Used VACUUM SYSTEMS TECHNOLOGY / VST TFSP-840 #293602592 for sale

URL successfully copied!

Tap to zoom

ID: 293602592

Sputtering system

Ultimate vacuum pressure: 3x10^-7 Torr

Base pressure: 1x10^5 Torr

Pirani gauge, 100 to 1x10^-5 Torr

Maximum allowable leak rate: <1x10^-9 mbar L/sec (Helium)

Vacuum pumping system

PLC Controlled power switching boxes

DC Blocked filters

Substrate holder

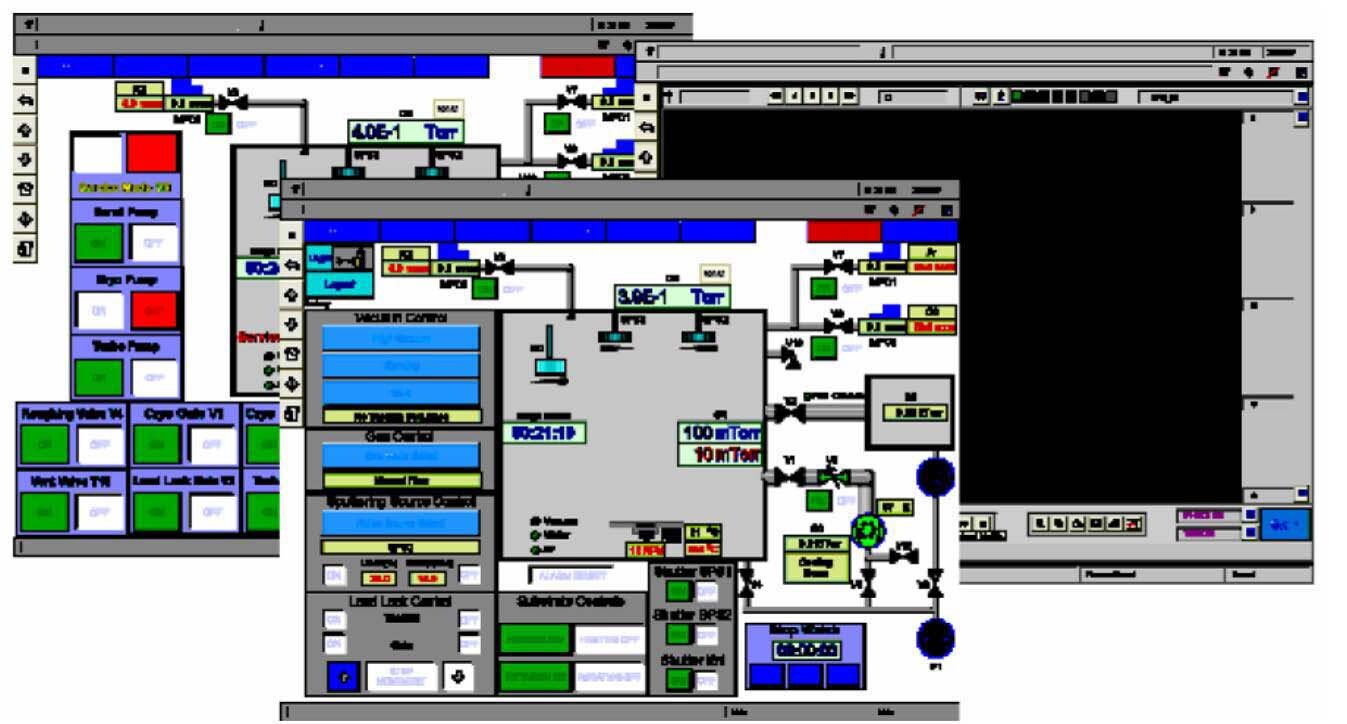

PLC / PC Computer control

Targets:

Titanium Tungsten: (Ti) 10 (W) 90 %

Copper (Cu)

Silicon Nitride (Si3N4)

Sputtering mode:

DC / DC Pulsed

RF

Combination of RF and DC

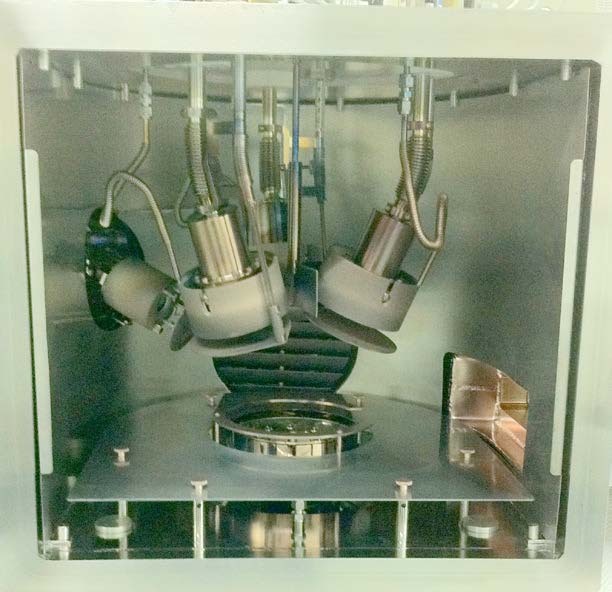

Chamber:

