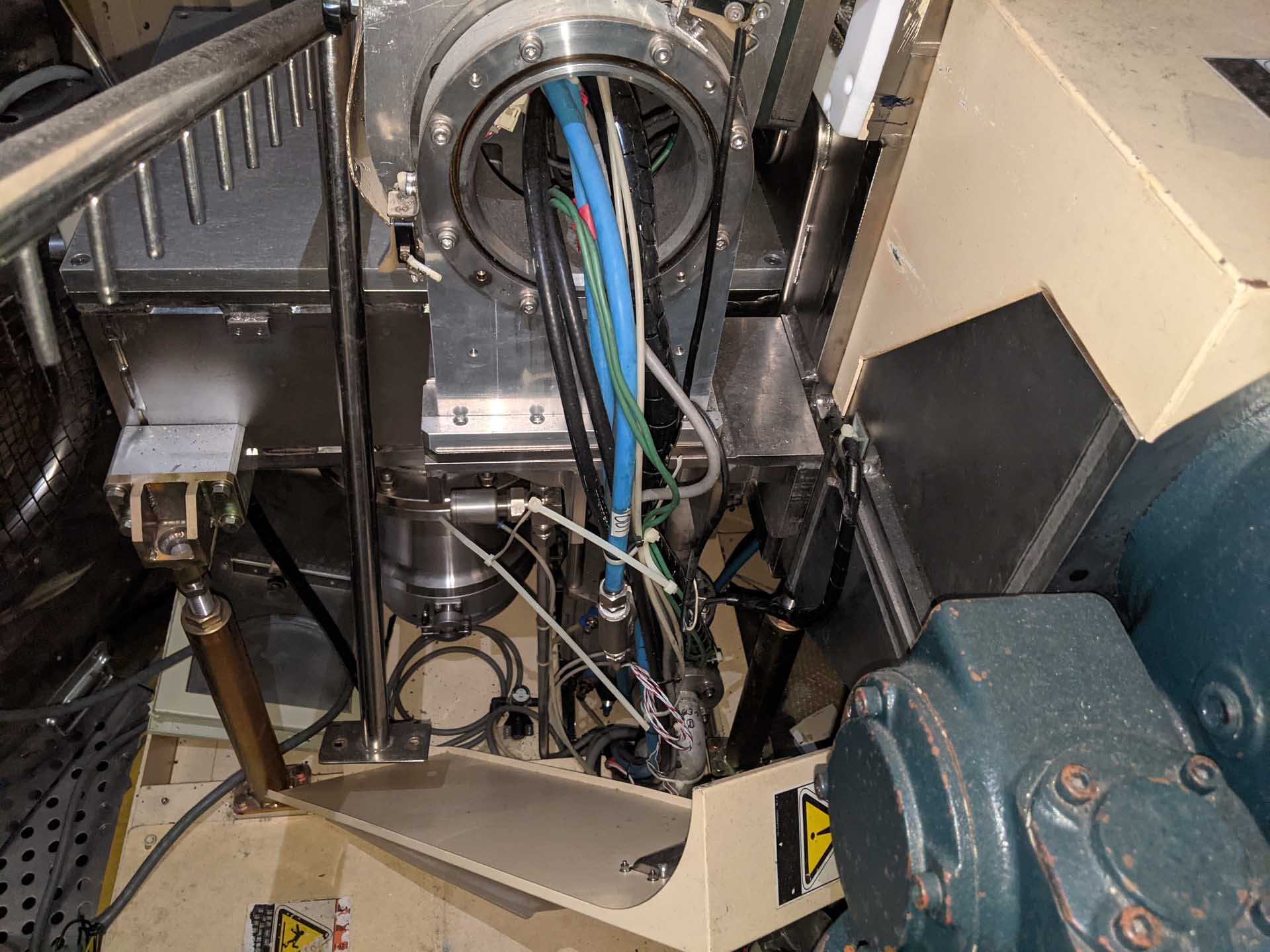

Used ULVAC SMD-450 #9412542 for sale

URL successfully copied!

