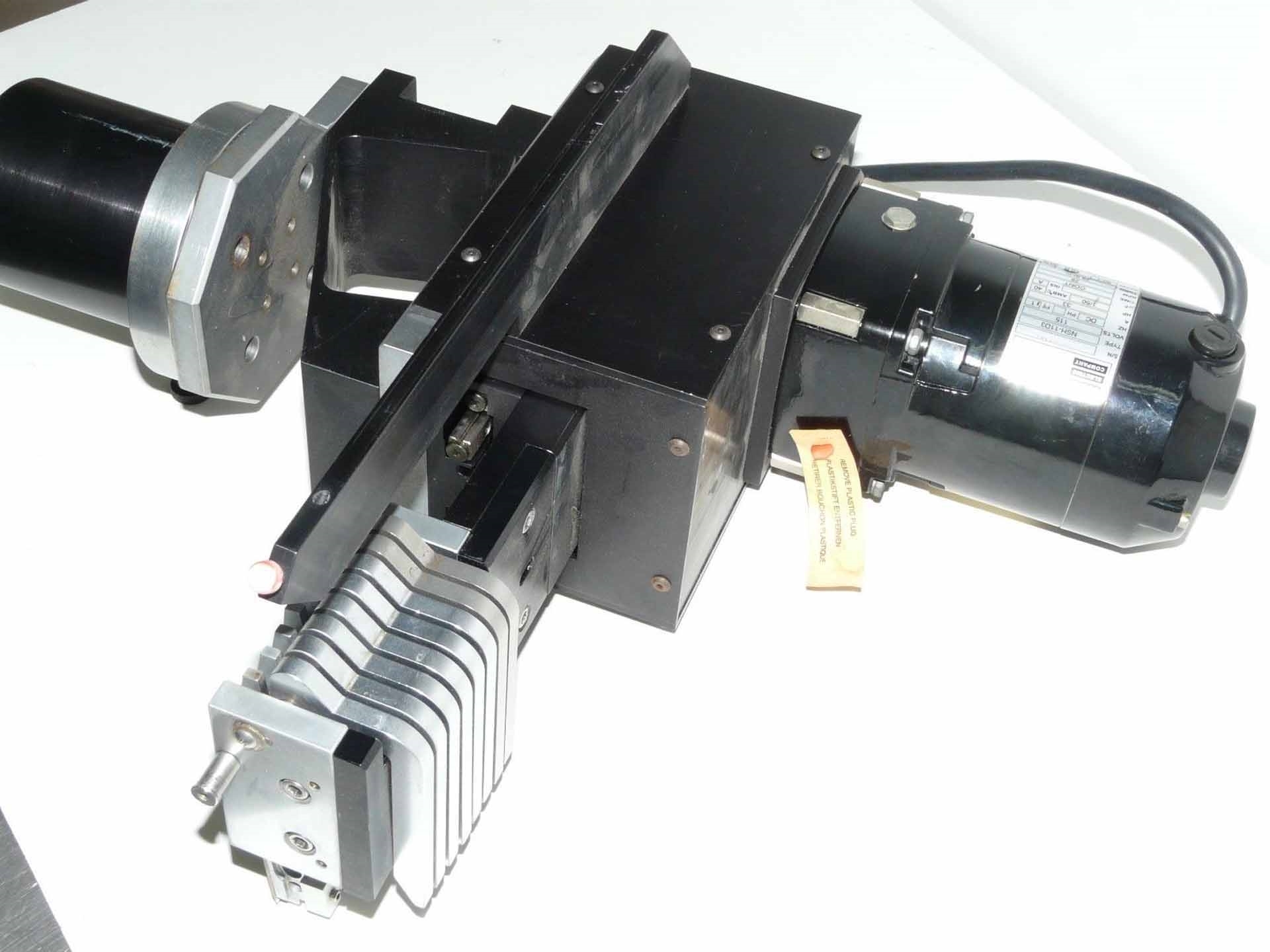

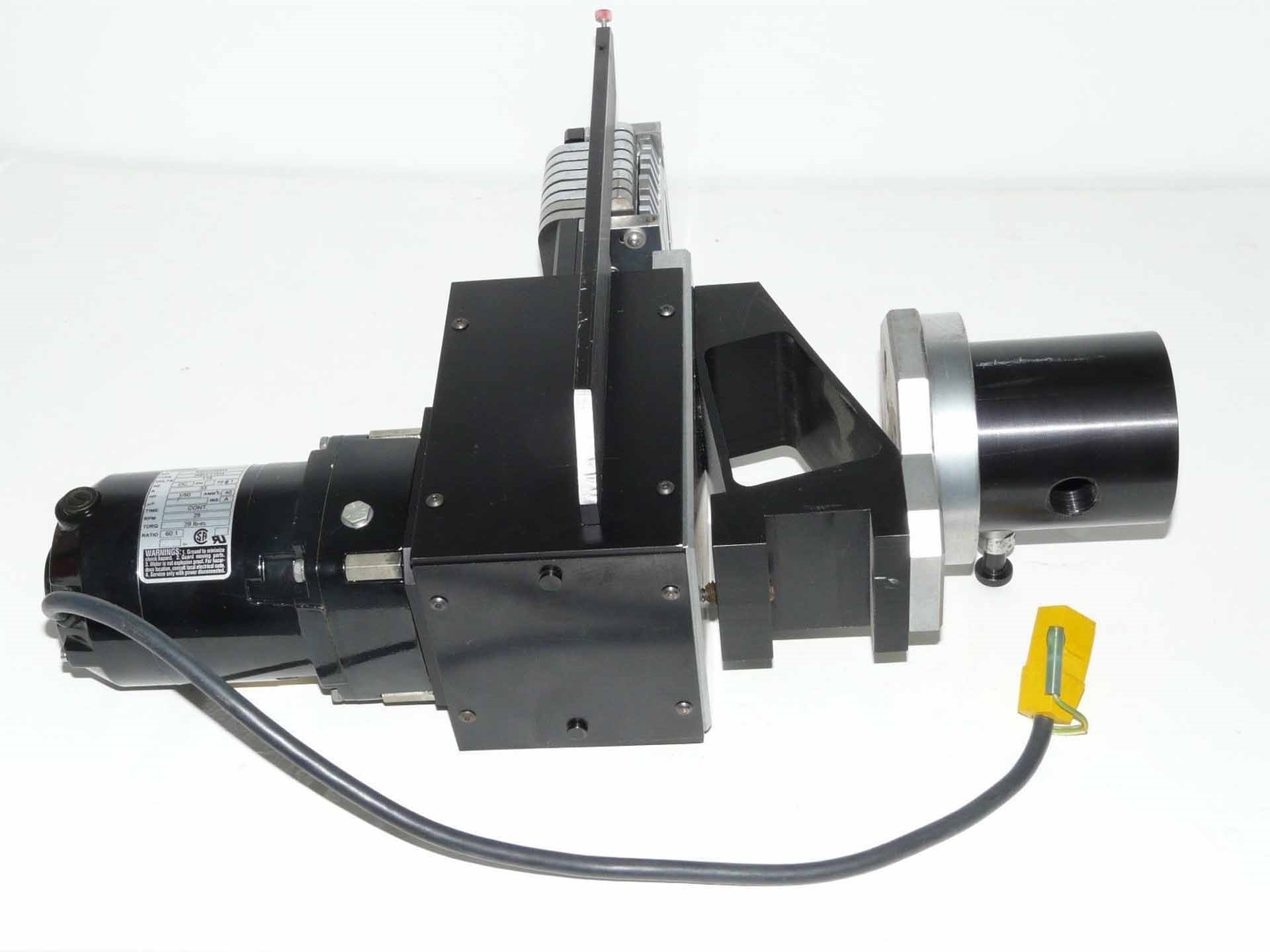

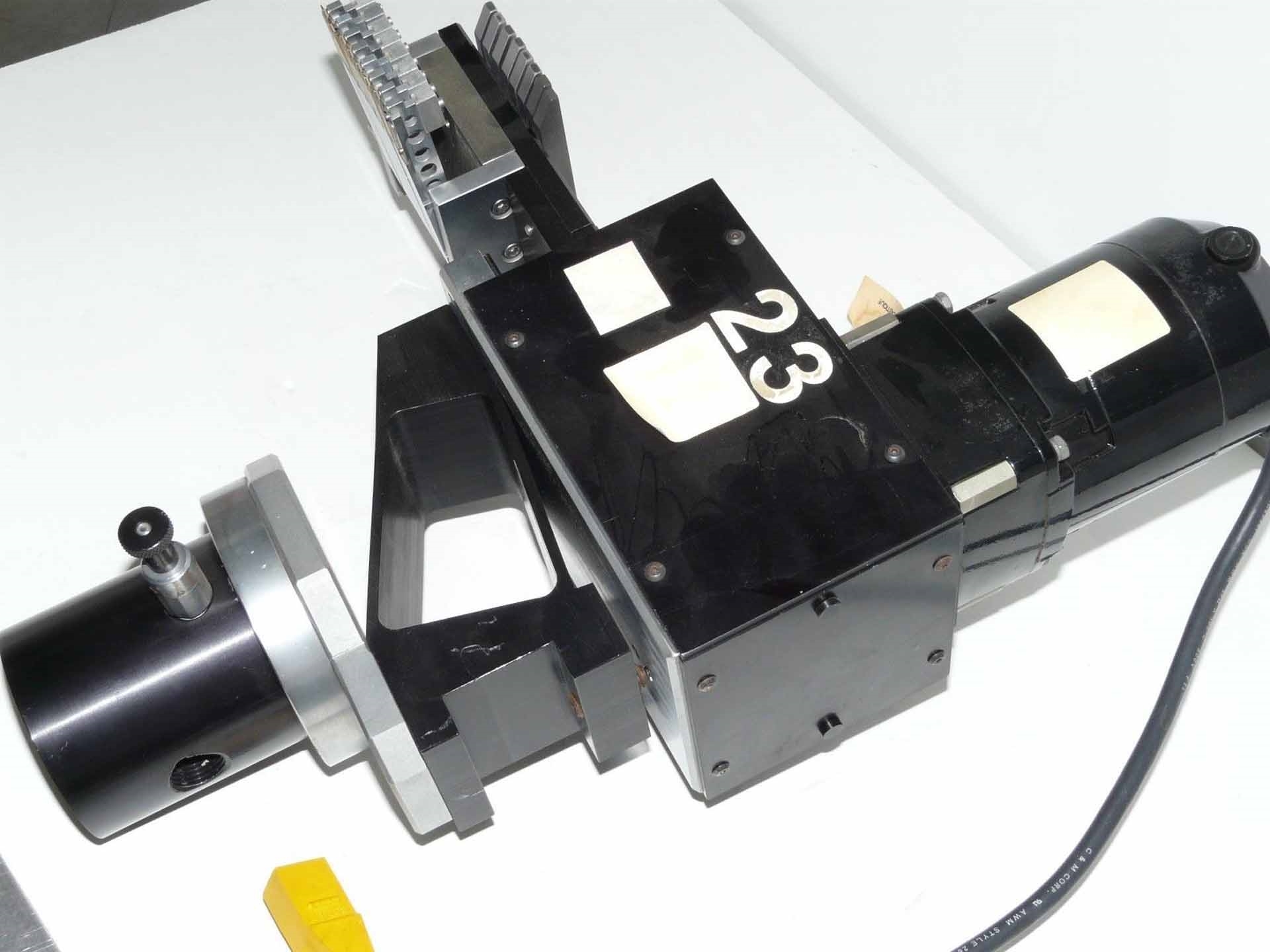

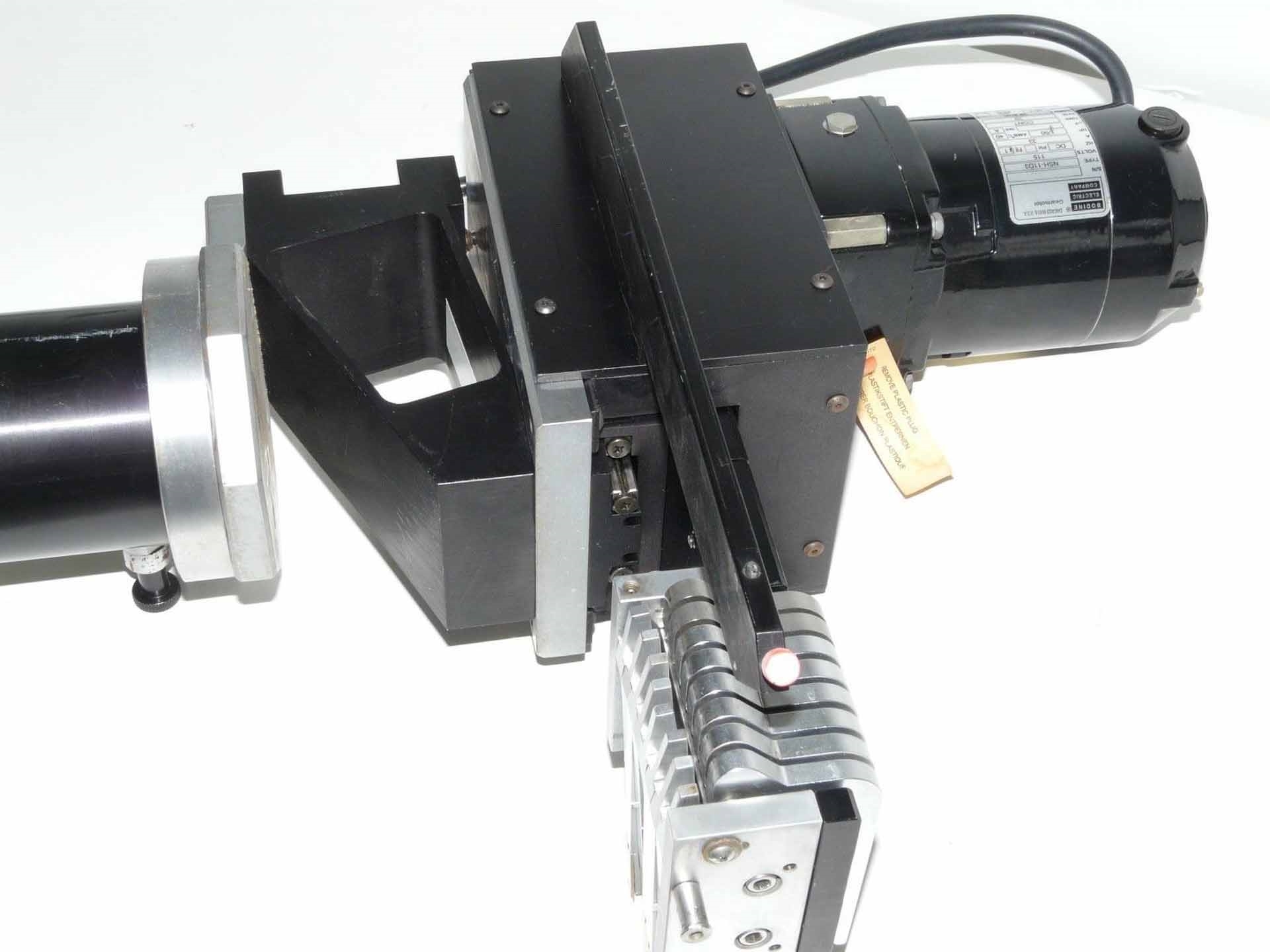

Used BODINE NSH-11D3 #9211701 for sale

URL successfully copied!

Tap to zoom

ID: 9211701

Gear motor

Vintage lapping machine head

Nominal rated input voltage: 115 V

Current type: DC

Gear ratio: 60:1

Base: 29 RPM

Rated load (HP): 1/50

Rated / Full-load torque: 29 RPM

Insulation class: A (Maximum 221°F).

BODINE NSH-11D3 is a high-quality wafer grinding, lapping and polishing equipment designed for semiconductor production. The system features a robust and powerful three-axis spindle drive