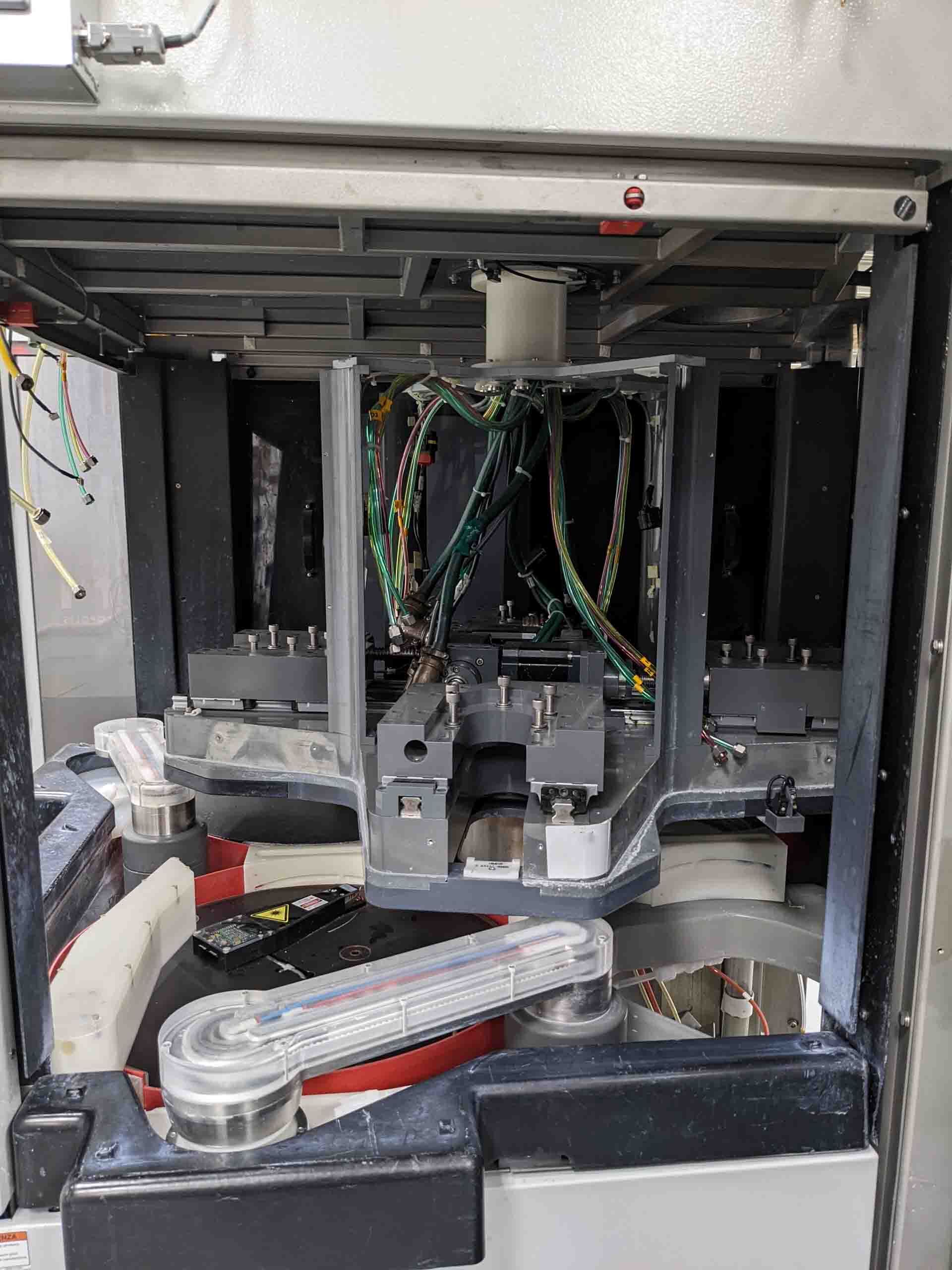

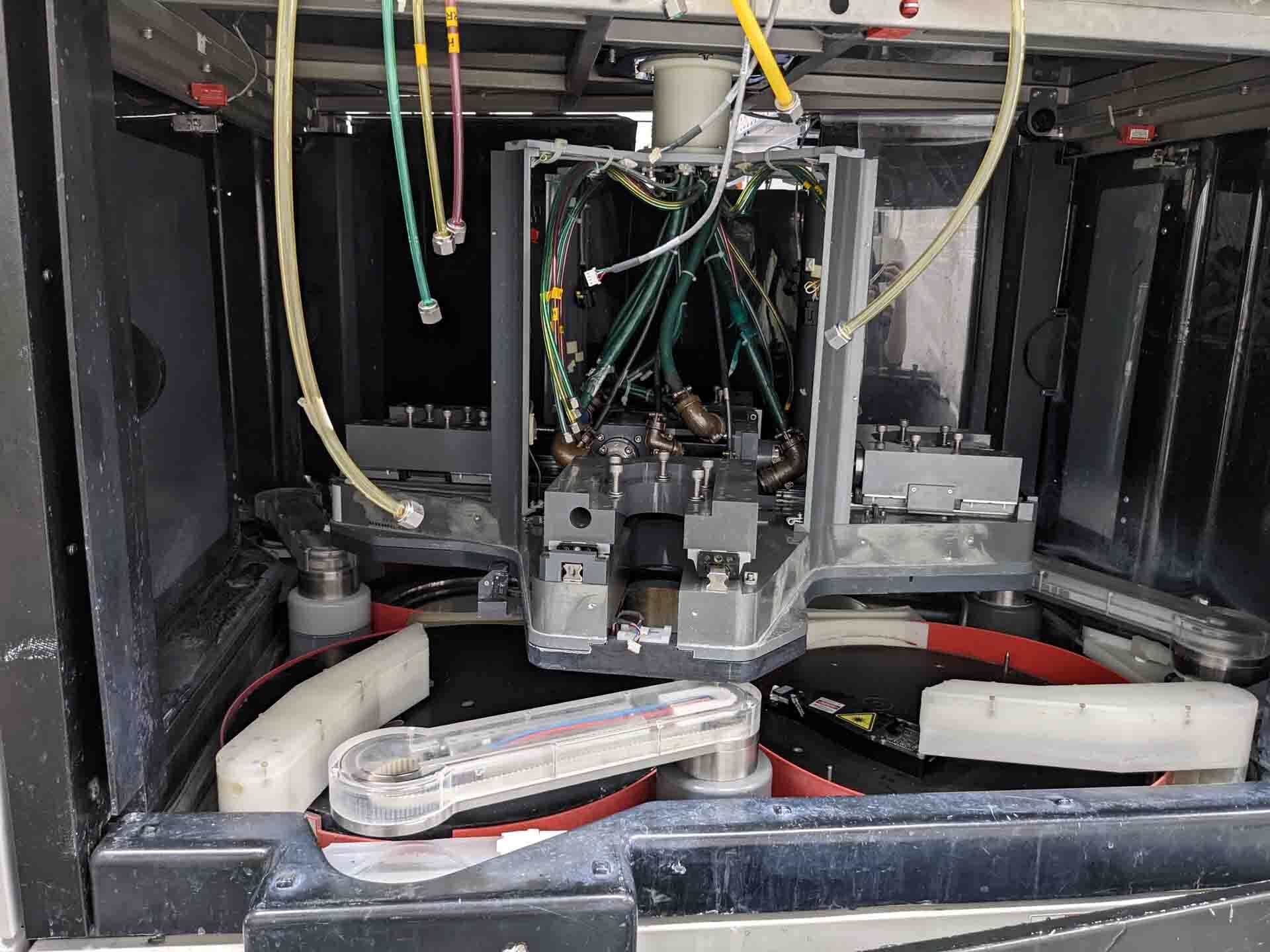

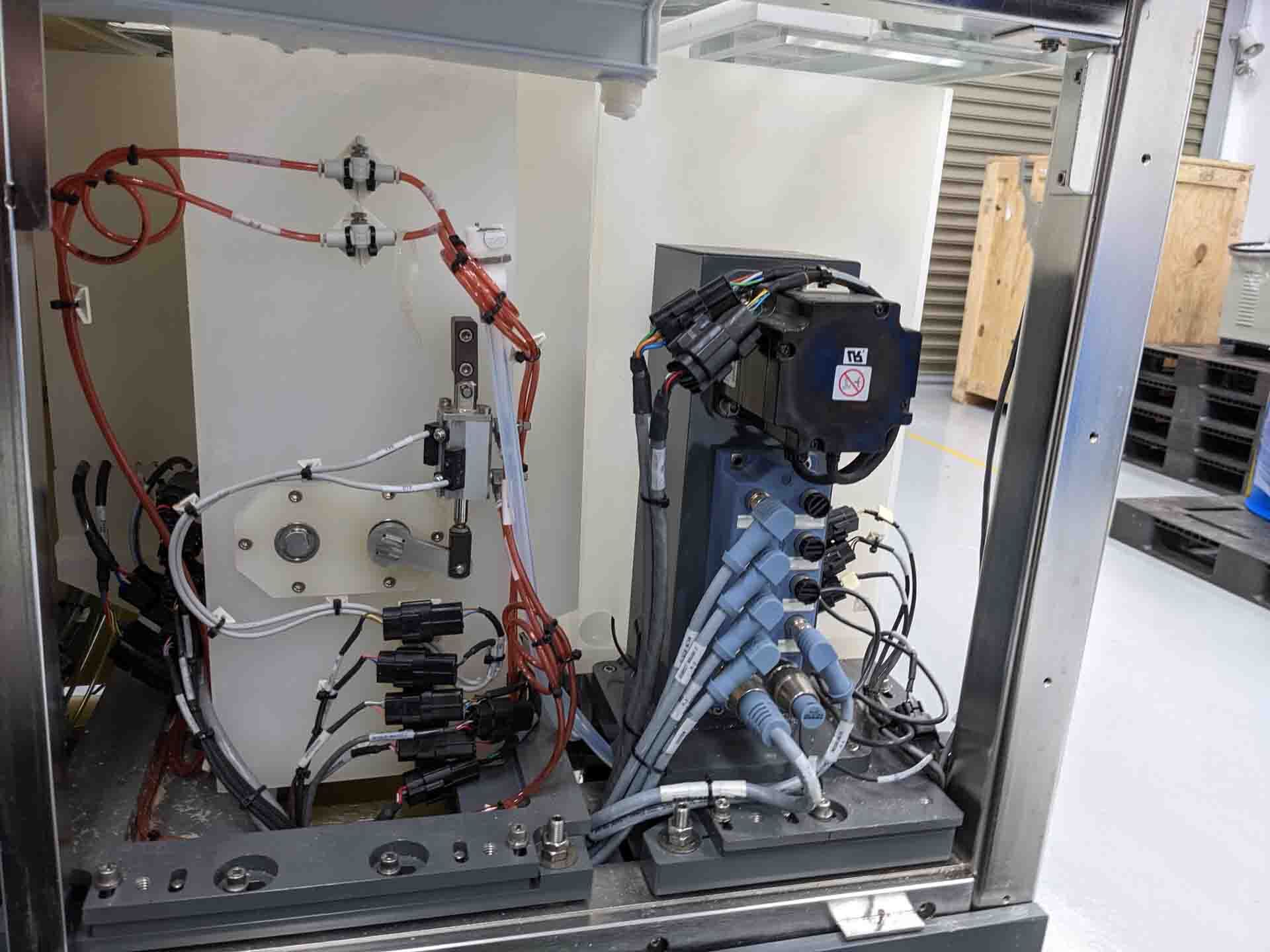

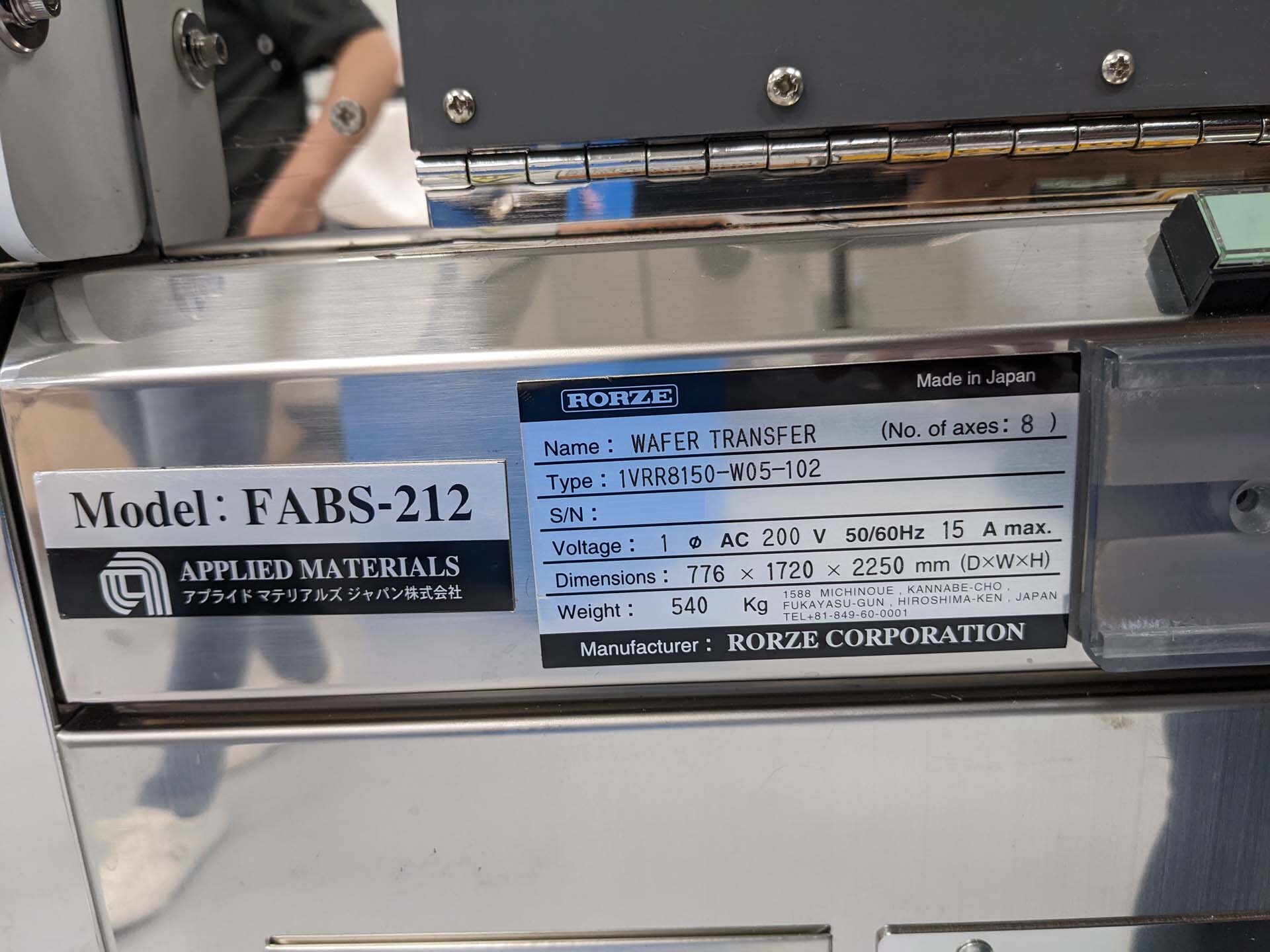

Used AMAT / APPLIED MATERIALS Mirra Mesa #293627305 for sale

URL successfully copied!

Tap to zoom

ID: 293627305

Wafer Size: 12"

