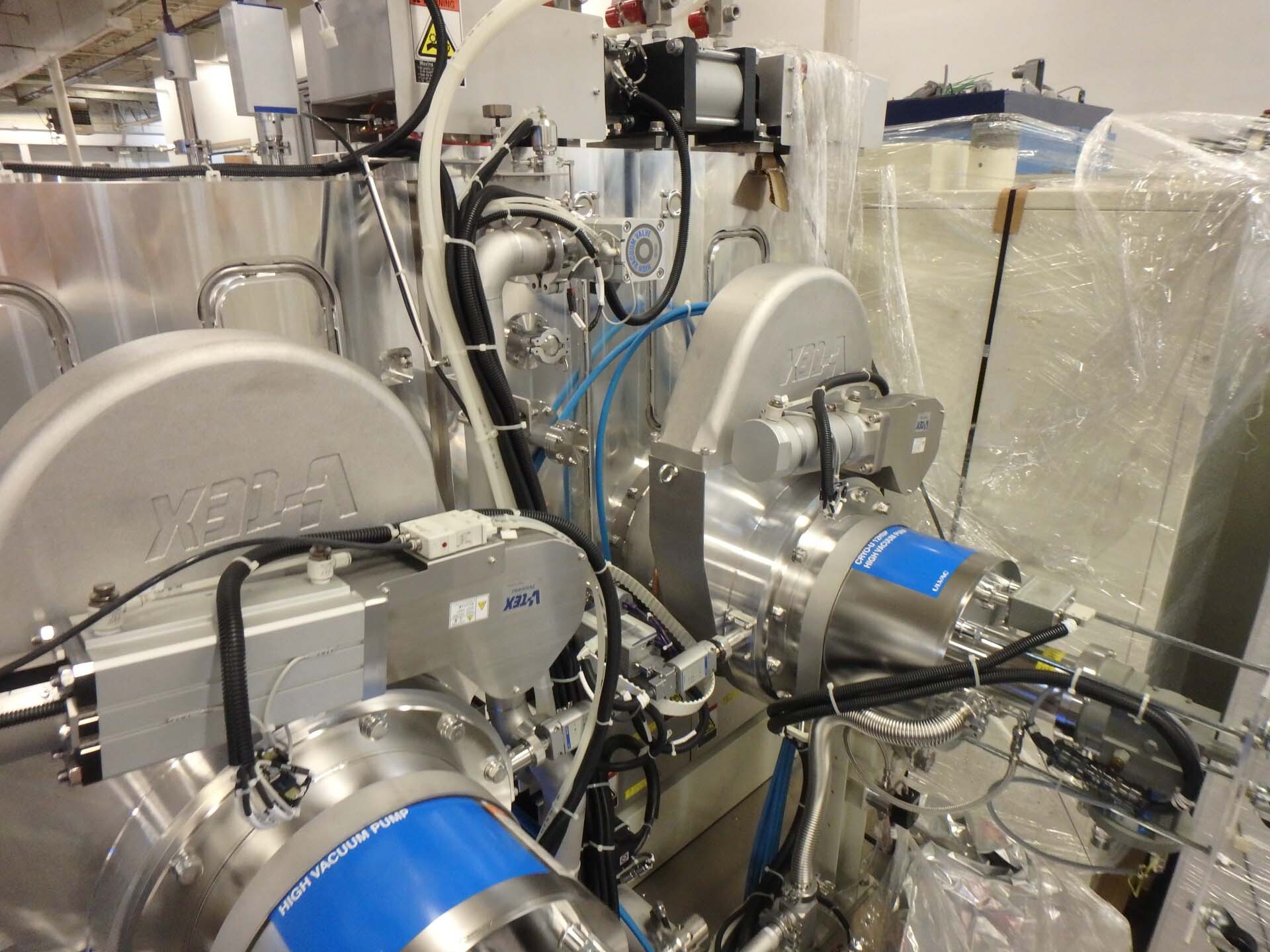

Used ULVAC SIV-500 #9382251 for sale

URL successfully copied!

Tap to zoom

ULVAC SIV-500 is a sputtering equipment that is used to create a thin film on the surface of a substrate, such as a computer chip. This sputtering system uses a rarefied gas, typically argon, as a source for depositing material onto the substrate. Using high voltage, the argon ions are accelerated toward the substrate surface, knocking away and depositing material from the top layer of the substrate. This process can be used to create two flat plates that are connected by a thin film, which is advantageous for creating computer chips. SIV-500 features a 500mm-by-420mm vacuum chamber with an internal volume of around 850 liters. It is equipped with a total of four sputter sources (three magnetrons and one DC planar) that can be moved around the substrate on an XYZ stage. It has the capability of low temperature sputtering and bias sputtering, which allows it to produce different densities of the films over the substrate surface. The unit also comes with a viewport and viewing software to monitor the sputtering process. ULVAC SIV-500 is also equipped with a load-lock and unload-lock module for loading and unloading of substrates up to 8 inches in diameter. It can handle wet process cassettes up to 5 kg in weight and can load up to three substrates at one time. It comes with a built-in substrate cooler to lower the temperature of the substrate and there is also an orthogonal view camera to check the deposition process in real time. SIV-500 is capable of making thin films between 10 nanometers up to a few microns thick. ULVAC SIV-500 is an ideal machine for an efficient sputtering process. It can handle a wide range of substrates which makes it ideal for various applications in the semiconductor, LED and display industries. It has advanced features such as the load-lock/unload-lock tool which provides high throughput as well as the real time process monitoring capabilities which ensure that each deposition process is running at its most optimum. All of these features, along with the modular design of SIV-500, make it the ideal asset for sputtering thin films.

There are no reviews yet