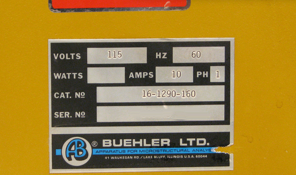

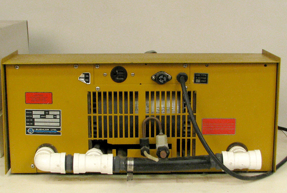

Used BUEHLER DuoMet 2 #127977 for sale

URL successfully copied!

Tap to zoom

ID: 127977

Belt Surfacer and Polisher

Includes:

Accessory belts

2 hp, 373W fused motor

Separate belt flushing

Coolant controls.

BUEHLER DuoMet 2 is a compact, powerful and versatile equipment built for wafer grinding, lapping and polishing. It is a dependable and modern system designed specifically for manufacturing high-quality substrates for various industries such as automotive, aerospace and semiconductor. It is able to perform backgrinding, wafer thinning, surface finishing, angle and radius grinding, milling and polishing operations with ease. The unit is equipped with a dedicated BUEHLER automatic wafer handling (AWH) machine with tool changers, high-precision glass scales and robot arm chassis. This ensures precise high-speed handling and uniformity of wafers prior to processing. BUEHLER grinding, lapping and polishing tool also includes a high-precision grinding spindle and a dual-platen design for improved accuracy and flexibility in production. Its high spindle speed can reach up to 7500 rpm and the matching polishing platen can rotate up to 5700 rpm. It also has a user-friendly touch-screen GUI interface for easy operation and automated parameters adjustment. The asset is also capable of grinding and polishing wafers to a large range of thicknesses ranging from 300 microns to 10 microns, as well as working with a wide range of substrates such as Sapphire, Glass, Graphene and Silicon. DuoMet 2 is a safe, reliable and precise model that has a long working life and produces uniform and quality results. It is fully automated and can be integrated into an automated manufacturing environment. The equipment also has a high production yield rate and is easy to maintain. The system has a small physical size and can be installed in tight spaces, making it ideal for production on single or multiple wafer lots. Overall, BUEHLER DuoMet 2 is an advanced wafer grinding, lapping and polishing unit with advanced features for smooth and fast operations. It is a practical solution for achieving high-quality substrates and can provide cost-effective substrate processing.

There are no reviews yet