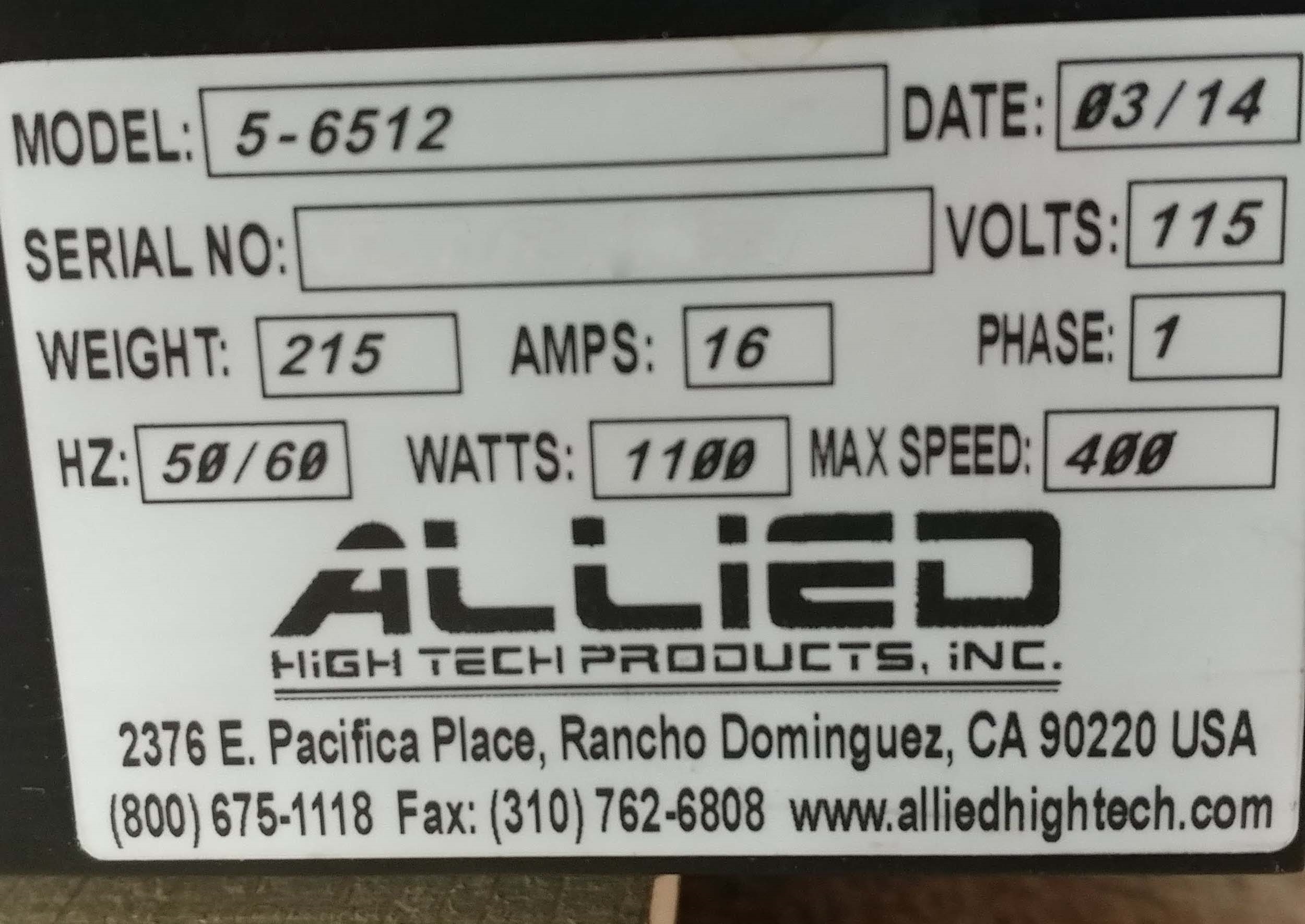

Used ALLIED HIGH TECH PRODUCTS 5-6512 #9269275 for sale

URL successfully copied!

