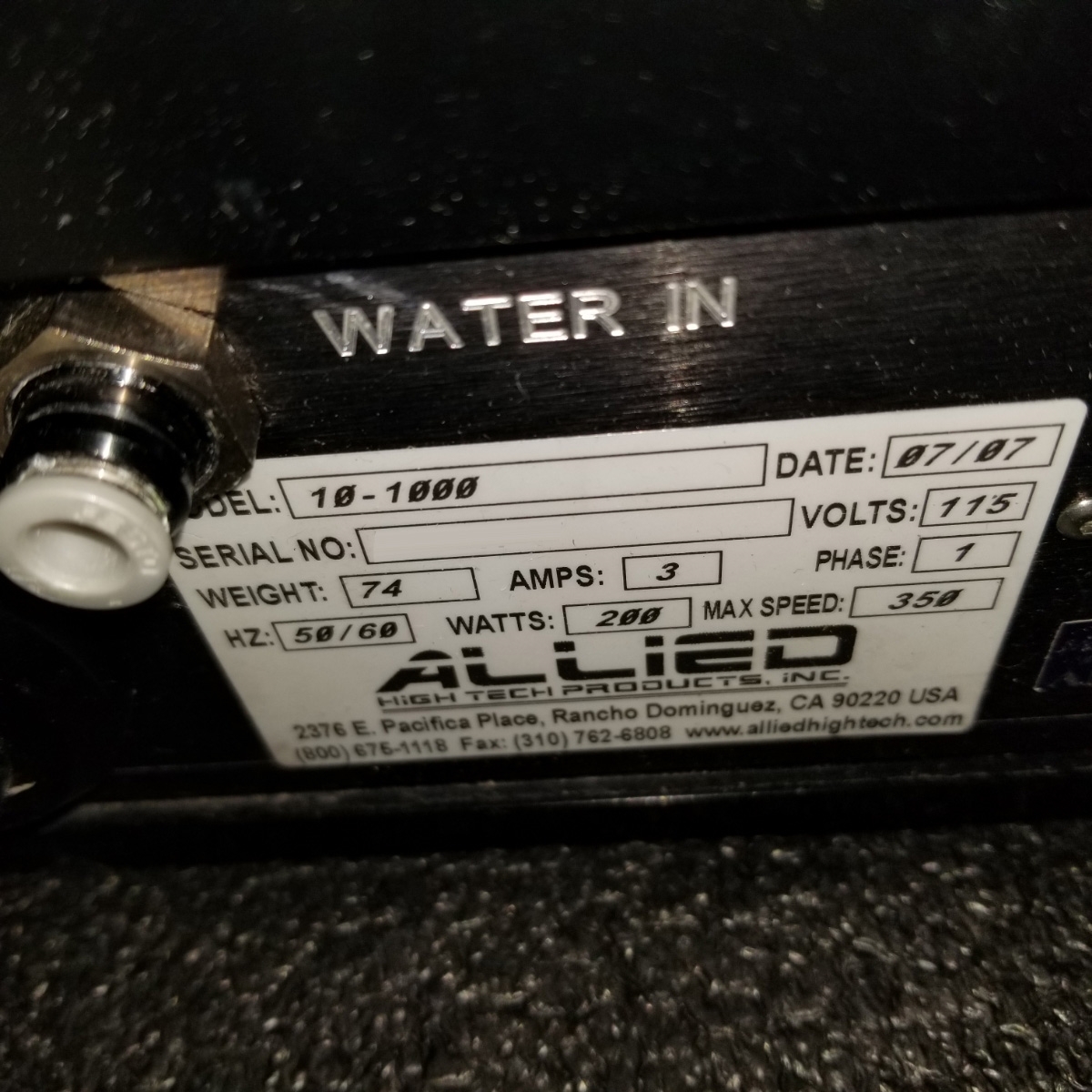

Used ALLIED HIGH TECH PRODUCTS 10-1000 #9263068 for sale

URL successfully copied!