Tap to zoom

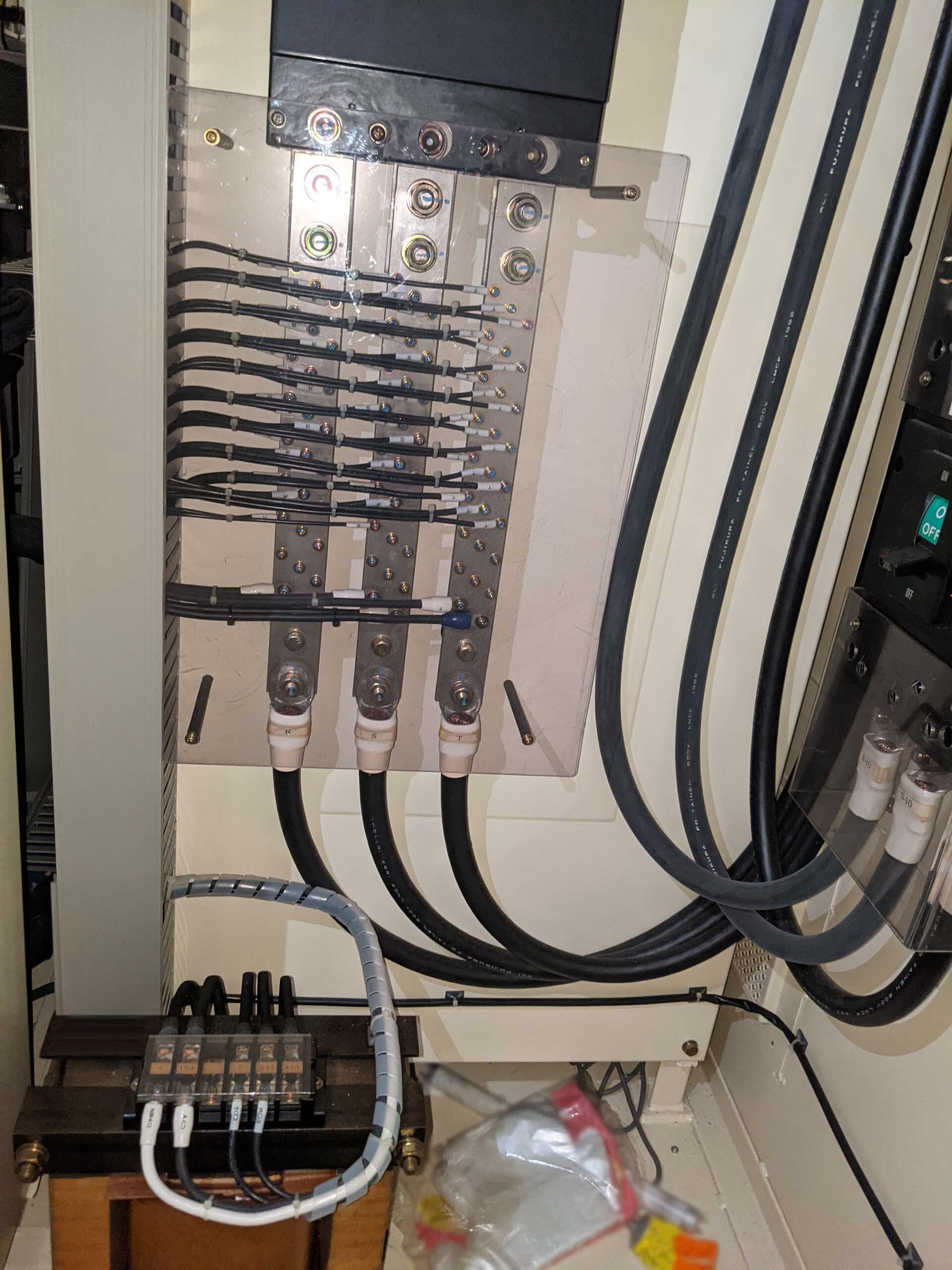

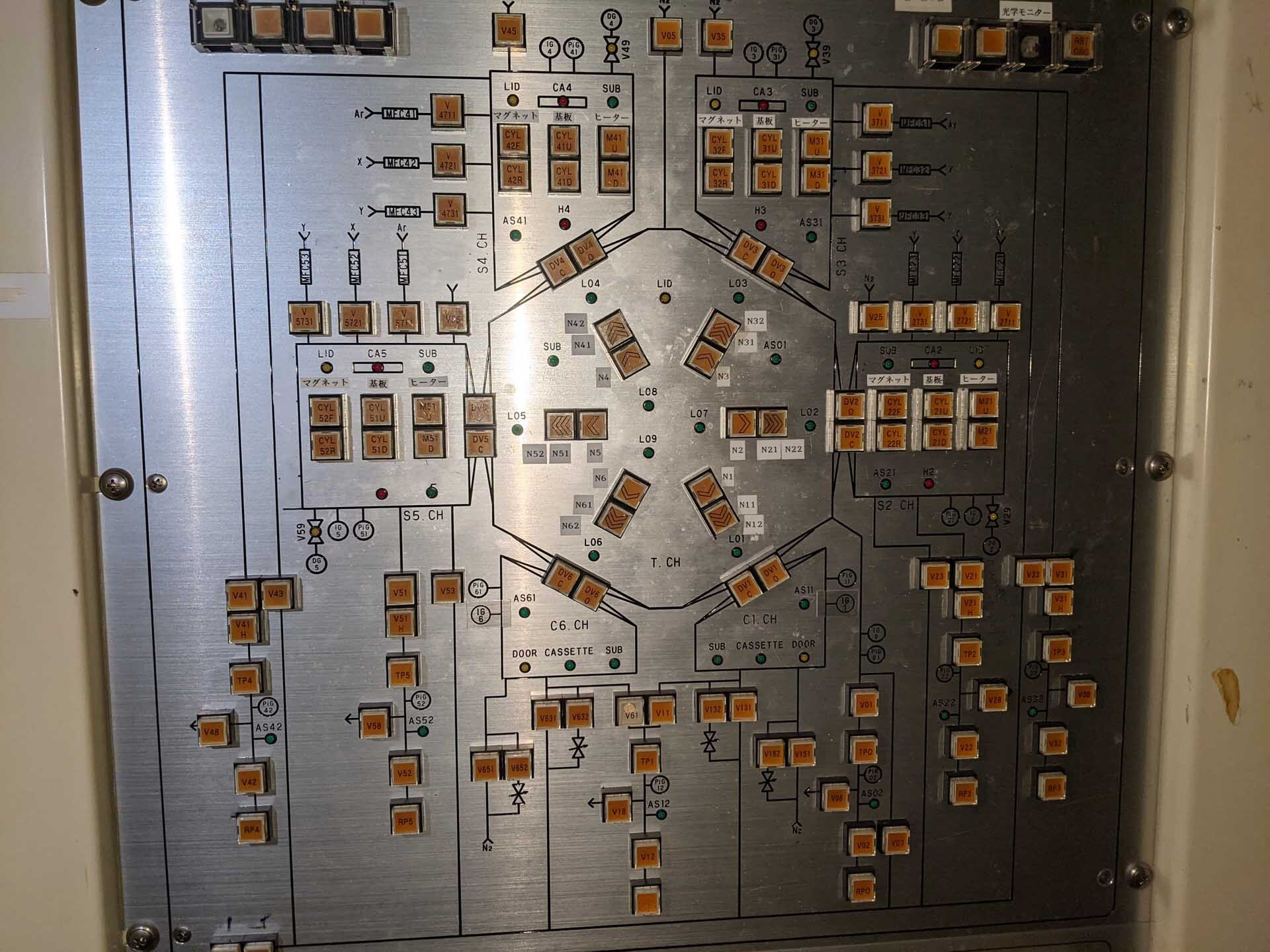

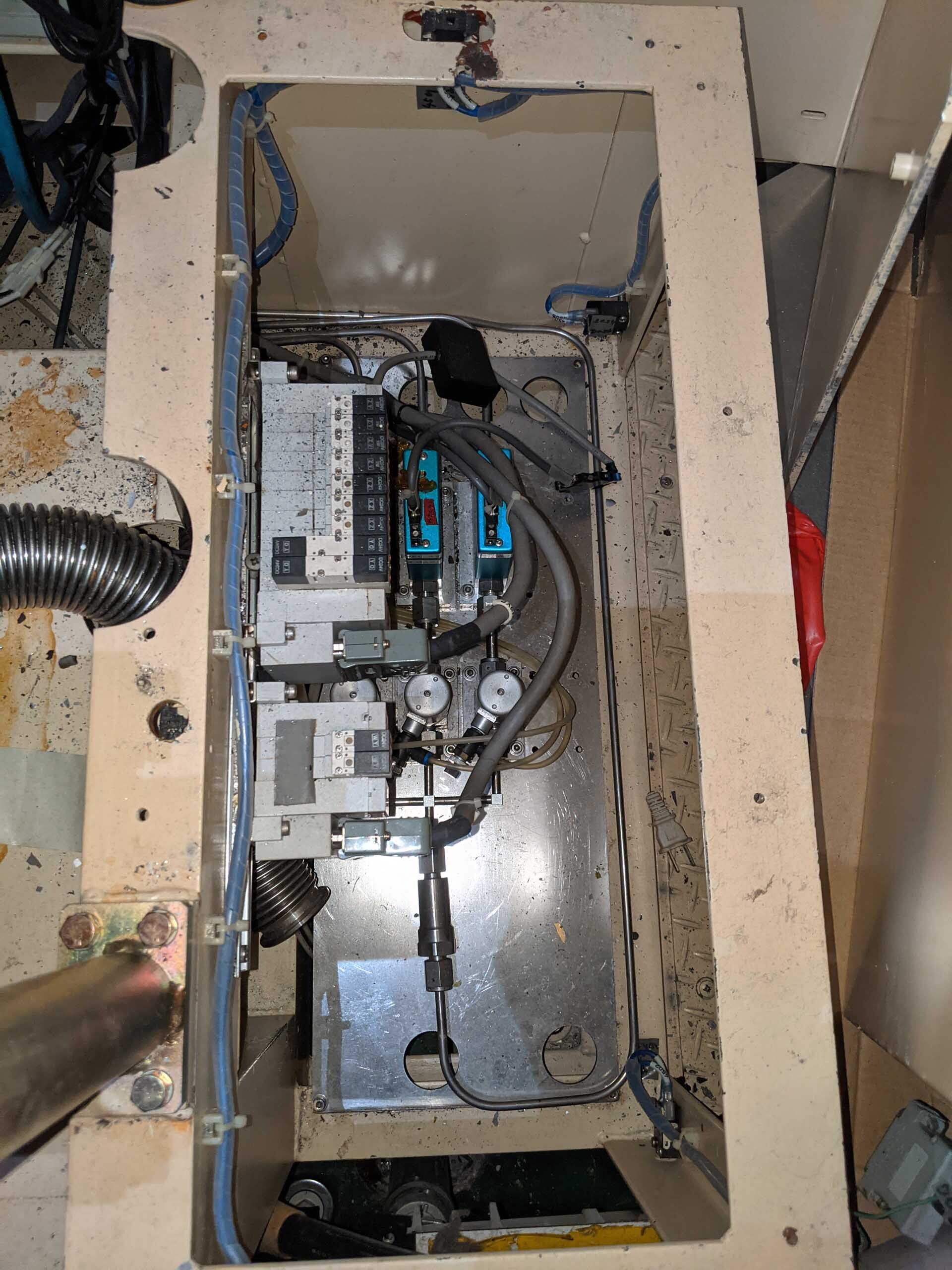

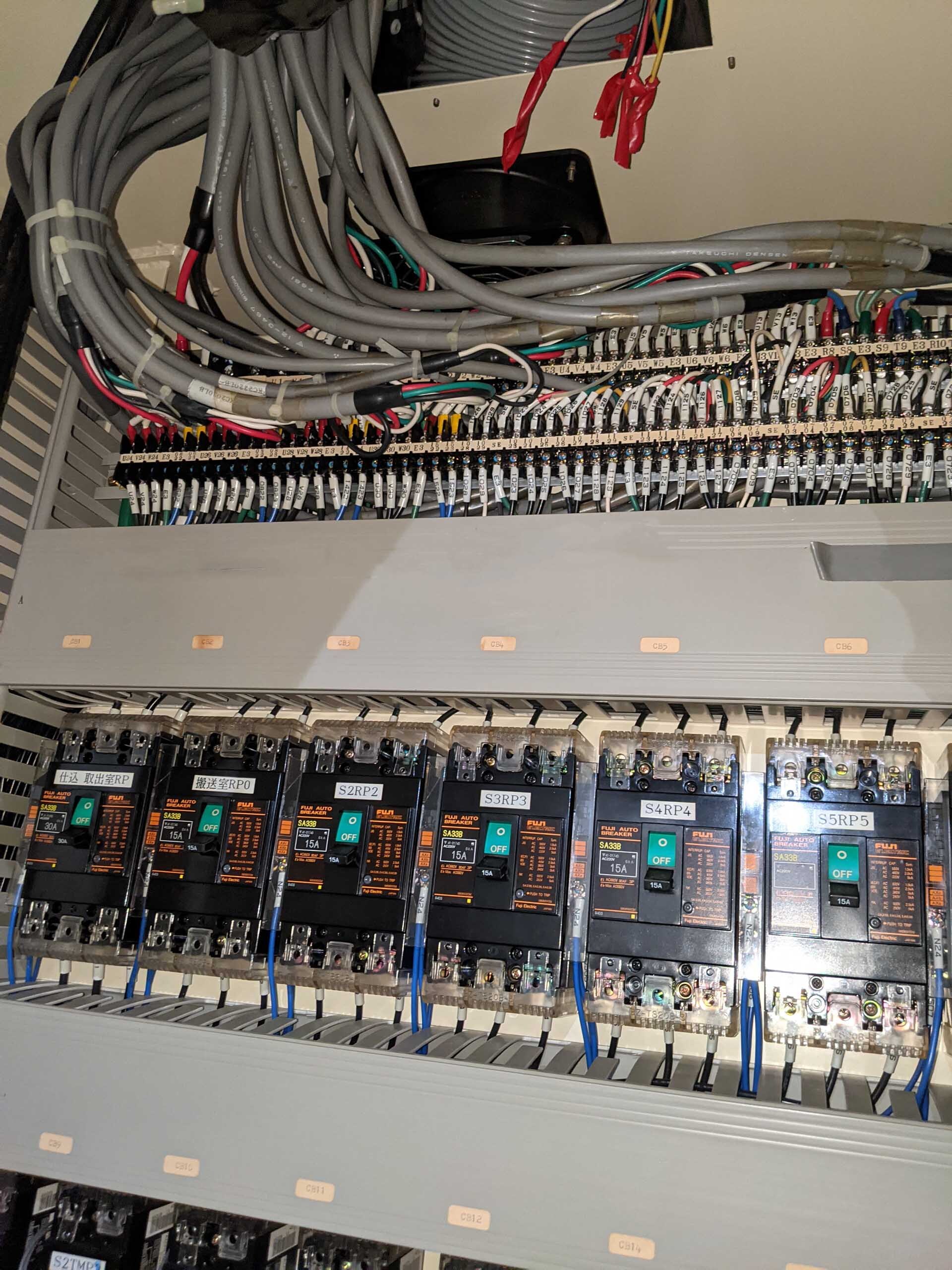

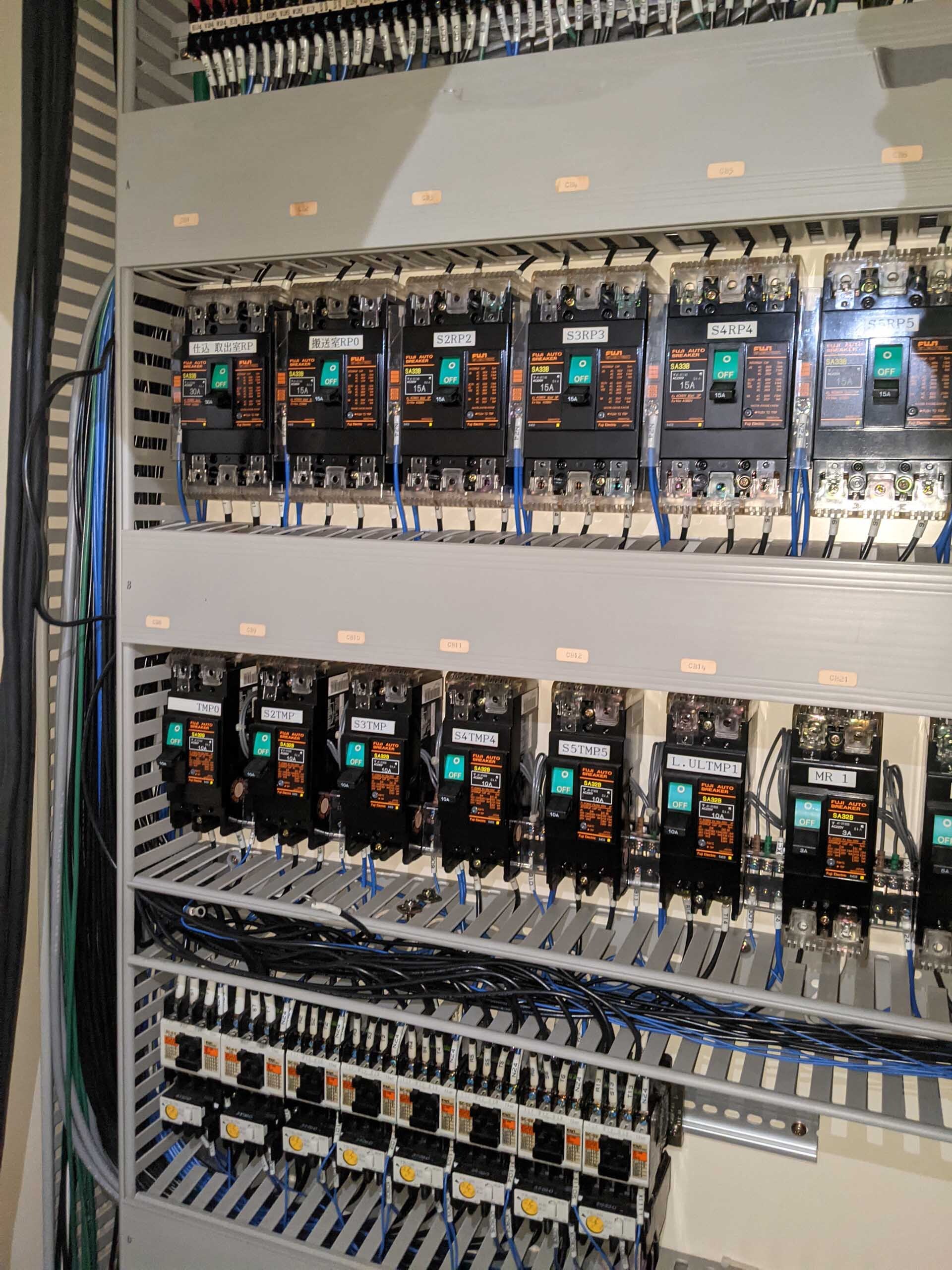

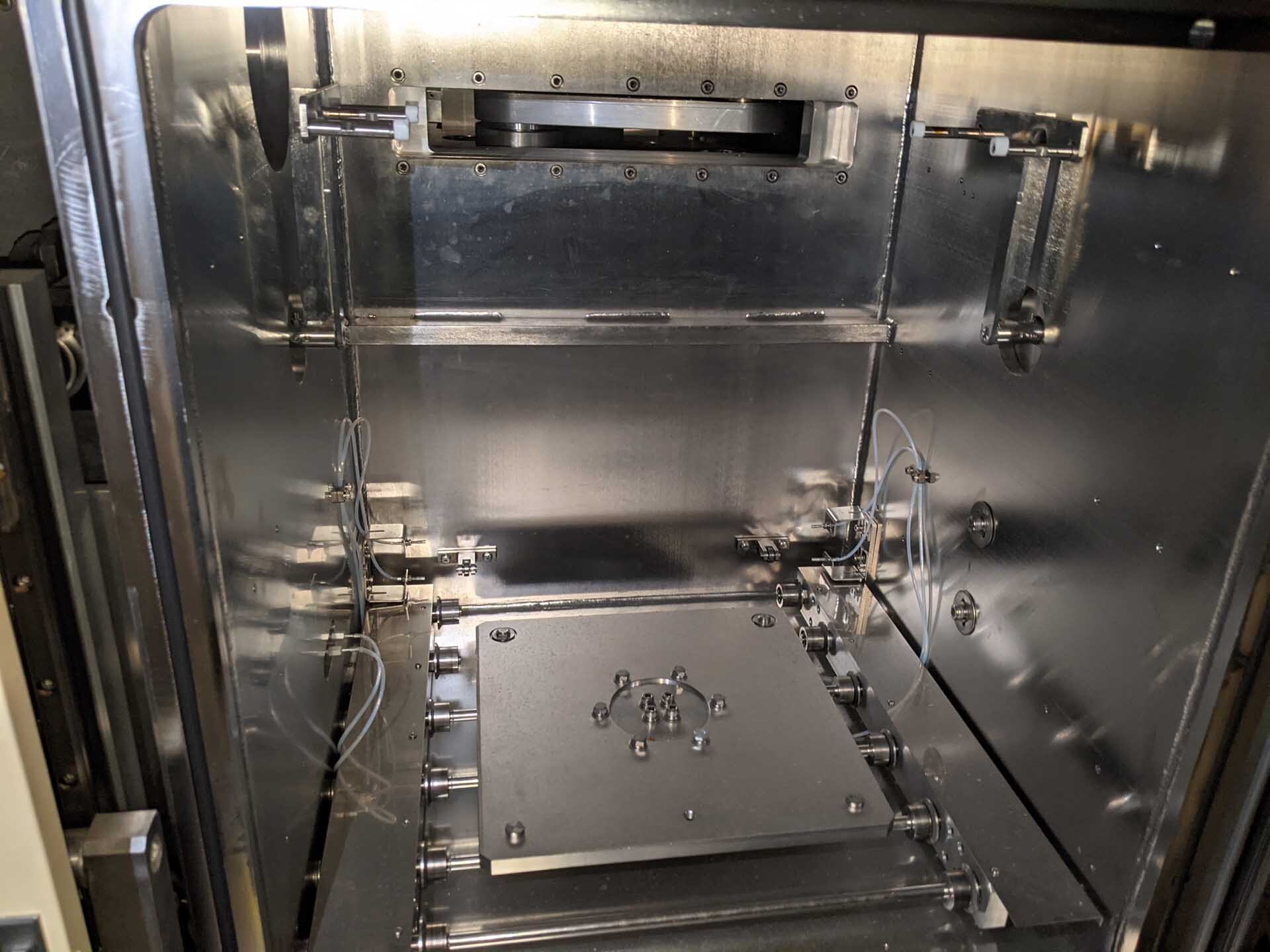

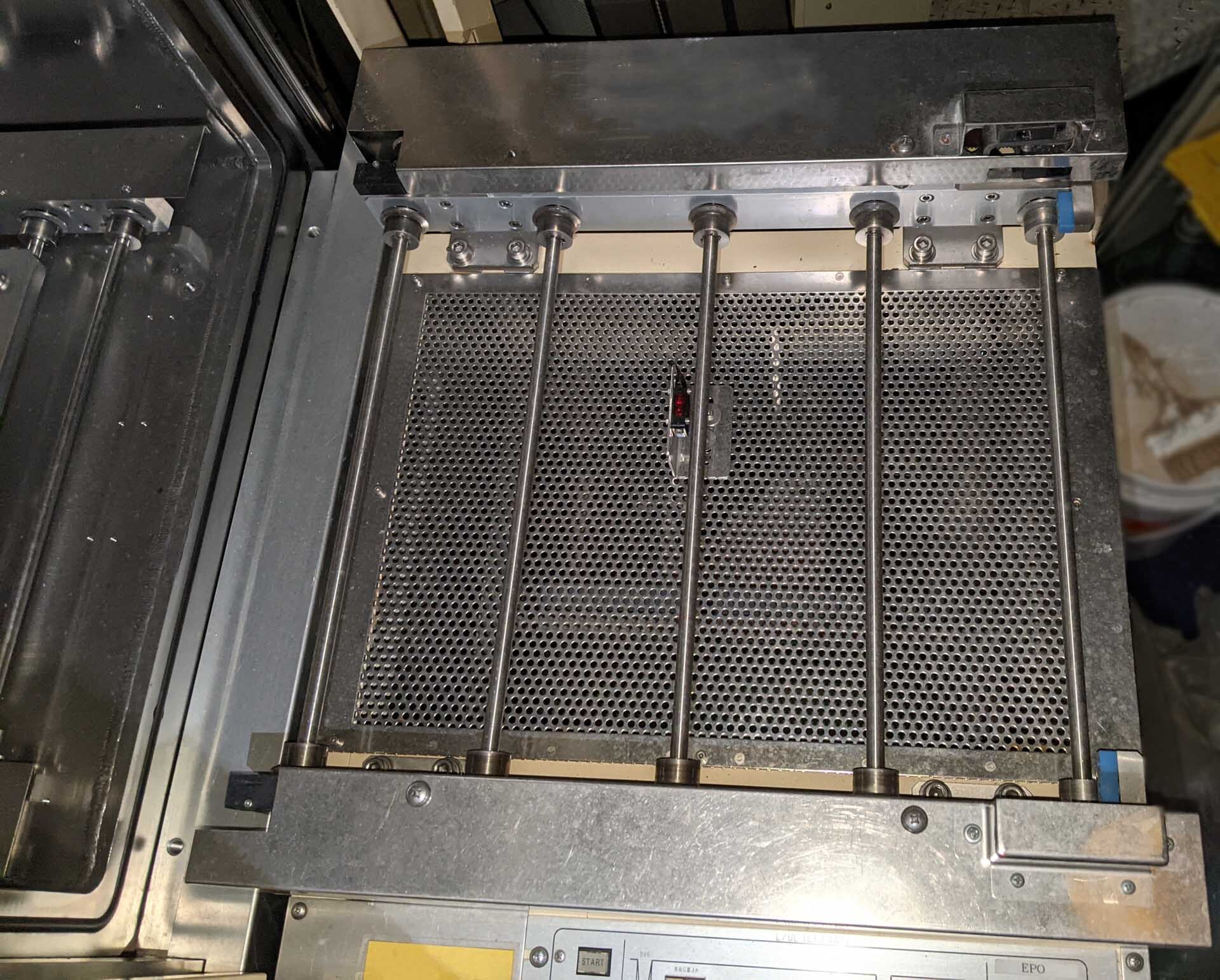

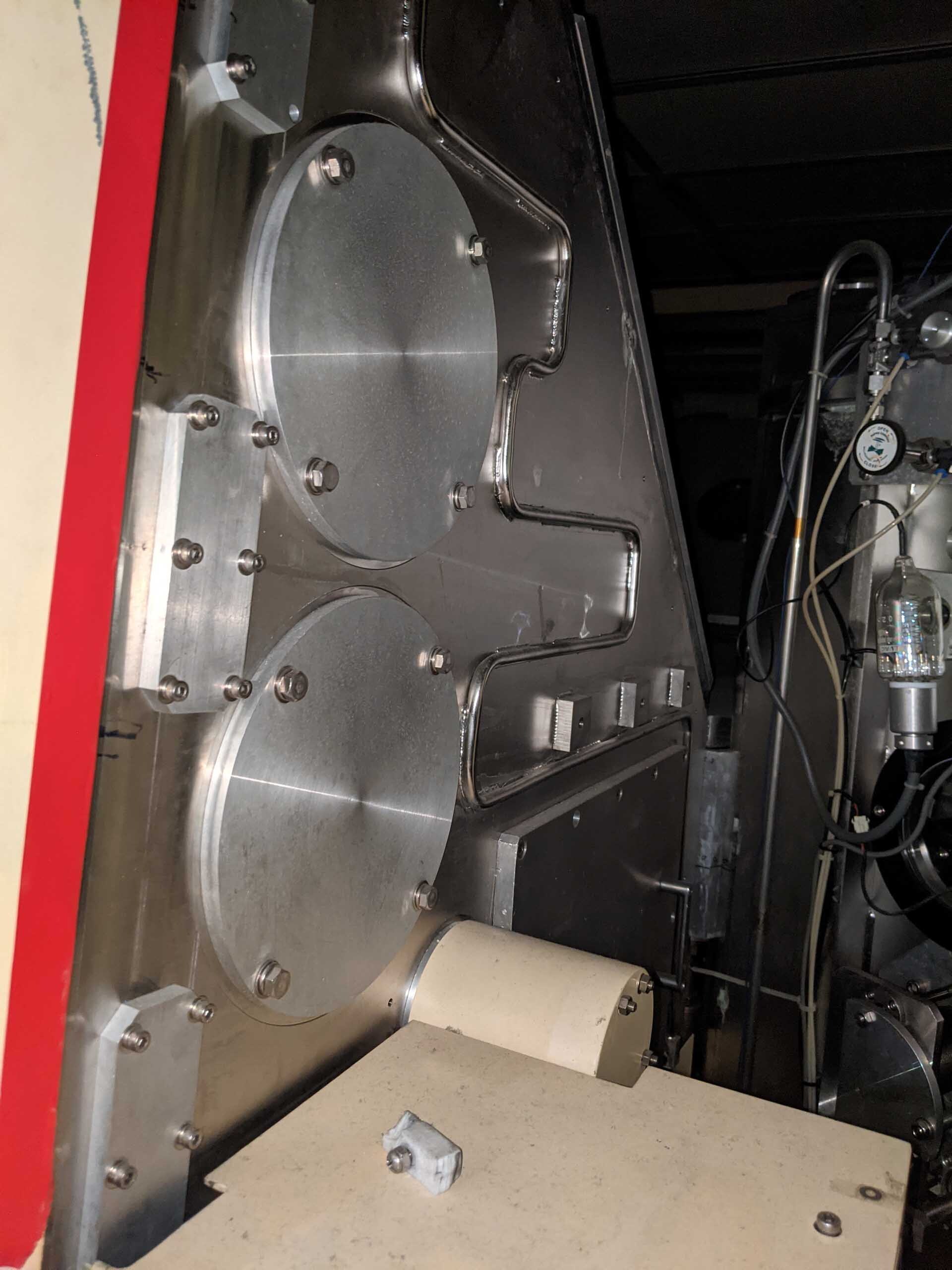

