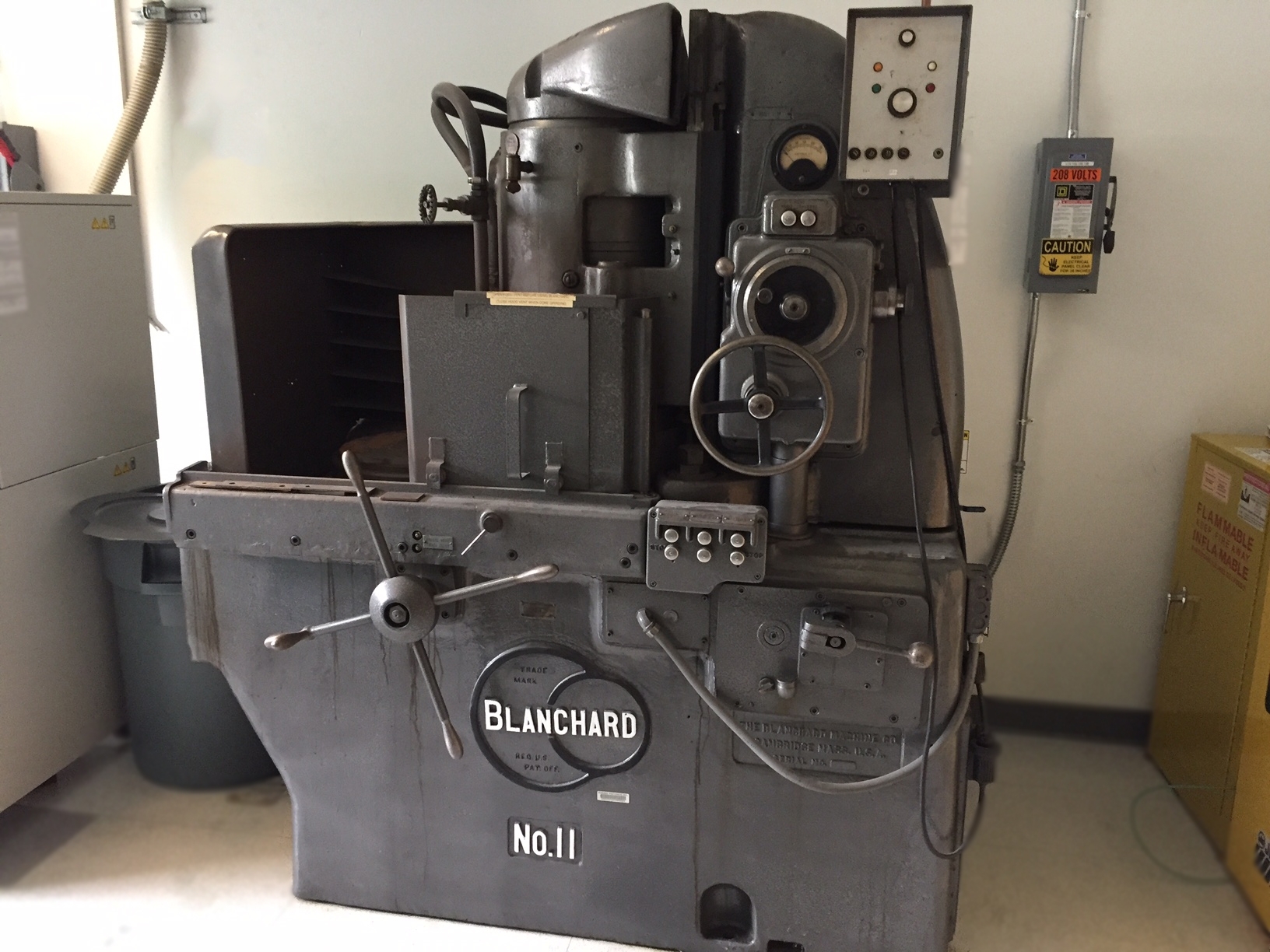

Used BLANCHARD 11 #9183467 for sale

It looks like this item has already been sold. Check similar products below or contact us and our experienced team will find it for you.

Tap to zoom

Sold

BLANCHARD 11 is a wafer grinding, lapping and polishing equipment. It is an ideal system for fine feature development, wafer refining, and mirror polish solutions. This advanced technology unit has a heavy-duty, heavy-gauge cast iron base for stability during operation. The device includes a special slotted platen which supports the wafer during operation. Underneath the platen, there is a round motor belt that moves the material during process. The grinding wheel is also attached to the motor belt and is supplied with 3 abrasive grits such as ceramic oxide, diamond lapping compound, and abrasive polishing compound. BLANCHARD 1 1 also includes a floating feed machine. The feed control dial regulates the grinding wheel speed and offers precision metering to achieve the desired surface finish. It also offers a choice of one-directional feed or reciprocating feed and the ability to work with a variety of wafer sizes ranging from 50mm to 600mm. Aside from the wafer grinding application, this tool offers lapping functions. It is equipped with an abrasive wheel for the most advanced lapidary applications. This wheel has superior wear resistance and creates a uniform surface finish, which is essential in achieving superior optical performance. The asset's polishing capabilities offer a variety of diamond and polishing compounds for application. It also offers a full range of polishing pads from diamond to ceramoelectric ceramics. These materials offer superior polishing performance and create a highly reflective surface. Just like with other BLANCHARD systems, 11 offers support-post installation for quick and easy model setup. It also provides a range of control features and safety interlocks to ensure a safe working environment. Overall, 1 1 is an advanced wafer grinding, lapping and polishing equipment. It is an ideal system for high-precision applications that require exacting performance. Its advanced features and construction create a reliable and easy to use unit, which make it suitable for many wafer finishing processes.

There are no reviews yet