Vintage: 2001

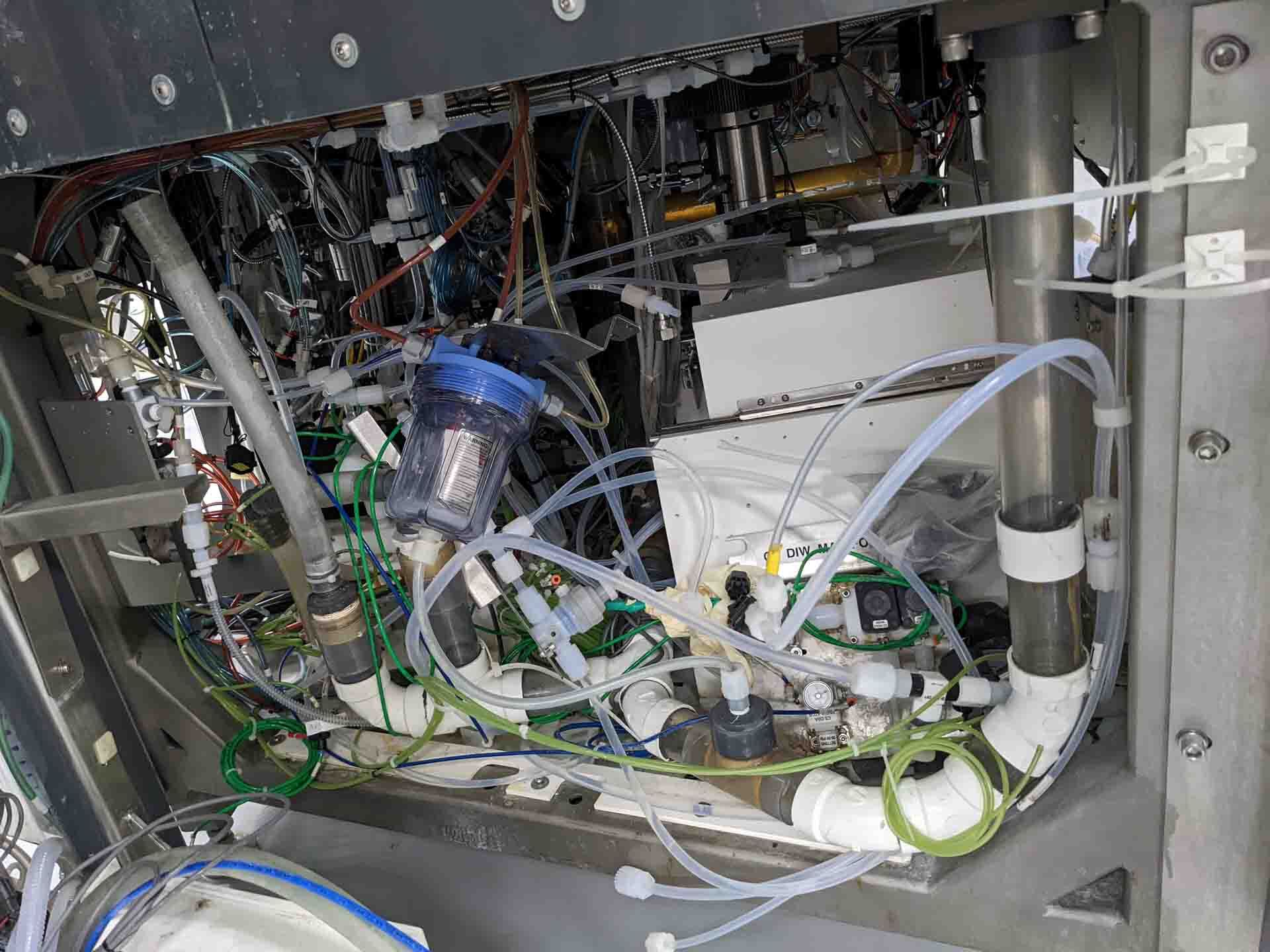

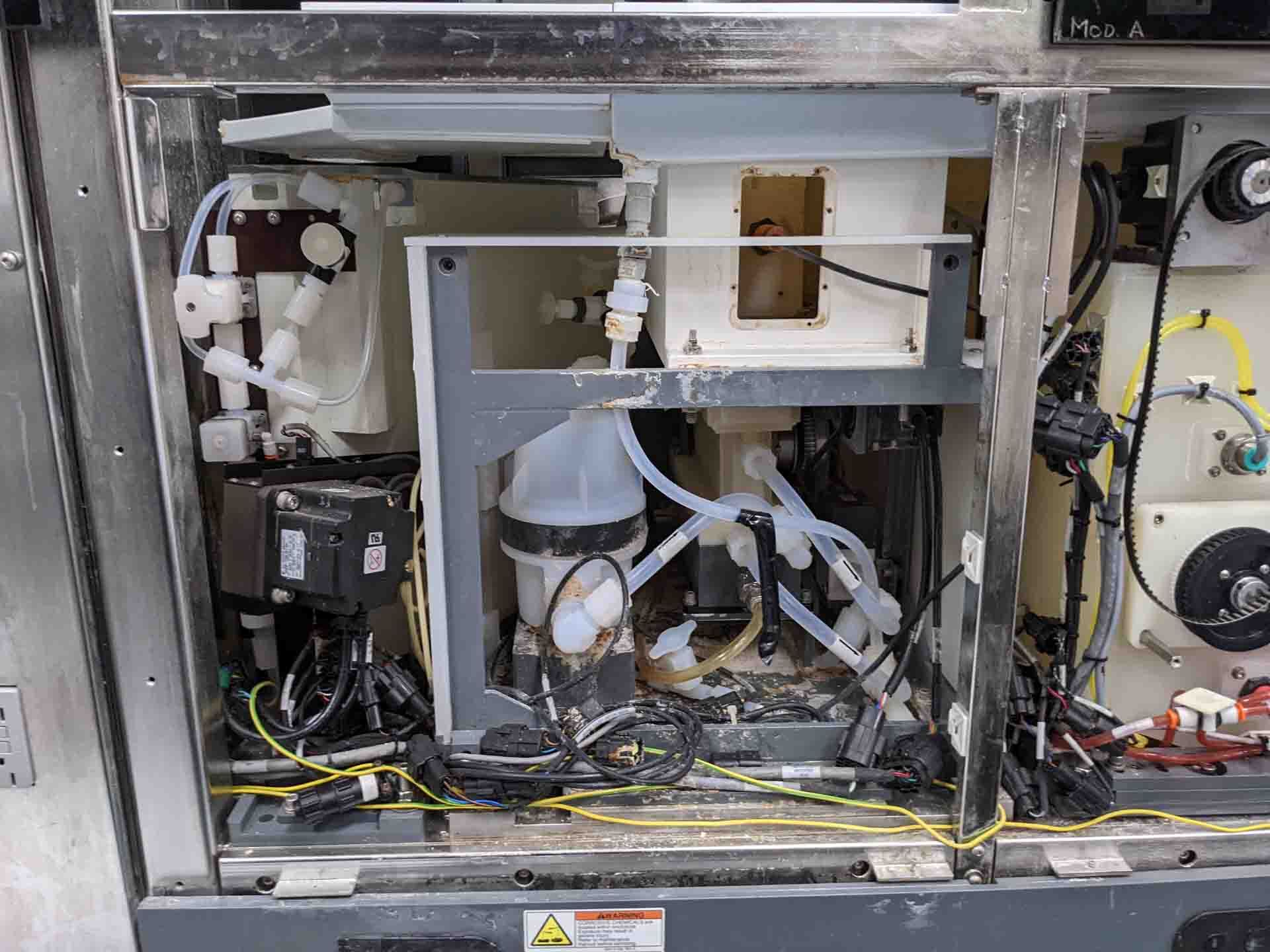

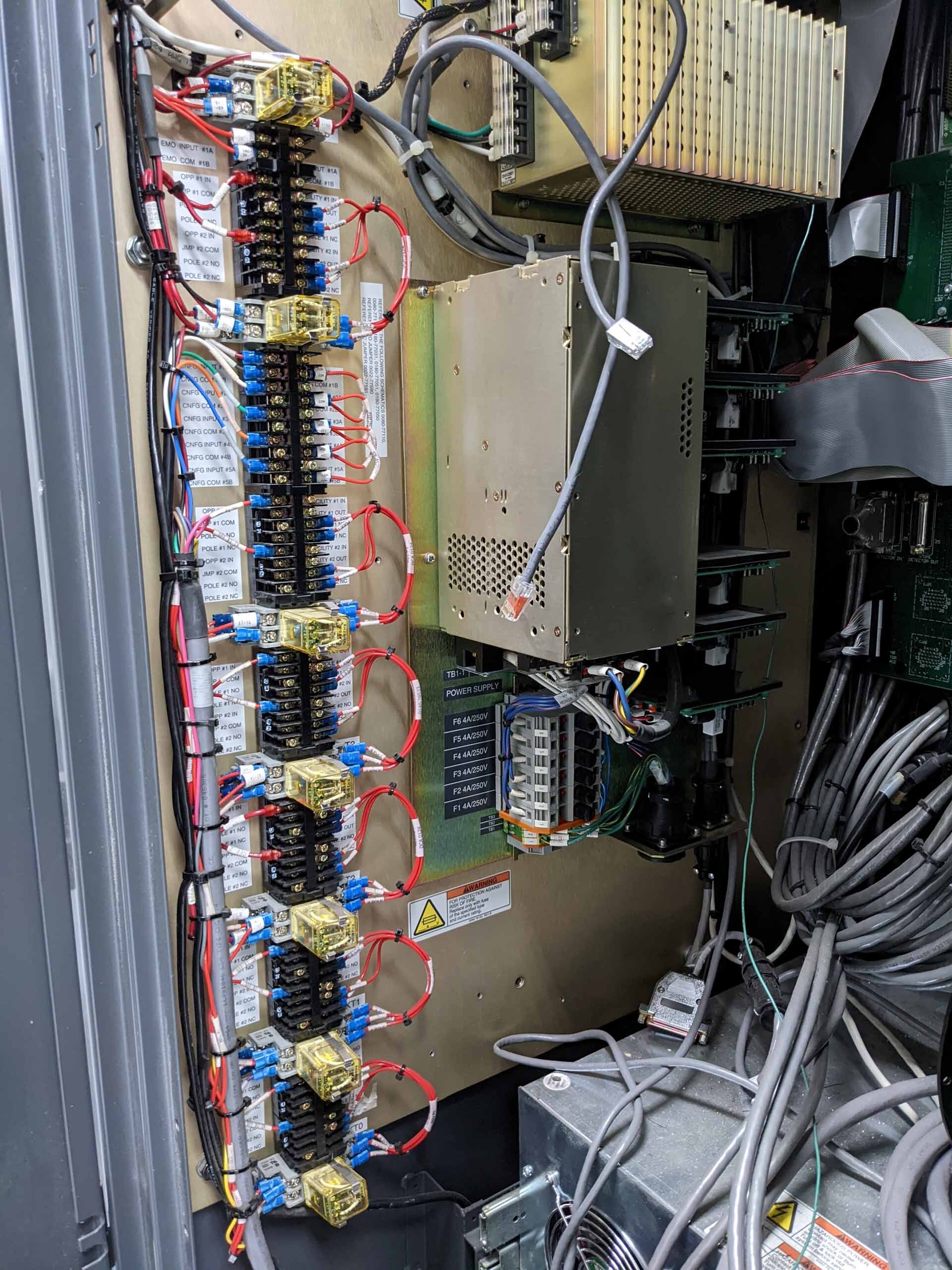

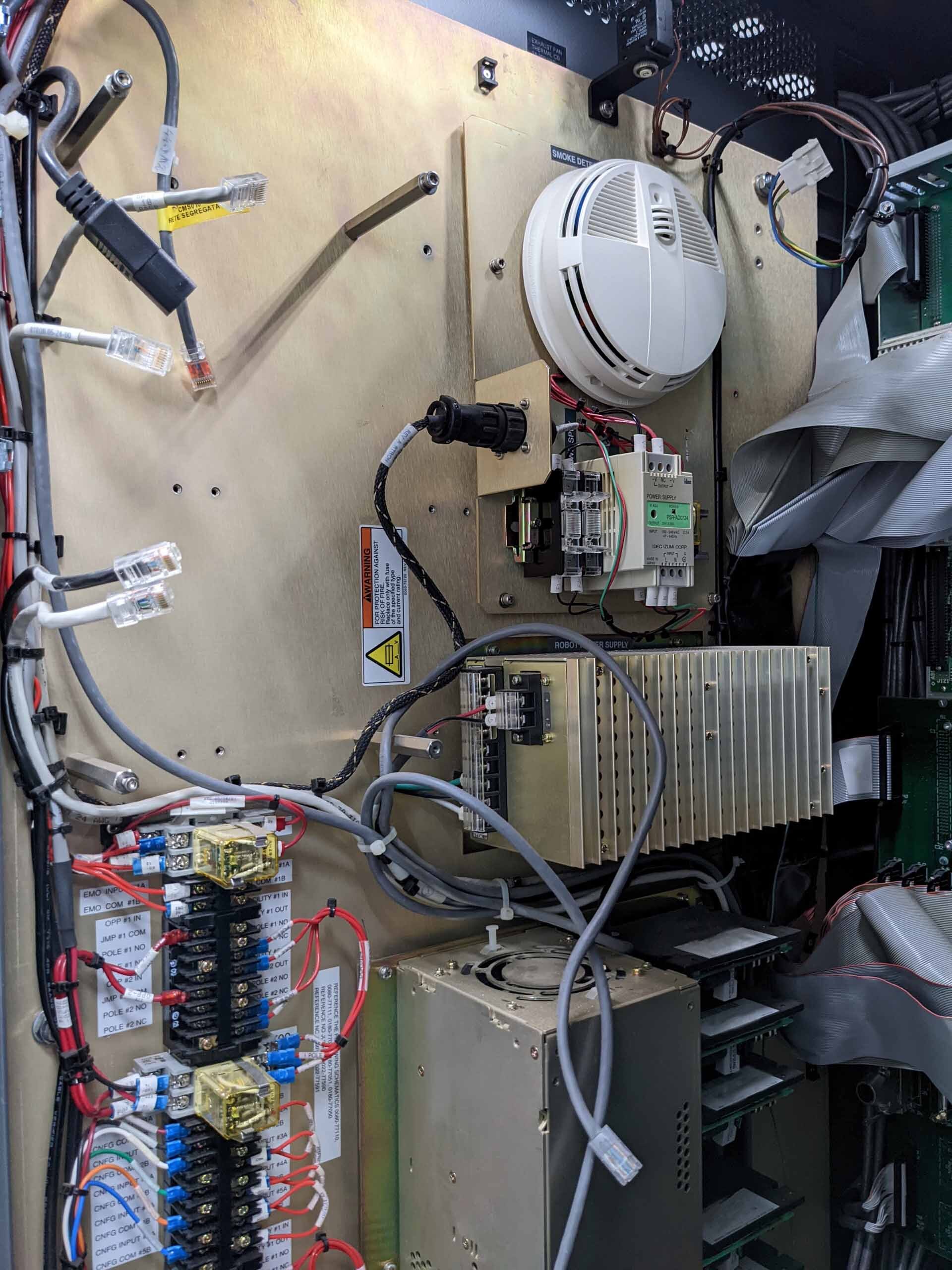

