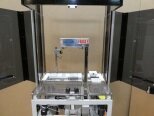

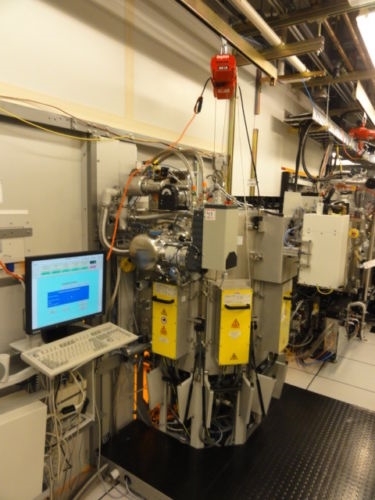

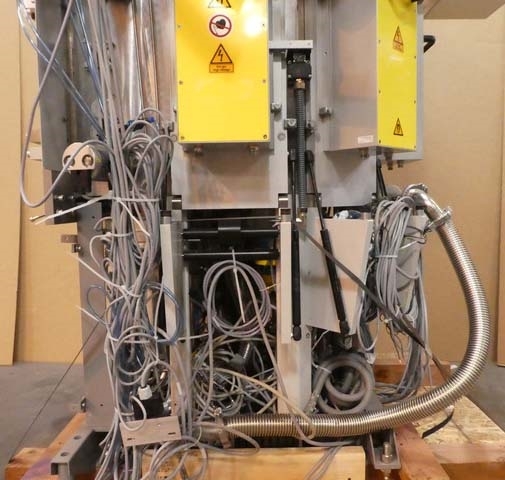

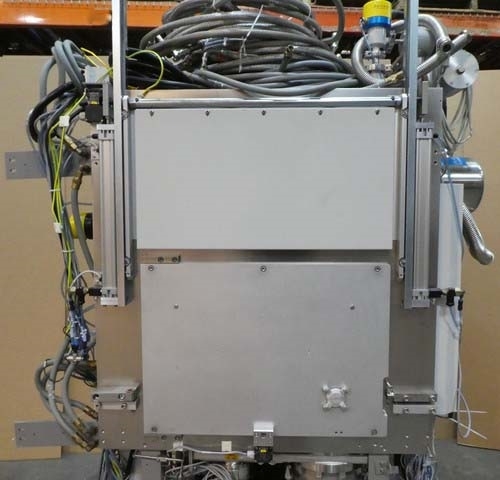

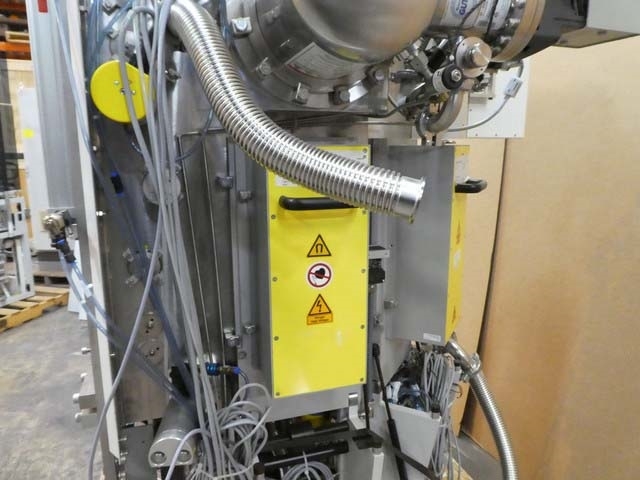

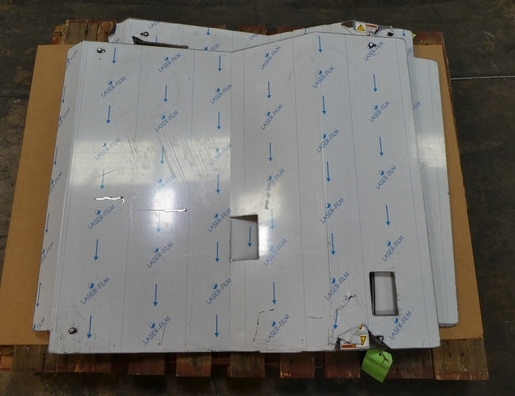

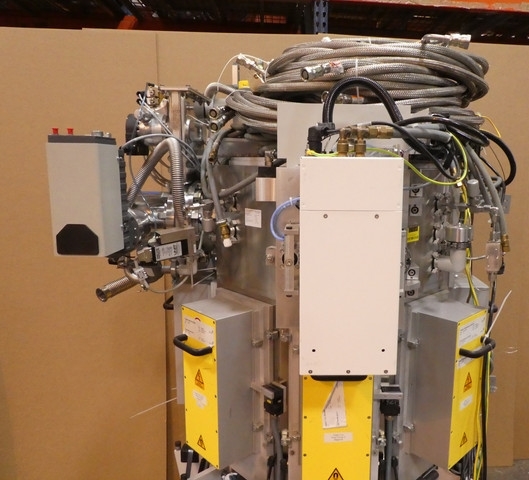

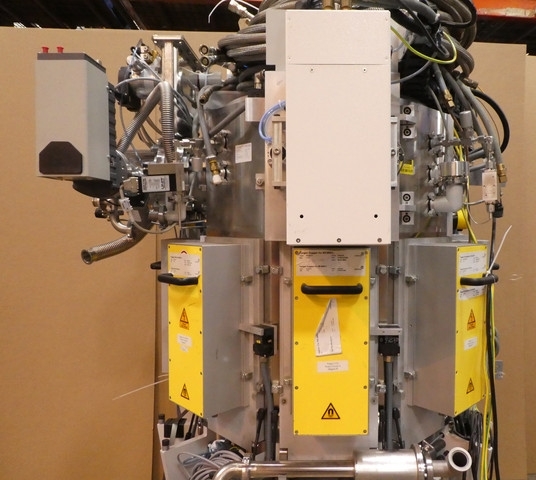

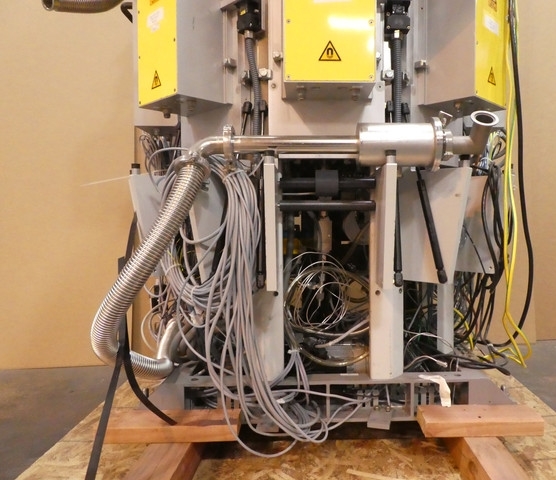

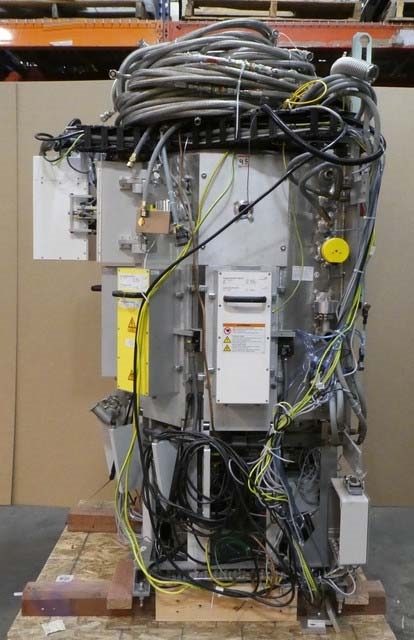

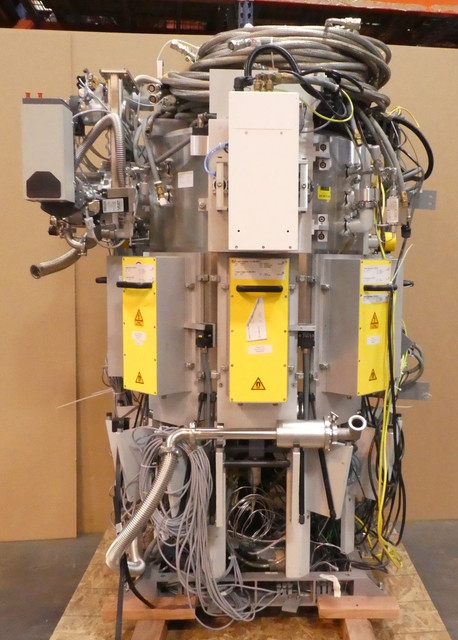

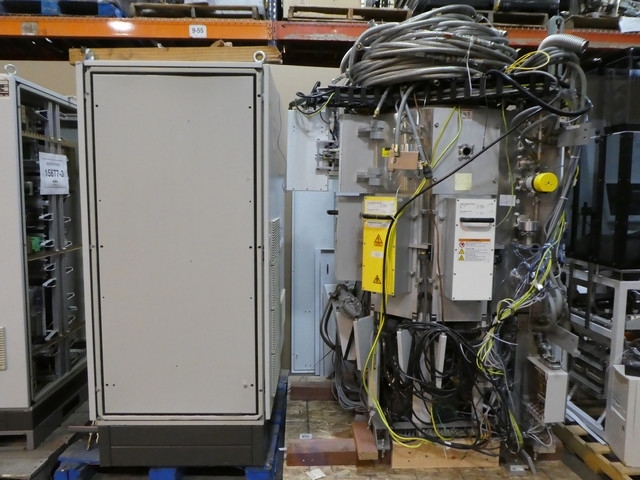

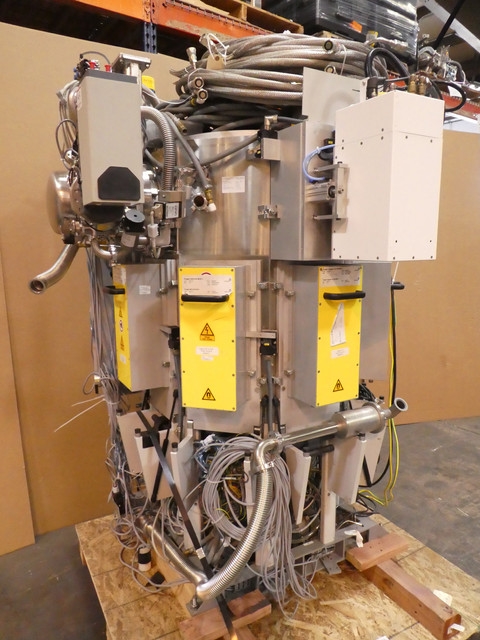

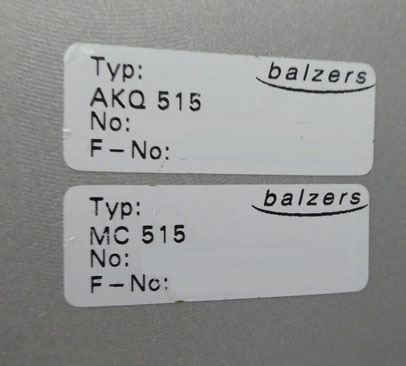

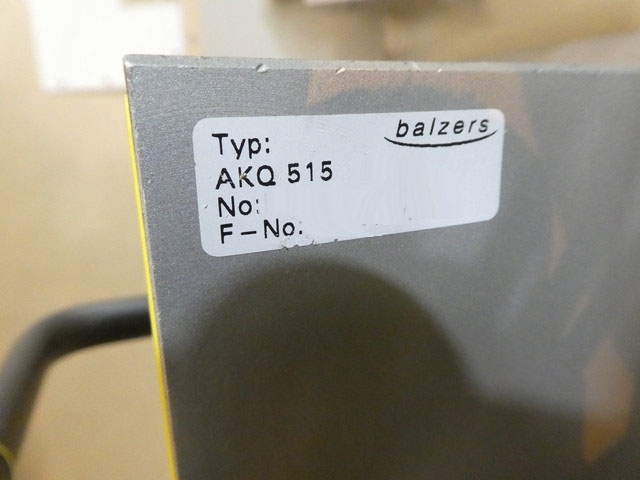

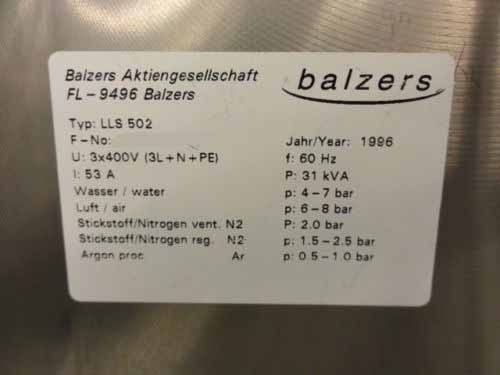

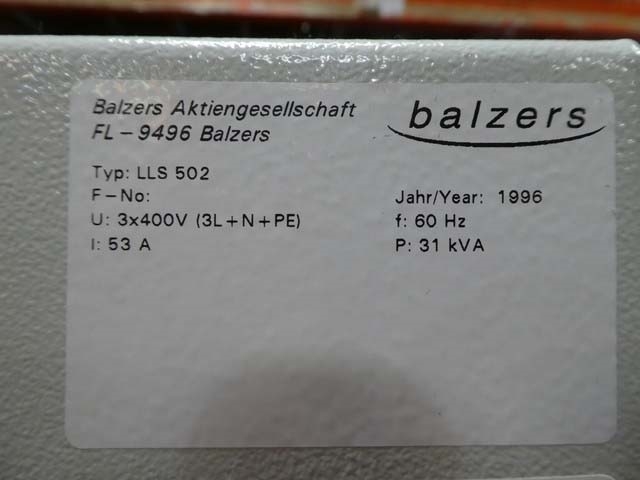

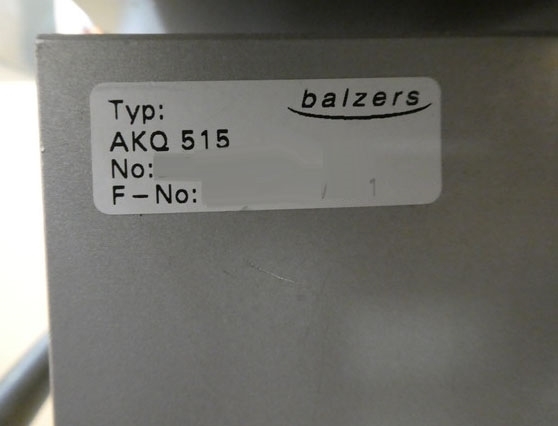

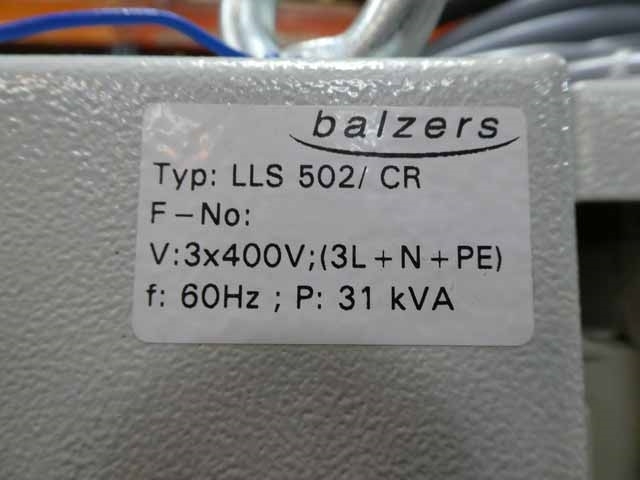

Used UNAXIS / BALZERS LLS 502 #9202971 for sale

URL successfully copied!