Tap to zoom

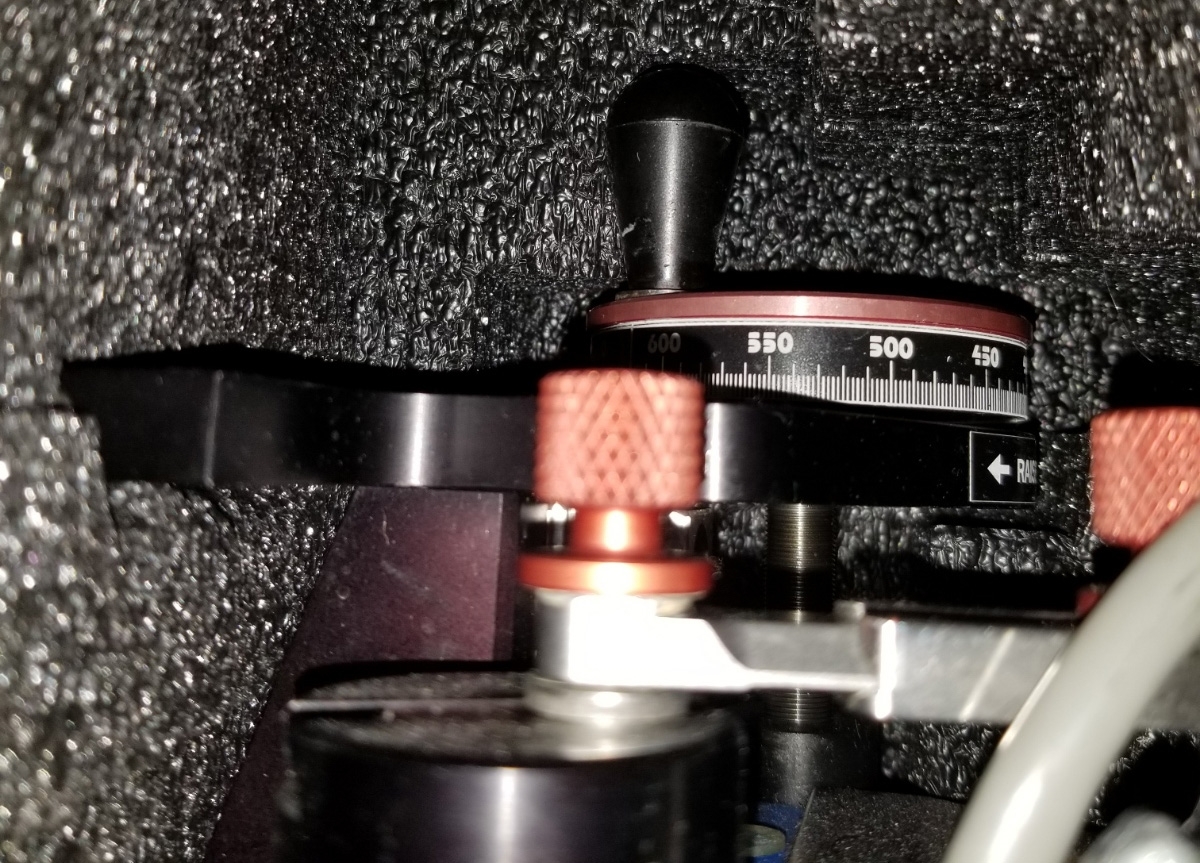

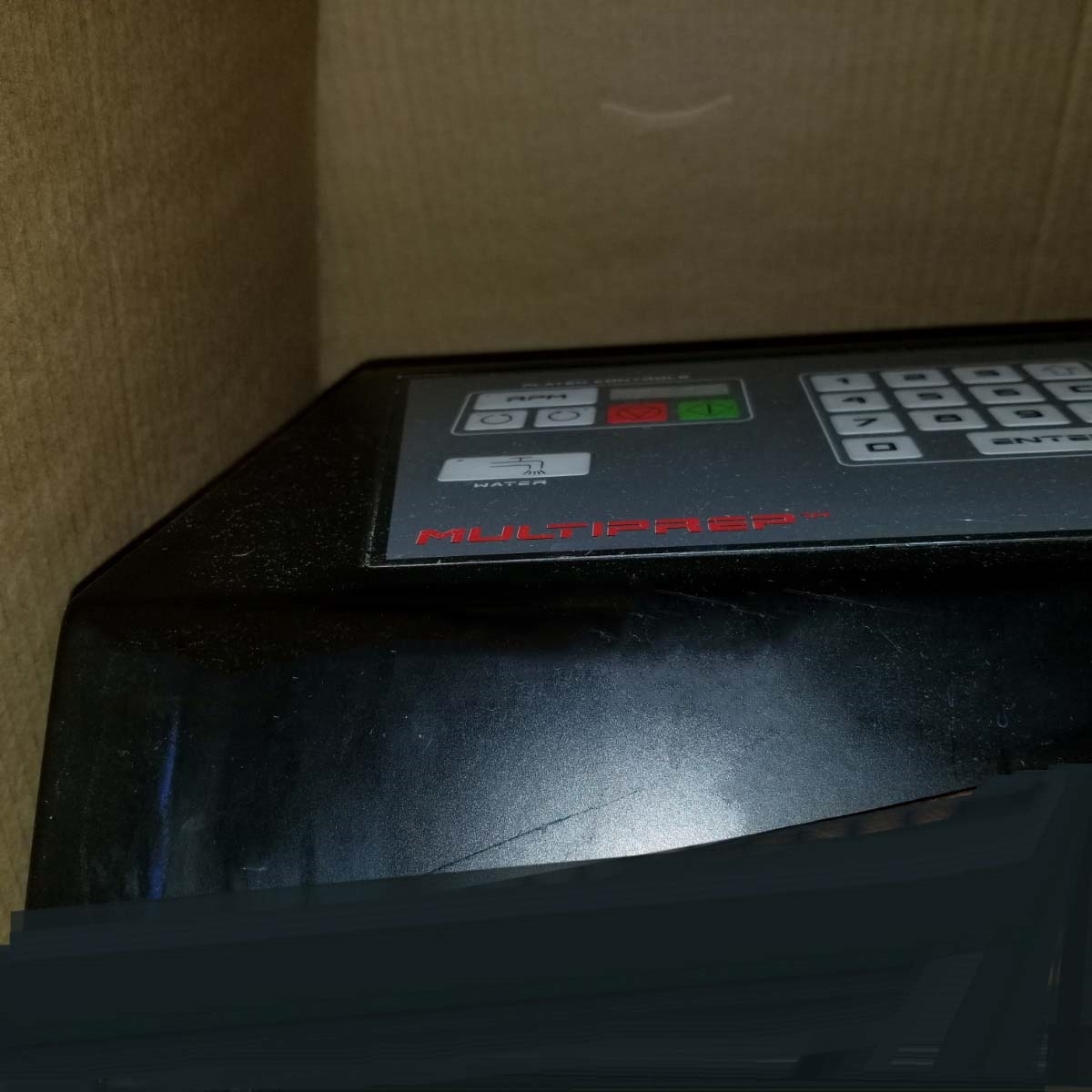

ALLIED HIGH TECH PRODUCTS 10-1000 is a wafer grinding, lapping, and polishing equipment designed to provide precision lapping and polishing of individual or multiple wafers. The system utilizes a precision diamond grooved lapping plate, a two-axis motorized optical table drive, and an automatic wafer panning unit in combination with diamond slurries and abrasive slurries to produce high quality lapped and polished wafers. The grooving pattern of the lapping plate provides an optimal grinding track that minimizes the extent of grinding damage on the wafer surfaces. The two-axis motorized optical table drive allows for easy movement of the panning table, while the wafer panning machine employs a variety of motions including rotating, tilting, and relative shifting to manipulate the wafer positioning. The goal of this tool is to reduce the depth of field and bring the entire wafer into focus. 10-1000 asset utilizes an automated slurry dispenser to evenly distribute diamond slurries and abrasive slurries to the lapping plate. The use of these slurries, including the abrasive suspensions, provides step by step grinding and polishing of the wafer surface. The abrasive suspensions involve the action of a rotating disc as it comes into contact with the wafer during lapping and polishing. This maintains equal pressure between the wafer and the lapping plate in order to ensure uniform grinding and polishing. ALLIED HIGH TECH PRODUCTS 10-1000 is capable of providing high quality lapping and wafer polishing, with subsequent results yielding less than 0.5 micrometer of root mean square (RMS) error in the flatness of the wafer surface. Additionally, 10-1000 model is capable of processing up to twelve 8-inch wafers at a time, with the option to configure four equipment configurations with two, four, or six wafer lapping positions. For added safety and security, ALLIED HIGH TECH PRODUCTS 10-1000 system is equipped with a stainless steel safety cabinet, complete with an automatic dust collection unit. The safety cabinet is designed to trap the dust during the wafer processing stages and prevents hazardous particles from being dispersed into the environment. 10-1000 machine from ALLIED HIGH TECH PRODUCTS is an ideal solution for precision wafer grinding, lapping, and polishing. The combination of its precision grooved lapping plate, two-axis motorized optical table drive, and automatic wafer panning tool, along with diamond slurries and abrasive suspensions, provide reliable, efficient, and precise results that meet the highest quality standards.

There are no reviews yet