motor, as well as a stepper motor for controlling the X, Y and Z axes of the unit. This allows the machine to achieve precise control over the grinding, lapping and polishing of wafer surfaces. The tool also features a positive-drive wheel, which enables it to grind, lapping, and polish the wafer at very high speeds. Its ability to operate at high speeds and high accuracy makes it a great choice for semiconductor processing. NSH-11D3 is based on a modular design, allowing for easy integration into any production environment. It utilizes a high-pressure, closed-loop asset with a specially designed high-pressure feed unit. The feed unit contributes to the precise speed control of the spindle motor. The grinding, lapping and polishing operations are powered by a series of servo motors, allowing the model to achieve extremely high levels of accuracy and precision. The equipment is also equipped with several safety mechanisms to ensure the operator does not exceed the limits of operation set by the machine. BODINE NSH-11D3 features a wide variety of grinding, lapping and polishing media, including ceramics, polymers, diamonds, plastics, silicon and more. The system is also equipped with a variety of accessories, such as polishing pads, lapping tools and grinding tools. The unit is designed to work with a wide range of grit sizes, from coarse to ultra-fine, allowing it to achieve the desired results for a wide variety of products and applications. NSH-11D3 is a great choice for any wafer grinding, lapping and polishing needs. Its modular design allows it to be integrated into any existing production environment. Its powerful spindle motor and the addition of the positive-drive wheel makes it capable of reaching extremely high speeds while maintaining the highest precision. Its ability to work with a wide variety of materials allows it to be used for many different products and applications. Furthermore, its safety measures make it ideal for use in production environments.

There are no reviews yet