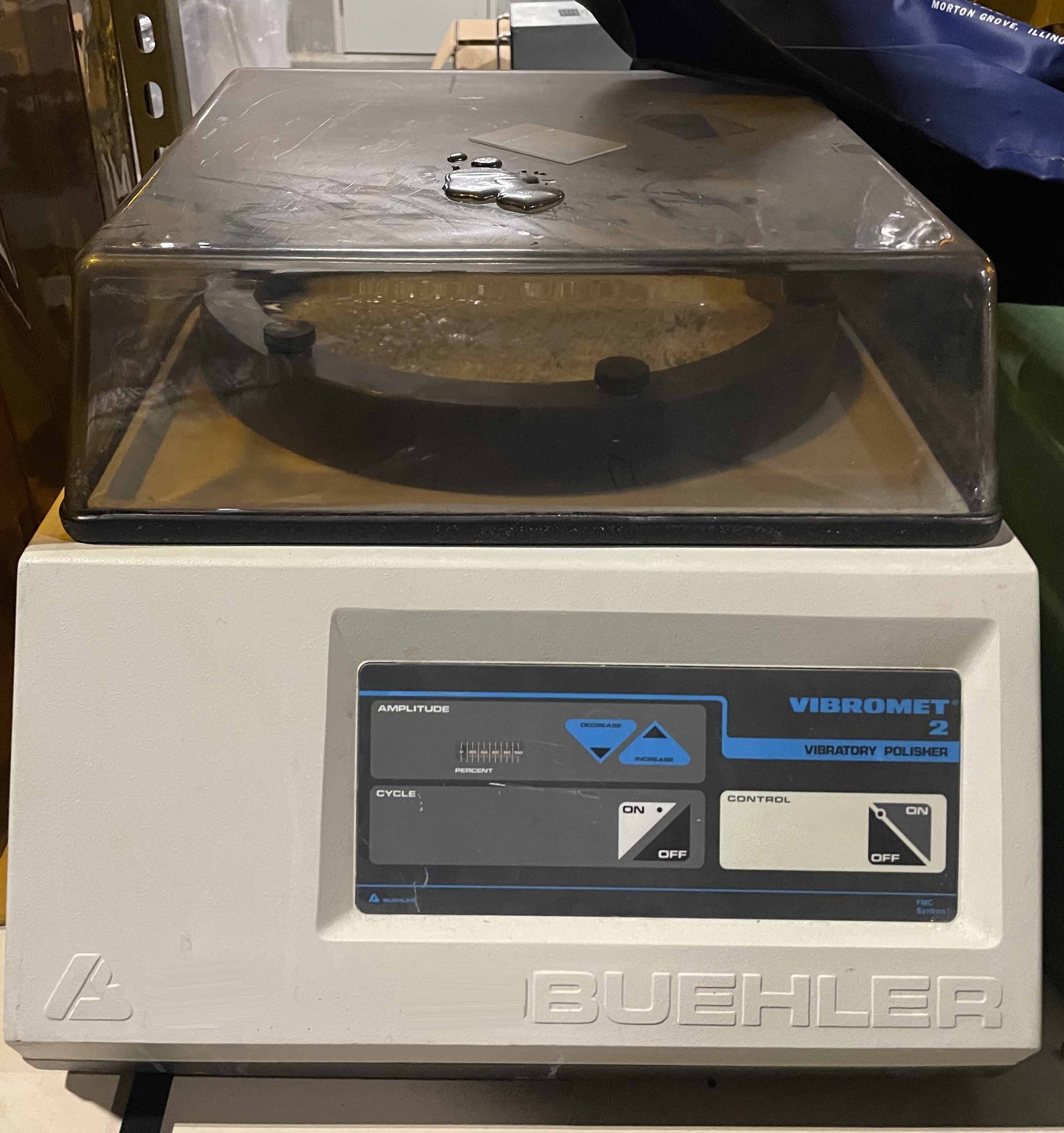

Used BUEHLER 67-1635-160 #9389295 for sale

URL successfully copied!

Tap to zoom

BUEHLER 67-1635-160 is a grinding, lapping and polishing equipment designed for semi-automatic sample preparation of semiconductor wafers. It is capable of providing rapidly varying pressure and velocities for a wide range of engineering materials such as silicon and gallium arsenide. The system utilizes state-of-the-art microprocessor-based technology that provides optimal efficiency and excellent control. The unit is composed of a wet processing station, lapping station, and a polishing station. It offers a quick change wafer cassette holder that accommodates 4-inch or 6-inch wafers, and a working height calculator that automatically adjusts the working height for optimal process control. The wet station is a single-chamber design has two integral tanks, one for cleaning and the other for rinsing. It provides precise and efficient wafer cleaning with consistent results. The lapping station has a rapid exchange positional table that provides fast and accurate levelling of the wafer surface. The lapping compound is applied to the wafer surface, and then the grinding head is set to the desired height. The head is oscillated at the preset velocities for uniform coverage. The ability to provide adjustable speed and pressure settings grants precise fine-tuning for desired results. The polishing station has two processing stages. The first is an aggressive polish that utilizes a slurry to remove scratches and residues left from the lapping process. This process is especially important if the semiconductor material needs to be evaluated for photoluminescence or electroluminescence. The second stage is a gentle polishing that removes fine surface particles and leaves the material with a matte finish. The machine is based on statically balanced, low-vibration motors and clutches that enable precise control over the polishing process with minimal heat buildup. 67-1635-160 is a powerful and reliable semi-automatic tool that provides exceptional control over grinding, lapping, and polishing processes. It is ideally suited for various types of semiconductor materials that require precise and uniform surface finish. The asset provides quick and easy operation, further accentuating its value for manufacturing industries.

There are no reviews yet