Used UNAXIS / BALZERS LLS EVO #9275953 for sale

URL successfully copied!

Tap to zoom

ID: 9275953

Vintage: 2001

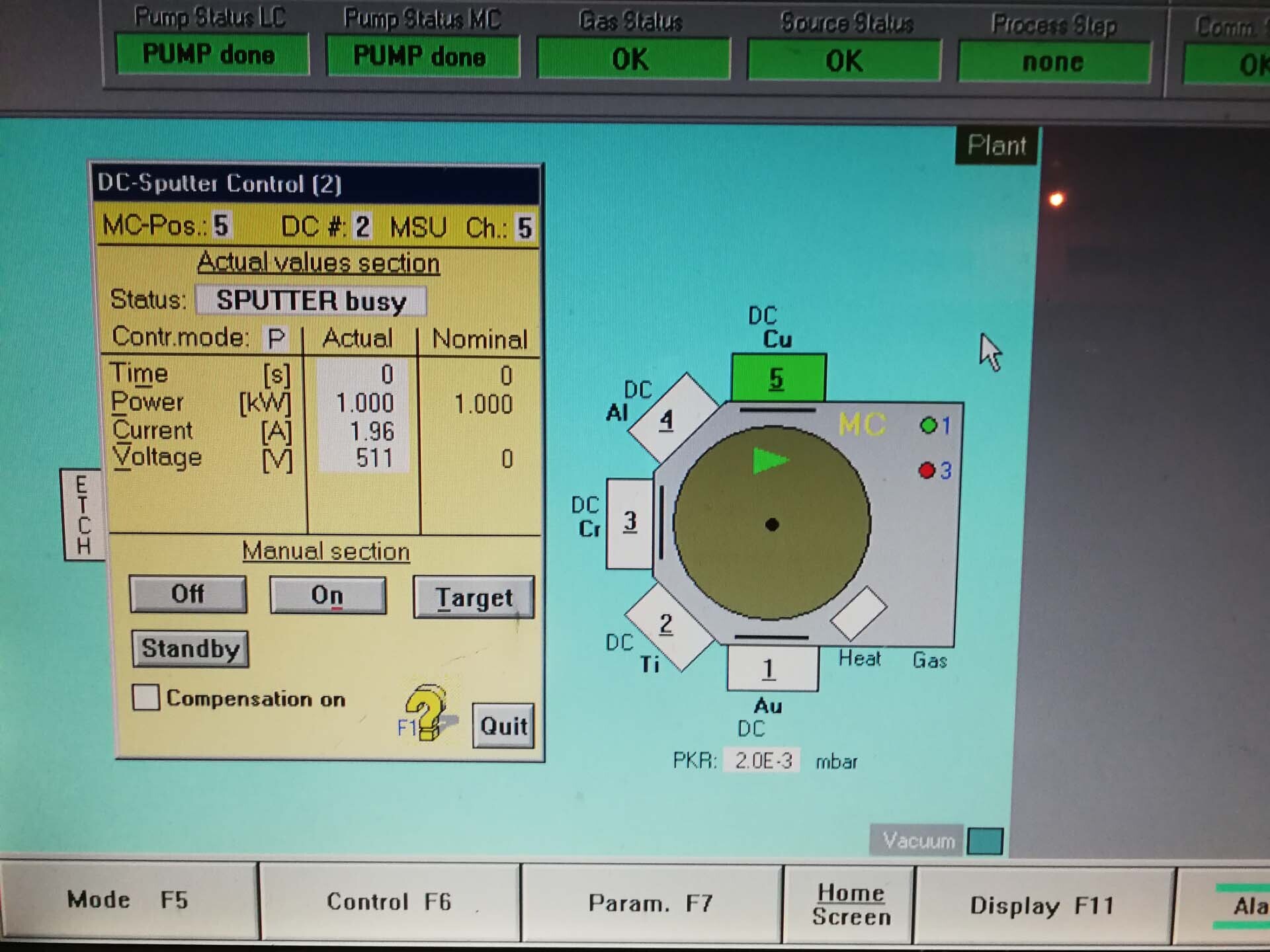

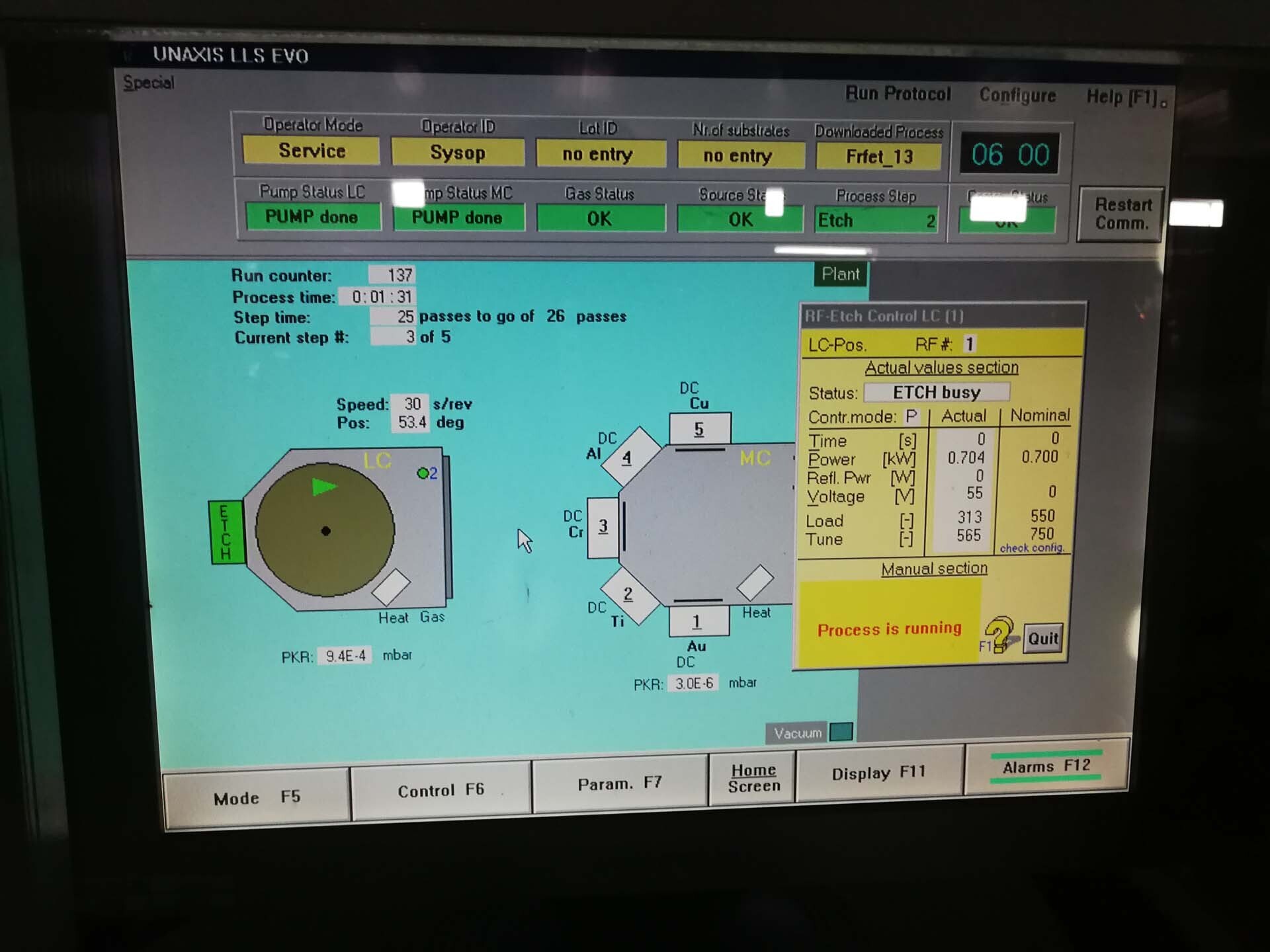

Sputtering system

Standard layout

RF Sputter (14 CM)

Includes:

TRIVAC D66B Rough pump

CTI 8F Cryo HV pump

POLYCOLD PFC400LT

Vent valves: VAP026-A

HV Valves:

VAT 014 2-Point

VAT 064 Servo

Heater:

LC Degas

MC Degas

Signal tower

UPS Power supply

Substrates:

Manual handling

Front side load pins

(12) Substrate sizes

Gases:

Ar / 200 scc

O2 / 100 scc

Ar / 60 scc

N2 / 100 scc

Damaged parts:

Pinnacle power 12 kW

RF Power 1.6 kW

Cryo pump 8F

Handling system removed

Power supply: 3 x 400 VAC, 50/60 Hz, 3 LNPE, 49kVA

2001 vintage.

UNAXIS / BALZERS LLS EVO is a sputtering equipment used for thin film coating, specifically designed for the deposition of Ti or TiN films. The sputtering system consists of a three-axis motion control and two sputtering source modules. The sputtering unit executes the X-axis and Y-axis movements of up to 200 mm with a high accuracy of ±0.1 μm. The movement of the third axis (Z-axis) is provided by means of an elevator machine. All coordinates are managed by a central controller, which also supports the process sequence. The sputtering tool features two sets of sputtering sources with six independent process chambers. Each sputtering source module is equipped with two up-to-date magnetron sputtering sources, high-precision process power supplies, and a control unit which manages the sputtering process. Depending on the type of thin film material, power ratings of up to 1kV peak are provided to the sputtering chamber. The sputtering asset is capable of processing any material with variable doping process parameters for achieving optimal thin film results. UNAXIS LLS EVO actively monitors the process parameters in the sputtering chamber during processing. Different process parameters such as sputtering time, sputtering power, or gas flow can be programmed for the entire model or individual sputtering sources. The sputter process can be monitored in real time using the integrated data logging equipment. This ensures that the high quality thin film deposition process is maintained throughout the fabrication process. The integrated gas system efficiently provides reactive gases to the sputtering sources. The flow and pressure of the gases are precisely regulated to create the desired deposition process. The gas unit is equipped with manual and automatic flow control, as well as pre-programmed leak detection and alarms to ensure a stable and reliable operation. BALZERS LLS EVO sputtering machine is a highly advanced sputtering tool capable of performing the precise deposition of thin films. Its integrated data logging asset, high-precision process power supplies, and specially designed motion control make it possible to get the best results in the deposition of any material.

There are no reviews yet