Tap to zoom

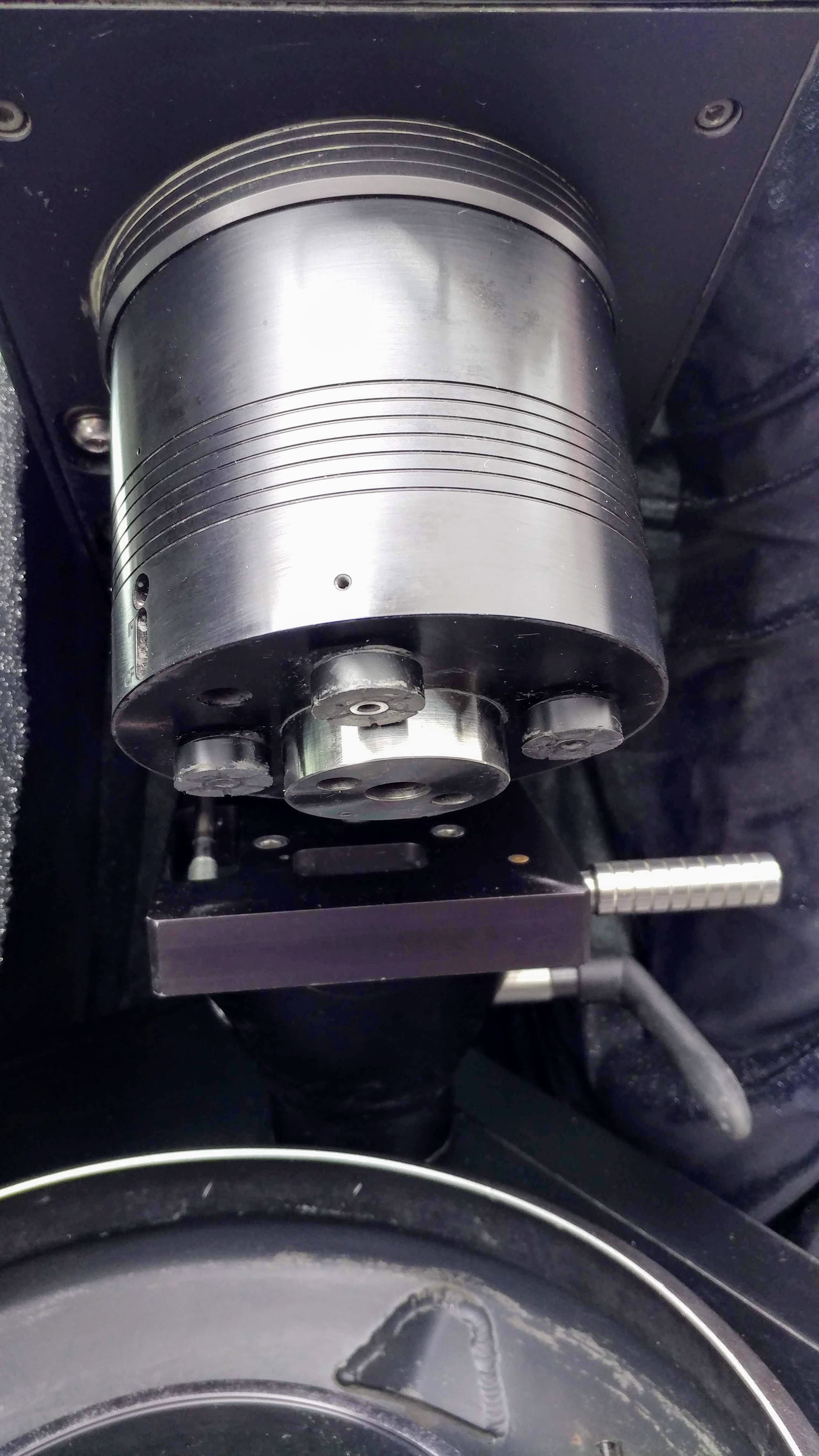

ALLIED HIGH TECH PRODUCTS 5-6512 Wafer Grinding, Lapping & Polishing Equipment is a precision controlled grinding and polishing system that can be configured to meet specific wafer grinding and polishing requirements. The unit includes a loading and positioning station, a grinding station, a polishing station, and a control station. The loading and positioning station allows users to place up to three substrates onto the platter. The platter has a spindle capable of rotating up to 6,000 RPM, which can be configured for variable speed control. This allows users to accurately position each substrate and set up the grinding and polishing parameters. The grinding station includes two grinders, one for grinding and one for polishing. The grinders are mounted on a fulcrum to provide fine-tune adjustment of the cutting blades at various angles. The grinding station also comes with a media collector, which minimizes particle escape. The polishing station includes two polishers, one for each side of the wafer. Each polisher has multiple speeds and pressure settings which allow users to control the polishing results. The air pressure and the speed control can be adjusted to provide the desired results. The actual work is controlled by an automated controller. This controller allows users to program the settings for each wafer in terms of grinding and polishing speed, angle, pressure and media size. 5-6512 is a versatile and reliable tool that can help users to achieve the required results in a fast and cost-effective way. This machine is suitable for a variety of wafer processing requirements such as grinding, lapping and polishing. The intuitive drag-and-drop interface allows users to set up the parameters quickly and accurately. With the right settings, the user can get optimal results with minimal effort.

There are no reviews yet