Tap to zoom

ID: 9202971

Vintage: 1996

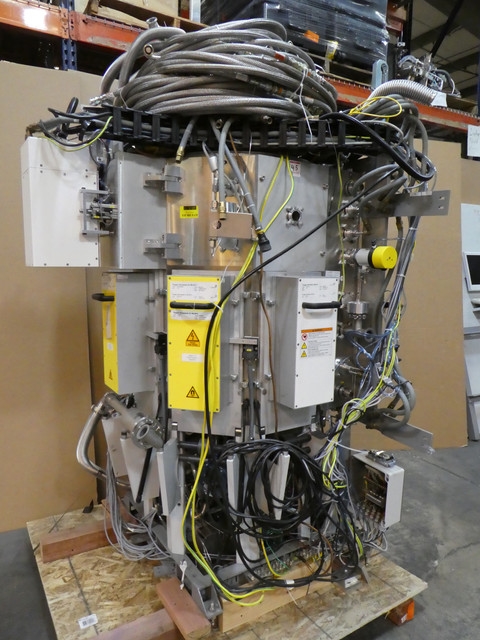

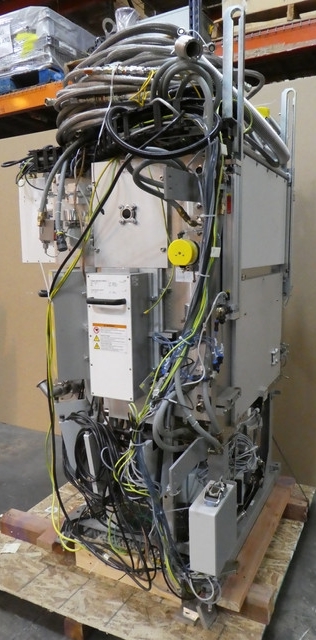

Sputtering system

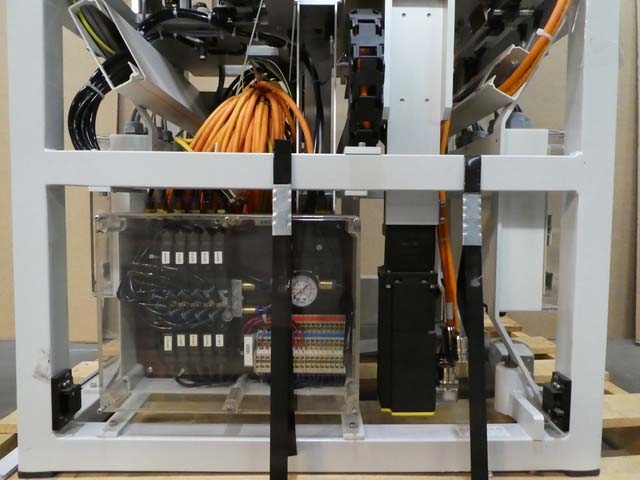

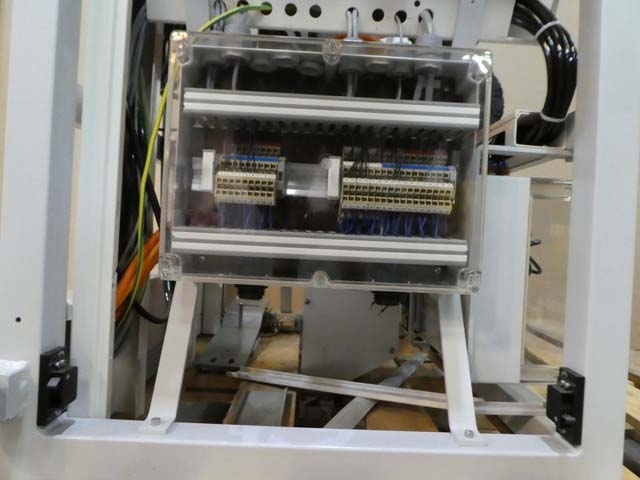

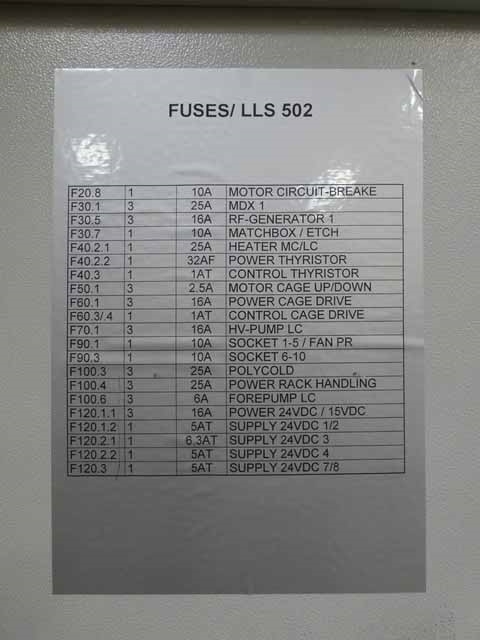

Includes:

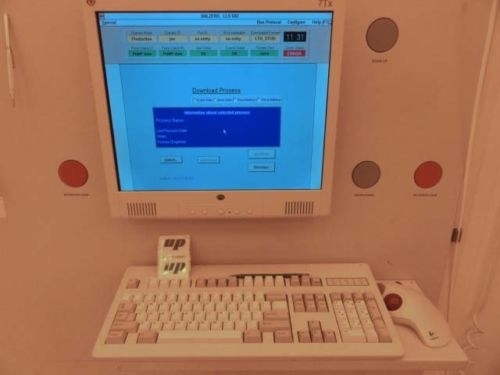

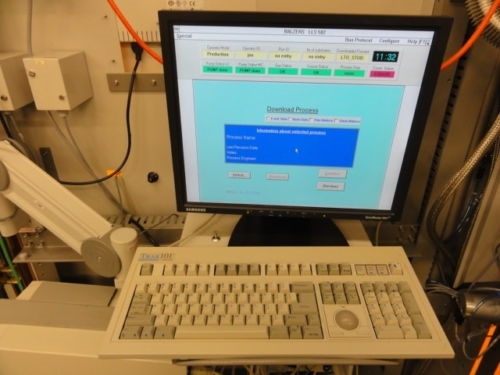

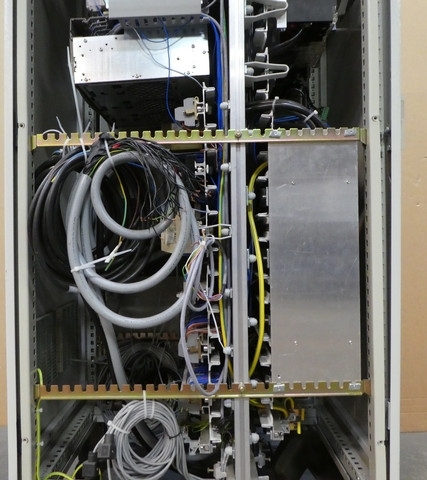

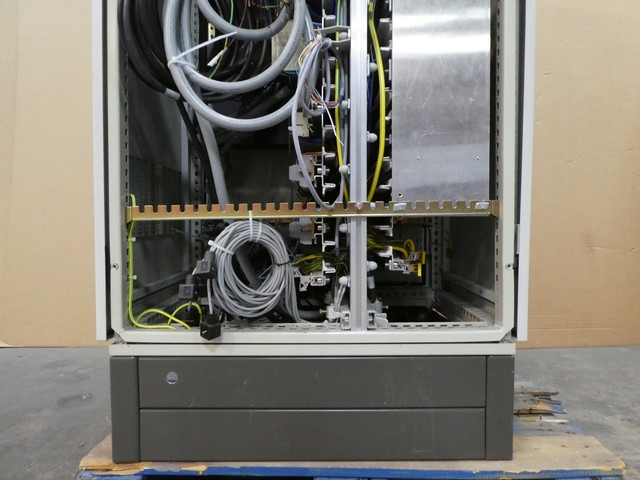

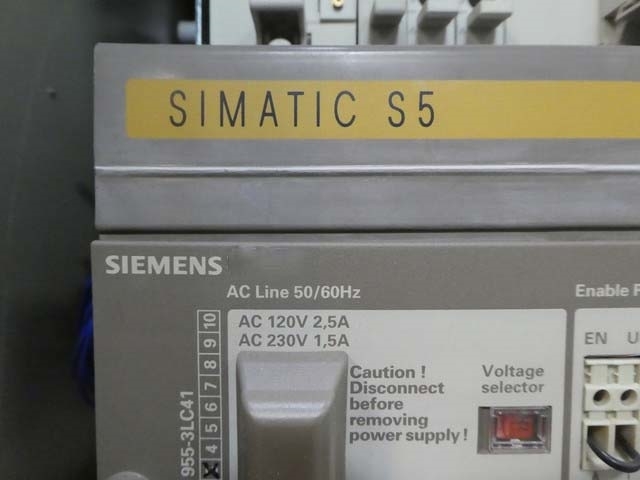

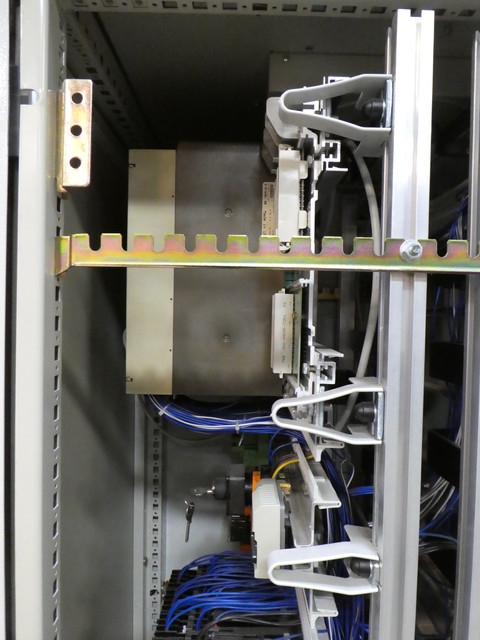

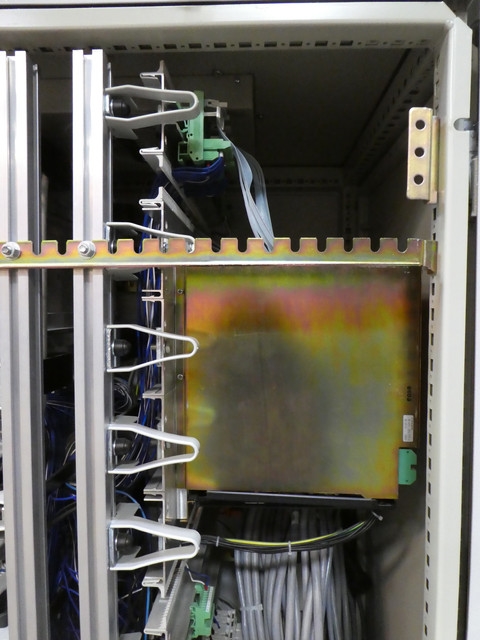

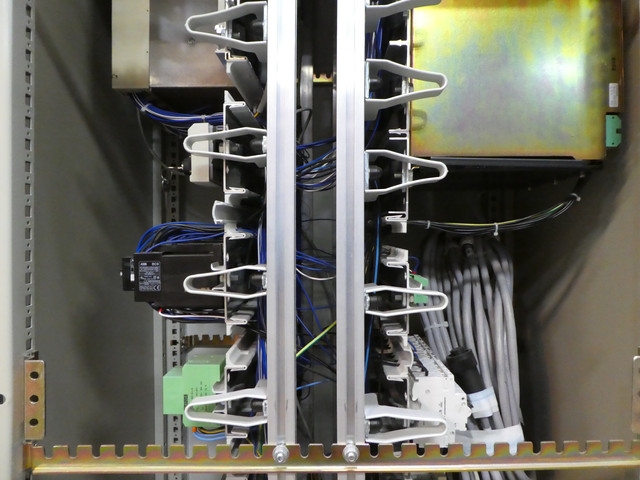

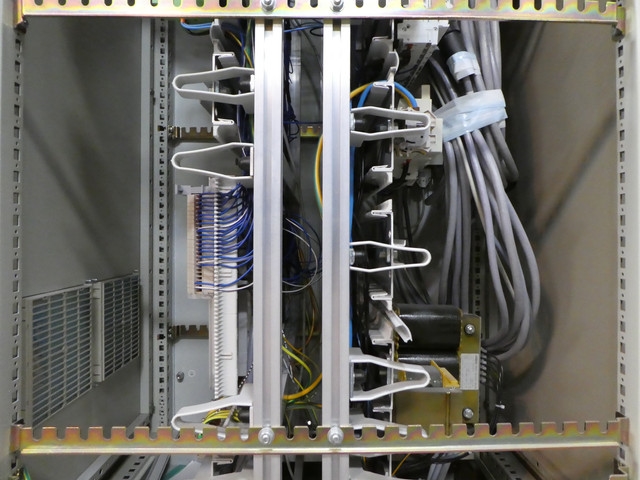

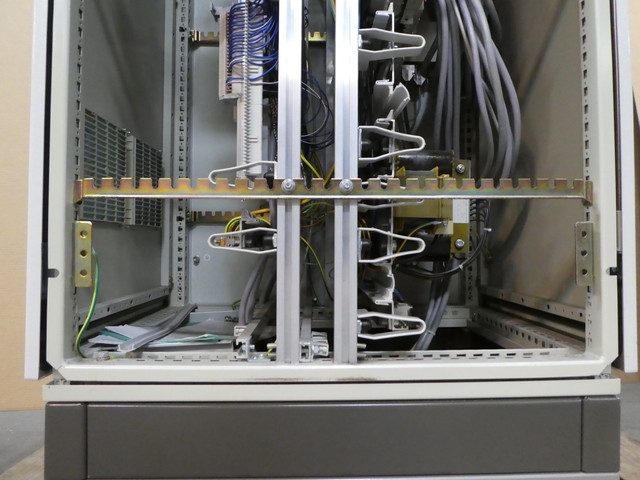

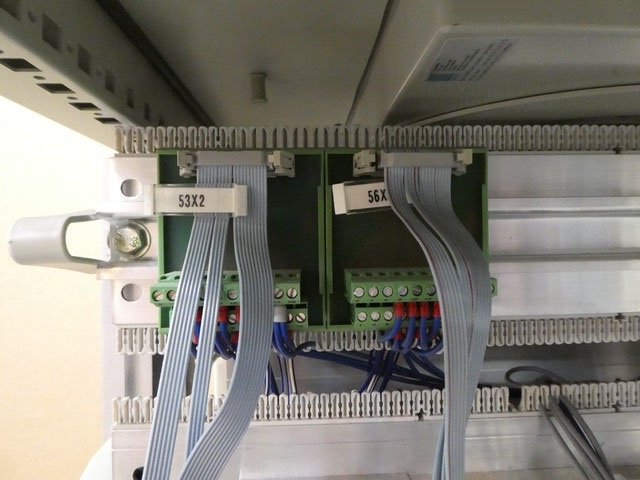

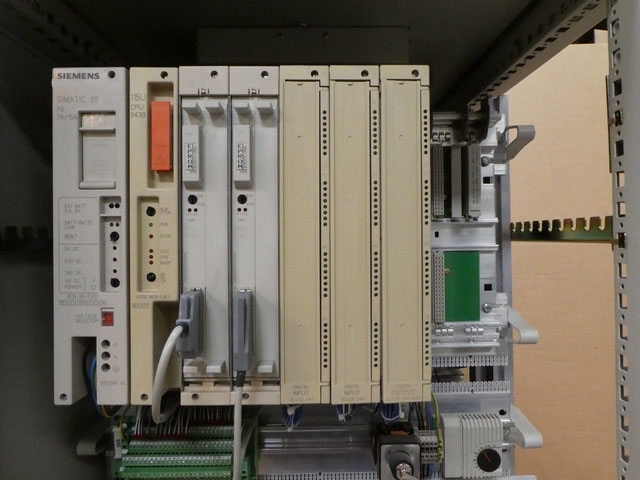