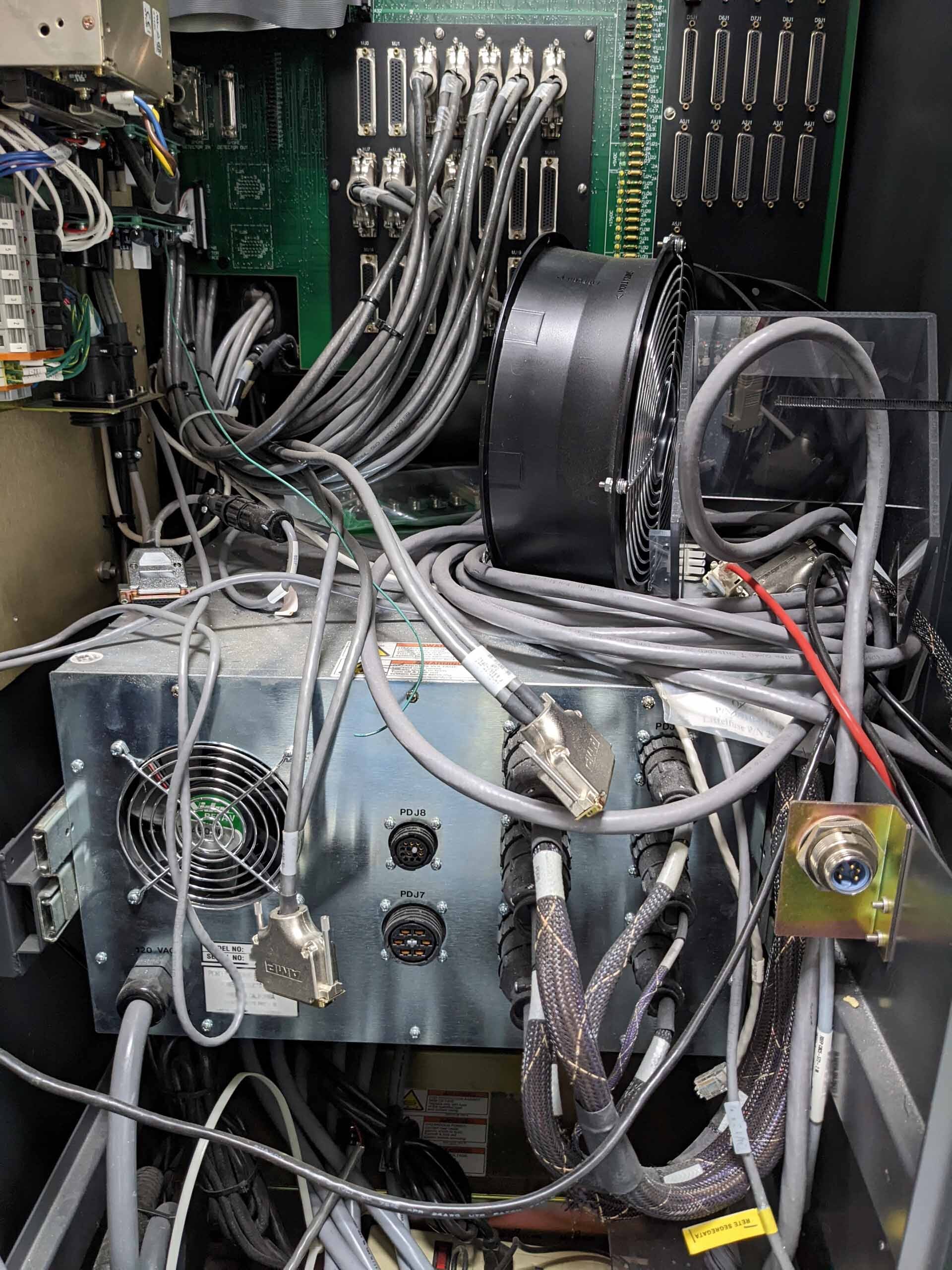

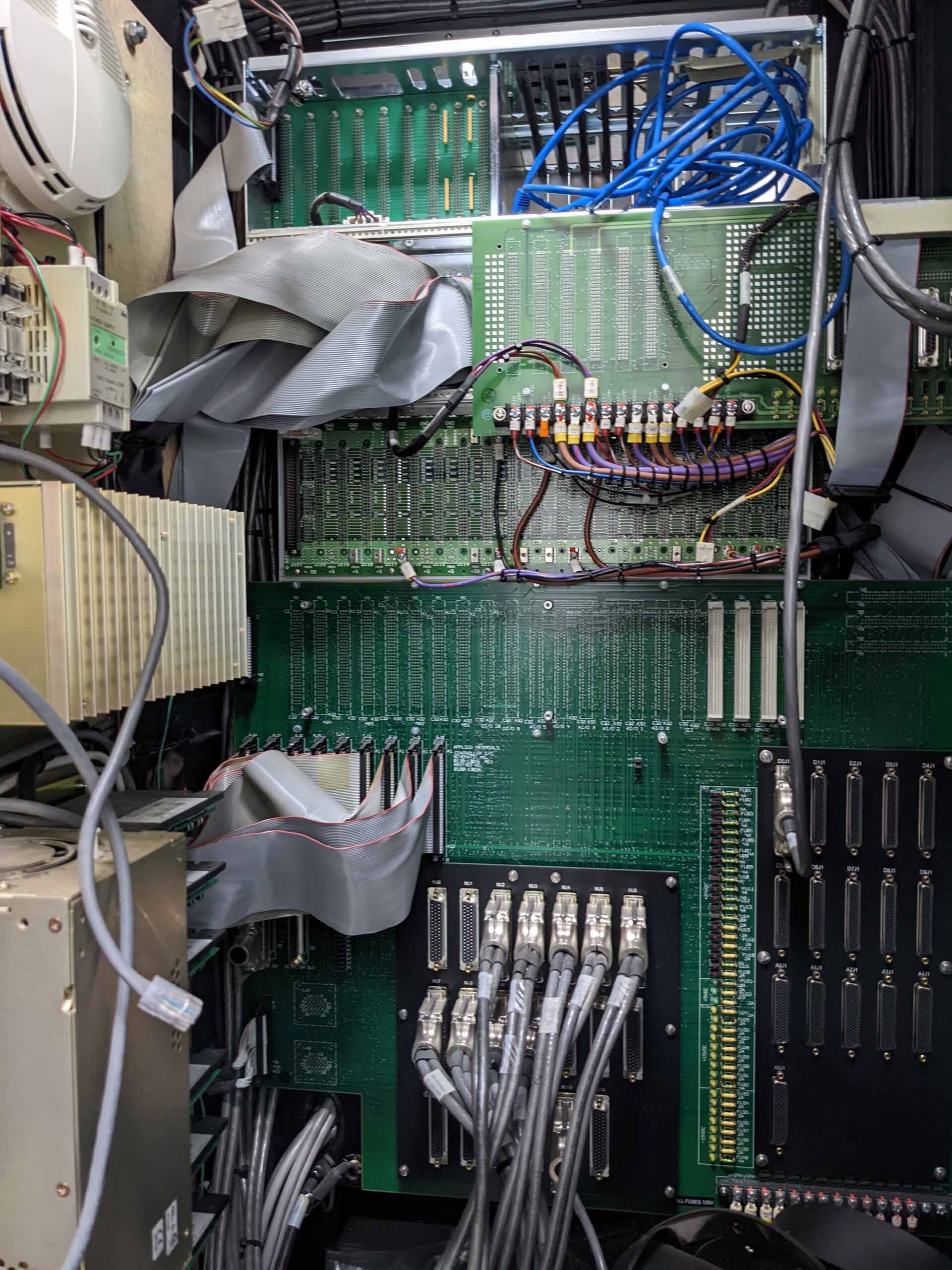

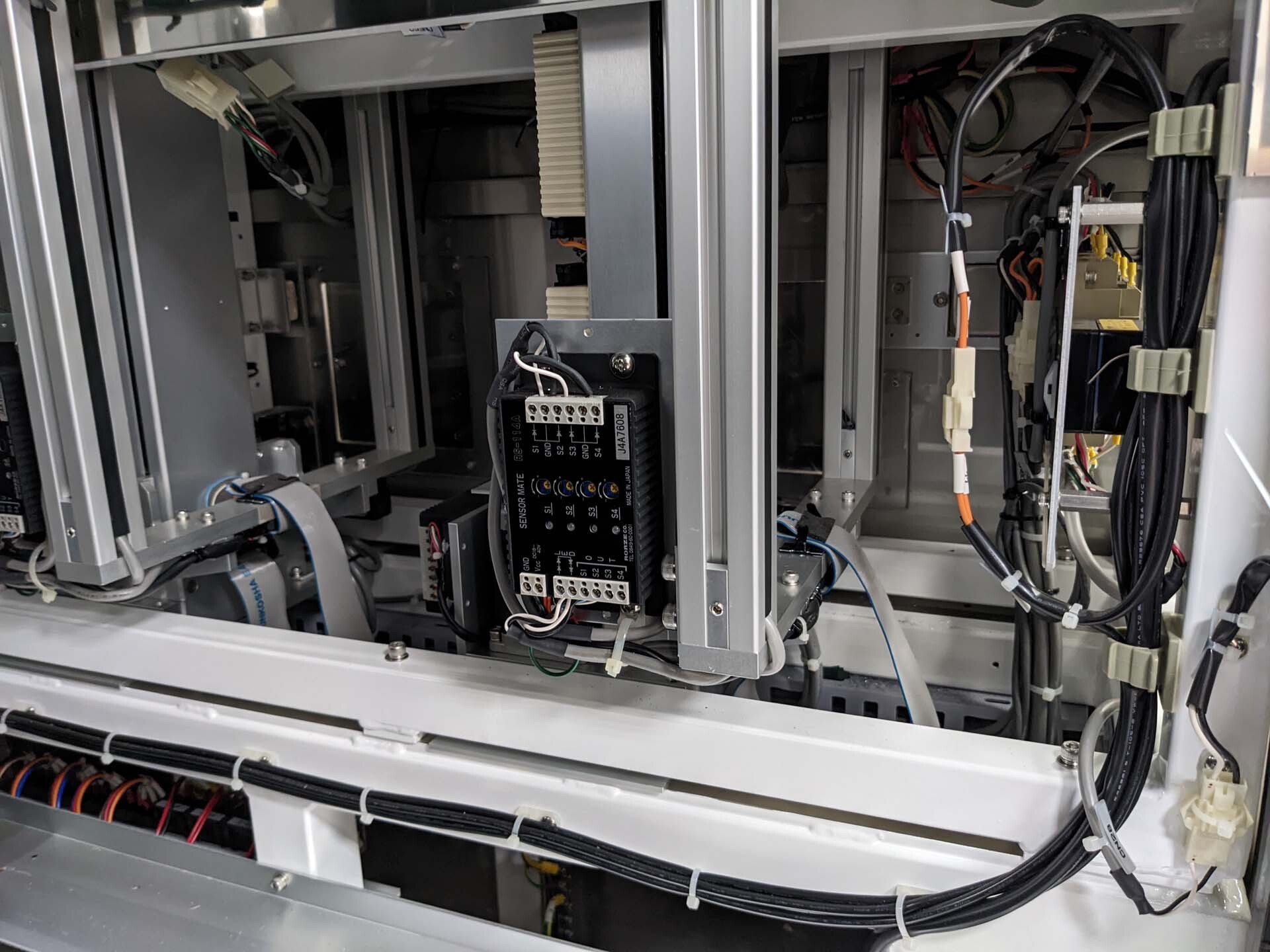

CMP System, 12"

