Used AMAT / APPLIED MATERIALS Mirra Mesa #9254128 for sale

URL successfully copied!

Tap to zoom

ID: 9254128

Wafer Size: 8"

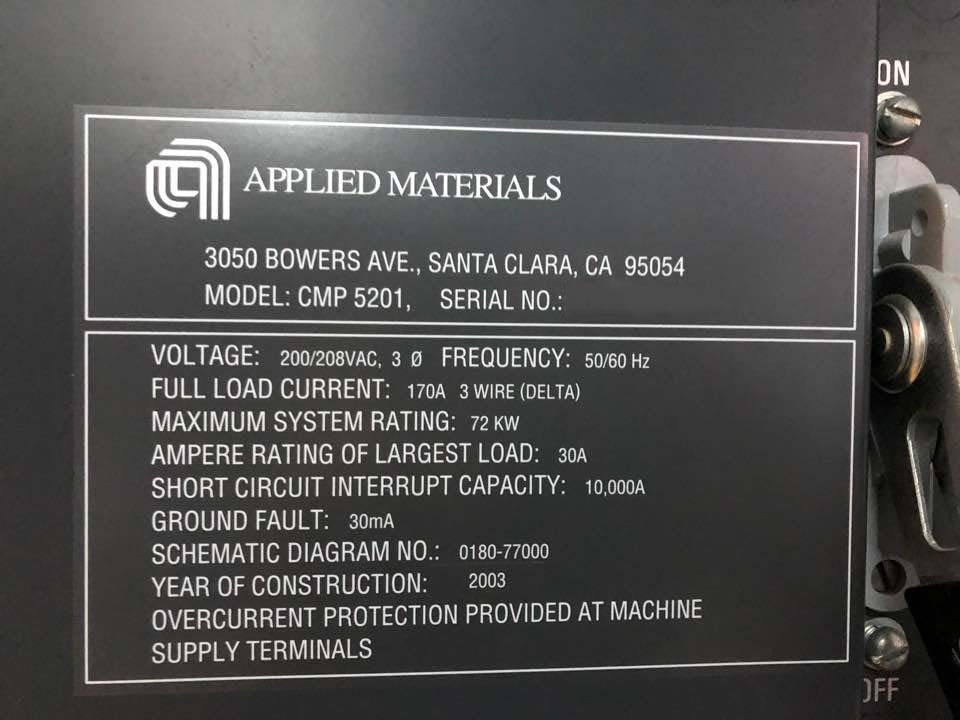

Vintage: 2003

CMP System, 8"

Technology: CMP Oxide

Wafer shape: Flat / Notch

Consumed process materials:

Polish slurry

Platen 1 pad: IC1010

Platen 2 pad: IC1010

Platen 3 pad: IC1010

Pad conditioner: Diaphragm

Pad conditioner head: DDF3

Pad conditioner holder

Factory interface options:

Cleaner type: MESA (Converted from reflexion)

