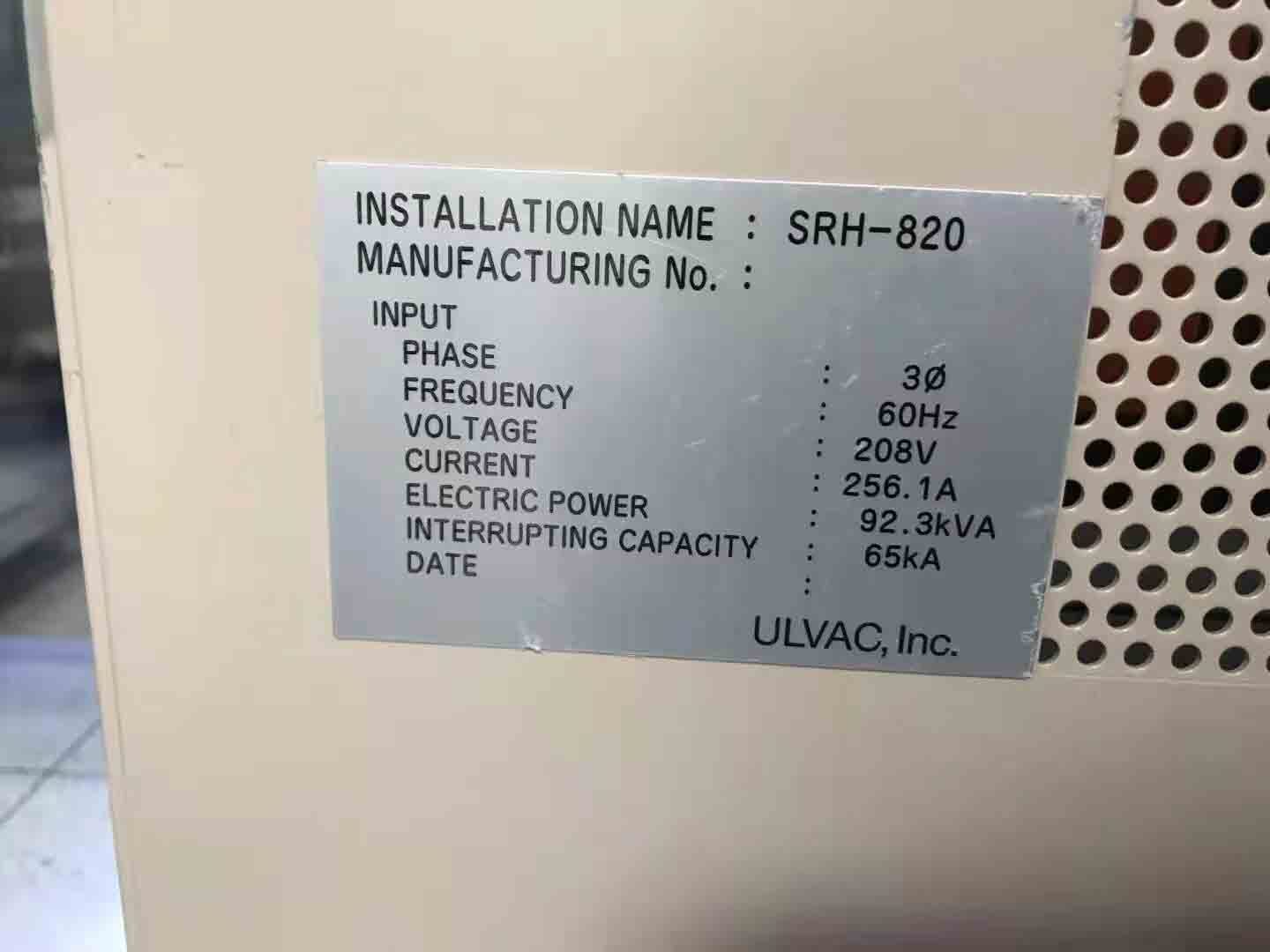

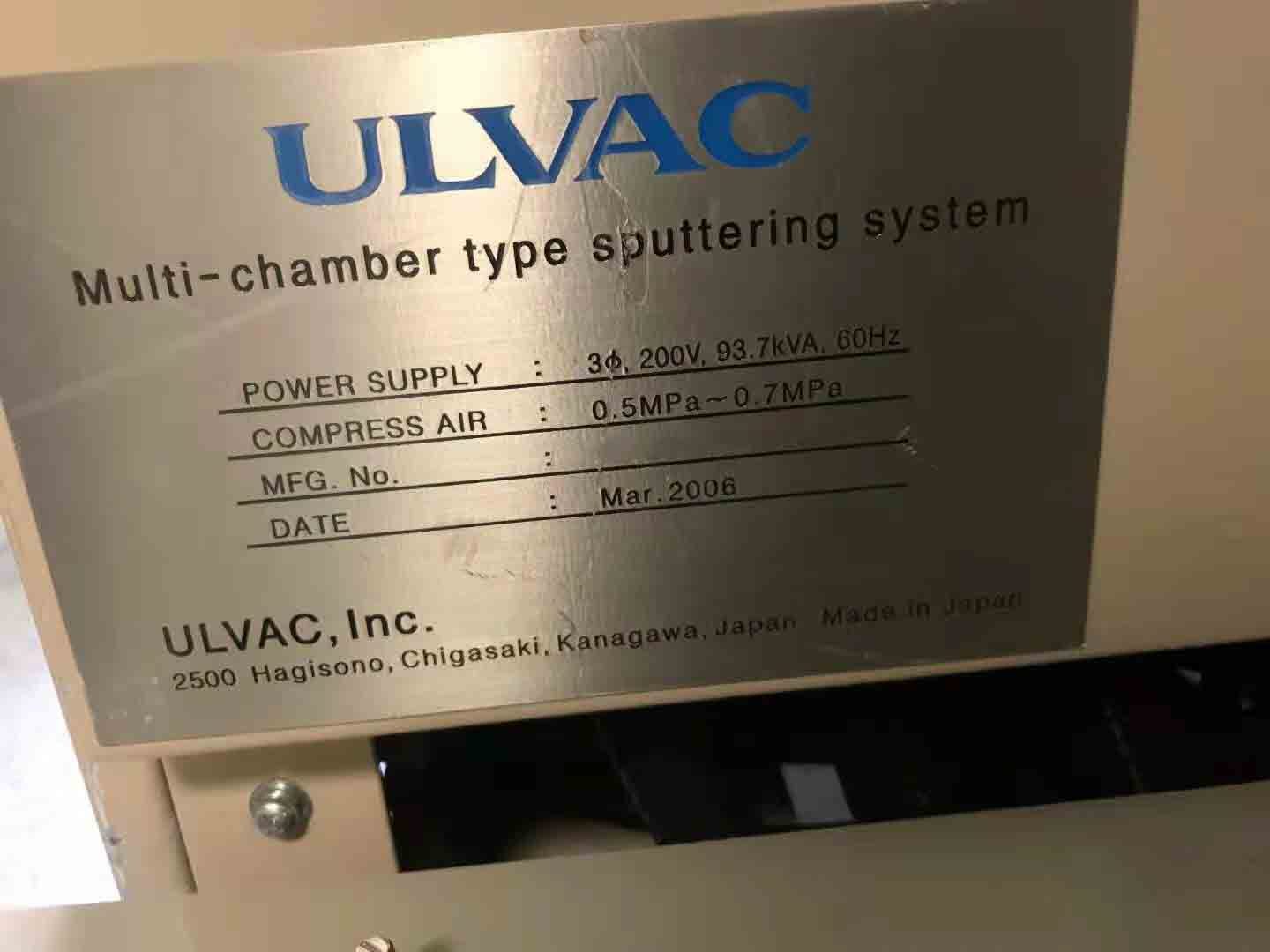

Used ULVAC SRH-820 #9384114 for sale

URL successfully copied!

Tap to zoom

ULVAC SRH-820 is an advanced sputtering equipment designed for research and production applications. The system utilizes DC/RF sputtering with dual targets and is capable of deposition on both planar and curved surfaces. It is most often used for thin film deposition of various materials such as metals, oxides, and nitrides. The unit includes a high-vacuum chamber with a gas-purging function, a magnetron source, an electrostatic substrate chuck, and an ultra-high frequency magnetron source. The ultra-high frequency magnetron source allows for stable sputtering performance with high throughput at lower power. The eight-axis electrostatic substrate stages are capable of rotation and tilt for efficient sputtering on different shaped substrates. The chamber also includes a gas-shielded turbulent jet for sputtering on curved surfaces and an array of magnet arrays for uniform sputtering over large surfaces. The chamber also includes a transmission line and media filter array to reduce the effects of particles and other impurities generated during the process. The high power magnetron source is also adjustable and can be used for short deposition times. The machine also offers a temperature-controlled substrate stage with a wide range of temperatures from -30 to +250°C, allowing for the deposition of various materials at different temperatures. The tool also includes a sputtering controller for automated control of the RF power, target current, and substrate temperature. It also comes with a variety of safety features, such as a safety switch and a warning display if an abnormality is detected. ULVAC SRH 820 is perfect for a variety of deposition applications, from small samples to large substrates. It is able to easily handle thin film deposition of a wide variety of materials with stability, uniformity, and reliability. With its advanced features, SRH-820 has become a popular choice for sputtering applications.

There are no reviews yet