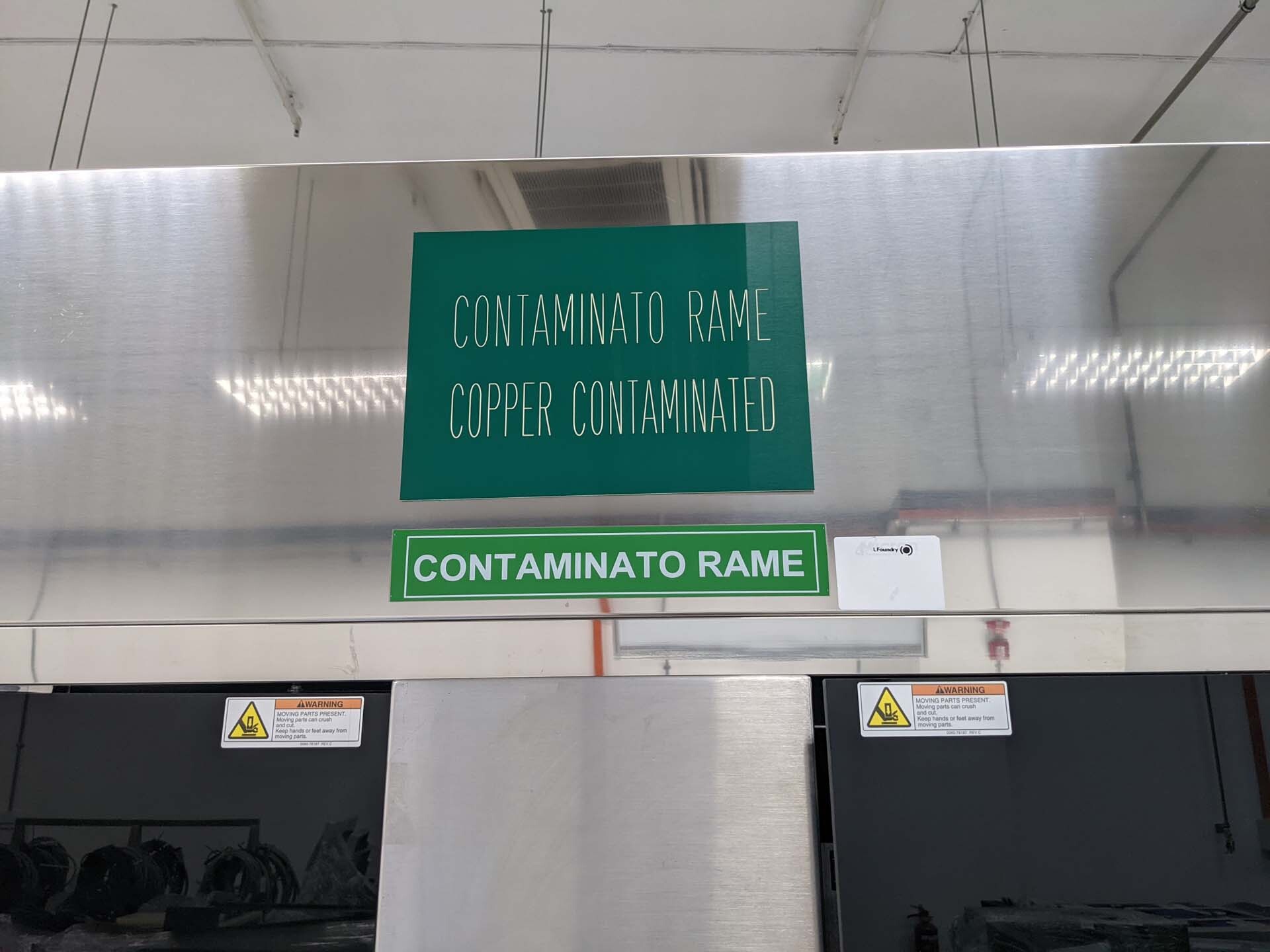

Copper processing system

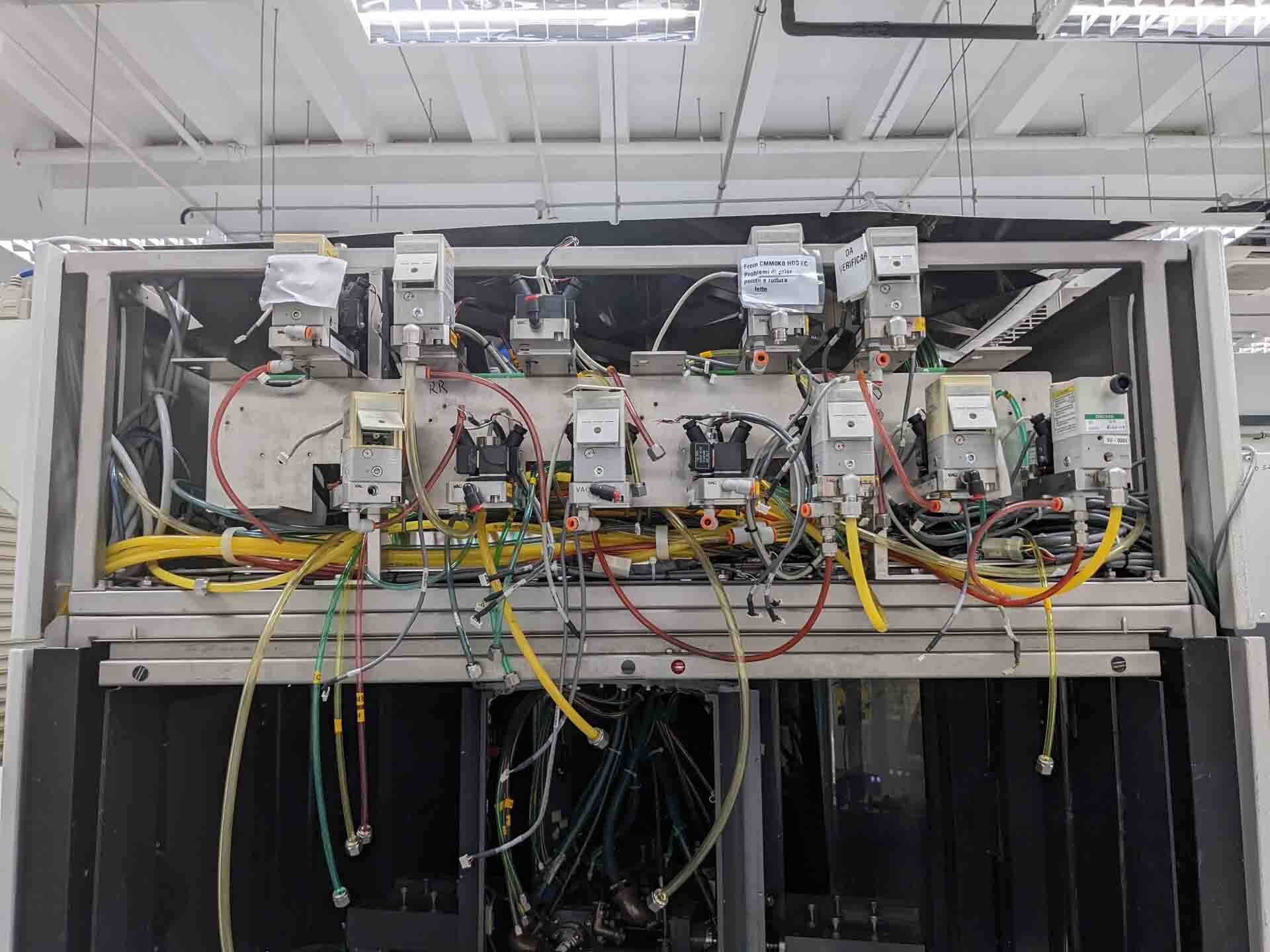

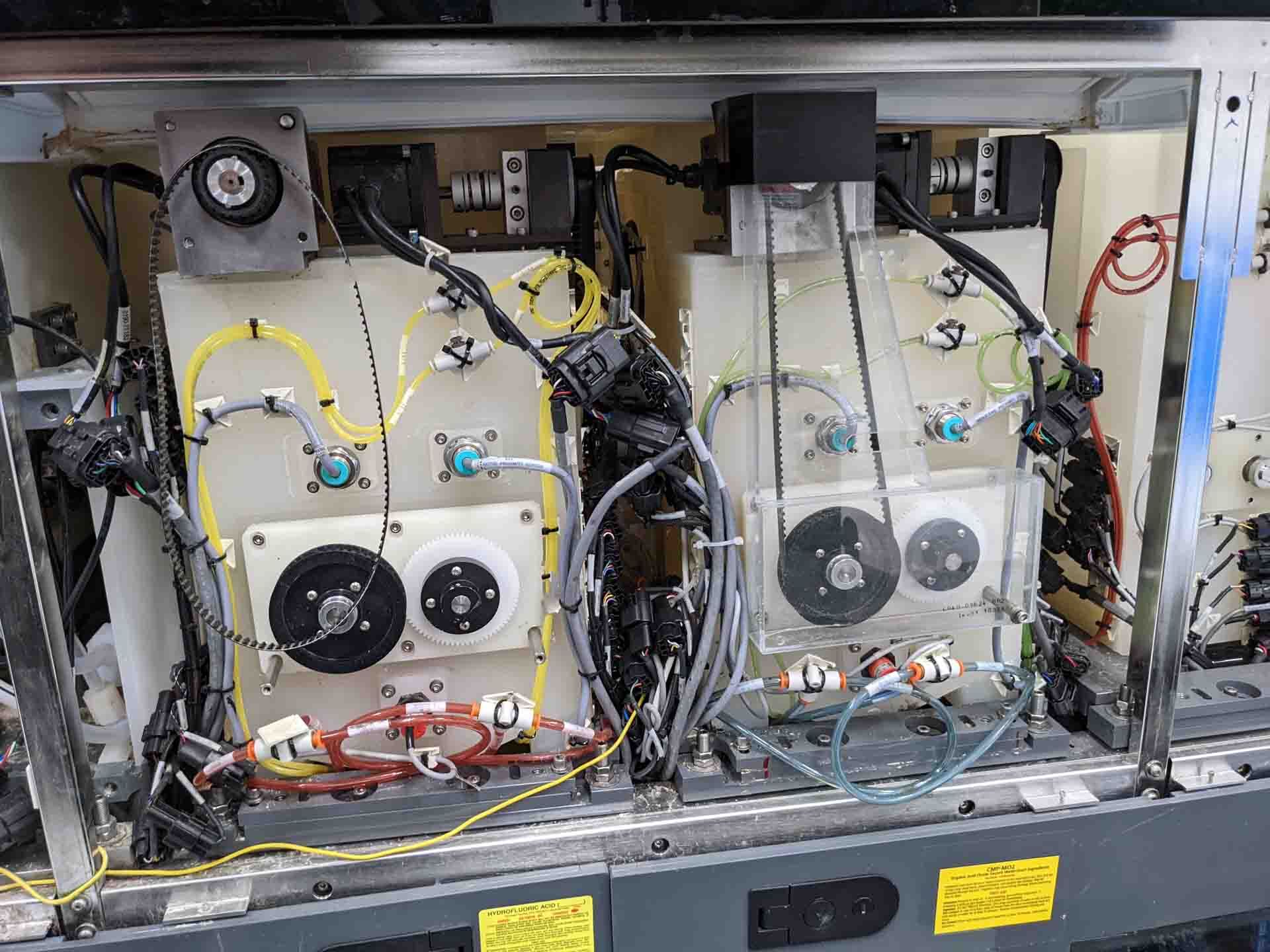

(4) Two line peristaltic pumps

(2) Slurry arm left arms

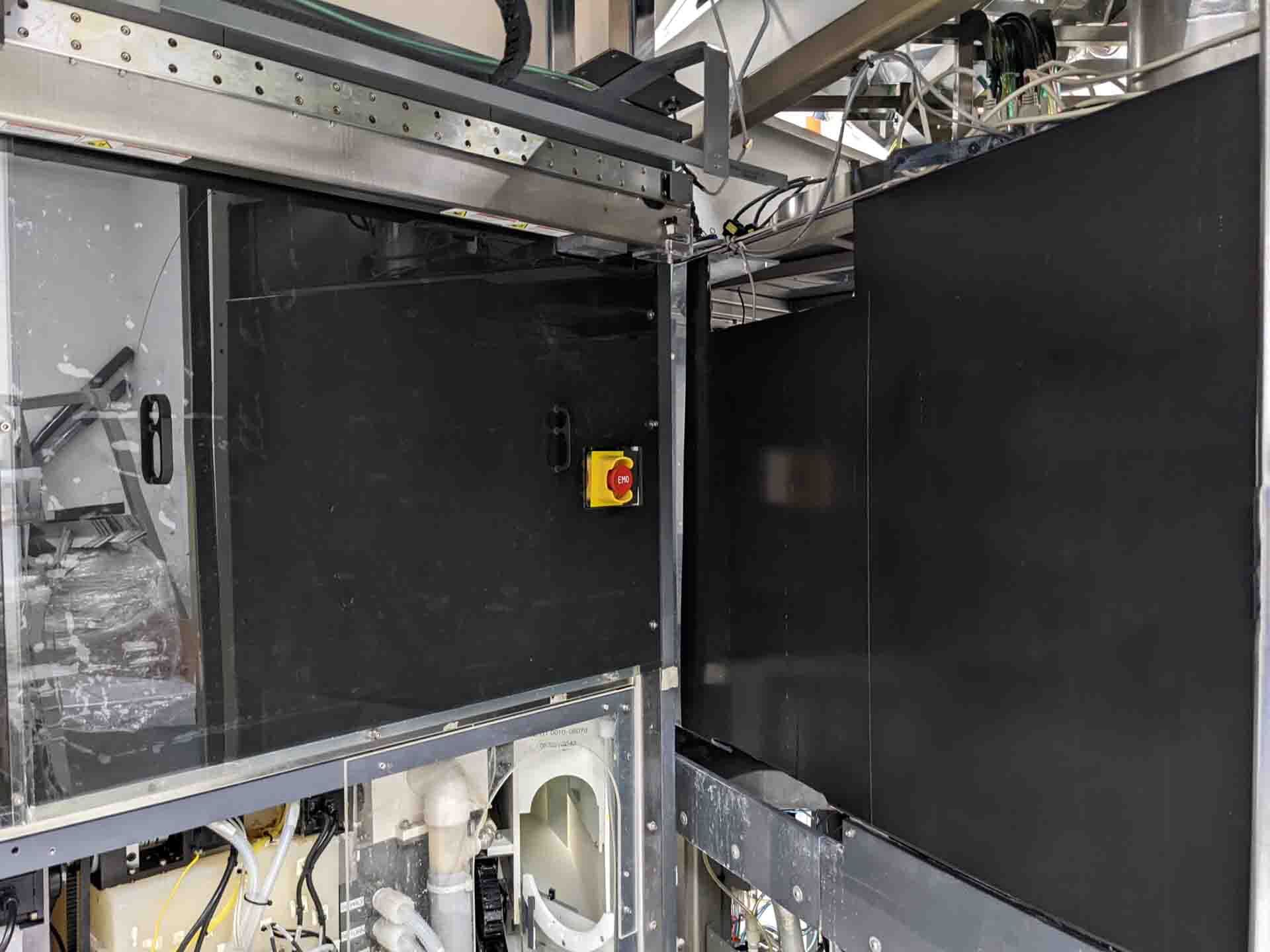

No polishing heads

Wet robot:

Wafer handler

Eject vacuum

Missing parts:

Controller boards

(4) UPA Zone

UPA Rotary union

HCLU

Upper and lower platens

Mega brush

Mega generator and chemical vessels

Brush:

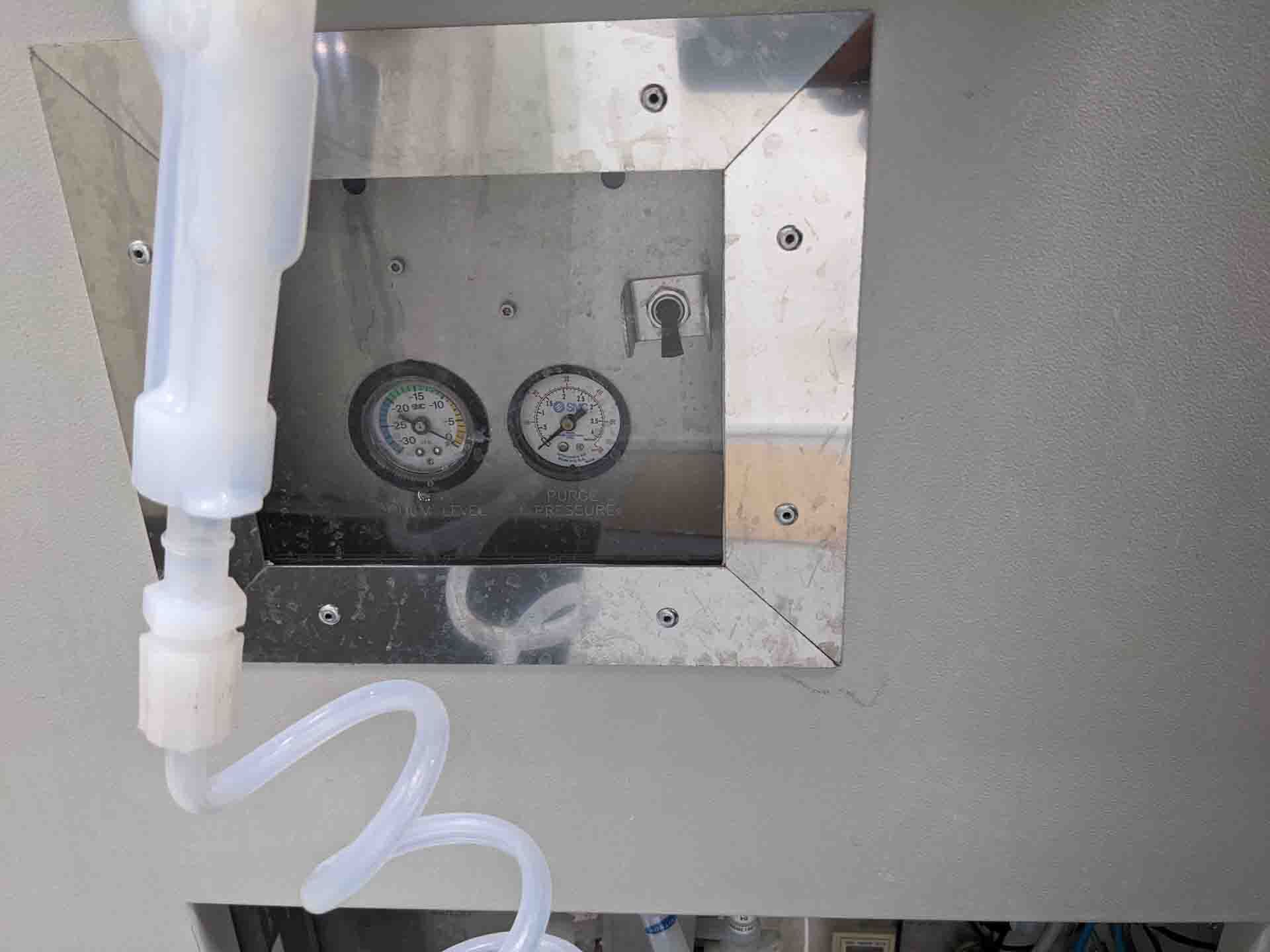

Pressurised vessels

(4) Vessels

Qty / Part number / Description

(1) / - / Megasonic RF Generator

(4) / - / Cleaner mega, brush1 and 2 chemical vessels

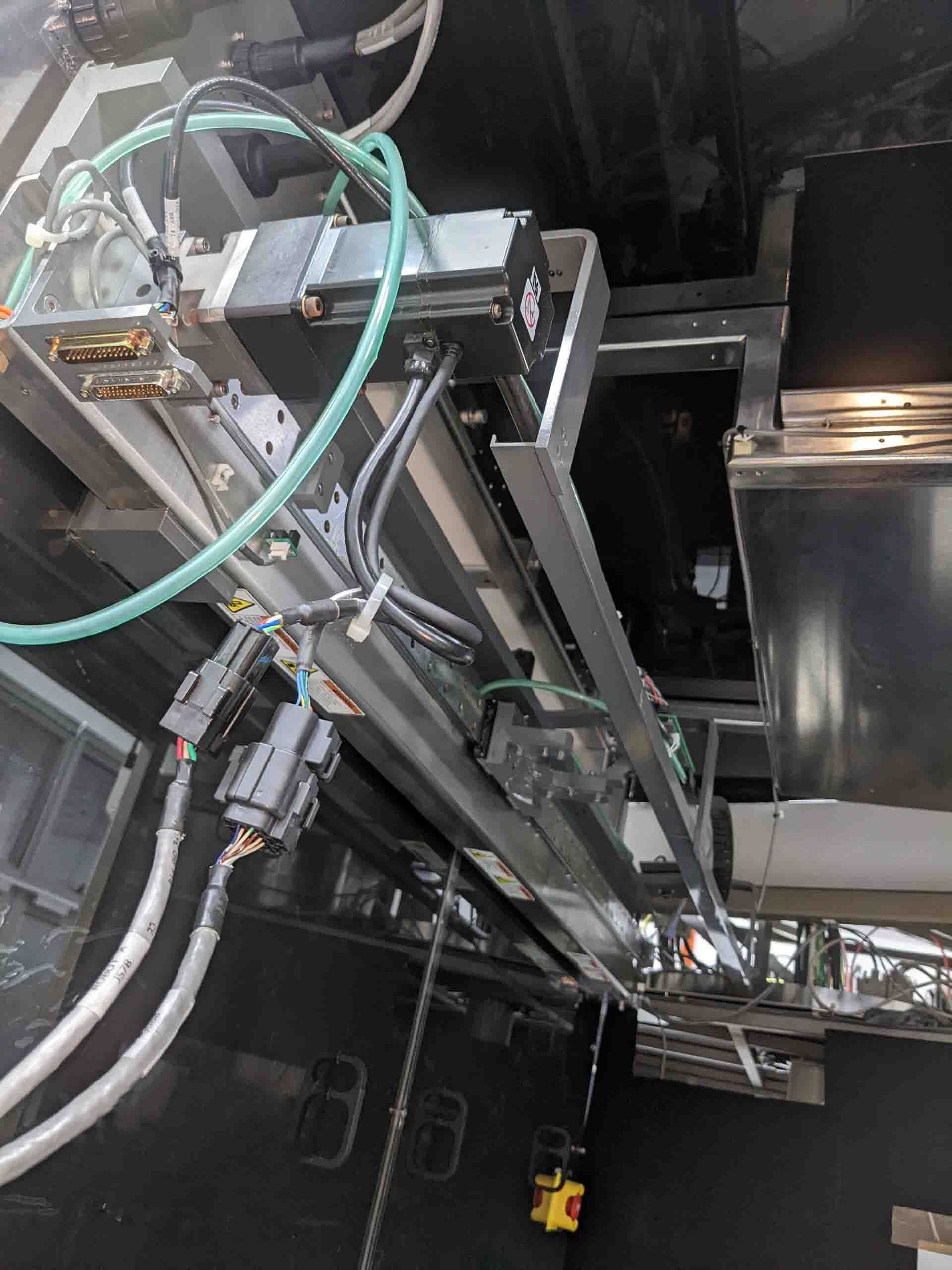

(4) / 0010-03697ER / Head sweep motors

(1) / 0010-37905 / i-Scan Endpoint

(2) / 0010-77428 / Assy, teflon coated upper platens

(2) / 0020-77924 / Bearing retainers

(4) / 0020-79068 / AMAT Brackets

(4) / 0021-77866 / Clamp drive spindles

(4) / 0021-77867 / Plate adapter motor spindle flex clamp kits

(1) / 0021-78095 / Manifold-II series valve, UPA Assy

(1) / 0021-78097 / Manifold-I valve, UPA Manifold assy

(1) / 0040-77085 / Lower platen

(4) / 0040-77461 / Spindle assys

(4) / 0090-06473 / Assy, wafer loss sensors

(4) / 0090-07553 / Assy, wafer loss sensors

(4) / 0090-77262 / UC Pressure tranducerassys

(4) / 0090-77263 / IC Pressure transducers -14.7 to 10

(4) / 0090-77297 / PP Pressure transducers -14.7 to 10

(4) / 0090-77298 / RR Pressure transducers -14.7 to 15

(4) / 0100-77043 / Dual slip out sensor boards

(4) / 0140-77491 / Cables, ER-44

(4) / 0140-77492 / Cables, ER-46

(4) / 0140-78202 / Cables, head pneumatic ER-45, UC

(4) / 0140-78203 / Cables, head pneumatic JD-SV43, SV45