Megasonics

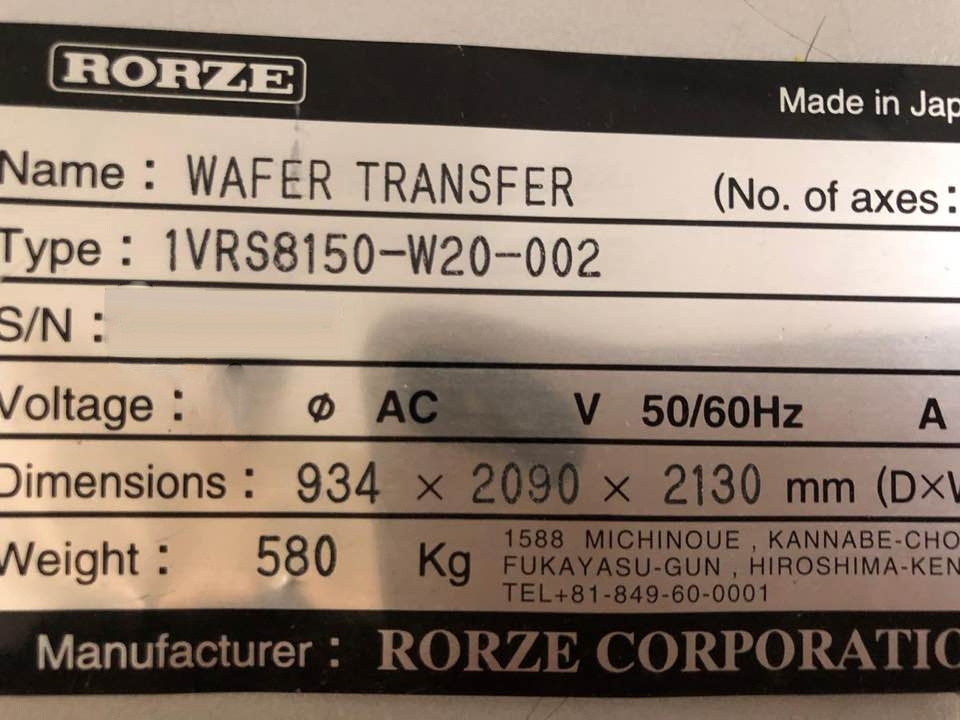

Robot type: AMAT / APPLIED MATERIALS

In-situ removal rate monitor: Full scan

SECS GEM Interface

Cassette tank

Cassette type: SMIF

Open cassette

Integrated system basic: FABS 212

FABS Robot blade: Ceramic

Cassette type: 25 Slots teflon PFA

Platen and head options:

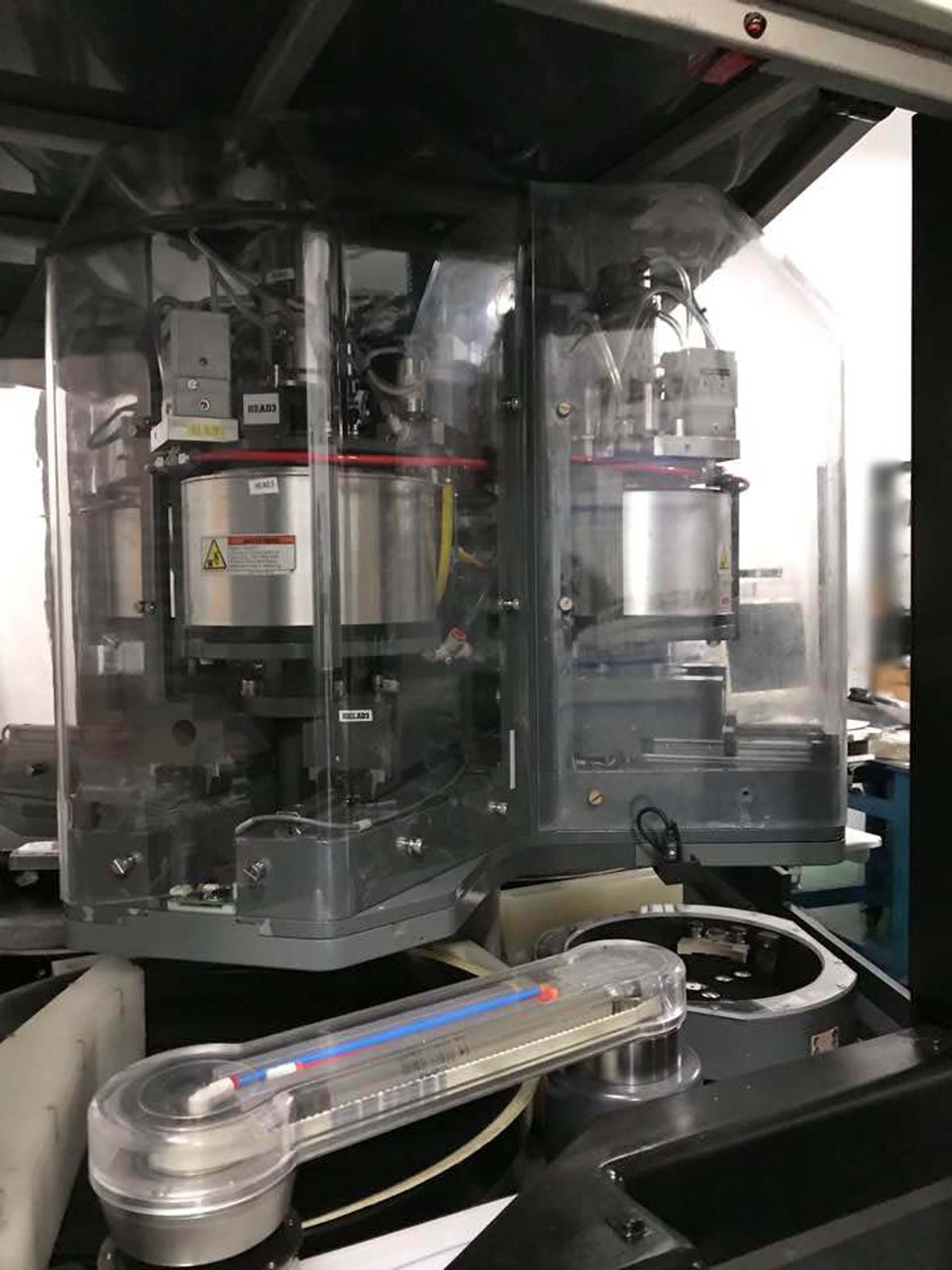

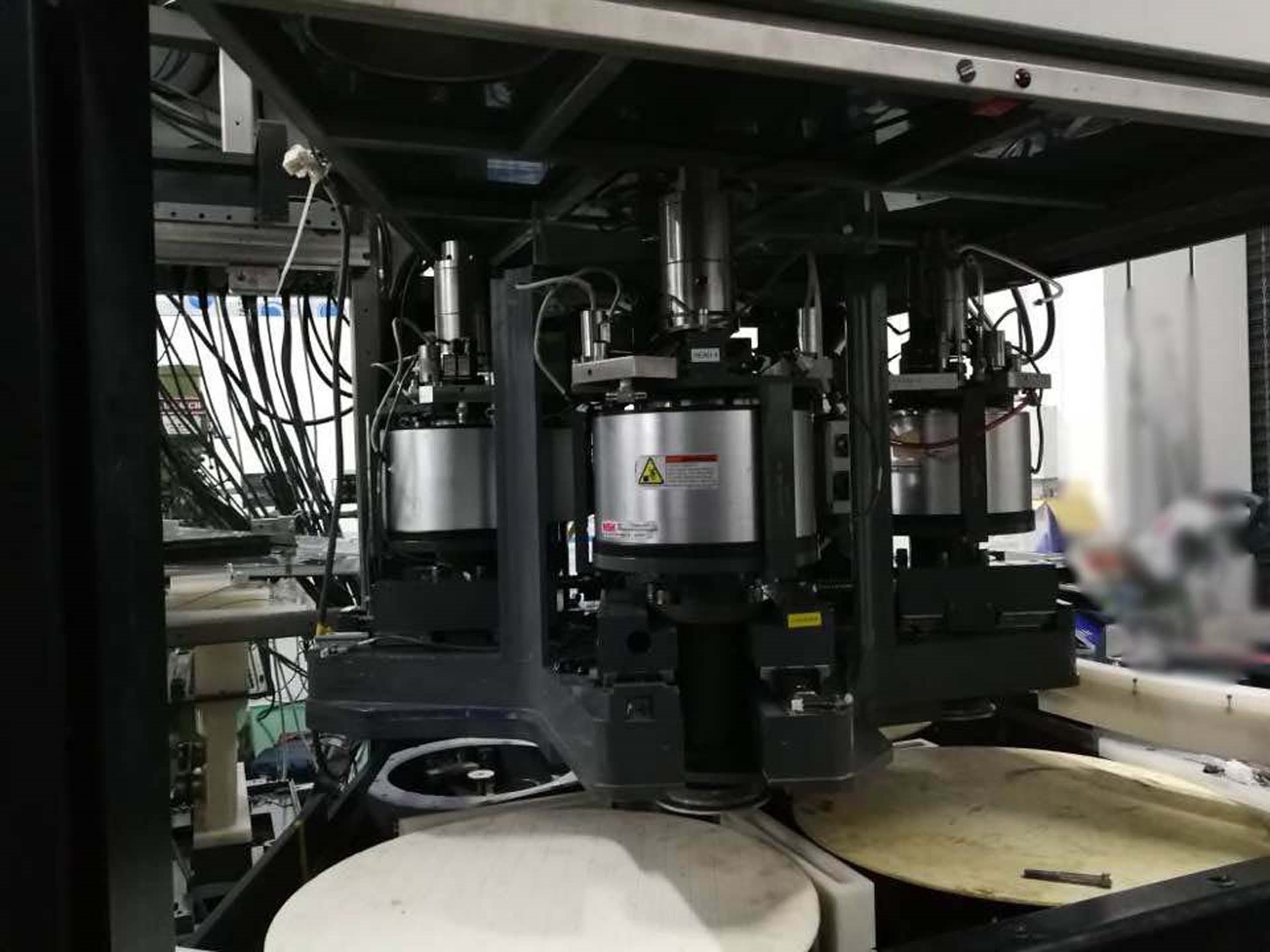

Polishing head: (4) TITAN I Heads

