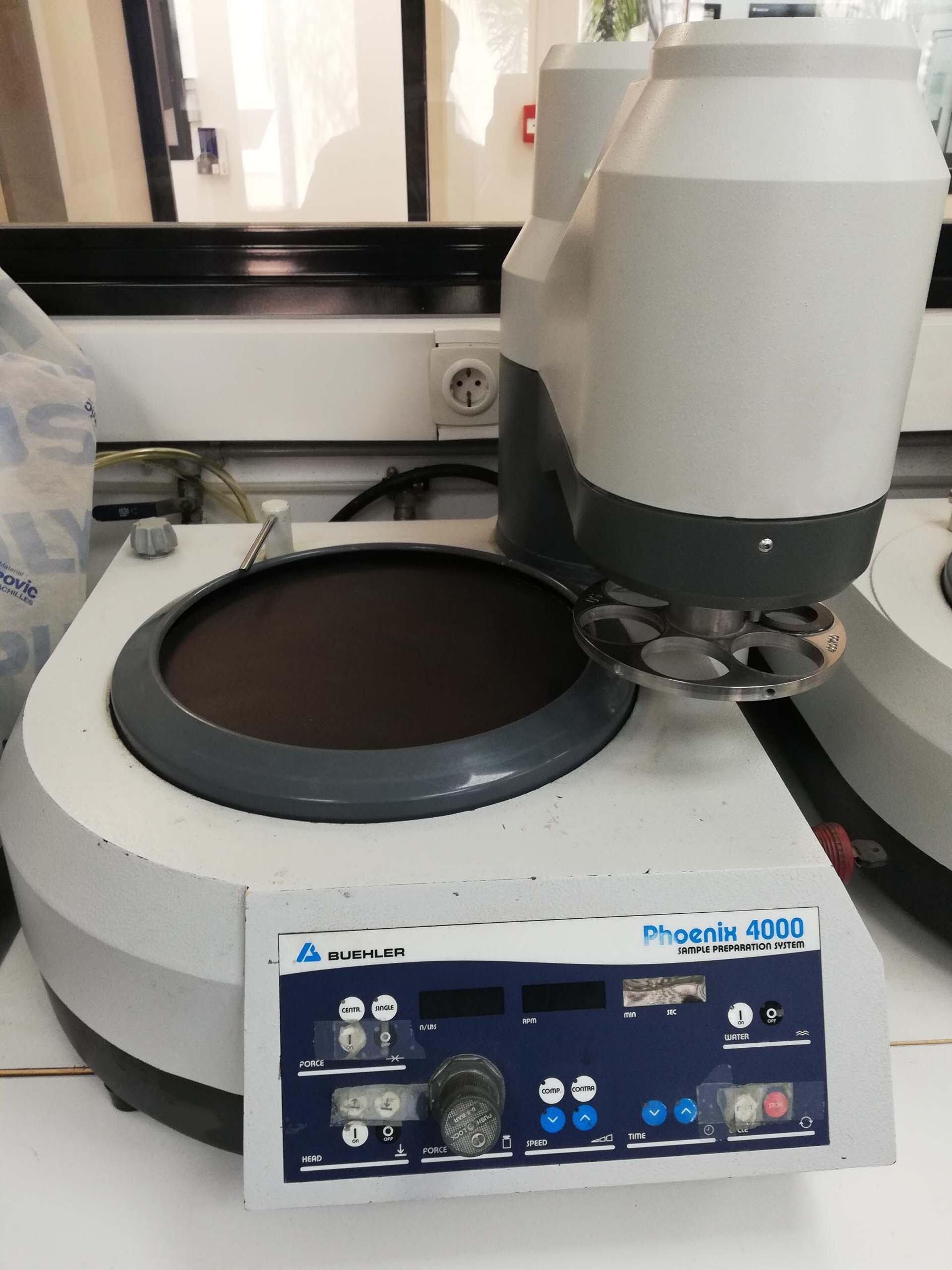

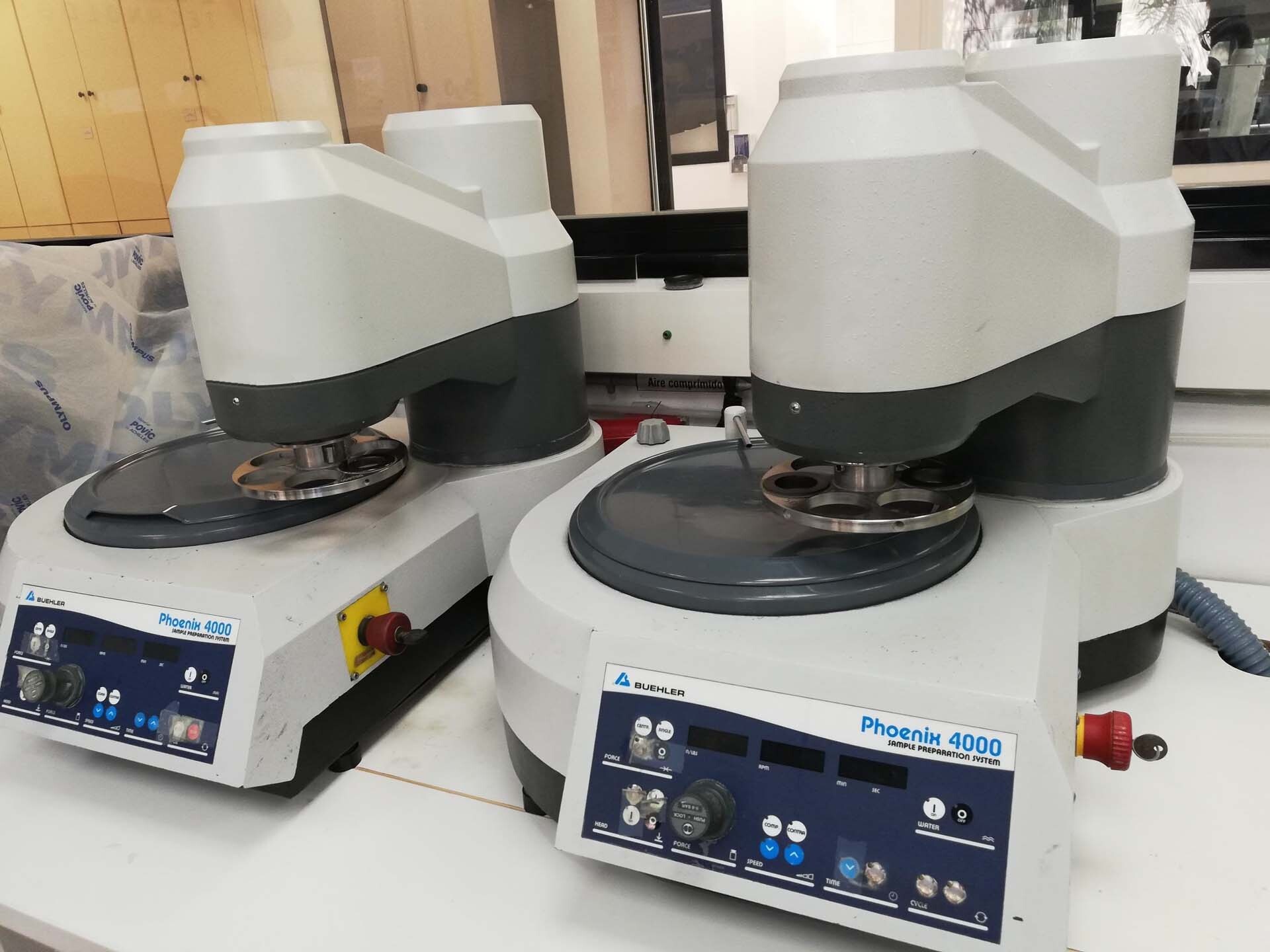

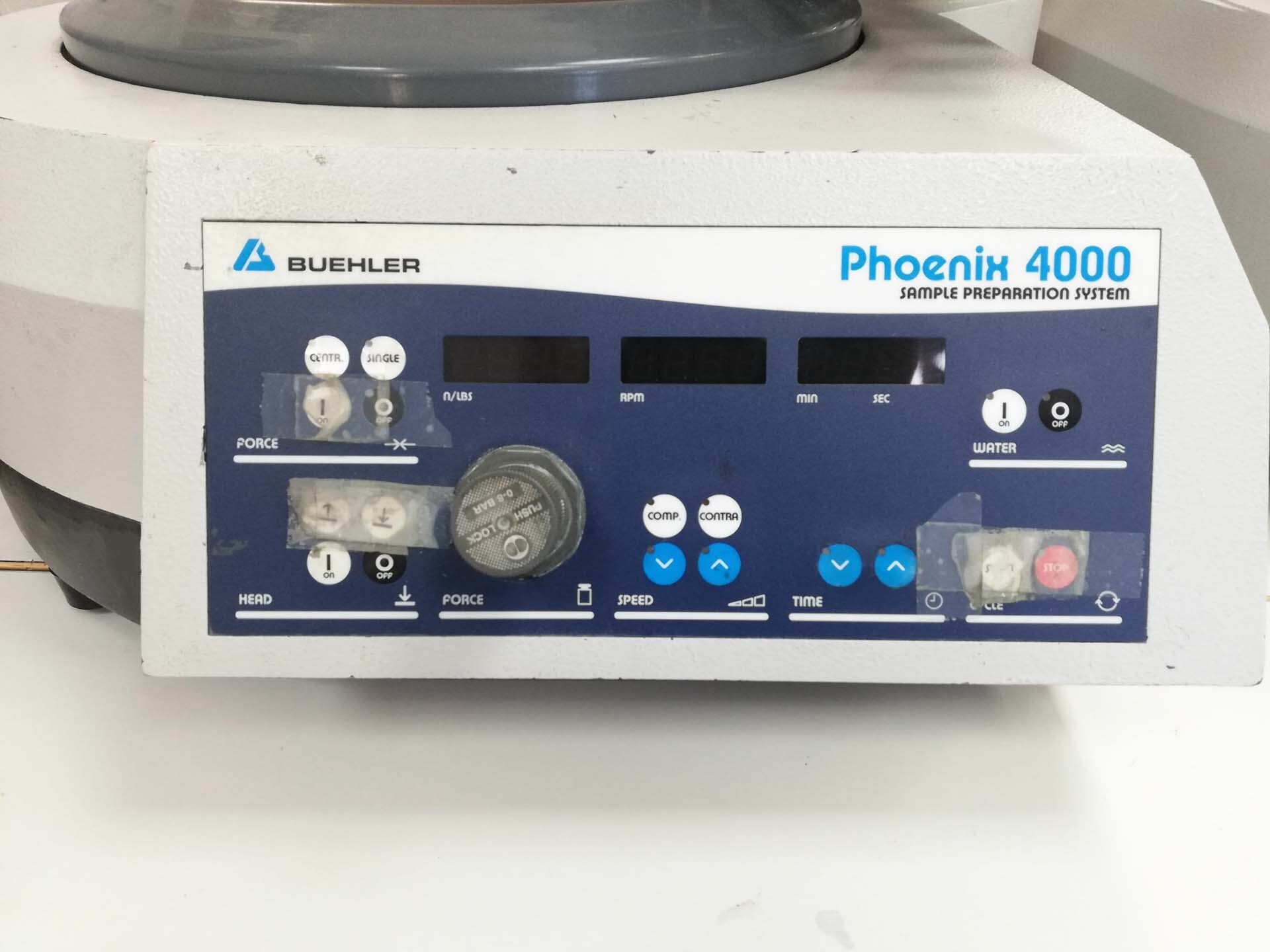

Used BUEHLER Phoenix 4000 #9377666 for sale

URL successfully copied!

Tap to zoom

BUEHLER Phoenix 4000 is a wafer grinding, lapping and polishing equipment for use in the semiconductor industry. This system is designed to grind, lap and polish wafers up to 8" in diameter in an automated, high precision environment. It is capable of handling large production runs, with process recipes stored in up to 50 onboard memory slots. Phoenix 4000 is equipped with a powerful DC motor and a high torque drive for precise grinding and lapping actions. The spindle speed and force are adjustable to fine tune the grinding and polishing parameters. An integrated water nozzle feature provides the necessary cooling and lubrication for the removal of imperfections in the wafer surface. BUEHLER Phoenix 4000 also features a diamond wafer head which is designed to provide a smooth grind with no burrs or pits. The wafer head can be adjusted for different thicknesses for optimal performance. A number of accessories are available to customize the wafer grinding, lapping and polishing process. These include a number of abrasive diamond grinding wheels, an active cooling unit, and a range of lapping slurries. Phoenix 4000 also includes an array of enhancements to automate the grinding and lapping process. These include an advanced vision machine to monitor the wafer's progress and a user-friendly interface with touch screen controls for easy process editing and analytical functions. A full range of analytical tools are available to monitor wafer temperature, wafer hardness, and surface finish. The built-in datalogging feature records and stores process parameters and data for future recall and analysis. BUEHLER Phoenix 4000 is an innovative tool for high precision grinding, lapping and polishing of wafers in the semiconductor industry. It offers superior performance, built in analytical tools, automated process control, and a range of accessories for a customized process.

There are no reviews yet