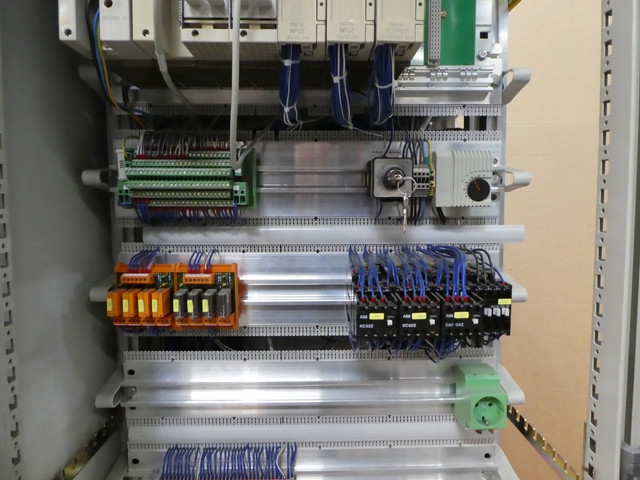

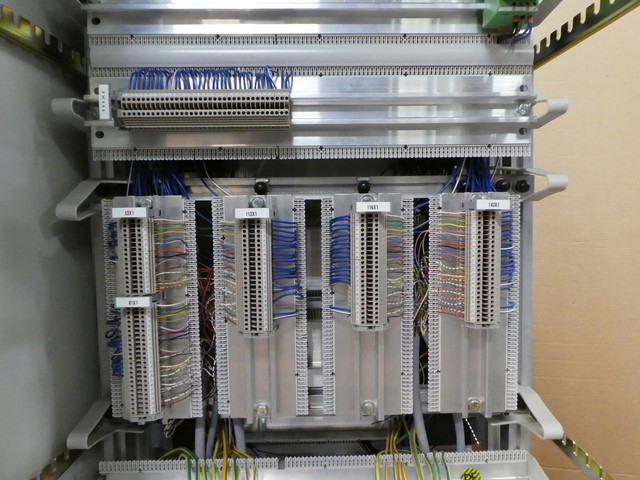

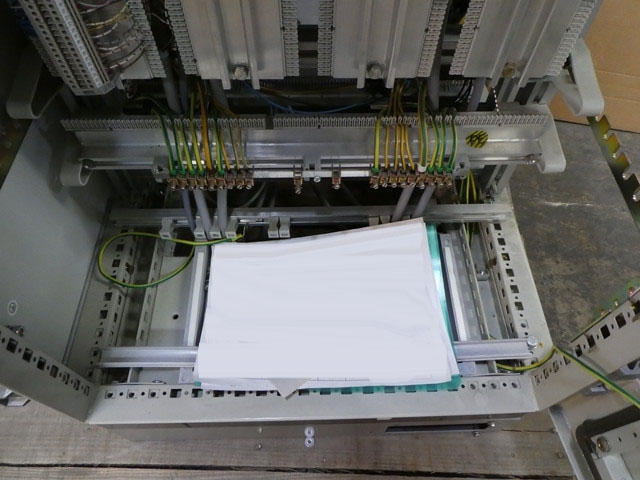

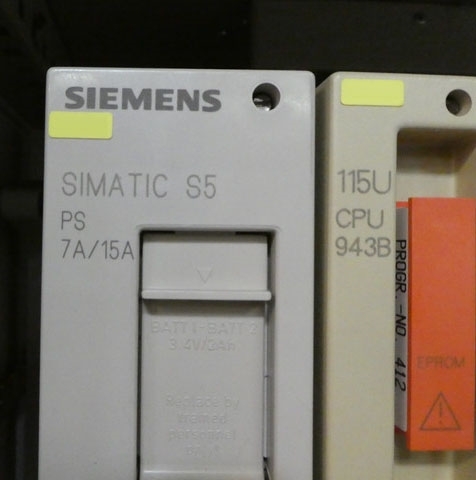

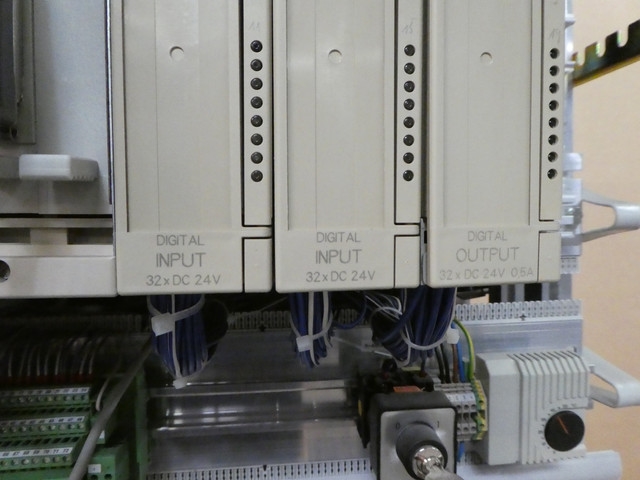

Computer control

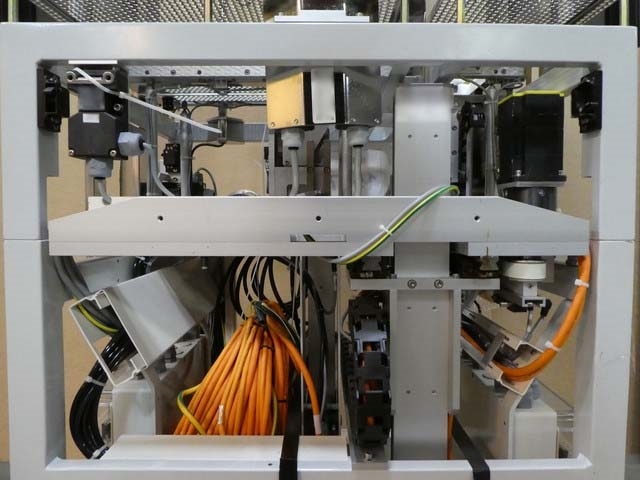

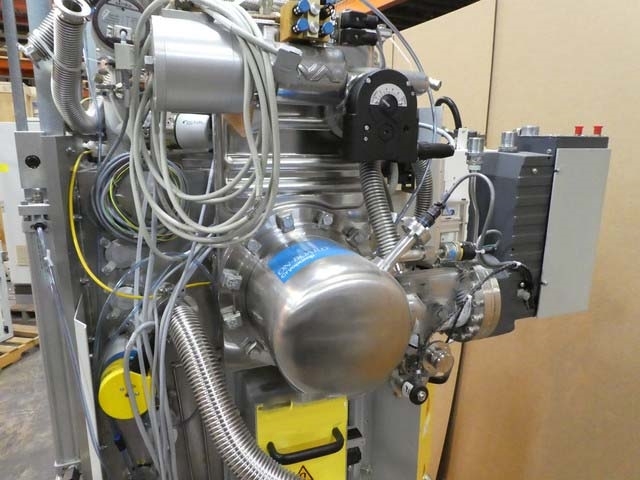

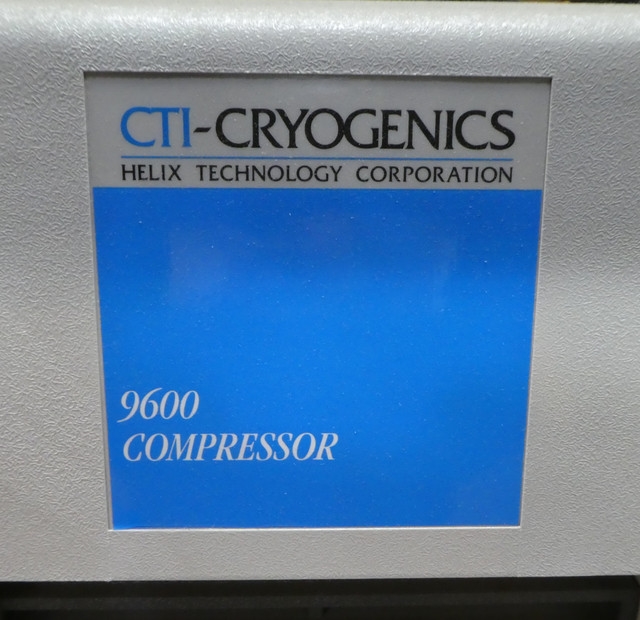

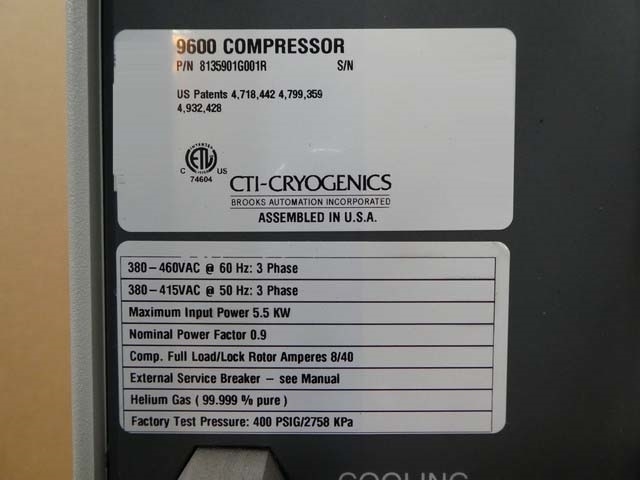

CTI CRYOGENICS 9600 Compressor

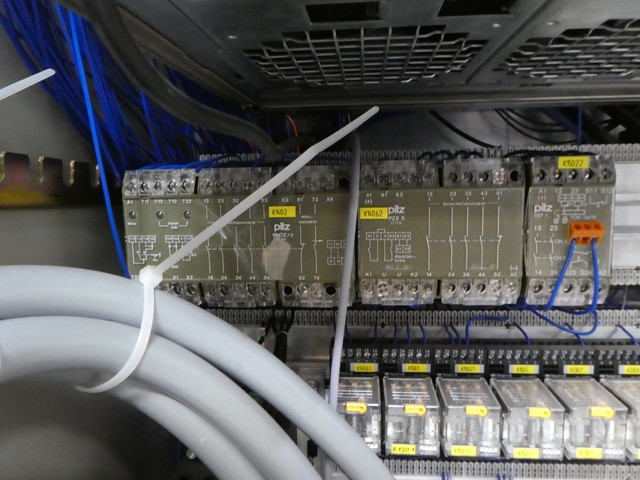

