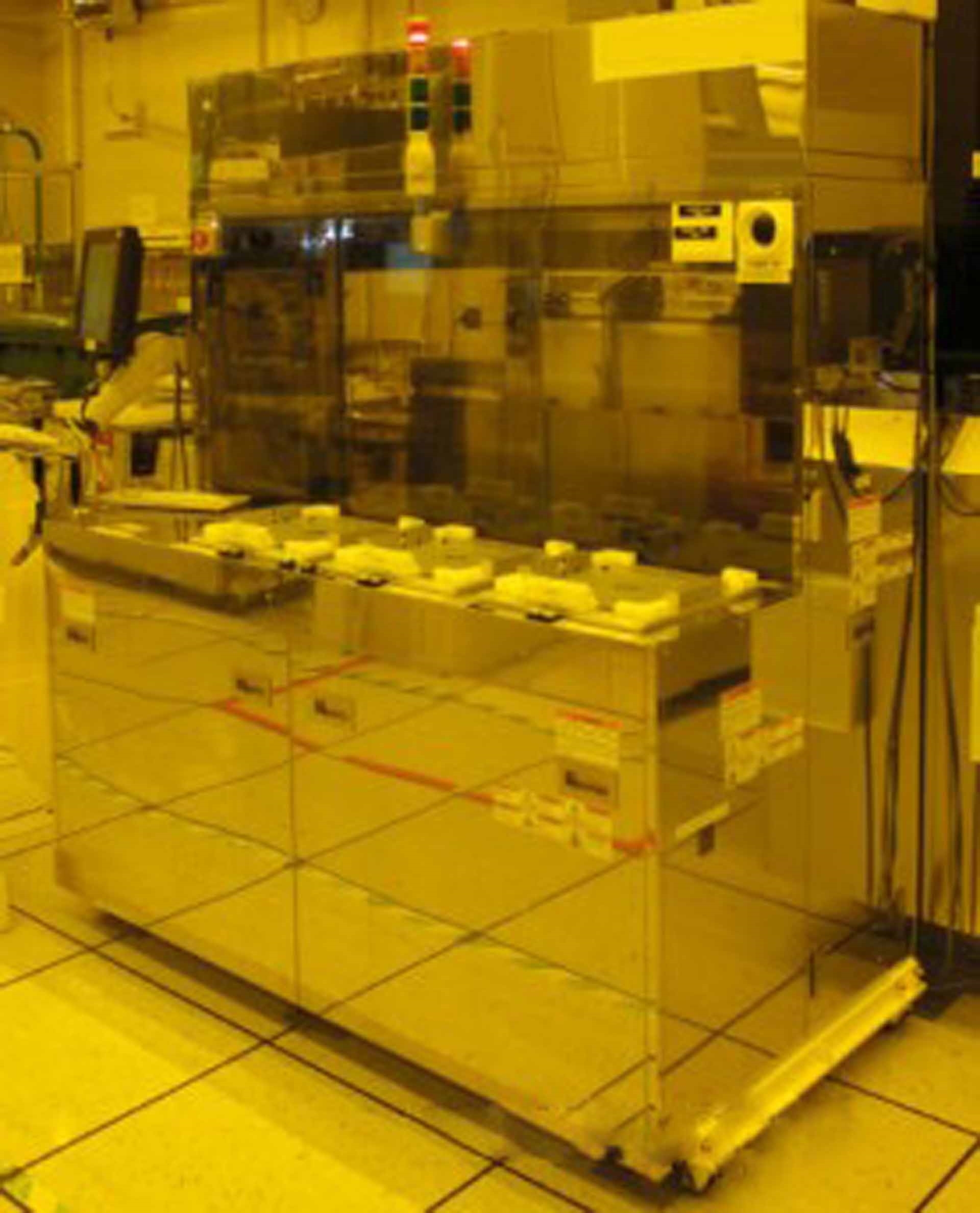

Used AMAT / APPLIED MATERIALS Mirra OnTrak #9223507 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

ID: 9223507

Wafer Size: 8"

Vintage: 2000

CMP System, 8"

System controller

Main system:

Polisher

Ontrak cleaner

FABS Cassette system

CPU: Pentium III 400 MHz

Dual RAID hard disk

Hard disk size: 68 GB

RAM: 128 MB

Hardware:

Polisher with controller: Mirra 3400 / 5201

Cleaner: Ontrak

Indexer: RORZE FABS

Slurry (P1+P2+P3): AB

Endpoint laser P2: Legacy non FS

Polisher middle skins: Clear middle skin

No chiller

Com port server: Digi EL160

Cleaner brush LDM: LDM With entegris flow sensors

Slurry in CLC

Slurry arm: (2) Lines

Polishing head: Titan I

Rotary union: (3) Ports

Cross type: Cattrack

Cassette slot run order (From slot 1 down to 25)

Consumable:

Platen teflon coated

Pad conditioner type: UNIVERSAL

Retainer ring type: AEP II

Membrane type: Silicone membrane

PC Diaphragm: DDF3 Diaphragm

Brush with core type: Aion ontrak brush has been replaced

Upgrade / CIP Retrofit details:

LLA Guide pin: Self align

UPA: Waterfall

No splash guard

Exhaust blower

Magnehelic pressure low level detection kit

SRD Exhaust interlock

Queue tub

No blackout covers

2000 vintage.

AMAT / APPLIED MATERIALS Mirra Track Wafer Grinding, Lapping and Polishing Equipment is a turnkey solution for high-precision, low-cost processing of semiconductor wafers. A robust and compact system, it performs front-side and back-side single-side grinding, lapping, and polishing with the highest accuracy available. One of its core features is a quick changeover capability which allows for wafer size range and lapping thicknesses to be changed quickly. It is used for a variety of semiconductor applications, such as mirror and flat wafer lapping, die separator and bevel grinding, and patterned film polishing. Furthermore, it employs a unique two-station processing method, which increases throughput and reduces overall cost and time-to-market. The unit's grinding and lapping uses a combination of the most advanced abrasive technology, diamond dust and ceramic wheel systems. This enables high-accuracy grinding, lapping, and polishing, to within that nanometer range. Furthermore, the modularized design includes a lapping and grinding station, as well as a cleaning, polishing, and inspection station, to ensure each wafer is of the highest precision. The machine has a software, Advanced Processing Technology (APT), to provide a user friendly interface to manage the lapping and grinding process. The software contains program controls for wafer size range, lapping thickness monitor, feedback control systems, lapping tape loading profiles, grinding parameters, polish parameters (pressure, time), and polishing cycle to further ensure accuracy and precision. Overall, AMAT Mirra Track Wafer Grinding, Lapping and Polishing Tool offers an advanced and robust solution for semiconductor manufacturers with low-cost and high-accuracy processing capabilities. Its unique two-stage processing and quick changeover feature enables the systems to process a variety of semiconductor applications with the highest precision. With its Advanced Processing Technology software, it offers further precision and control of the process.

There are no reviews yet