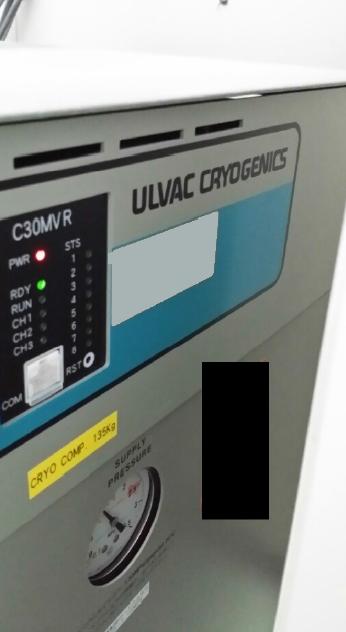

Used ULVAC SIV-200S #9107294 for sale

URL successfully copied!

Tap to zoom

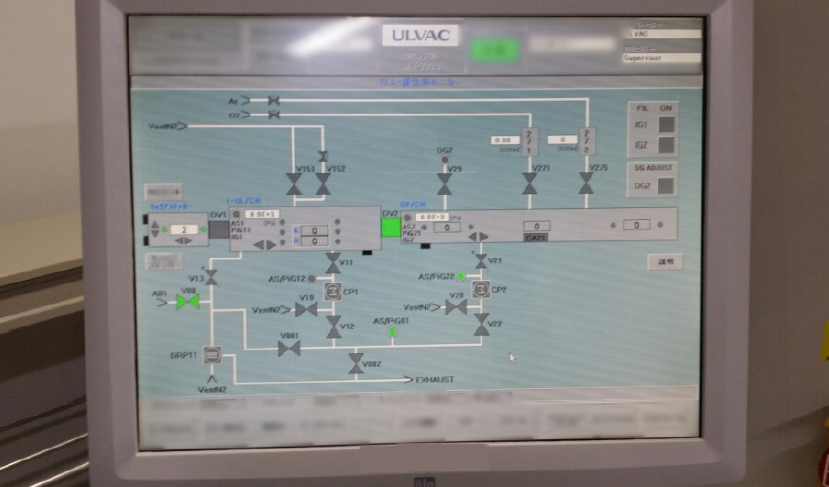

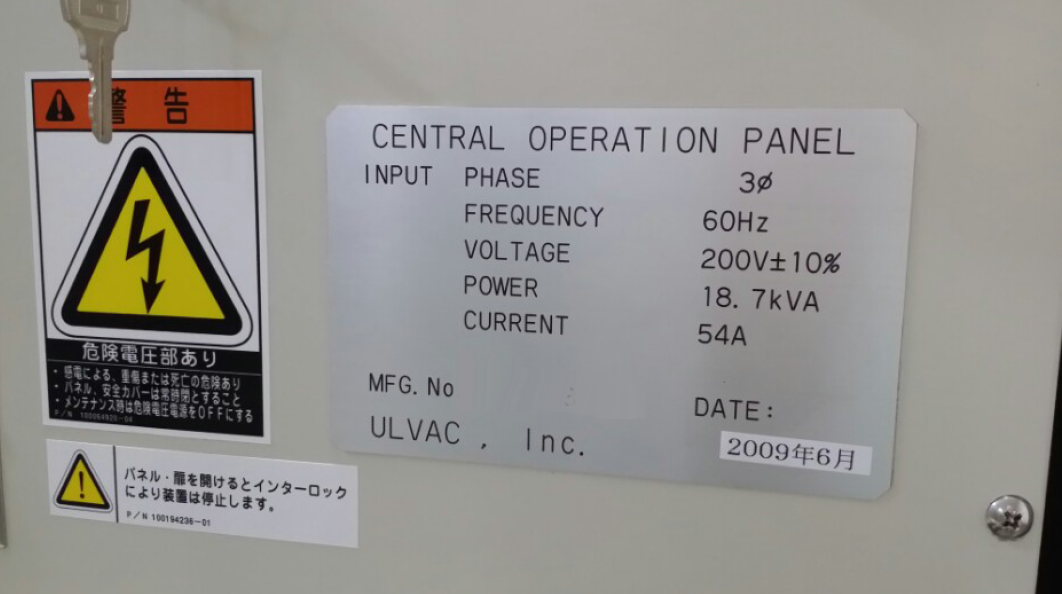

ULVAC SIV-200S is a sputtering equipment manufactured by ULVAC (Ultra-Precision Vacuum Technology). It is an ultra-small sputter deposition system designed for coating of high-transparency films such as ITO and A-Si, on large substrates such as flat panels. The unit features a 2-source sputtering chamber, a single-source reactive sputtering chamber, and a high temperature atmospheric-pressure oxidation chamber, allowing for deposition of both conductive and insulative films. SIV-200S is a closed-loop, micro-processing machine featuring low energy consumption and high throughput. ULVAC SIV-200S utilizes a unique, 2-source magnetron sputtering technology to deposit films. This technology minimizes the risk of sputtered particles from the samples' surfaces while optimizing the ion bombardment in order to ensure film homogeneity. The sputtering process is highly efficient as confirmed by the high deposition rates (up to 50nm/min). Additionally, with the ability to deposit up to 4 targets simultaneously, the tool has high throughput capabilities. The single-source reactive sputtering chamber utilizes a compact RF magnetron to deposit oxide films such as ITO and A-Si. The unique single-source sputtering technology is capable of reducing contamination risk, improving film uniformity, and increasing the deposition rate up to 1500nm/min. The asset is also capable of incorporating scavenging mechanisms to ensure optimal ion bombardment. SIV-200S also features a high temperature atmospheric-pressure oxidation chamber for the deposition of refractory oxide films. This feature allows for the oxidation of metals for 4x increased oxidation rate while maintaining a high purity and homogeneity in the film. Overall, ULVAC SIV-200S Sputtering model is an ideal choice for highly efficient deposition of both conductive and insulative films. Its advanced technology and features make it perfect for tasks such as deposition of high-transparency films on large substrates, making the equipment well suited for flat panel display production.

There are no reviews yet