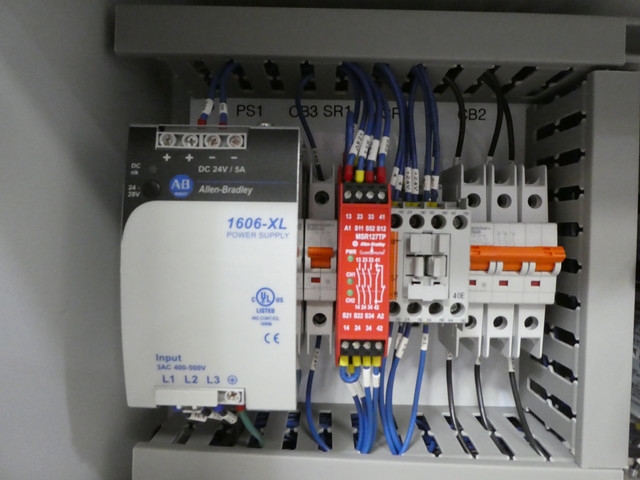

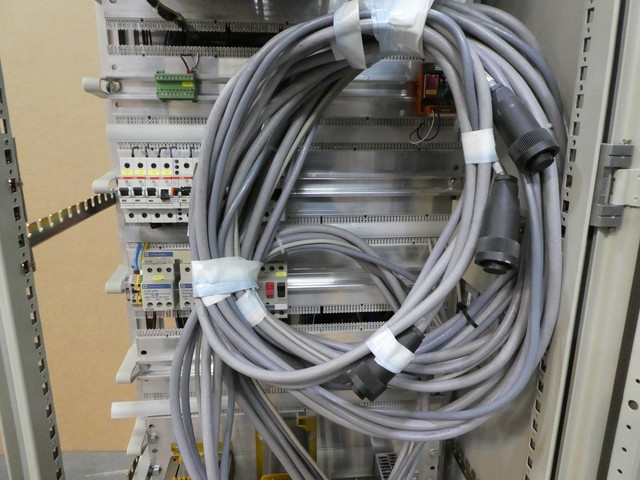

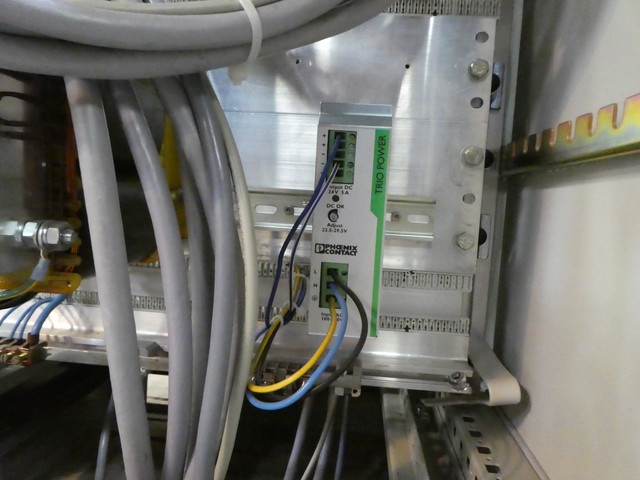

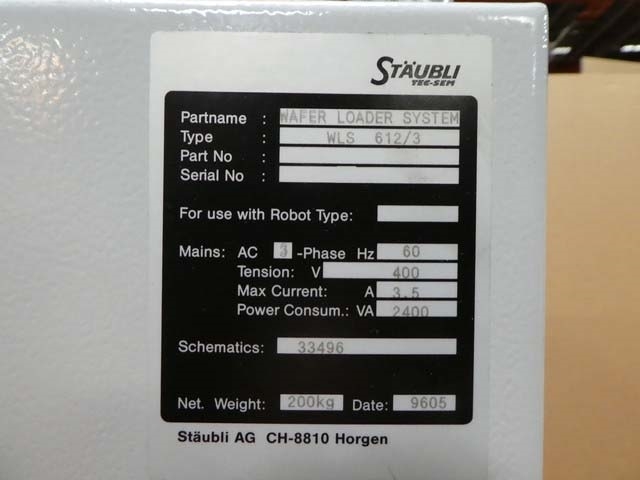

Wafer loader system electrical cabinet and controls

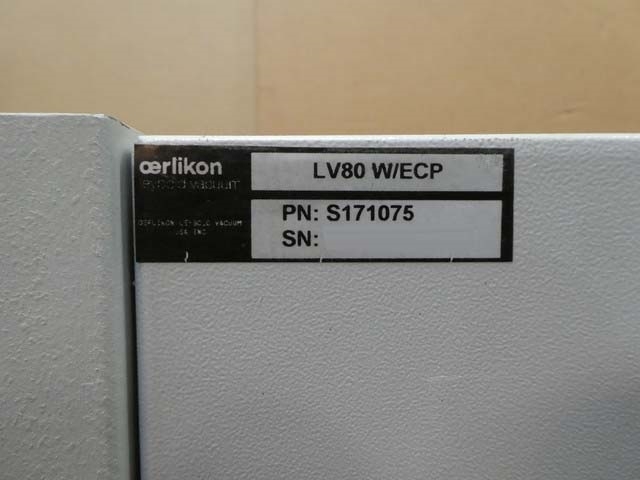

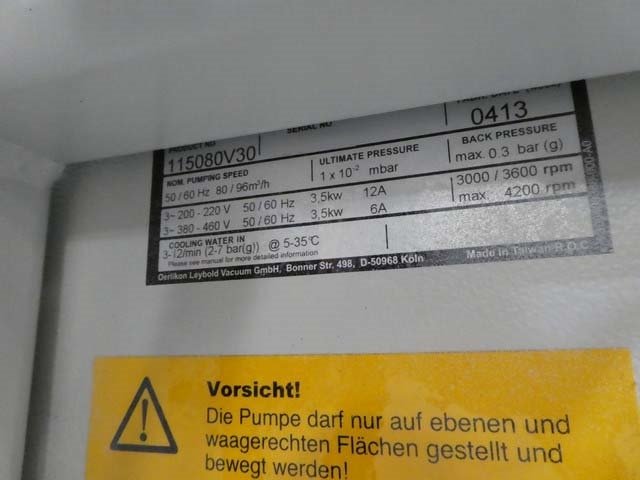

LEYBOLD LEYVAC LV80C Vacuum pump

ADVANCED ENERGY MDX-10X Power supply

BALZERS MSU200 Power supply

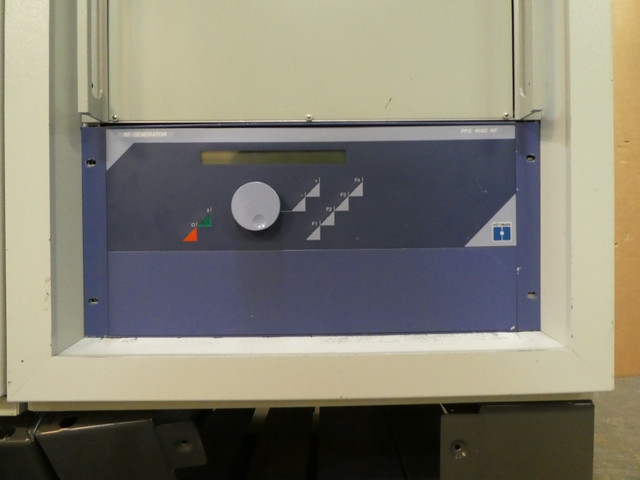

HUTTINGER PFG 1600 RF Generator