(4) Retaining rings

Pad wafer loss sensor

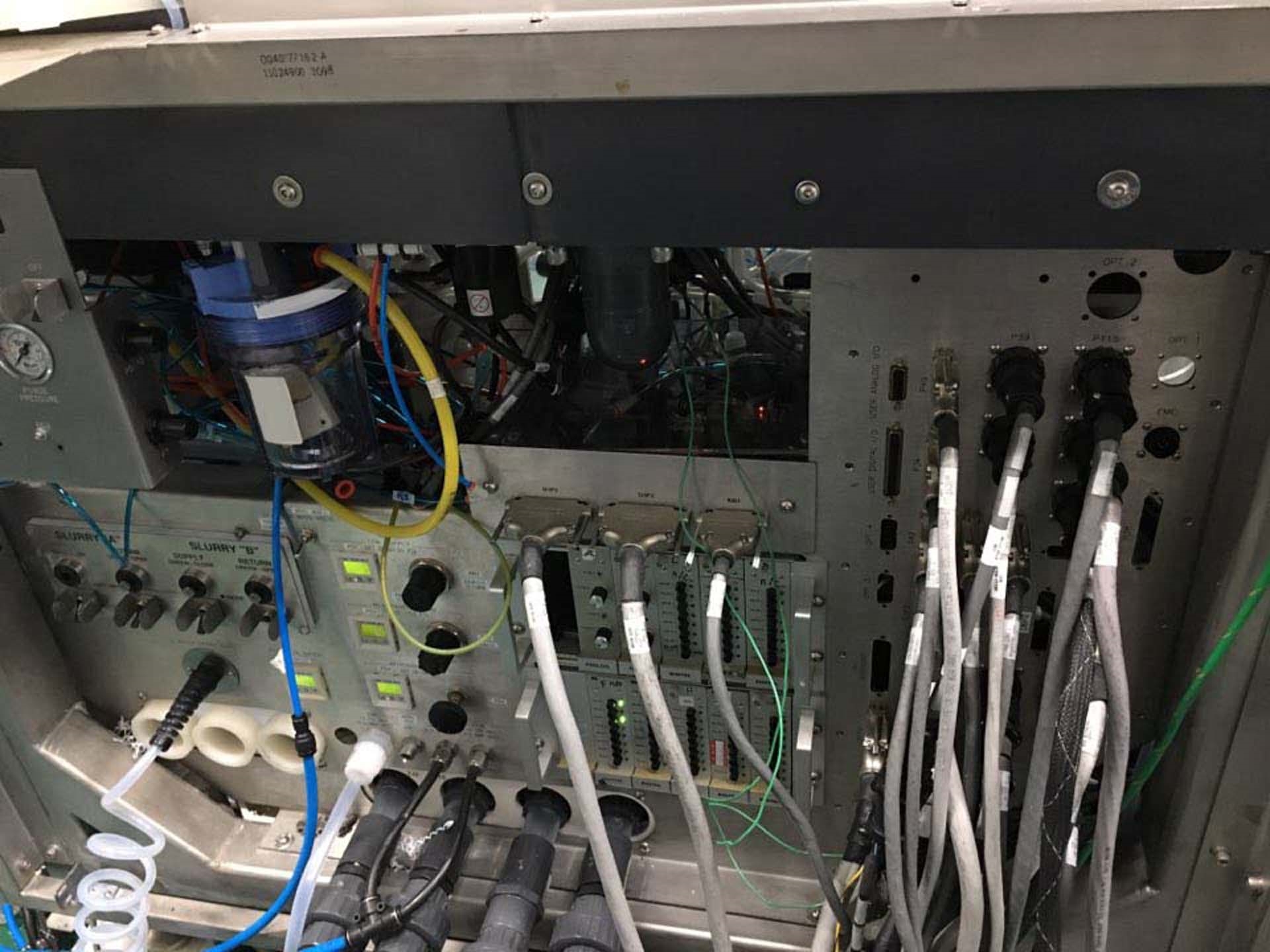

Slurry delivery options:

Slurry delivery: Peristaltic pump

Slurry flow rate

Slurry flow monitor

Slurry loop line

Slurry loop line A

Slurry loop line B

Slurry dispense arm

DI Water

High pressure rinse

Safety equipment:

Red turn to release EMO button

EMO Guard ring

Smoke detector

Polisher slurry leak sensor

Mesa brush leak sensor

Umbilicals:

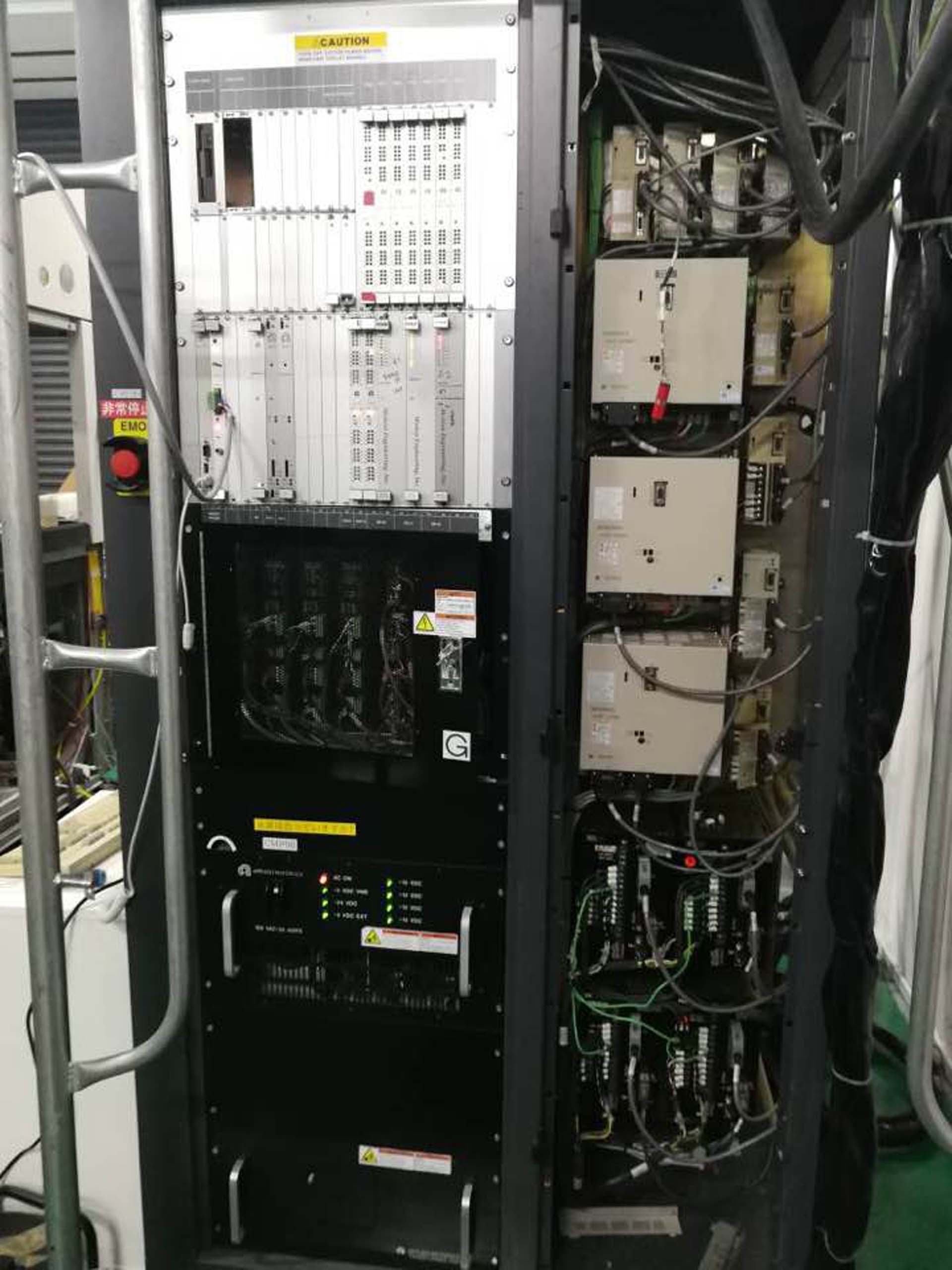

Polisher to controller cable: 50 Ft

Controller to monitor cable: 50 Ft

Factory hookup:

Upper exhaust

Upper exhaust material: SS

Exhaust vent interlock: Upper and lower

Upper exhaust connection: 8"

Drain manifold:(4) Lines to FAC

Drain adapter: NPT Fitting

DIW Inlet assy: W/O CDA Regulator

User interface:

Monitor selection: LCD Monitor

Monitor 1 location: LCD Monitor on cart

Class 1 cart for monitor 1

Mouse

Start stop button: Controller

Light tower selection: Controller and FABs

Polisher light tower:

Controller tower mounting type: Horizon flush mounted

Controller tower

Controller tower lamp type: Incandescent

Light tower:

Tower mounting type: Pole mounted

Tower lamp type: Incandescent

Tower colors sequence

Cleaner options:

Mesa cleaner

Walking beam assemble

Megasonic module: Delivery tank

Megasonic delivery type: Pressurized

Chemical A

Chemical B

Scrubber module:

Scrubber delivery type: Direct feed

Brush chemical

Scrubber 1 delivery type: Direct feed

Brush 2 chemical

Brush 1, 2 spray bar

SRD Module:

SRD Shield

SRD Exhaust and drain lines: Single

Upper electronic box: UEB

Signal tower

Pad conditioner head: DDF3

Pad con disk holder

Polishing head: TITAN 1 Head

Upper Pneumatic assy: UPA

Slurry delivery: (2) Slurry line for each platens (6 Slurry line)

Endpoint system full scan ISRM (P1, P2)

No slurry containment bulkhead

No slurry loop line C

No Uninterruptible Power Supply (UPS)

No delta connection

No power connected lamp

No AC outlet box

No isolation transformer for Mesa

No elbow fitting for drain pan

No castors

No weight distribution plate

No internal vacuum ventury

No SRD heater lamp

Power requirements:

Line voltage: 200~230 V

