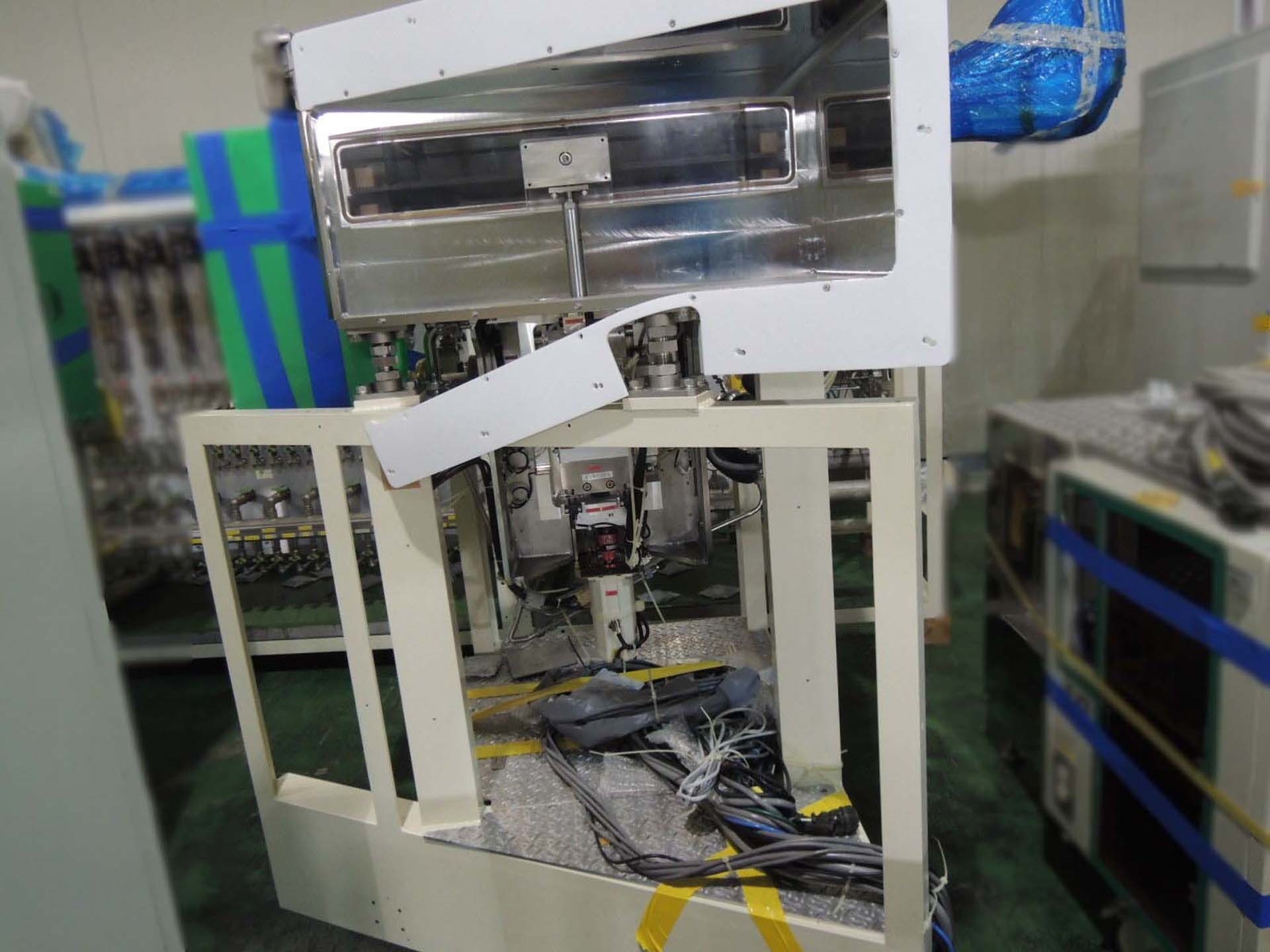

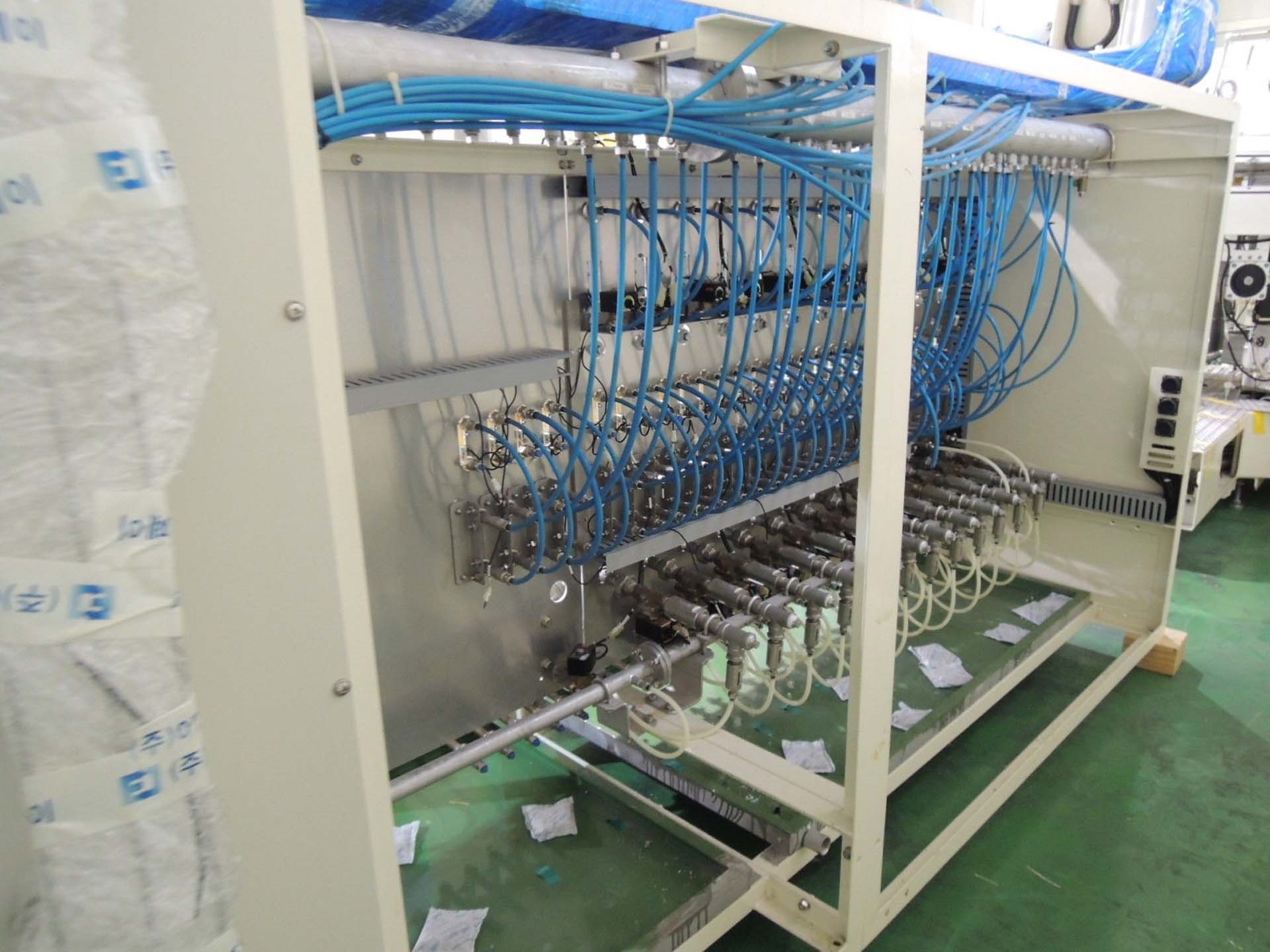

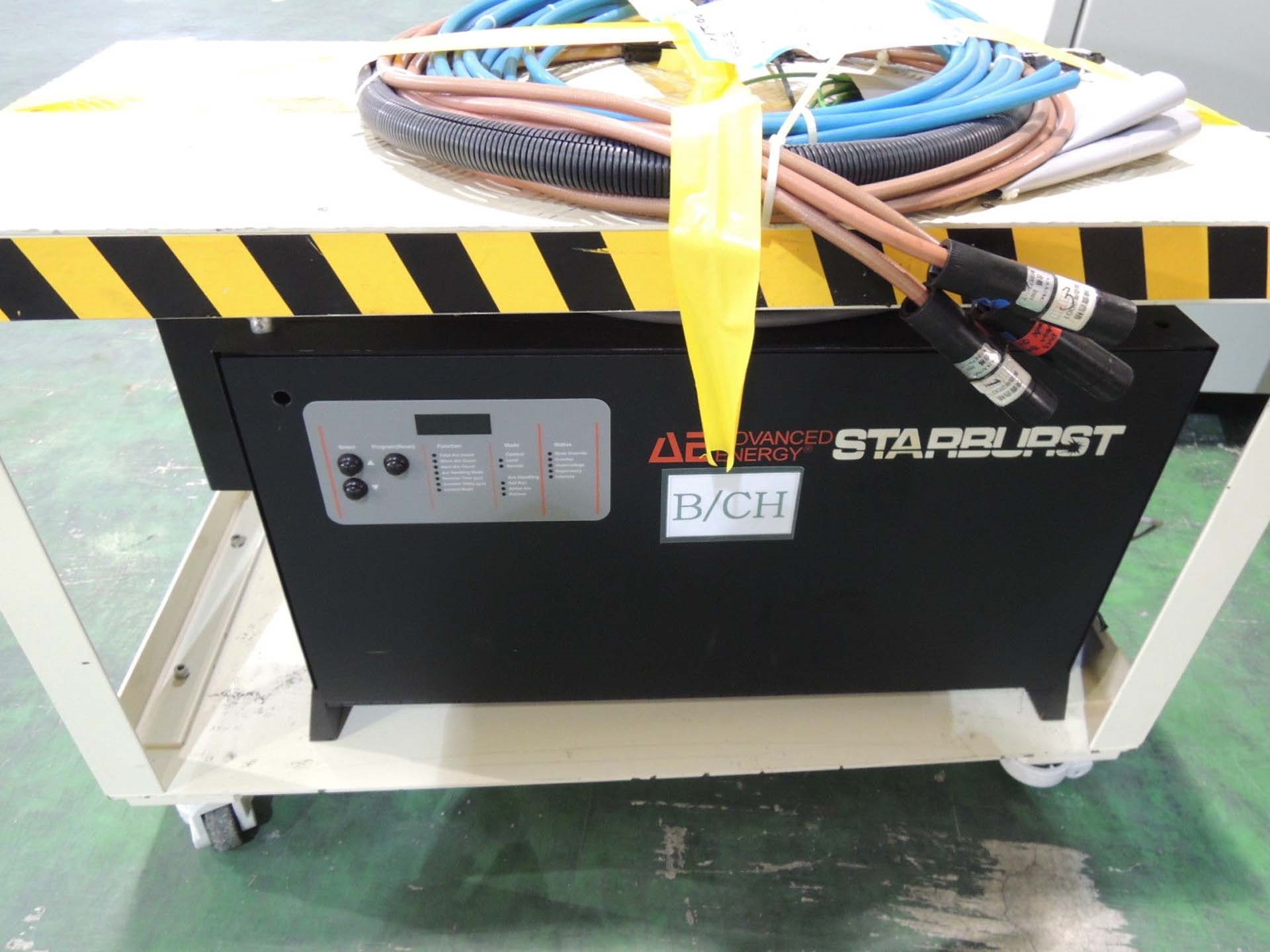

Used ULVAC SMD-750 #9213455 for sale

URL successfully copied!

Tap to zoom

ULVAC SMD-750 sputtering equipment is a versatile, user-friendly sputtering system used to deposit thin films on various types of substrates. It is designed to provide the highest quality thin films for a wide range of applications such as semiconductor devices, flat panel displays, and optoelectronics. The unit is composed of a vacuum chamber, a process chamber, and a control machine. The vacuum chamber is equipped with an automated roughing and fine-tuning vacuum process. This is used to achieve a predetermined base pressure of 5 x 10-8 Pa, which is necessary for optimal film deposition. The control tool is programmed to monitor and adjust the pressure within the working chamber to achieve optimal film deposition. The process chamber is constructed using stainless steel coated surfaces to ensure a clean environment for optimal sputtering of material. The chamber is fitted with up to eight independent sputter sources, allowing for multiple targets and materials to be deposited simultaneously. ULVAC SMD 750 is able to process a wide range of target materials such as metal, dielectric, ceramic, and semiconductor, as well as combinations of materials. SMD-750 features a closed-loop process control asset that allows for precise control of the substrate position, gas flow, and temperature. This ensures that the films have a uniform thickness and composition. The model also features an automatic corrosion protection equipment that maintains optimal process parameters for long-term production. SMD 750 is a reliable and versatile sputtering system that can be used to deposit thin films of metal, dielectric, ceramic, and semiconductor materials with uniform thickness and composition. The unit is equipped with an automated roughing and fine-tuning vacuum process and a closed-loop process control machine for precise control of the substrate positioning, gas flow, and temperature. The tool's corrosion protection asset ensures long-term operation and makes it an ideal choice for a wide range of thin film deposition applications.

There are no reviews yet