DAYTON 500 lbs

Capacity overhead hoist with pendant / Rail system

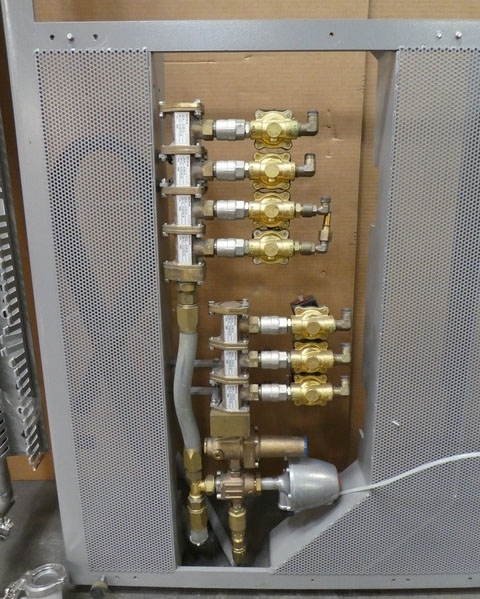

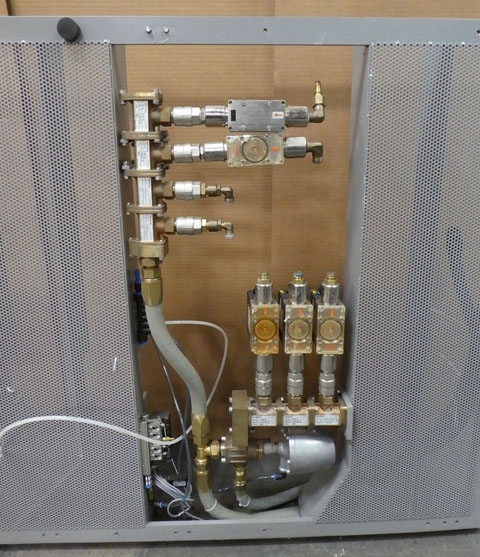

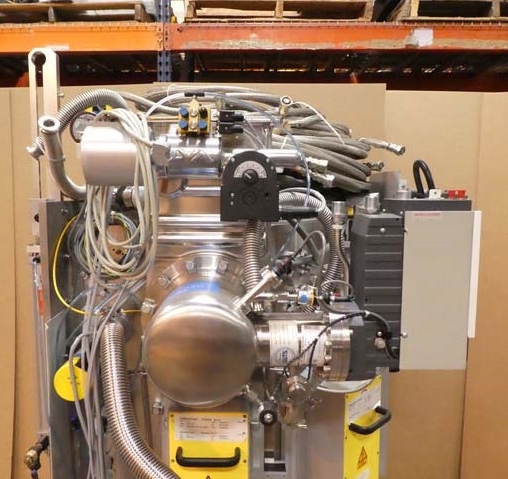

Pumps:

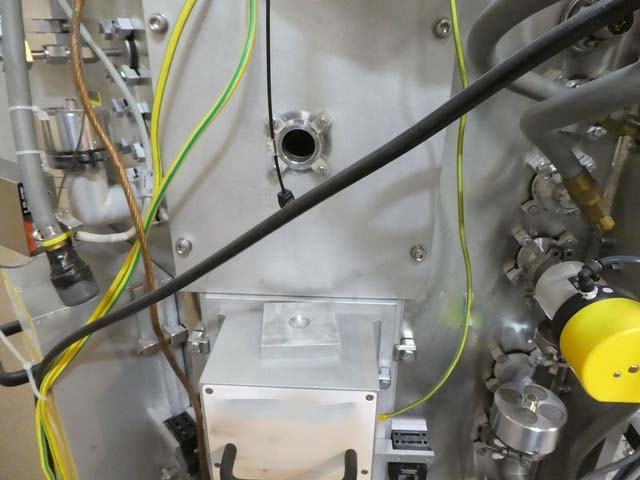

HV Pump LC: Cryo CTI 8F onboard, VAT 2 Point

HV Pump MC: Cryo CTI 8F onboard, VAT Stepless

Fore pump LC / MC: Dryvac 50B

Meissnertrap MC cooled with LN2

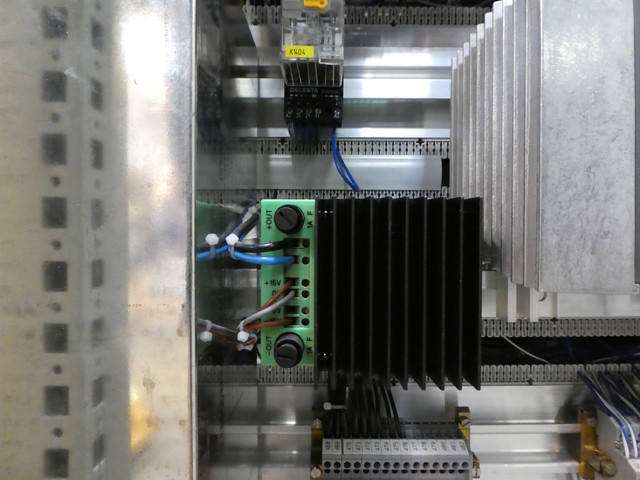

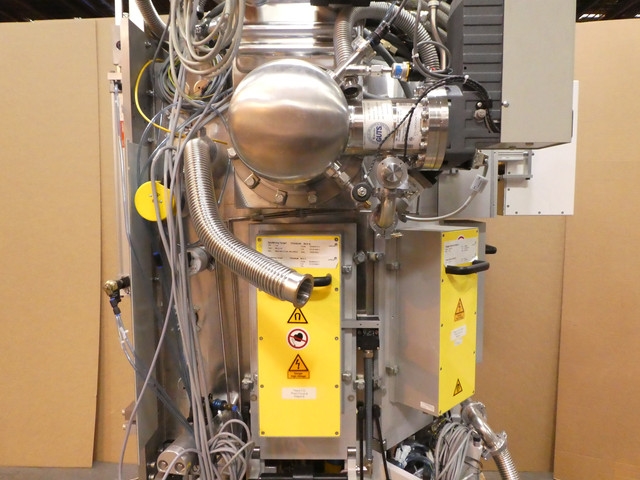

Heater:

