Used BUEHLER Techmet #9033153 for sale

URL successfully copied!

Tap to zoom

ID: 9033153

Table

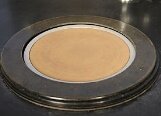

Dual 8” variable speed Polimet I polisher/grinders

100-1200 RPM

Stainless steel sink

Cat no. 48-1582/ 47-1870

52.5” x 27” x 36” working height

115v, 60hz, 12.48amps.

BUEHLER Techmet is a state-of-the-art wafer grinding, lapping and polishing equipment from BUEHLER, an ITW Company. The system is designed for both production and research applications, providing precise, repeatable results. The unit consists of an integrated, tabletop chassis that houses several subsystems. The lapping and polishing operation is supported by an automated platen computer-controlled planetary machine. This can accommodate up to six 8" wafer carriers, each with a maximum diameter of up to 200mm. The tool is designed to provide lapping and polishing parameters to achieve specific performance requirements. The grinding stage features an advanced high speed, servo-controlled linear motor asset with a wide range of motion over the wafer surface. The adjustable spindle depth ranges from 6 to 64 microns to precisely control the grinding process. Additionally, the model features an Intelligent End Point Detection subsystem that allows one to accurately monitor and adjust the grinding parameters. The polishing operation is also automated and controlled via adjustable speed, run-time, and force parameters. Techmet features an on-board high-resolution Imaging profiler, programmed to measure the reshapen profile of the wafer surface. This allows for the precise measurement of critical dimensions for optimization, as well as verification and quality control. The intuitive user interface consists of Windows-based operator control, featuring a touchscreen for ease of use. Additionally, BUEHLER Techmet is designed to provide analysis and SPC data acquisition. This allows for greater process control, helping to ensure that desired specifications are consistently achieved, higher yields are realized, and waste is reduced. In summary, Techmet is an advanced wafer grinding, lapping and polishing equipment designed to make precision parts with accuracy and repeatability. The integrated and automated system features a high speed, servo-controlled linear motor unit, adjustable speed, run-time, and force parameters, and an on-board high-resolution Imaging profiler. The intuitive user interface, diagnostic systems and SPC data acquisition provide the powerful tools necessary to ensure optimal performance.

There are no reviews yet