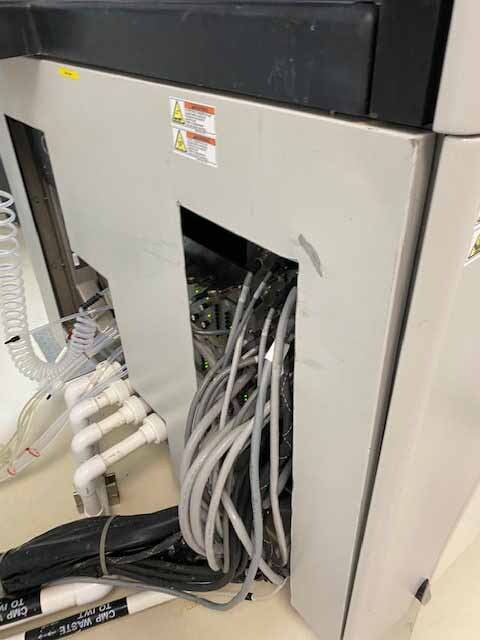

Used AMAT / APPLIED MATERIALS / AMJ Mirra 3400 #293620932 for sale

URL successfully copied!

Tap to zoom

ID: 293620932

Wafer Size: 8"

Vintage: 2001

CMP System, 8"

ISRM

Controller type: 5201

Titan heads: (3) Zones

Inner tube

Membrane

Retaining ring

2001 vintage.

AMAT / APPLIED MATERIALS / AMJ Mirra 3400 is an advanced wafer grinding, lapping and polishing equipment. This unique system utilizes advanced technologies such as precision dynamic polishing, surface leveling, and thermal control. The unit is capable of achieving high levels of accuracy and surface flatness, as well as creating fine finishes in one process. The machine features an automated dynamic polishing tool that precisely and quickly removes material to achieve extremely flat surfaces. This asset features an ultra-durable diamond polishing wheel that can efficiently process a variety of wafer substrates. Furthermore, it is capable of accurately measuring, analyzing, and controlling the polishing process. In addition, the model offers the flexibility to customize polishing parameters for different customer requirements. The equipment also utilizes advanced lapping and polishing technologies which include surface leveling, step grinding, and module patterning. These advanced processes create a uniform, uniformed wafer finish. Additionally, the system incorporates a high-precision thermal control unit that helps maintain a stable temperature during the lapping and polishing process. As a result, the machine can deliver consistent performance with high yield and throughput. The tool is further designed for high speed production processing. It features high repeatability and low process cycle times. This, in turn, reduces the overall manufacturing cost of the asset and increases production efficiency. Additionally, the model offers high-end security features that help protect proprietary information and customer data. Overall, AMJ Mirra 3400 is an incredibly advanced equipment that offers impressive levels of accuracy and repeatability. This system is ideal for wafer grinding, lapping, polishing, and other production processing, as it offers users the ability to customize and control the polishing process with precision dynamic polishing, surface leveling, and high-precision thermal control. Additionally, it provides high-end security features and high speed production processing, making it an excellent choice for many production applications.

There are no reviews yet