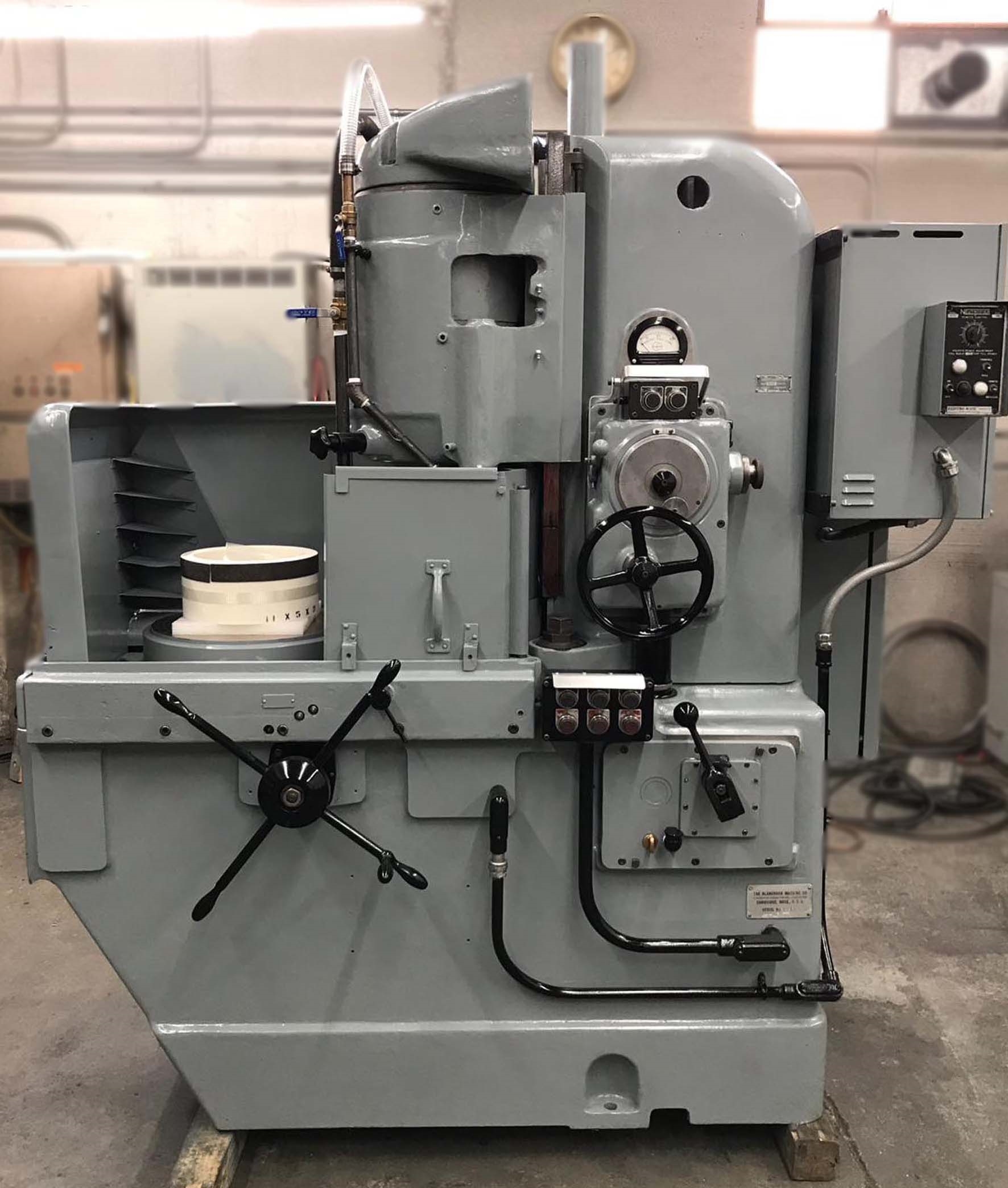

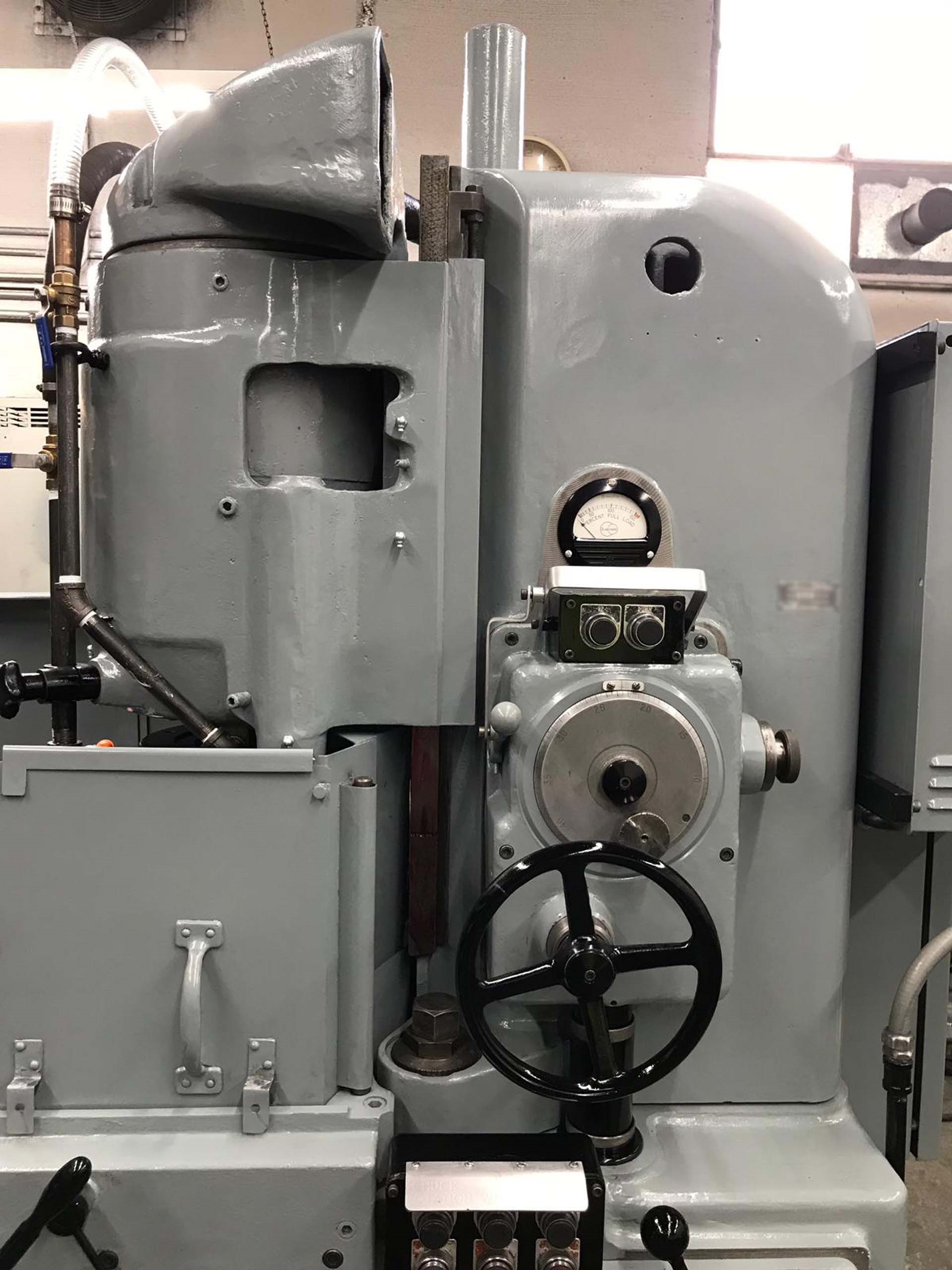

Used BLANCHARD 11-16 #9237347 for sale

URL successfully copied!

Tap to zoom

ID: 9237347

Grinder

Wheel

Coupling chuck

Coolant pump chuck

Magnetic chuck control

Power supply: 440 V.

BLANCHARD 11-16 is a wafer grinding, lapping, and polishing equipment designed to efficiently process large wafers and complicated workpieces. This system is capable of handling large wafers up to 12" in diameter. It features a circular grinding and polishing table which can be rotated up to two revolutions per minute. The grinding table is thermally regulated to ensure precise and uniform surface finish. 11-16 is designed to accommodate multiple workpieces on one table, allowing for high production rates and improved efficiency. The machine is designed to provide superior performance in precision flatness, parallelism, and surface finish of workpieces. This is achieved through the use of a high torque drive unit and a precisely machined seat that holds the workpiece in place. The workpiece is secured in place by a spring loaded plate, which ensures consistent and accurate grinding without slipping. The machine's spindle is driven by a high efficiency motor to achieve optimal surface finish. BLANCHARD 11-16 also features a counterweight machine that helps reduce vibration and ensures that the wafers and the machine are in precise balance during operation. 11-16 is equipped with a patented sapphire surface lapping ball that aids in the optimization of the grinding & polishing process. The sapphire ball rotates in a precisely machined seat, which creates a uniform process on the wafers. The ball is cooled by a nitrogen cycle to ensure optimal grinding performance. The lapping tool is also equipped with a ring chuck, allowing the user to effectively hold larger wafers in place. In addition, the asset includes a water-cooled polishing cloth wheel that is designed to produce high-quality results while reducing operating and labor costs. This wheel uses a dry polishing process that produces a smooth and highly polished surface. BLANCHARD 11-16 is capable of producing a surface finish of 8 Ra on small parts and can easily achieve a surface finish of 2 Ra or better on large parts. An optional electrical model is available for the machine that allows the user to monitor and control the spindle speeds to achieve an optimal surface finish. It also features an emergency stop button for added safety and a control panel that allows for easy access to the necessary machine settings. Overall, 11-16 is a highly advanced wafer grinding, lapping, and polishing equipment that is designed for improved efficiency and to deliver superior performance. Its unique features allow for the production of high-quality workpieces with an excellent finish and flatness.

There are no reviews yet