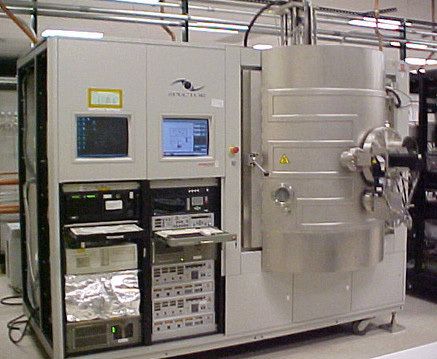

Used VEECO / IONTECH Spector #9033598 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9033598

Ion beam deposition system

Pumping system:

CTI-400 On Board cryo pump

Leybold mechanical pump

Chamber: vertical split bell jar, 42" diameter x 36" high

Target holder: 4 each 10 x 14" diameter

Sourcer 32 Ion Beam system manager

(1) RF12 cm ion beam assist source

(1) RF16 cam ion beam deposition source

(2) RF neutralizers

(2) Gas flow controllers.

VEECO / IONTECH Spector is a high-performance sputtering equipment that is renowned for its ability to produce uniform thin films and coatings. The system is a self-contained vacuum deposition tool suitable for a variety of industries including semiconductor, memory, opto-electronics, surface engineering, research and development, and industrial applications. At its core, VEECO Spector utilizes several electron beam guns, or multi-magnetrons, combined with advanced motion control and automation technologies to efficiently create high-quality coatings. These guns are integrated into a single chamber design, allowing for fast and easy target loading and unloading with minimal manual intervention. The highly efficient motion control technology ensures uniform particle distribution and deposition rates while the sophisticated vacuum technologies enable high processing rates with low defectivity. This unit is also equipped with a variety of process control and analyzation tools, giving users the ability to monitor and adjust layer parameters in real time. These tools include software such as SENTech, which is a data-logging and analytics tool for efficient monitoring and analysis of the deposition process, as well as a Layer Mapping Machine (LMS) and a Range of Motion (ROM) tool. Additionally, IONTECH Spector is equipped with a Load Lock tool, allowing users to transfer samples into and out of the asset without breaking vacuum, thus saving time in the coating process. Finally, Spector is capable of providing a variety of substrates, including flat panels, to virtually any shape or contour, while the sophisticated gas handling enables precise gas delivery and control, resulting in superior film uniformity and defect performance. The process control capabilities enable users to accurately and reliably produce film layers with near perfect uniformity while also allowing for a high degree of process optimization and repeatability. Overall, VEECO / IONTECH Spector offers an impressive range of features and capabilities for advanced coating production, making it an ideal choice for a variety of industries. Its powerful guns and motion control technologies ensure reliable and uniform deposition rates, while its sophisticated process control and analysis tools allow for highly accurate and repeatable thin film layers. Additionally, its ability to handle a range of substrates in virtually any shape make it perfectly suited for numerous production and research applications.

There are no reviews yet