LC: QUARTZ Heater 2.0 kW

MC: QUARTZ Heater 4.0 kW

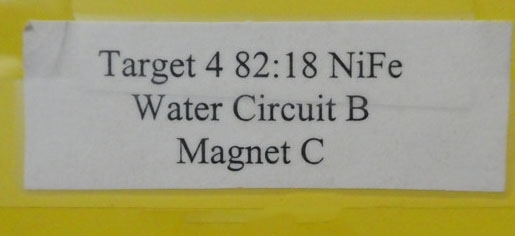

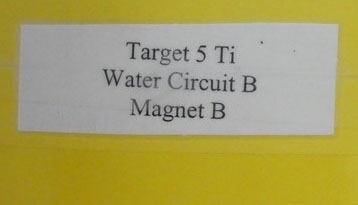

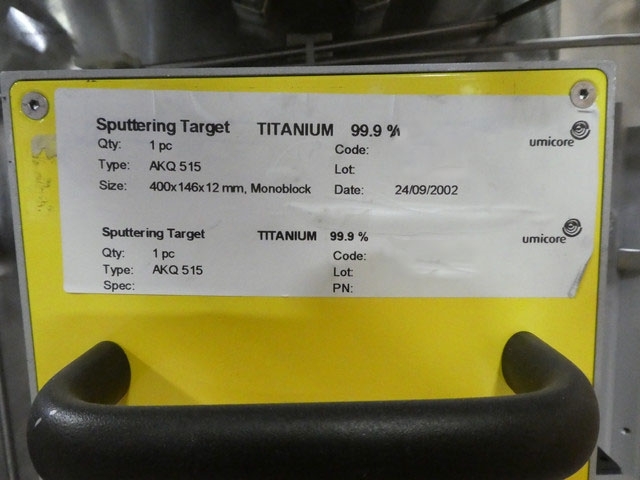

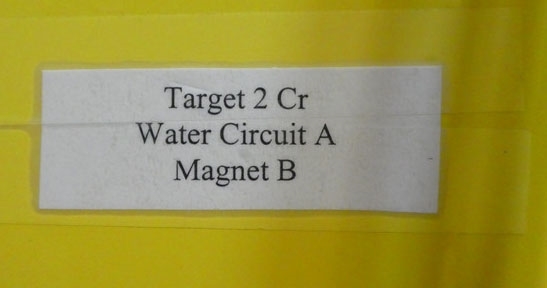

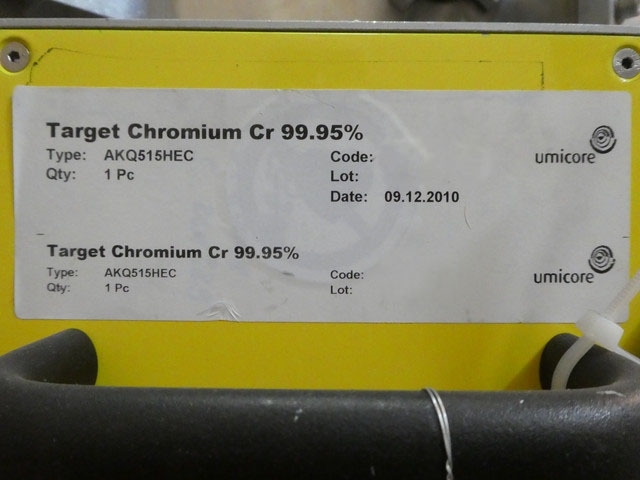

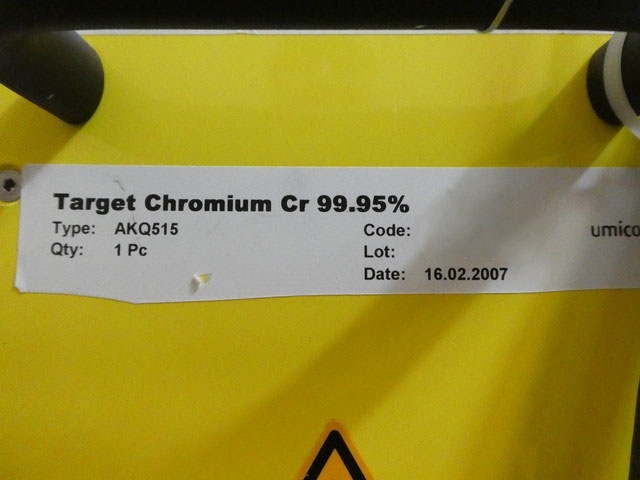

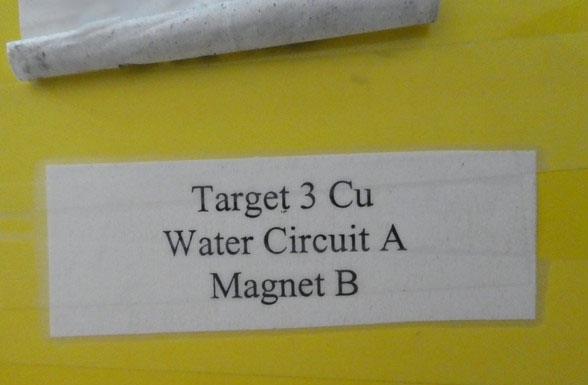

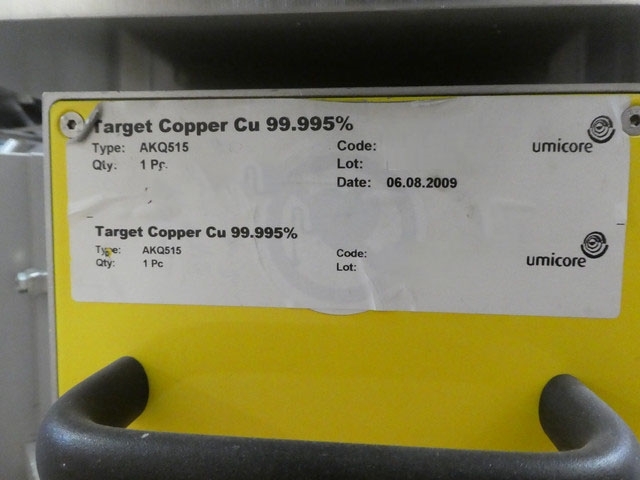

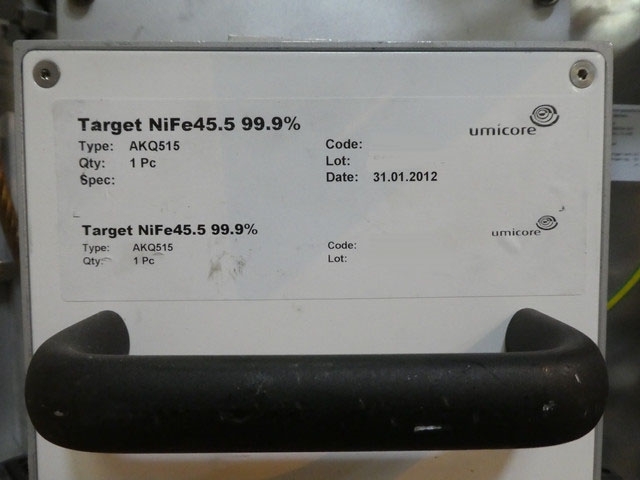

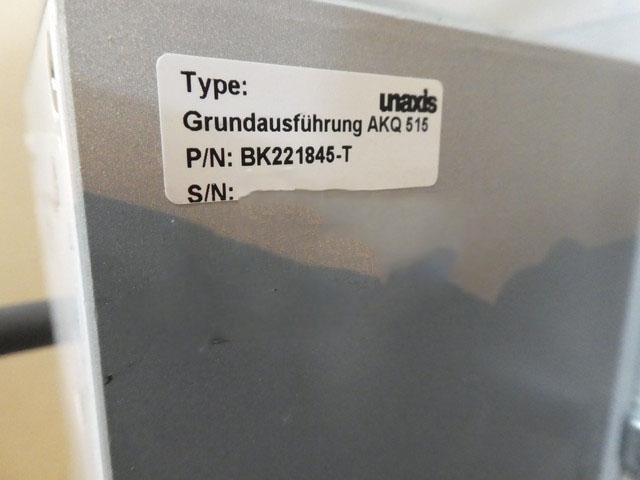

Sputtering:

Sources: Planner management AK 517 DC

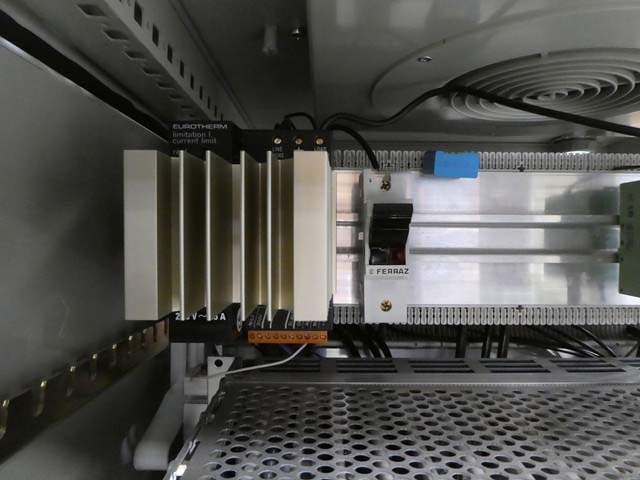

Power supply: ADVANCED ENERGY Pinnacle, 12 kW

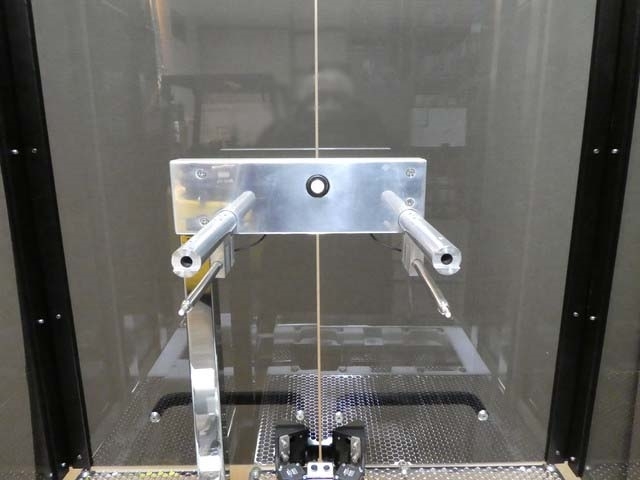

Etch:

