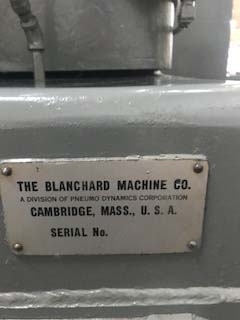

Used BLANCHARD 20 #9252555 for sale

URL successfully copied!

Tap to zoom

BLANCHARD 20 is a 'wafer grinding, lapping & polishing' system - a type of large-scale cutting and polishing machine used in the semiconductor industry. This system is composed of a massive, custom-made, and highly-tiered grinding wheel, mounted to a rotating table, surrounded by a protective enclosure. The entire cutting and polishing process is powered by an induction-electric motor passing alternating current through the grinding wheel, which is connected to an electrical switching unit. This switching unit delivers a variable amount of power, causing the wheel to spin at up to 15,000 RPM. The wafer-grinding wheel is composed of diamond-impregnated abrasive-stones fixed onto a durable metal surface. High-performance inserts, made from a special type of ceramic, are placed into special pockets allowing for a more effective grinding. The wafer-grinding process is done in a precise, pre-programmed sequence. The wafer is inserted into a jig placed onto the rotating table, and then the grinding begins. The grinding wheel spins, rapidly removing material from the wafer's surface in accordance to the pre-set program. Depending on the wafer, the desired polishing effect, or edge conduction, is achieved with varying levels of speed and amount of pressure. Once the grinding process is complete, the wafer is transferred into the polishing station. In this process, a special manual or automated polishing tool, is used to finish the wafer and give it a smooth, shiny surface. Typically, an abrasive slurry or paste is used to polish the wafer evenly. The wafers then undergo an important lapping operation where they are polished both sides and are further machined to fine tolerances. Finally, inspection and testing of the wafer for quality control are performed before the wafer is released for use. 20's popularity in the industry is evidence of its dependability and repeatability. In addition to its reliability, it offers many advantages such as precise control of surface geometries, repeatability, and cost savings in labor and material costs.

There are no reviews yet