Used AMAT / APPLIED MATERIALS Mirra Track #9223509 for sale

URL successfully copied!

Tap to zoom

ID: 9223509

Wafer Size: 8"

Vintage: 2000

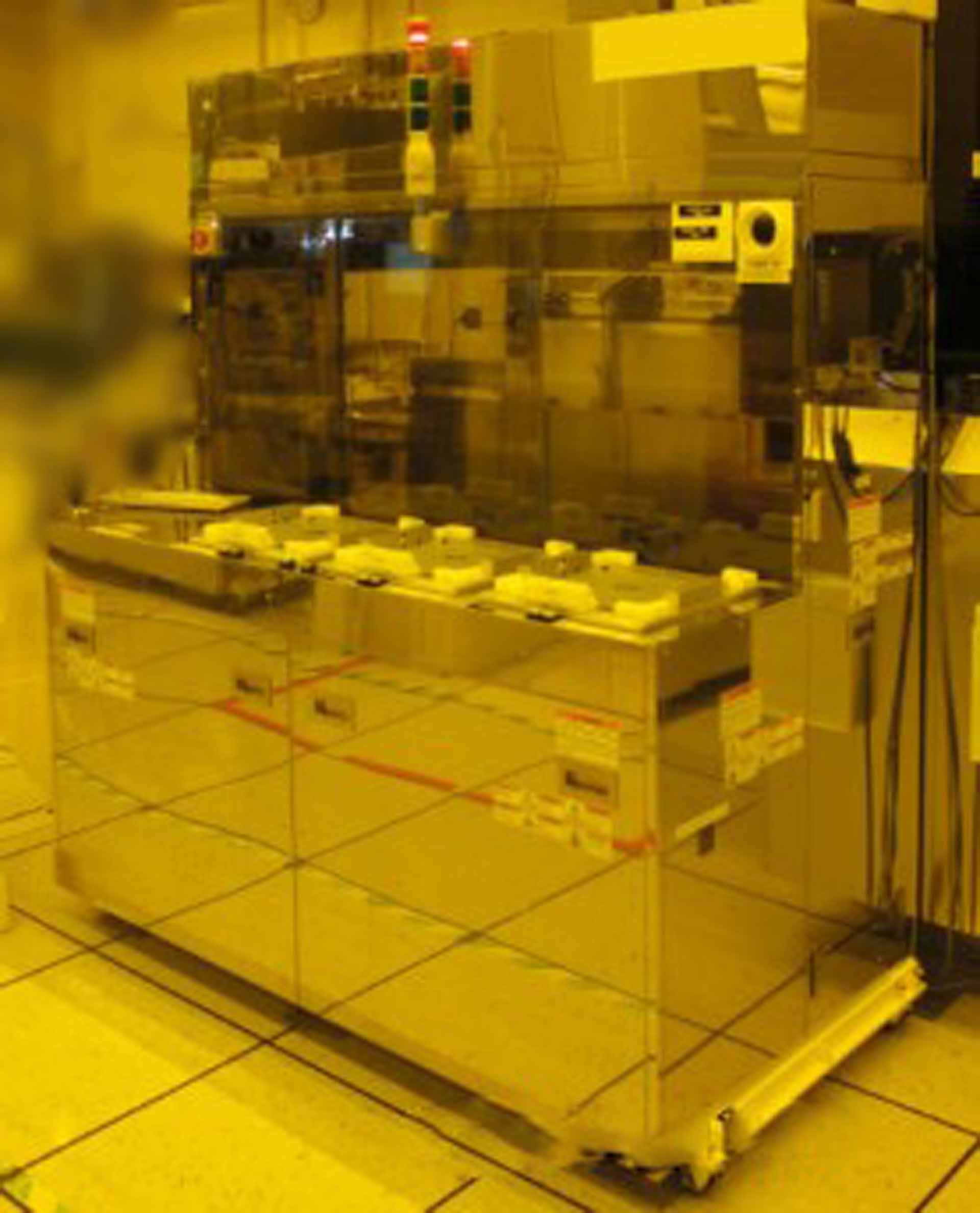

CMP System, 8"

Process: PCUD

System controller

Main system:

Polisher

Ontrak cleaner

FABS Cassette system

Missing / Faulty parts:

Pneutronic board

(2) Slip rings

Analog board

Cross motor

CPU: Pentium III 400 MHz

Dual RAID hard disk

Hard disk size: 68 GB

RAM: 128 MB

Hardware:

Polisher with controller: Mirra 3400 / 5201

Cleaner: Ontrak

Indexer: RORZE FABS

Slurry (P1+P2+P3): AB

Endpoint laser P1: IScan

Endpoint laser P2: FullScan

Polisher middle skins: P1 & P3 Dark skin, P2 clear skin

No chiller

Com port server: Digi EL160

Cleaner brush LDM: LDM With entegris flow sensors

Slurry in CLC

Slurry arm: (4) Lines

Polishing head: Titan I

Rotary union: (3) Ports

Cross type: Cattrack

Cassette slot run order (From slot 1 down to 25)

Platen teflon coated

Pad conditioner type: UNIVERSAL

Retainer ring type: AEP II

Membrane type: Silicone membrane

PC Diaphragm: DDF3 Diaphragm

Brush with core type: MYKROLIS Ontrak brush

Upgrade / CIP Retrofit details:

LLA Guide pin: Self align

PM Reduction kit: Partial

UPA: Waterfall

No splash guard

Exhaust blower

Magnehelic pressure low level detection kit

SRD Exhaust interlock

Queue tub

Blackout covers

2000 vintage.

AMAT / APPLIED MATERIALS Mirra Track is a wafer grinding, lapping and polishing equipment designed for the semiconductor and related industries. This system is designed to provide superior surface flatness and surface defect reduction at high production speeds. The versatility of this unit enables it to handle multiple wafer configurations and sizes. The main components of AMAT Mirra Track include a multi-blade coated wafer carrier, a keyless ring clamp, a keyless, multi-port alignment machine, and a surface flatness metrology tool. The coated wafer carrier is designed to hold multiple wafers securely and in the correct orientation to ensure maximum flatness and defect reduction. The keyless ring clamp ensures proper wafer mounting and swing. The multi-port alignment asset allows for both manual and automated alignment of the wafer singularly or in a batch, while the surface flatness metrology model allows for direct surface flatness measurement. The equipment is capable of grinding, lapping and polishing wafers with a range of up to 25mm. This can be achieved through the use of different grit sizes and polishing pads, allowing for a wide range of process recipes to be used. The system can also be programmed for fully automated, closed loop operation with direct user control over the process recipe and parameters. This allows users to customize the wafer processing steps to the specific application. APPLIED MATERIALS Mirra Track is designed with a high level of data-tracking capabilities, including event logging, process data storage, and remote software diagnostics. These features enable users to monitor wafer process quality and adjust parameters on the fly to maintain a high level of quality control. Overall, Mirra Track is a versatile unit that can be used for a number of different applications. Its advanced features and capability to customize the wafer processing steps make it a valuable asset in the semiconductor and related industries.

There are no reviews yet