(4) / 0140-78204 / Cables, head pneumaticjd SV43, SV43, SV45

(4) / 0140-78205 / Cables, head IC/IT JB-SV-46,47, SV43, SV45

(4) / 0140-78258 / Cables, head pneumatic EC/PP JA-SV-42, SV44

(4) / 0140-78261 / Cables, head pneumatic ER-42, EC/PP

(1) / 0140-03497 / Cables, platen 2 encoder

(4) / 0190-77116 / Flexible disks

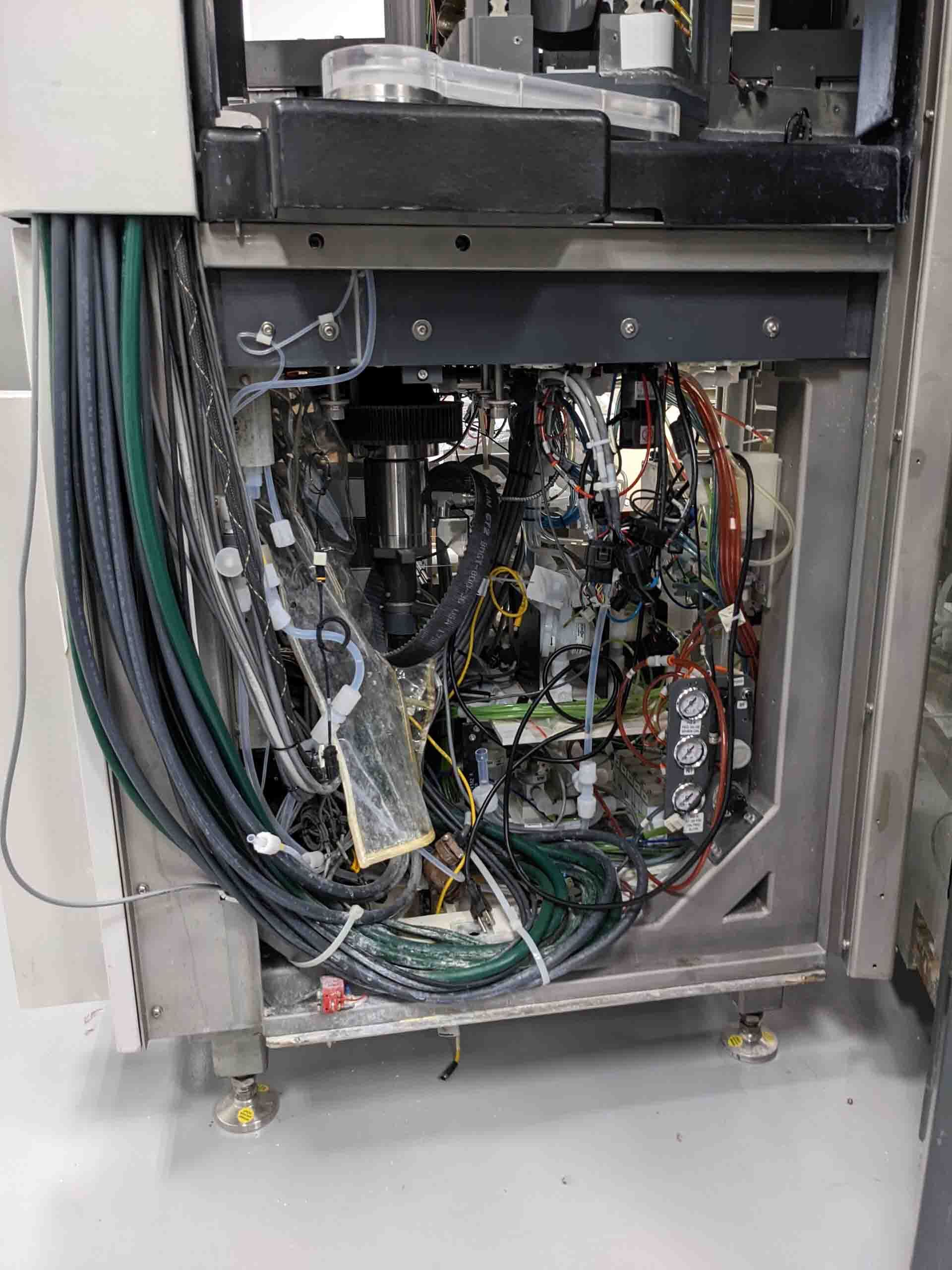

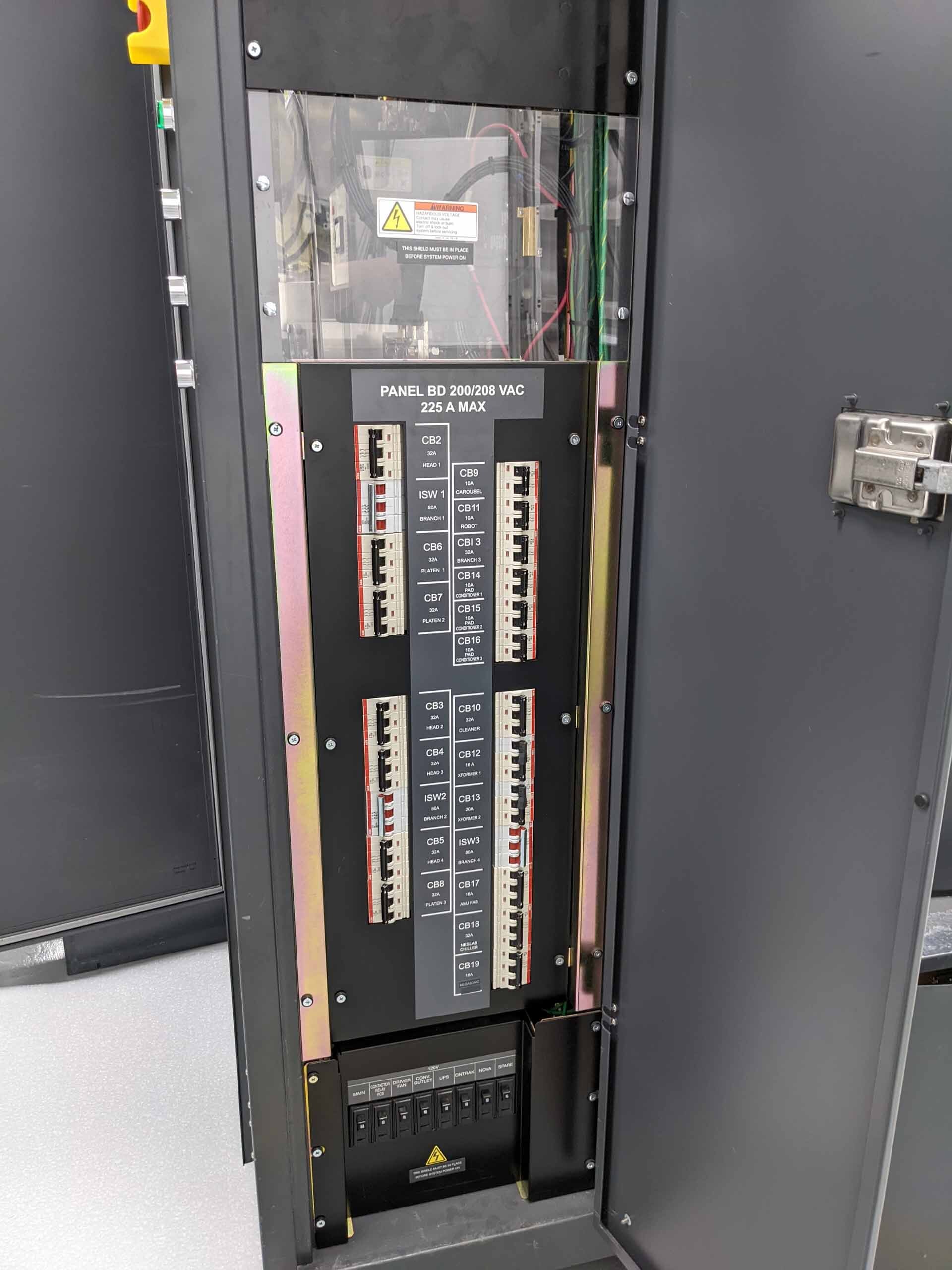

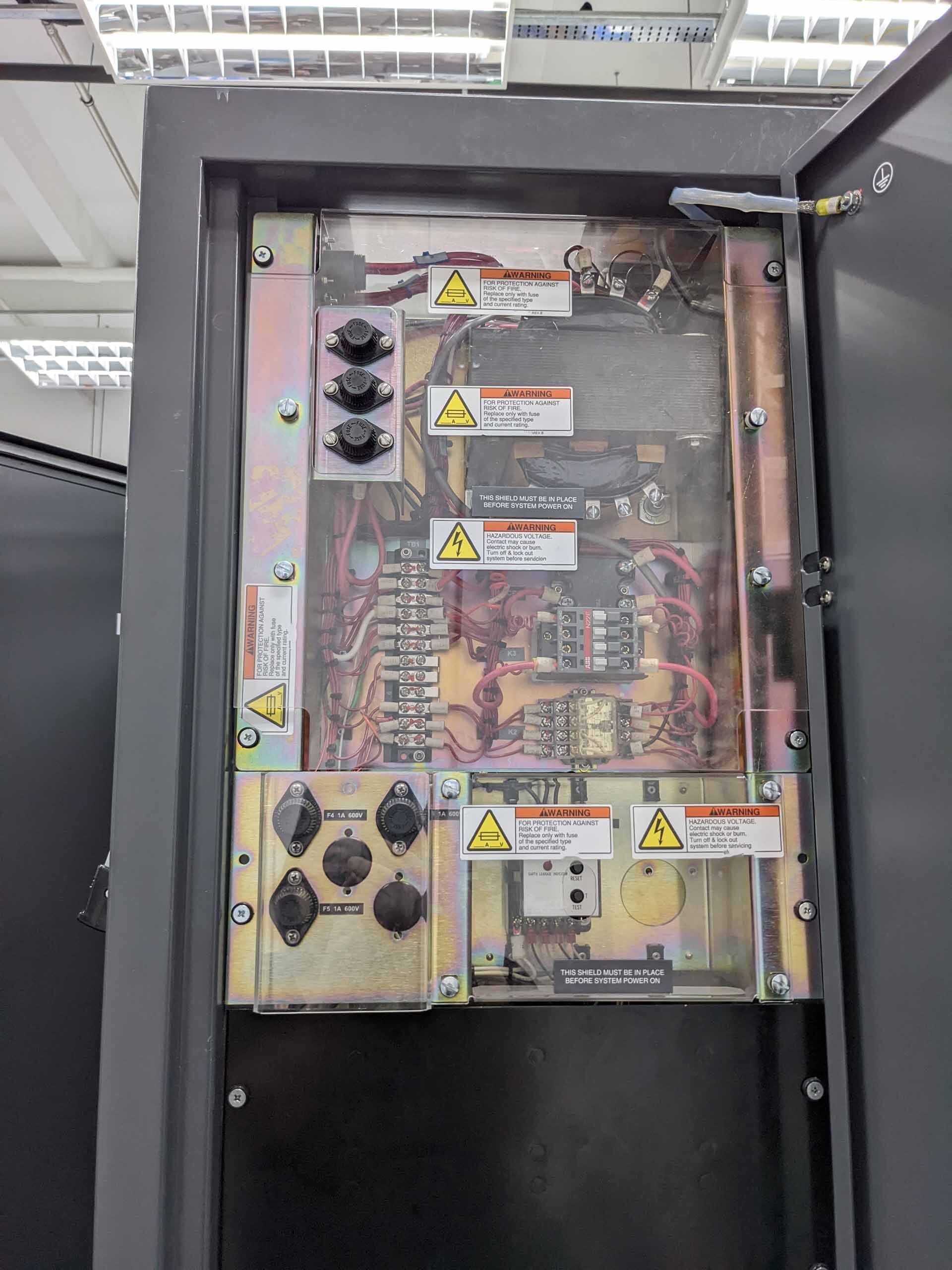

(2) / 0240-77490 / Platen motors

(4) / 0760-01037 / CPLG Union rotary 4-port

(3) / 3870-02365 / Valve modules 8-PNEU

(1) / 3870-02366 / Valve module 8-PNEU

(1) / 0010-77157 / Load cup

(4) / 0190-14344R / Head rotation motors

(4) / 0190-14344 / NSK Driver, mega torque, with motor

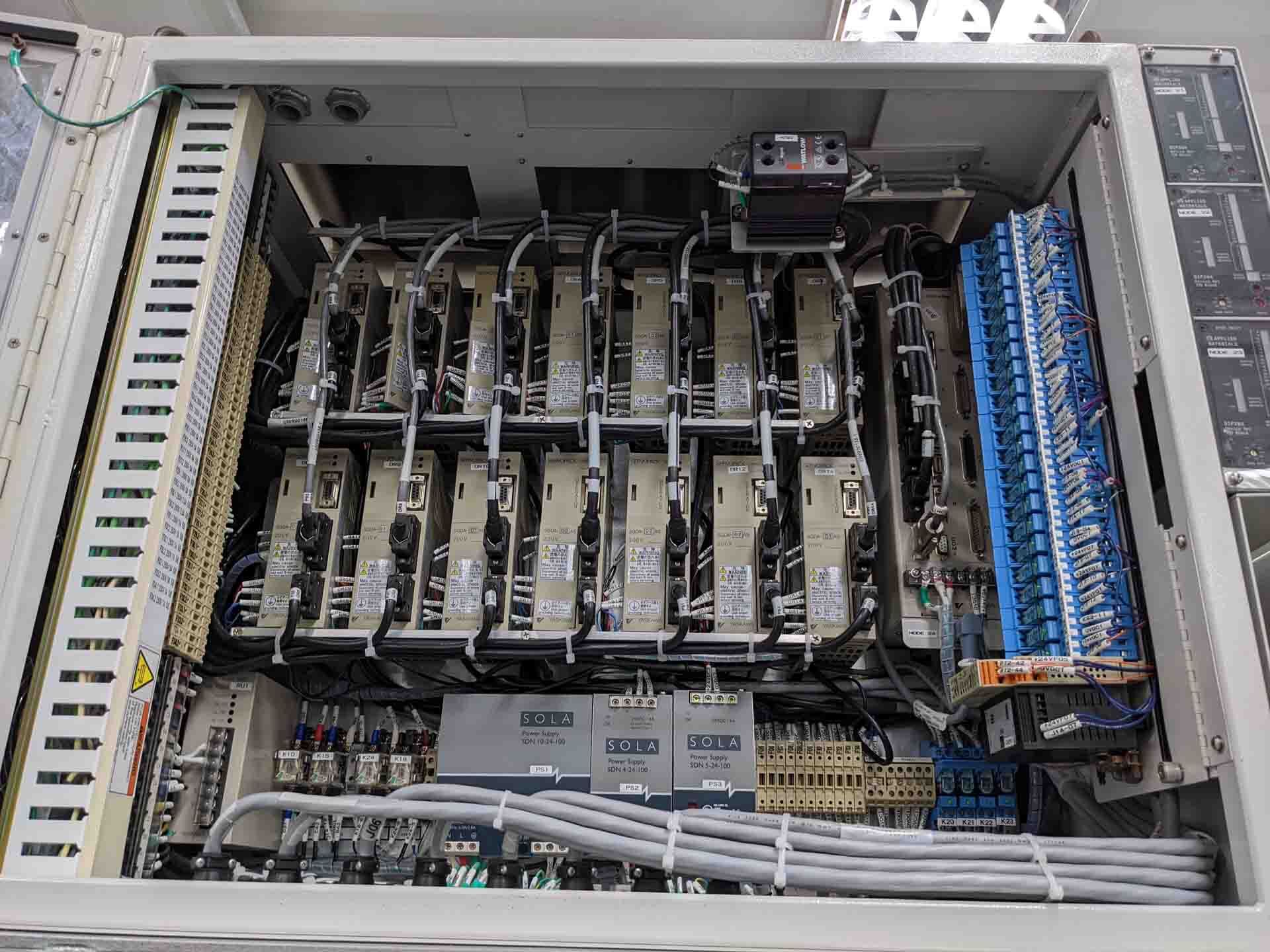

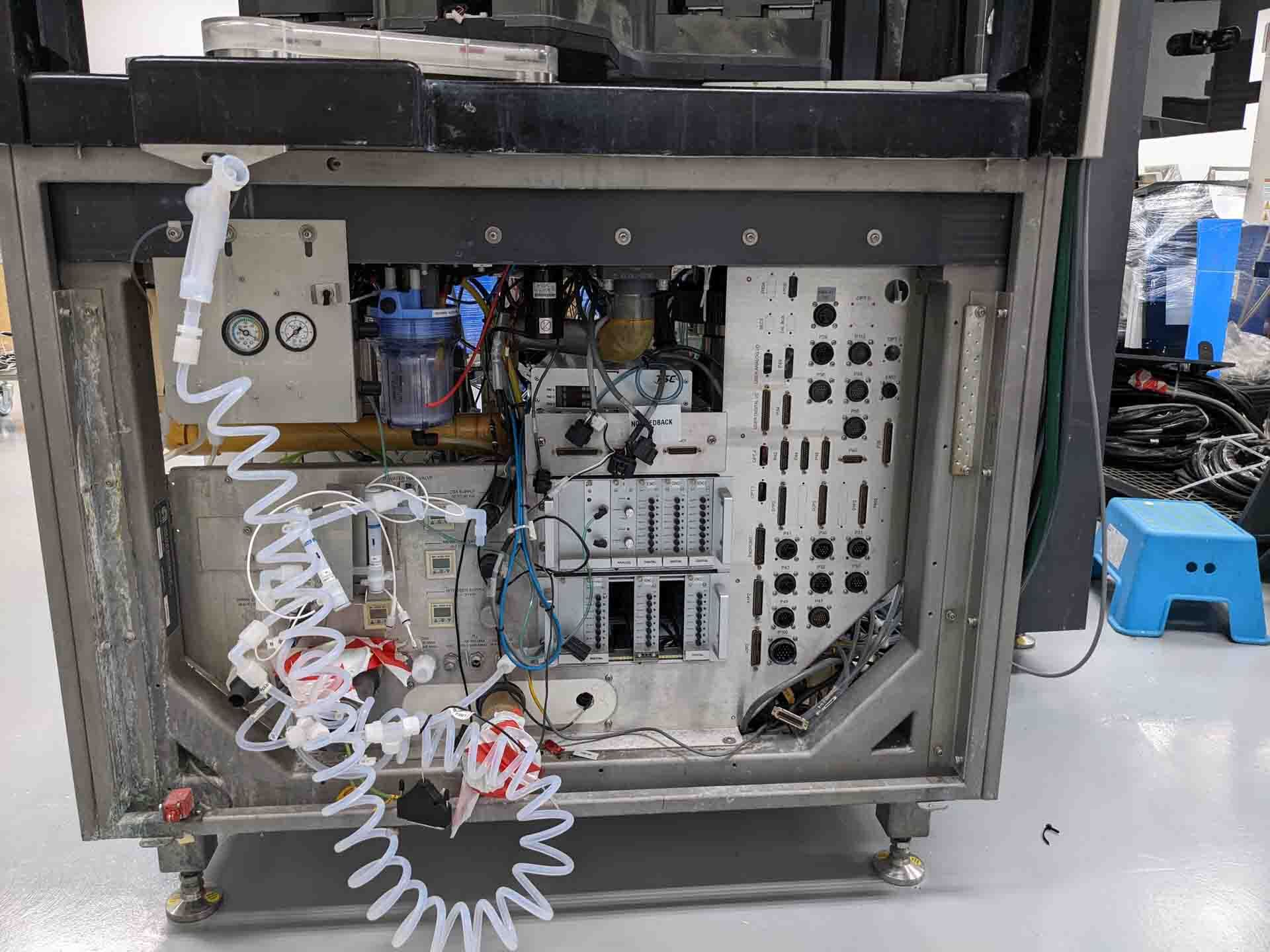

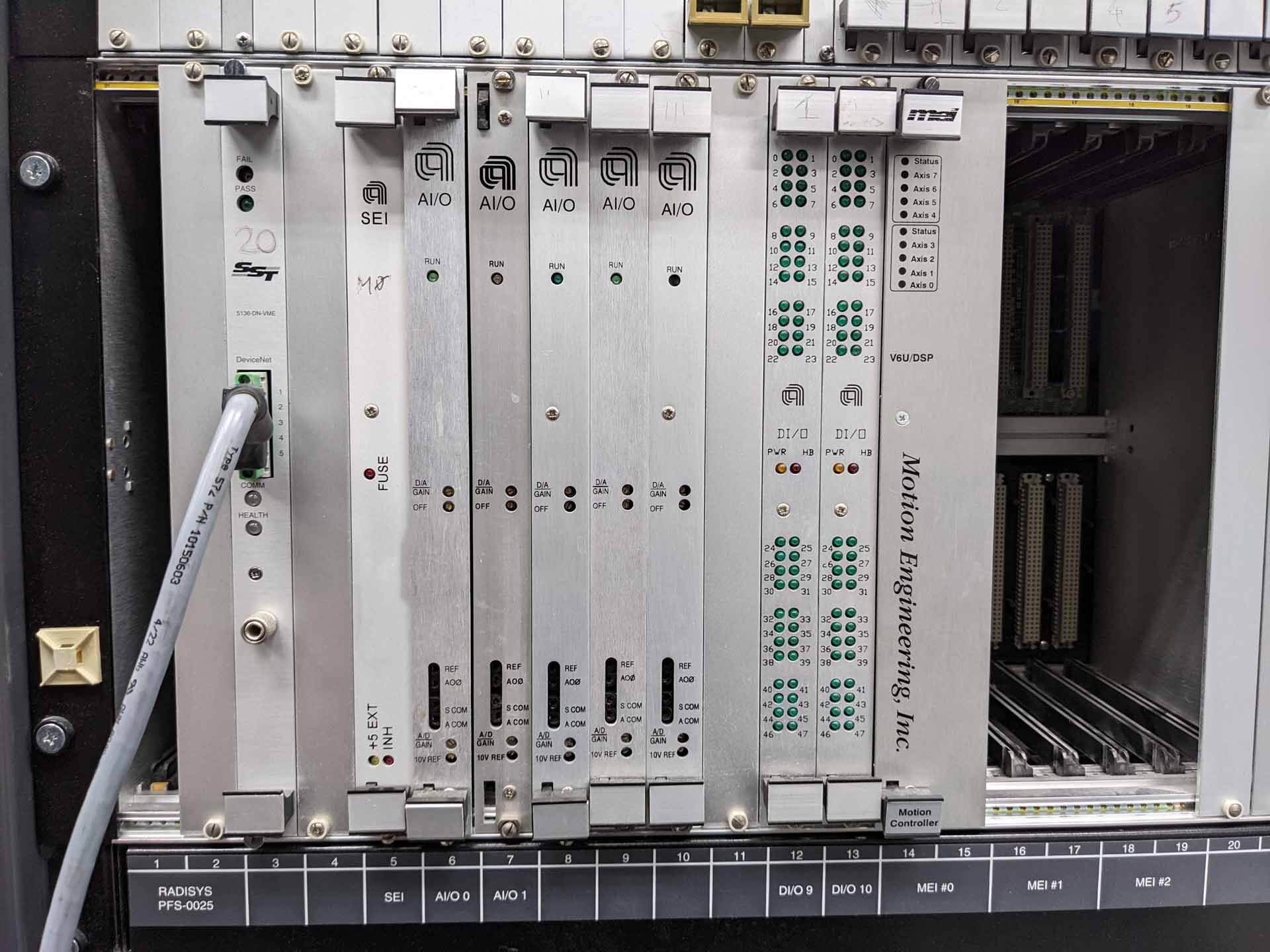

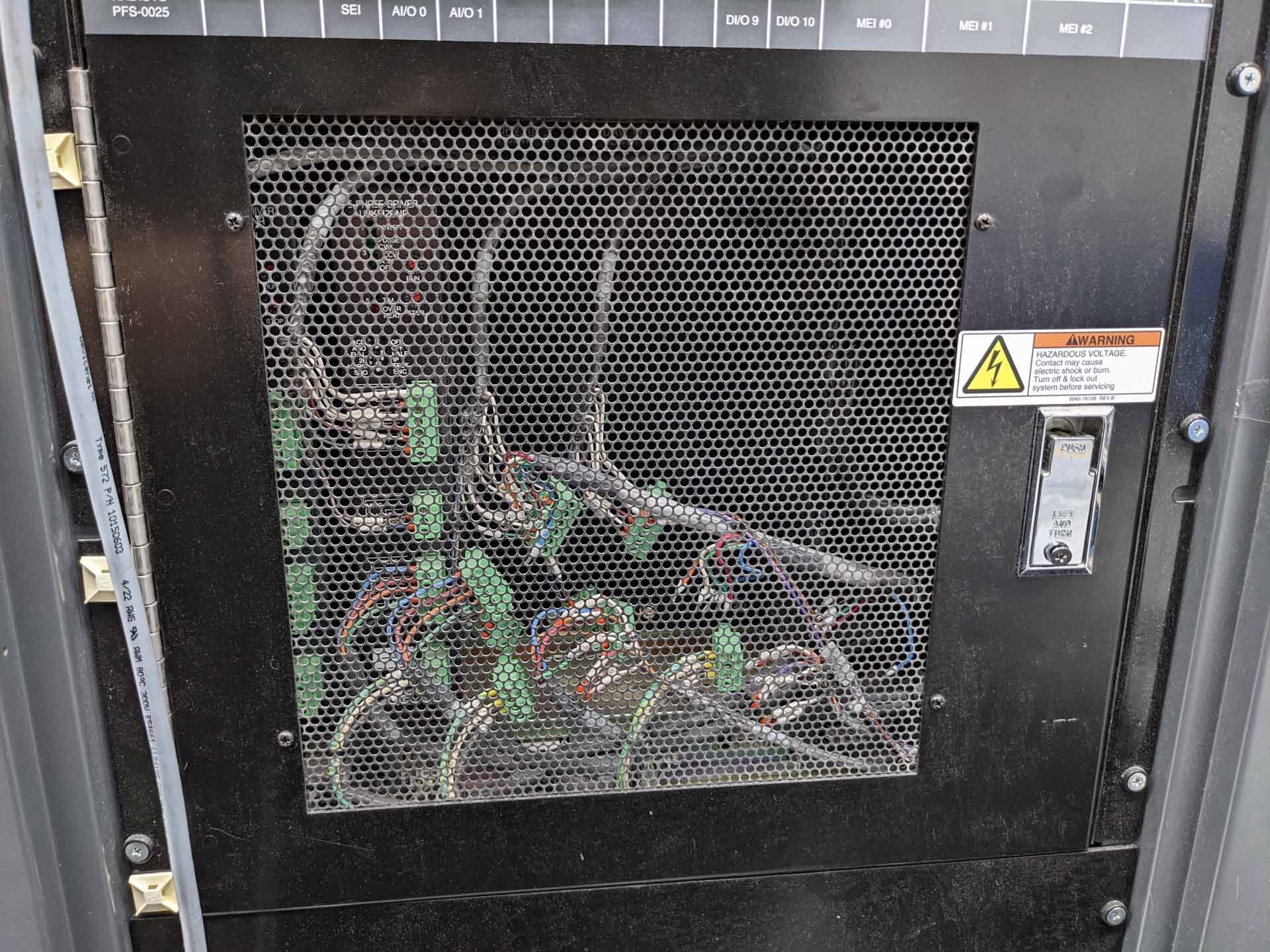

(2) / 0190-14502 / MEI Motion control boards

(6) / 0190-14372 / DRVR Servopacks AC SGD, Power supply: 200 V, 100 W

(1) / 0190-19549 / Card P-M 1.6GHZ 512MB RAM VME Bus single

(1) / 0190-42525 / Network port server, EL160 (16) Channels, with PWRSP Power supply: 100-250 V AC, 50/60 Hz

