccm), O2 (50 sccm)

Control system: Sequencer, touch panel system

2005 vintage.

ULVAC SIH-4545 is an advanced sputtering equipment used in the manufacture of microelectronic devices. It has been designed to provide uniform and precise deposition of thin films onto substrates, with great accuracy and repeatability. The system can also be used for thin-film deposition for complex structures, such as interconnects and metal oxide resistors. SIH-4545 unit consists of four independent sputter sources and a load-lock chamber. The sources, which are each powered by 2800W magnetrons, are mounted on the front side of the machine. This allows for even and uniform sputtering of the target material of choice, and features a wide range of process gases, including argon, nitrogen and oxygen. A repeatable, high-resolution shutter tool is included for precise control over the plasma sputtering process. The load-lock chamber is designed for rapid sample loading, and provides automated sample analysis and sample surface pre-treatments (such as Plasma Activated Cleaning and Plasma Enhanced Chemical Vapor Deposition). This feature further enhances the versatility of the asset. ULVAC SIH-4545 has a number of other features designed to improve productivity. For example, it can achieve high deposition rates of up to 2000 nm/min. Depending on the material, it can also achieve high uniformity over large areas of greater than 90%. Its average deposition uniformity is within 1-2%, and the model is also designed to meet the most demanding requirements for defect-free thin films. The equipment is designed to meet safety standards and is rugged and reliable with a lifetime of more than 30,000 hours. It also comes with an integrated refrigeration system and a low-maintenance water recycling unit. Finally, ULVAC provide a wide range of accessories, such as measuring tools, process automation systems, and an upgradeable Film Monitor Module. In sum, SIH-4545 is a versatile, reliable and powerful sputtering machine. Its wide range of features allow for high-quality and accurate thin-film deposition over large substrates. It is designed to be user friendly and offers high performance and reliability for a wide range of microelectronic device fabrication applications.

There are no reviews yet