Used AMAT / APPLIED MATERIALS CMP 5201 #9093212 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9093212

Wafer Size: 8"

Vintage: 2003

Cleaner, 8"

Process: PCUDCU

SMIF Type. FABS

Runs oxide application

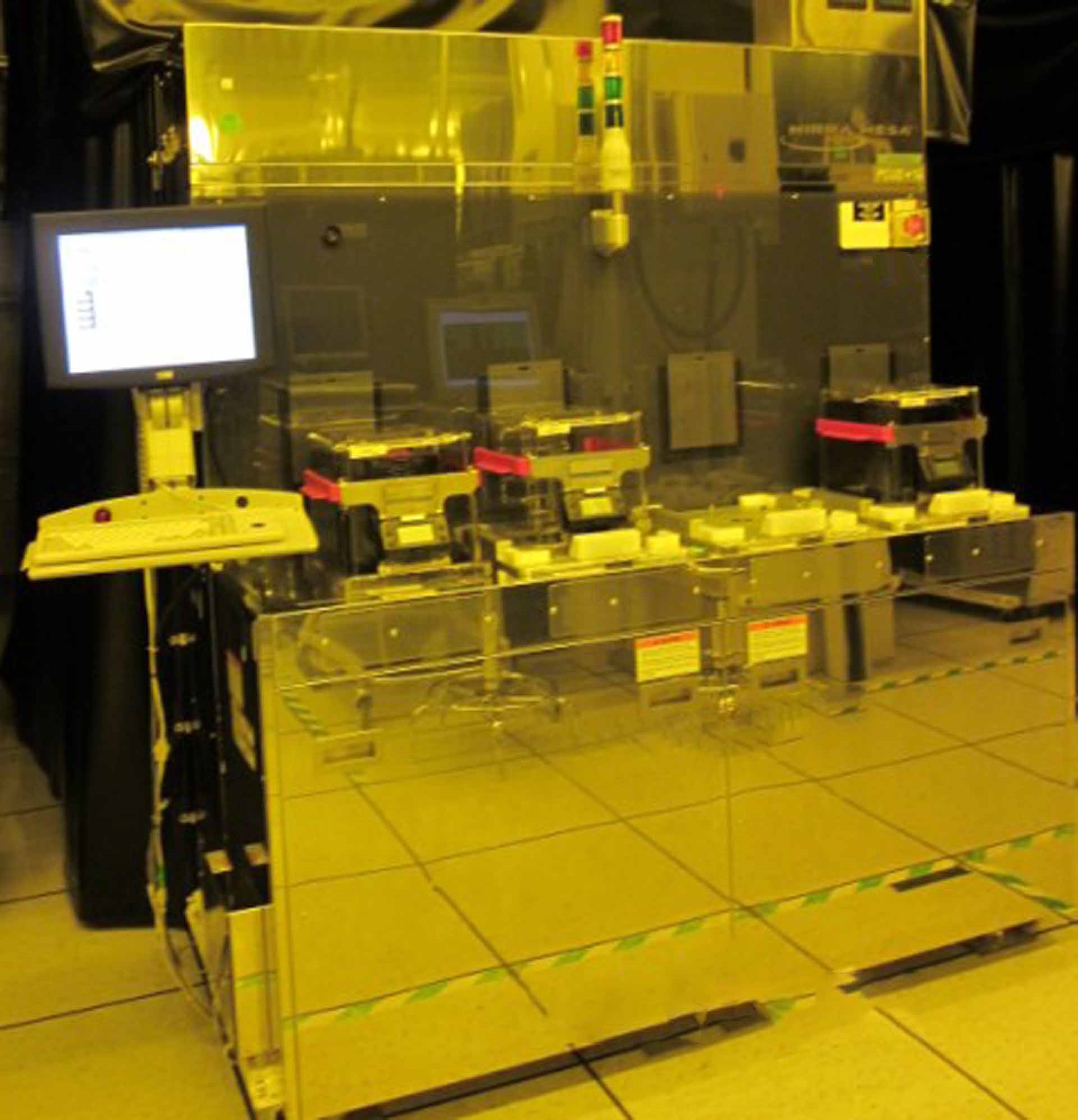

Mirra polisher

Mesa cleaner

FABS Cassette system

System controller

Polisher: MB60a1

Cleaner: CB22p2

Endpoint: IB11h7

CPU: Pentium III 400 MHz

Dual RAID hard disk

Hard disk size: 68 GB

RAM: 128 MB

Configurations:

Polisher / with controller Mirra 3400 / 5200

Indexer RORZE FABS

(3) Foup

Slurry (P1+P2+P3) ABCD each

Endpoint laser P1: IScan

Endpoint laser P2: Full scan

Polisher middle skins: Opaque

UPA: Standard

No chiller

Com port server: Digi EL160

Cleaner brush LDM: User modified direct feed LDM

With ENTEGRIS flow sensors

Walking beam: PEEK Fingers with PP grippers

Slurry in CLC

Slurry arm 4 lines

Polishing head: Titan I

Rotary union: 4 ports

Cross type: Cattrack

Platen teflon coated

Pad conditioner type: Universal

Retainer ring type: AEP III

Membrane type: Center bump

PC Diaphragm: Silicon

Brush with core type: PP Core

Upgrade / CIP Retrofit:

LLA Guide pin: Self align

Slider motor 200 W

PM Reduction kit

Queue tub

Membrane UPA filter

Blackout covers

Splash guard

Wind tunnel

Exhaust blower

Magnehelic pressure low level detection kit

SRD Exhaust interlock

Cassette slot run order (From slot 25 down to 1)

2003 vintage.

AMAT / APPLIED MATERIALS CMP 5201 is a precision wafer grinding, lapping and polishing equipment designed to provide the highest level of performance and quality for semiconductor applications. This system uses an automated CMP process to deliver exceptional control over the grinding, lapping and polishing processes to produce the highest levels of surface finishes. AMAT CMP 5201 features a range of configurable parameters, enabling users to adjust the process as needed to achieve precision results. The unit is equipped with a high-precision, high-speed grinding head that uses diamond-tipped abrasive disks to accurately grind the material to a precise depth. The grinding head also has an adjustable pitch that allows for further control of the grinding process. The grinding process is designed to improve surface finish, eliminate defects, and reduce waste. APPLIED MATERIALS CMP 5201 is also equipped with a lapping module for polishing the wafer to a desired finish level. The lapping module uses a combination of diamond lapping compounds and polishing pads to grind and polish the surface of the wafer. This process produces a highly reflective surface that is highly suitable for use in semiconductor applications. CMP 5201 has also been integrated with a wafer chamfering module, which is designed to provide accurate chamfering of the wafers. This technology uses diamond-tipped blades to producing uniform and consistent chamfer cuts on the edges of the wafers. AMAT / APPLIED MATERIALS CMP 5201 also has a fully modular design which allows users to customize the machine to meet specific process requirements. The modular design makes it easy to reconfigure the tool to accommodate new process requirements or to integrate with other components of the production process. Overall, AMAT CMP 5201 is a highly effective asset for producing precision finished wafers for use in semiconductor applications. The combination of reliable grinding, lapping and polishing technology makes it an ideal choice for use in production lines and for achieving the highest levels of semiconductor performance.

There are no reviews yet