(1) / 0100-01793 / PCB Assy, i/o interface board with COM

(3) / 0140-04819 / Cable bulkhead platenisrms

(1) / 0140-75170 / AMAT Head ROT 3 and 4 MP3-DVR 4 and 5

(1) / 0650-01088 / Transmitter

(2) / 0870-01013 / VEXTA Head Sweep drivers, 5-Phase

(4) / 1080-01166 / VEXTA Robot Z-W-S stepping motors, 2-Phase

2001 vintage.

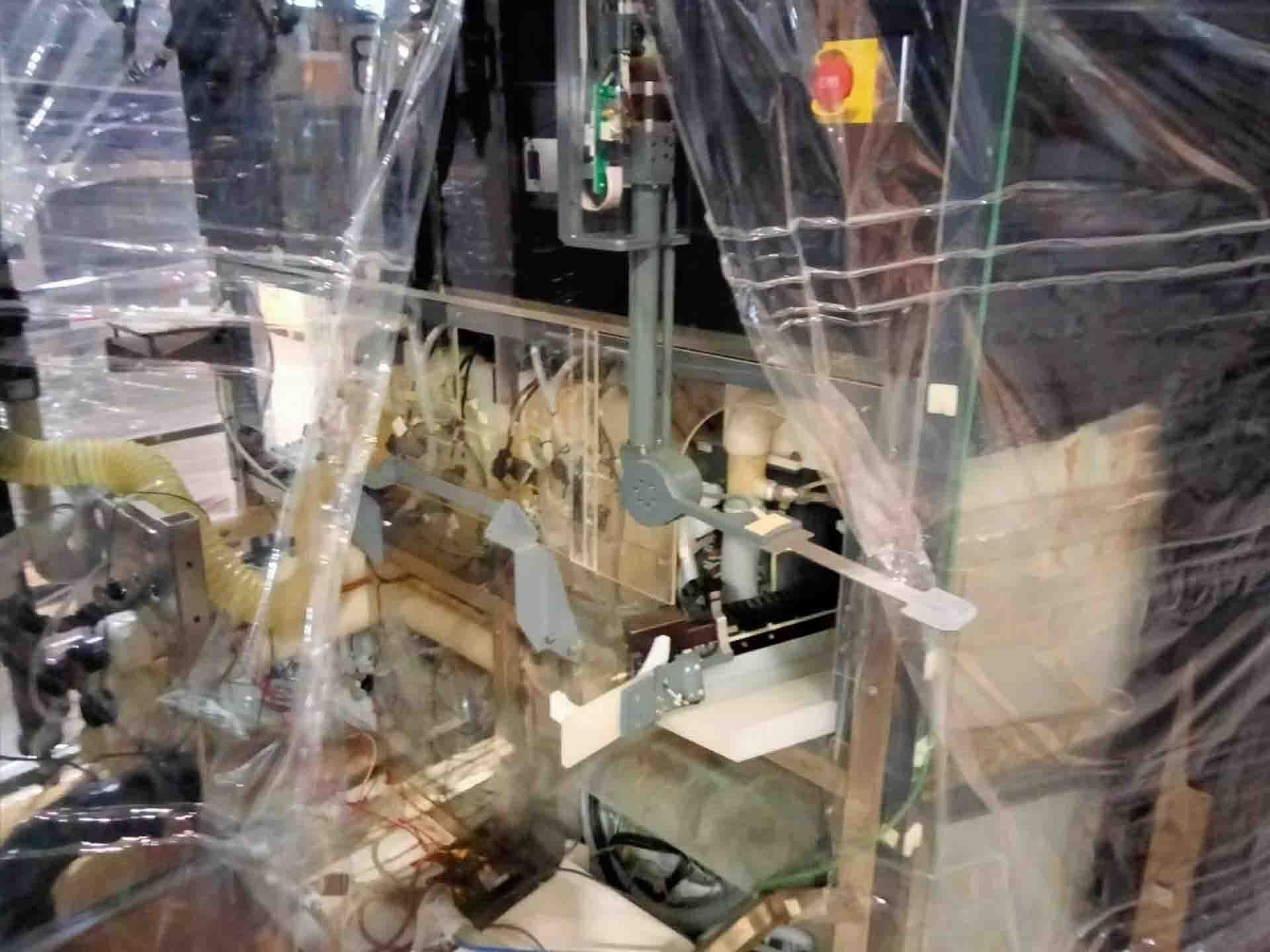

AMAT / APPLIED MATERIALS / AKT Mirra Mesa Equipment is a wafer grinding, lapping & polishing system developed to deliver high quality wafer surfaces with increased precision, repeatability and throughput. The unit is designed to improve surface roughness and flatness while also minimizing defects. The MA/AT is available in both manual and fully automated configurations, allowing for flexibility and scalability depending on the user's needs. AKT Mirra Mesa Machine uses a series of pressure and grinding tools along with chemical and physical processes to achieve the desired wafer finish. The tool utilizes 4-axis motion, allowing for simultaneous grinding and lapping of the entire wafer surface which increases speed and efficiency and minimizes cost. The MA/AT also employs compressed air to keep the abrasive material conditioned and eliminating unwanted particles. AMAT Mirra Mesa Asset incorporates particle metrology techniques to improve the process, ensuring optimal results and consistency. These techniques measure the parameters of the particles including size, shape, hardness, and contact angle of the abrasive material. By measuring these metrics the MA/AT can adjust the process accordingly, ensuring the best finish and wafer quality. APPLIED MATERIALS Mirra Mesa model is based on a modular platform that can be customized to meet the needs of the user. The equipment can also be configured for various wafer sizes and thicknesses. The system is easy to install and is designed for easy maintenance, allowing for increased uptime and reduced downtime during operation. Mirra Mesa Unit also provides a dust-free work environment, eliminating the need for an expensive cleanroom. Overall, AMAT / APPLIED MATERIALS / AKT Mirra Mesa Machine is a highly dependable wafer grinding, lapping & polishing tool that allows for increased speed, automation and accuracy that produces top-quality wafers. With its advanced particle metrology techniques, modular platform and ease of maintenance, it is an ideal solution for a wide range of wafer processing applications.

There are no reviews yet