Line frequency: 50/60 Hz

Delta connection

Power lamp

Circuit breaker: 200 A

Configurable IO: 10 Channels

GFI Type: 30 mA

2003 vintage.

AMAT / APPLIED MATERIALS / AKT Mirra Mesa is a high precision computer-controlled wafer grinding, lapping and polishing equipment. It is designed for use in the semiconductor industry for the precise grinding, lapping and polishing of complex wafers. The system utilizes precise motion control and advanced feature sets to achieve exceptionally precise geometries, specifically for the semiconductor market. The unit includes a programmable rotary platen, which allows for the precise polar and azimuthal control of rotational motion. This motion is used in combination with brushing, grinding and polishing techniques to produce precise surface geometries. The motion is controlled and monitored via a series of rotary encoders, providing precise and repeatable performance. The machine also features a sophisticated heating and cooling tool, designed to ensure the optimal temperature range for the processes being performed, helping to reduce wear and tear on the parts. The asset is engineered to perform grinding, lapping and polishing applications with very tight tolerances (> 0.02 μm). All parts and materials form the model, including the aluminum baseplate, bearing carriers and shafts, are all designed and built to exacting tolerances and specs. The equipment is NSF approved and designed to meet all applicable HEPA Filter Standards. Additionally, AKT Mirra Mesa provides advanced software control, allowing for precise and repeatable operation. The system supports both on-board and off-board computers for operation, monitoring and diagnostics. It also includes a range of tooling options, allowing for a wide range of applications. Overall, AMAT Mirra Mesa is a cutting-edge unit designed to deliver precise and repeatable grinding, lapping and polishing applications, especially in the semiconductor industry. Its advanced feature set yields top-notch, quality results that are sure to exceed customer expectations.

There are no reviews yet