Used BROWN & SHARPE 612 #9209352 for sale

URL successfully copied!

Tap to zoom

ID: 9209352

Surface grinder

With magnetic chuck

Travels: 6 x 12

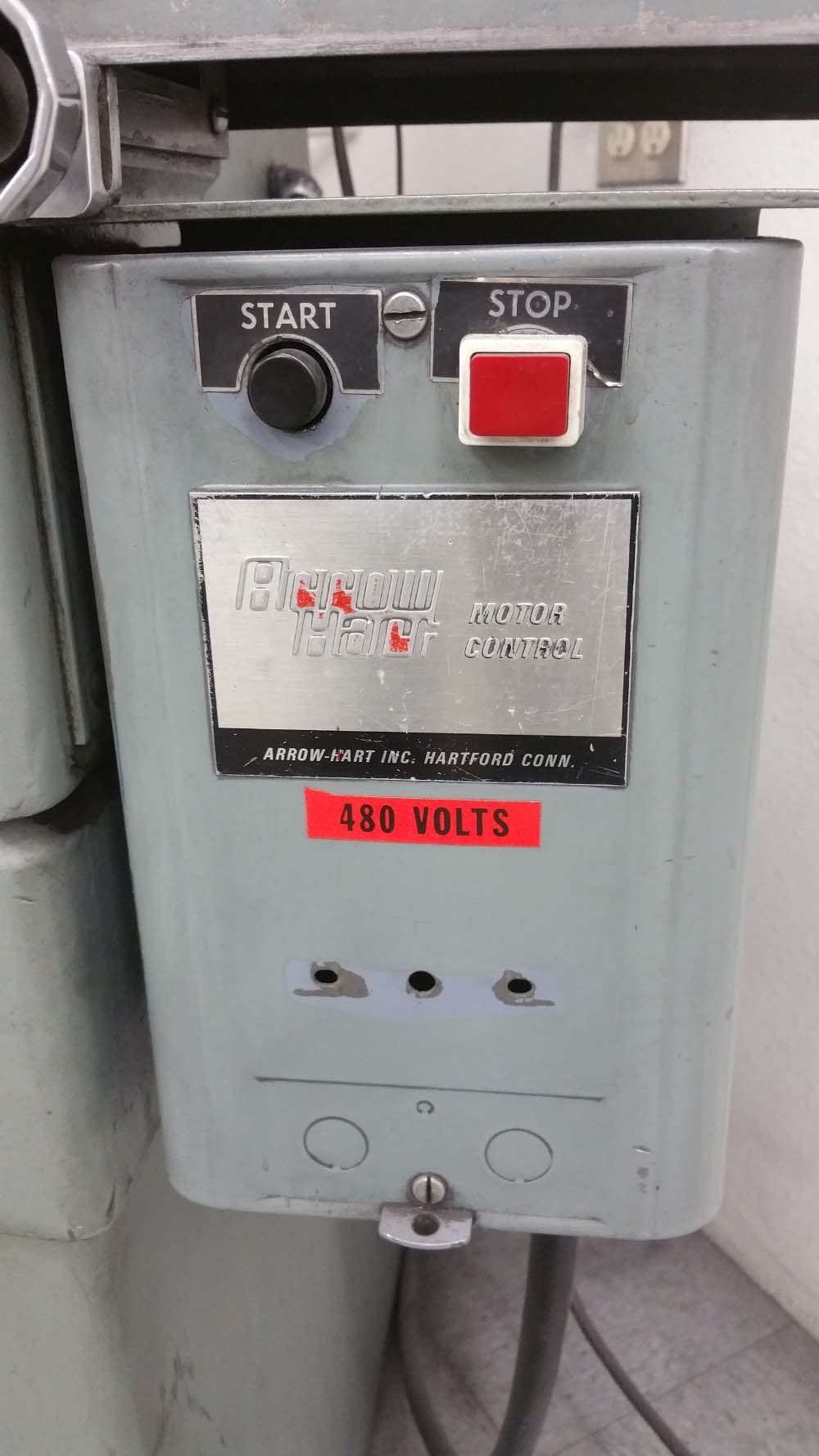

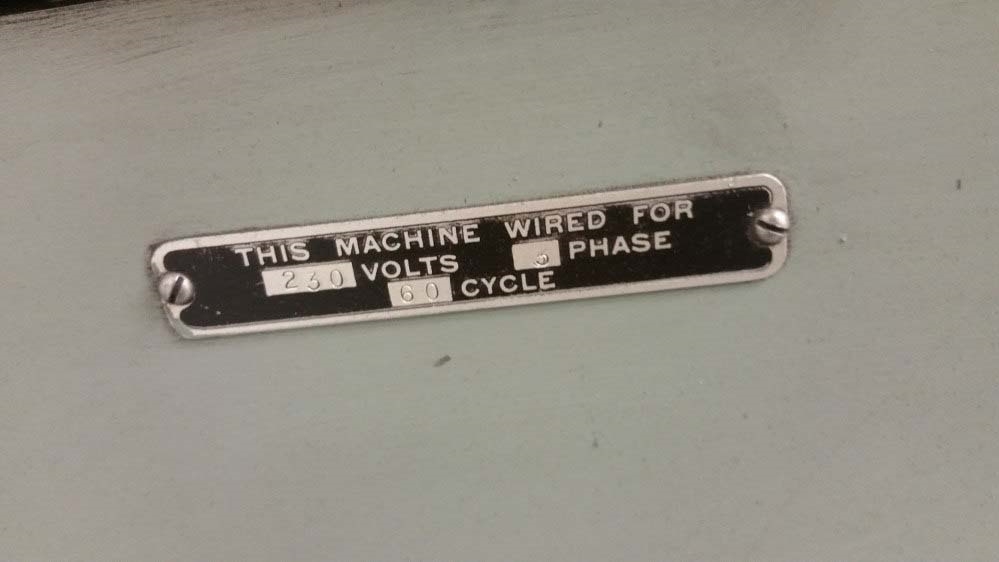

Power: 480 V / 3 Phase

Features:

HITACHI Magnetic chuck: 6 x 12

Electro-magnet chuck control.

BROWN & SHARPE 612 is an automated wafer grinding, lapping, and polishing equipment from UNITED GRINDING. The system is designed for high-precision wafer processing and the utmost precision in lapping and polishing. It is an efficient, versatile, and high-performance unit that is suitable for virtually any wafer production process. The machine features a powerful dual grinding head, each with a dedicated spindle for maximum productivity. The spindles are driven by high-torque four-pole synchronous motors for superior accuracy and repeatability. The unit also features a large cooling fan, preventing damage to the motor and grinders. The unit is customized with a variety of tools, discs, and lapping supplies specifically designed for wafer grinding. The grinding discs are manufactured with a special diamond grinding compound to provide ultimate accuracy and precision. The polishing disc is constructed with an aluminum oxide surface to reduce surface abrasion and distortion. The wafer lapping discs use a combination of diamond particles and spindle-power to achieve smooth and consistent edges. 612 is a fully automated grinding and polishing tool that is programmed to grind and polish multiple wafers simultaneously. The asset includes an intuitive operator control panel for full programming flexibility. With the operator control panel, it is possible to create an accurate and repeatable sequence of grind and polish steps. All of these steps can be modified or customized as needed for any specific wafer production process. Furthermore, the unit offers a self-diagnostic feature which is capable of quickly detecting and correcting any errors in the grinding and polishing process. This model also includes an automatic stop detection function, which is designed to shut down the unit in case of abnormal pressure, temperature, or noise. BROWN & SHARPE 612 uses a user-friendly visualisation equipment, making it possible to easily and quickly visually inspect wafer processing. This feature provides both usability and reliability. Finally, the system is equipped with an integrated dust monitoring and extraction unit, ensuring a clean and safe work environment. 612 is an extremely versatile, precise, and high-performance machine that is ideal for any wafer grinding, lapping, and polishing needs. Its fully-automated settings, intuitive control panel, and visualisation tool provide a comprehensive and advanced asset for any wafer production process.

There are no reviews yet