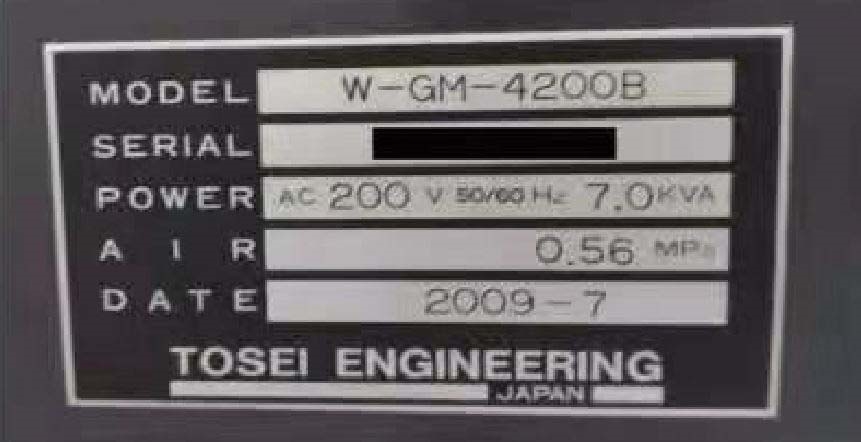

Used ACCRETECH / TSK W-GM-4200B #9250482 for sale

URL successfully copied!

Tap to zoom

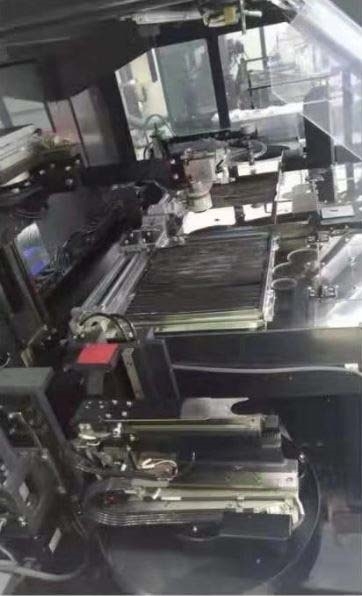

ACCRETECH / TSK W-GM-4200B is a fully automated wafer grinding, lapping and polishing equipment. The system is designed to accommodate up to four wafers for uniform processing across each wafer. TSK W-GM-4200B is designed to ensure that all surfaces and edges of the wafer are uniformly processed and consistent in size. The wafer grinding, lapping and polishing unit is a multi-step process. The first step is the grinding of the wafer surface with either a diamond or CBN abrasive wheel. During this step the surface is leveled and the sizes of defects is reduced. The next step is lapping, where a flexible polishing pad and abrasive particles are used to remove material from the surface of the wafer. During this step, the roughness of the wafer surface is reduced and any remaining irregularities are smoothed out. The final step is polishing, where a polishing surface is used to remove residual material from the surface of the wafer. ACCRETECH W-GM-4200B is equipped with an advanced process control machine that ensures the smooth running of the wafer grinding, lapping and polishing process. The tool includes a software programmable timer and a motion control asset for the positioning and combination of the individual grinding, lapping and polishing steps. The model is also outfitted with a closed loop feedback control equipment, allowing the system to check the uniformity of the wafer grinding, lapping and polishing variable parameters and make the necessary adjustments if required. W-GM-4200B is capable of processing wafers of up to 4 inches in diameter at a rate of 17 wafers per hour. The unit is designed to be easy to operate and maintain, with minimal operator intervention required. The machine is also designed to be safely enclosed, helping to prevent any accidental contact with hazardous materials. Overall, ACCRETECH / TSK W-GM-4200B is a fully automated wafer grinding, lapping and polishing tool designed to provide uniform processing across each wafer, as well as maintain high levels of product quality and reproducibility. The asset is designed to be accurate, reliable and easy to operate, and is a great solution for handling projects involving wafer grinding, lapping and polishing.

There are no reviews yet