ULVAC SMD-450 is a versatile and powerful sputtering system designed for industrial use. It utilizes ultra high-vacuum technology to deposit thin films of various materials onto items of varying shapes and sizes. The system is capable of depositing a wide range of materials such as metals, oxides, nitrides, and amorphous silicon. As such, it is useful for research in sectors such as opto-electronics, microstructures, and nanotechnology. The machine is composed of two basic sections; the chamber and the exhaust unit. The chamber section includes a sample Heating/Cooling Rear Cover, 250mm Front Cover, Vacuum Vent Valve, a Gas Inlet/Outlet and Vacuum Pump Lines. The processing chamber is constituted of an evacuated stainless steel cylinder. This chamber provides a high degree of uniformity in terms of pressure and temperature, promoting homogeneous sputtering. The chamber is capable of accepting samples with a dimension up to 200 mm in diameter and 50 mm thick. The exhaust unit consists of a load lock system, vacuum pumps, exhaust lines and a Variable Magnetic field. It allows for fast material transfer between vacuum and atmospheric environments, without compromising the atmosphere in the main chamber. The load lock enables quick and efficient sample exchange. The vacuum pumps are responsible for providing a high degree of vacuum in the chamber and maintaining it throughout the process. The Variable Magnetic field allows for manipulation of the angle of incidence of the target ion beam, and thus controlling the uniformity of the sputtered films. In addition, SMD-450 is equipped with a target power supply, an RF matching network, an RF generator and a high-voltage power supply. The target power supply applies DC power to the target material, allowing for tailored sputter deposition. The RF matching network provides impedance matching between the target material and the plasma. The RF generator produces the high frequency power which energizes the gas molecules, leading to a self-sustaining plasma discharge. Finally, the high-voltage power supply is responsible for creating the bias voltage which is applied to the substrate, allowing for control of the film thickness and uniformity. ULVAC SMD-450 is designed to provide consistent and reliable sputtering deposition for industrial applications. Highly efficient, it is an ideal choice for research into materials engineering and nanotechnology.

There are no reviews yet