Used AMAT / APPLIED MATERIALS Mirra Integra #9265796 for sale

URL successfully copied!

Tap to zoom

ID: 9265796

Wafer Size: 6"

Vintage: 1998

System, 6"

Box 1:

Type: Through-the-wall

(4) SMIFs

CPU Board type: 400 MHz or Higher

Box 2: Mirra Track

Box 3: Oxide

Box 4: Dry in / Dry out

Box 5:

Signal lamp tower

No Bolt-on SMIF

No integrated SMIF

Box 6:

Cassette tank: Standard

Robot type: 112" Stand alone

Cleaner type: ONTRAK

Spray gun: Single

No In-situ removal rate monitor

No IPM

Box 7:

Polish heads: Titan 1

Rings: AFP

Wafer loss sensor: Dual sensor

Box 8:

Teflon coated platens

Pad type: IC 1000

Pad conditioner head: DDF3

Pad conditioner disc: TBW

Universal disk holder

Temperature control: None

Box 9:

Slurry / Platen used

Flow rate: Standard

Dispense arm: Standard

No slurry flow monitors

Box 10:

Nova type: Wet out

No interface monitor

No notch finder

Box 11:

Membrane type: FPDM

4-Port UPA upper

Box 12:

Polish heads: 6" Titan

Grooved retaining rings

Dark pad wafer loss sensor

Box 13:

Pad type: IC 1000

Pad conditioner disc: ABT

Universal disc holder

Box 14:

MESA Cleaner type

On-board mixing

Chemical A: Ammonia Hydroxide

Pressurized delivery type

Precision spray bar

CLC Brush box with on-board mixing

Scrubber 1 and 2:

Brush type: Rippey microclean

Delivery type: Direct feed

Manuals and cables included

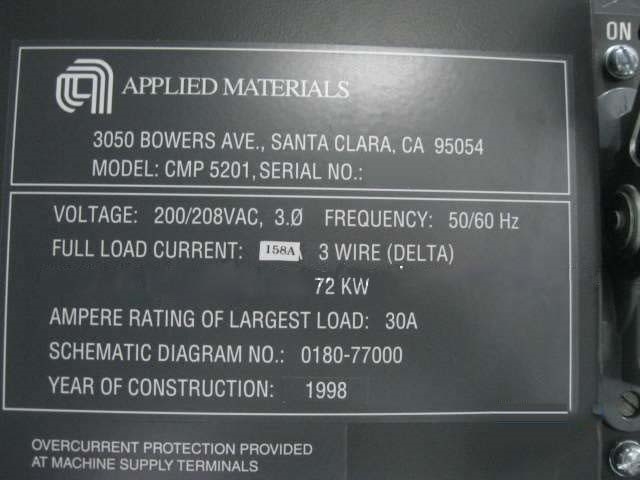

Power supply: 208 V, 3 Phase

1998 vintage.

AMAT / APPLIED MATERIALS Mirra Integra is a wafer grinding, lapping and polishing equipment that is designed for high efficiency machining of brittle materials with a wide range of abrasive media. This system is used for a variety of applications including the production of semiconductor and MEMS devices. The unit is composed of a base unit, which houses the grinding wheels and lapping plates, and a controller unit which allows the user to control the grinding equipment and adjust the parameters to meet the desired results. AMAT Mirra Integra has a robust construction with an aluminum chassis, stainless steel work plates and ceramic components. The grinding machines used in APPLIED MATERIALS Mirra Integra have a high degree of precision and accuracy. The grinding wheels are designed to provide consistent results across the entire material surface. The grinding media is optimized to reduce plate abrasion and minimize damage to the workpieces. In addition, the grinding media is also capable of accommodating surface-disparate substrates. Mirra Integra's lapping plates are designed to provide a uniform grinding surface, which evenly distributes the stress across the work surface. This helps to reduce the stress on the workpiece, resulting in lower surface roughness and improved part life. The lapping plates are equipped with two adjustable clamps that enable them to be adjusted to suit the specific application requirements. AMAT / APPLIED MATERIALS Mirra Integra's polishing process uses a combination of chemical and mechanical methods to achieve a high quality polished result. The polishing media used is engineered to enable a controlled and consistent finishing procedure, resulting in highly precise results. AMAT Mirra Integra's automated process control machine allows the user to adjust the grinding equipment parameters to ensure optimal results. The controller also provides feedback on the workpiece surface roughness and can trigger an alarm when pre-determined thresholds are exceeded. Overall, APPLIED MATERIALS Mirra Integra is an exceptionally advanced and reliable wafer grinding, lapping and polishing tool that can be used to achieve high precision results in a fraction of the time.

There are no reviews yet