High grade stainless steel, water cooled, SS 304L

3-Ports

RF Shielded view port, 4"

Pumping port

Load lock chamber:

Loading sample holder, Up to 6"

EDWARDS nXDS10 Dry pump:

Pressure: 8x10^-3 Torr

Nominal pumping speed: 10 m³/hrs

EDWARDS EXT75iDX Turbo molecular pump:

Pumping speed: 61 L/sec

Compression ratio N2: >1x10^11

Ultimate pressure: 5x10^-8 mbar

Nominal rotational speed: 90,000 rpm

Air cooling

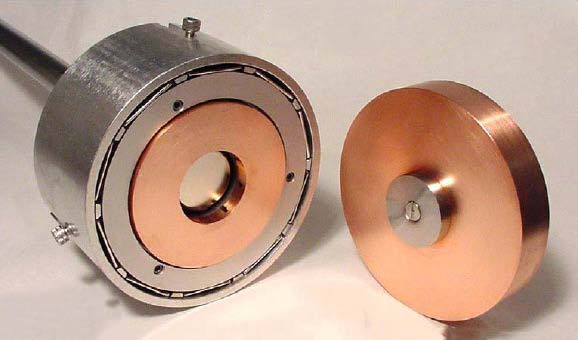

Sputtering sources:

Source dimension: MAK, 4"

Mounting feedthrough: Quick coupler, 0.75"

Target specifications:

Target diameter: 4"

Target mounting: Magnetic

Magnetic materials

Magnet design:

Type: Nd/Fe B

Configuration: Balanced/Unbalanced

Operation specifications:

DC Max power: 3000W

RF Max power: 1200W

Cathode voltage (Volts): 200-1000V

Discharge current (Max amps): 7 amp

Cooling water:

Flow rate 1.0 gpm

Vacuum interlock

High voltage switch

Chamber switch

Load-lock switch

Dry air pressure switch

Water flow switches

Substrate temperature

Emergency stop

Electrical overload protection

Gas line:

Gas / MFC

Ar / 1-100 SCCM

N2 / 1-50 SCCM

O2 / 1 – 50 SCCM

Maximum beam current:

25 to 35% of discharge current

280mA (Ar @ 1A)

350mA (O2 @ 1A)

Beam energy (Mean): 50 to 180eV (~60% of Anode voltage set point)

Max discharge power: 300W (200W Continuous)

Discharge voltage range:

Ar: 50 to 300V

O2: 100 to 300V

Discharge current range: 0.2 to 1A (Mark I + Ion Source Controller)

Max operating pressure: 1 x 10^-3 Torr (0.13Pa)

Gas use: Inert Gases, O2, N2 and other reactive gases

Typical gas flow range: 2-20sccm

Ion beam neutralization: Filament cathode

Ion beam size (at opening): 1.1 in (28mm) Diameter

MFC 20 sccm

Power supply:

RF Power supply: 13.56 MHz, 600 W

DC Power supply: 1500 W.

VACUUM SYSTEMS TECHNOLOGY / VST TFSP-840 is a versatile sputtering equipment that delivers robust and consistent sputtering performance. The system is equipped with several chamber configurations and can accommodate a variety of tools and accessories. The unit is capable of processing both thin and flexible substrates, allowing for reliable and repeatable deposition on a variety of materials. VST TFSP-840 utilizes a state-of-the-art two chamber design with an isolated loading chamber and a separate process chamber. The loading chamber is designed to reduce particle contamination and allow for quick, easy sample loading. Each chamber is equipped with a 2" roughing pump to create a stable, low-pressure environment and ensure efficient operation. The loading chamber utilizes a load-lock door to minimize airborne contaminants and ensure smooth operation. In the process chamber, VACUUM SYSTEMS TECHNOLOGY TFSP-840 is equipped with eight cathodes and a powered substrate rotation mechanism. Each cathode can independently adjust power settings and sputtering targets. The high-performance substrate rotation mechanism provides consistent and even deposition over the entire substrate. The top-mounted sputter gun allows the machine to be easily containerised for in-situ processing of large area samples. The TSFSP-840 is equipped with a range of accessories, including retrofitted substrates holders, external substrate heating, roller transport tool, onboard lift/direct access arm and safety lock that ensures safe and uninterrupted operation. The added features make the TSFSP-840 an ideal candidate for industrial applications. Thanks to its extensive features, the TFSFP-840 provides consistent and repeatable results, ensuring reliable thin-film deposition on a variety of substrates. The asset offers precise process control and reliably repeatable performance, making it well-suited for high throughput applications. Moreover, the model's user-friendly touchscreen interface allows for simple and convenient operation.

There are no reviews yet