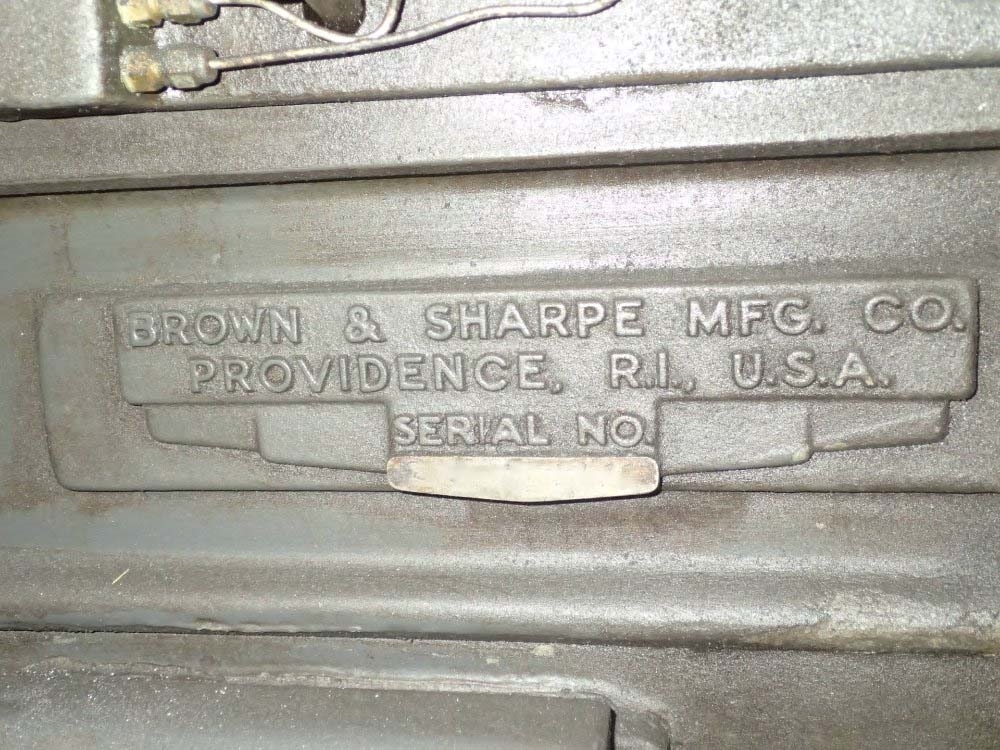

Used BROWN & SHARPE 2L #9209183 for sale

URL successfully copied!

Tap to zoom

ID: 9209183

Surface grinder

Magnetic chuck

Aisle: 06A

Bay: 1900

Power: 3 Phase / 60Hz

Voltage: 110 / 220.

BROWN & SHARPE 2L is a wafer grinding, lapping and polishing equipment used to achieve precise and uniform geometries on the surface of semiconductor wafer. It is designed for high volume production in research and development and in process and production control. 2L system uses two lapping heads and a precision grinding head to grind, lap and polish the wafer surface. The grinding head utilizes diamond impregnated wheels to grind the wafer to a precise depth, shape and form. The lapping heads use specially formulated abrasives to lap the wafer to quickly and efficiently achieve a uniform geometry on the wafer surface. The lapping heads also use a fluid slurry to help in the lapping process and reduce the buildup of fine particles on the surface of the wafer. BROWN & SHARPE 2L unit is capable of achieving very precise tolerances on the wafer surface. It is equipped with a position encoder machine and specialize software to ensure precision and repeatability. The encoder tool is calibrated to move the grinding and lapping wheels on an absolute scale so that the motion of the wheel and the accuracies are repeatable. Additionally, the software provides for different lapping modes, which provide the ability to lap, grind and polish either very accurately or rapidly depending on the needs of the wafer production. 2L is designed to be user friendly and allow for rapid setup and operation. To initiate the process, a simple control panel is used to enter the parameters for the wafer grinding, lapping and polishing process. This includes the grinding time required, the lapping mode, and the desired grind and lapping properties. Once these parameters have been entered, the asset automates the process and begins grinding, lapping and polishing the wafer automatically while monitoring progress. BROWN & SHARPE 2L is designed for a wide range of applications and provides a precision finish on wafers with high throughput and yield. With a long lifecycle and low energy consumption, it is the perfect model for both production and research and development.

There are no reviews yet