Sources: Matchbox

Power supply: PFG 1.6 kW and HUTTINGER

(12) Tooling substrates, 6"

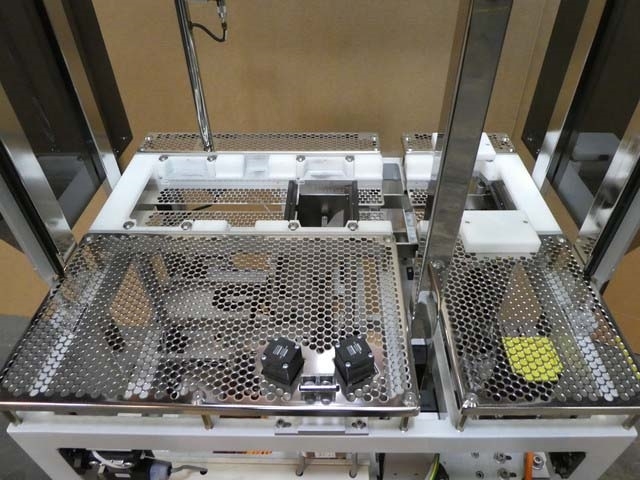

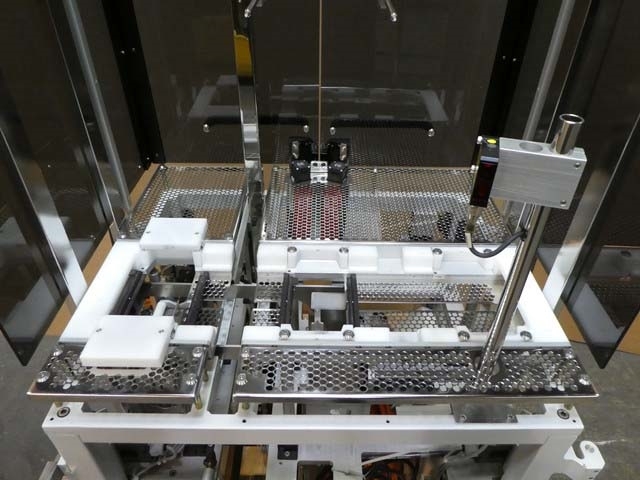

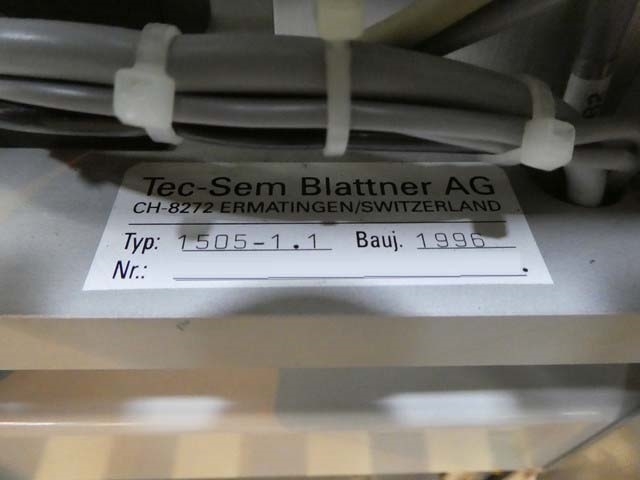

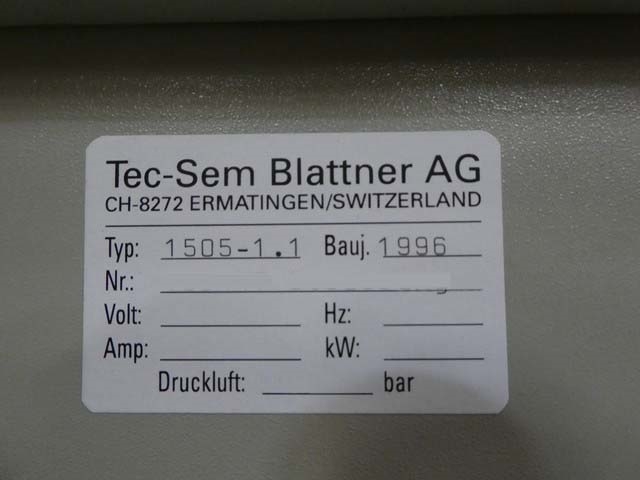

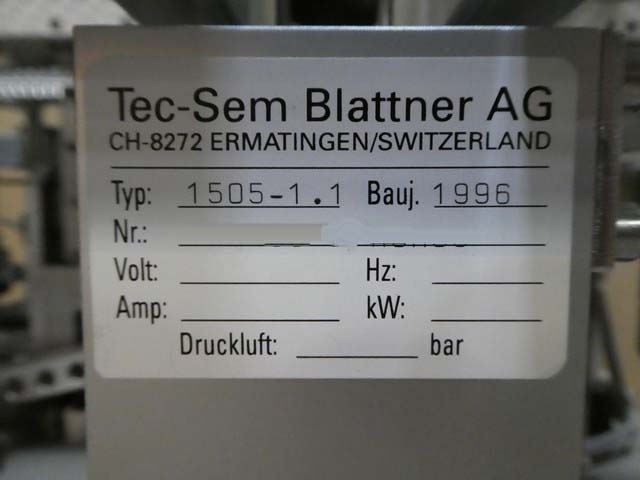

Handling: TECSEM With notch finder

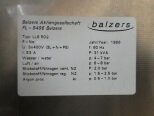

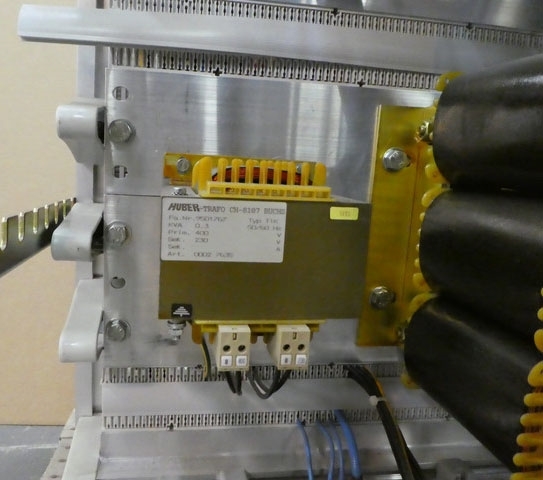

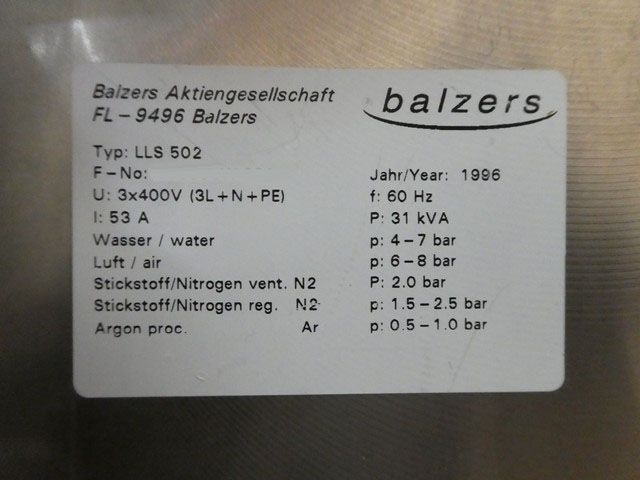

Input: 3x400 VAC (3L+N+PE), 60 Hz, 53 A

1996 vintage.

UNAXIS / BALZERS LLS 502 is a High Rate RF/DC Sputtering equipment used to deposit high-precision thin film layers on substrates. This system utilizes both RF and DC power to sputter target materials into an electron bombardment-like atmosphere to create an efficient deposition rate using a balanced Ion Cyclotron Resonance (ICR) technique. UNAXIS LLS 502 features a 600 kHz high-frequency power supply, with a 150 W RF power source, and 150 kW DC power source, allowing for an easy and adjustable deposition of high-purity films. BALZERS LLS 502 has an integrated and precise control unit that provides a wide range of variable parameters along with a wide range of process modes to allow for the deposition of a variety of thin films. Its advanced software allows for real-time process monitoring and control, while its mechanical design allows for decades of repeatable operation without required maintenance. LLS 502 has an advanced chamber design that provides for precise control of working temperatures up to 600 °C, as well as a broad process window for improved deposition rates of metals and dielectrics. This allows researchers to take advantage of different process parameters for optimal thin film deposition. It also has a gas mixing machine that is fully automatic and allows for simultaneous and cumulative control over individual gases. In addition, UNAXIS / BALZERS LLS 502 offers an array of optical components to provide the user with controlling/monitoring capabilities, which includes a real-time reflectometer, an automated optical microscope, an automated ellipsometer, and photometry capabilities. Overall, UNAXIS LLS 502 is a reliable and precise sputtering tool used for the deposition of high-quality thin film layers with a high degree of control over the deposition process. Its sophisticated design ensures a repeatable and precise deposition process and provides exceptional process performance and superior user flexibility.

There are no reviews yet