Used CHEVALIER FSG-3A818 #9242311 for sale

URL successfully copied!

Tap to zoom

ID: 9242311

Grinding machine

Table surface to spindle center line: 17"

Includes:

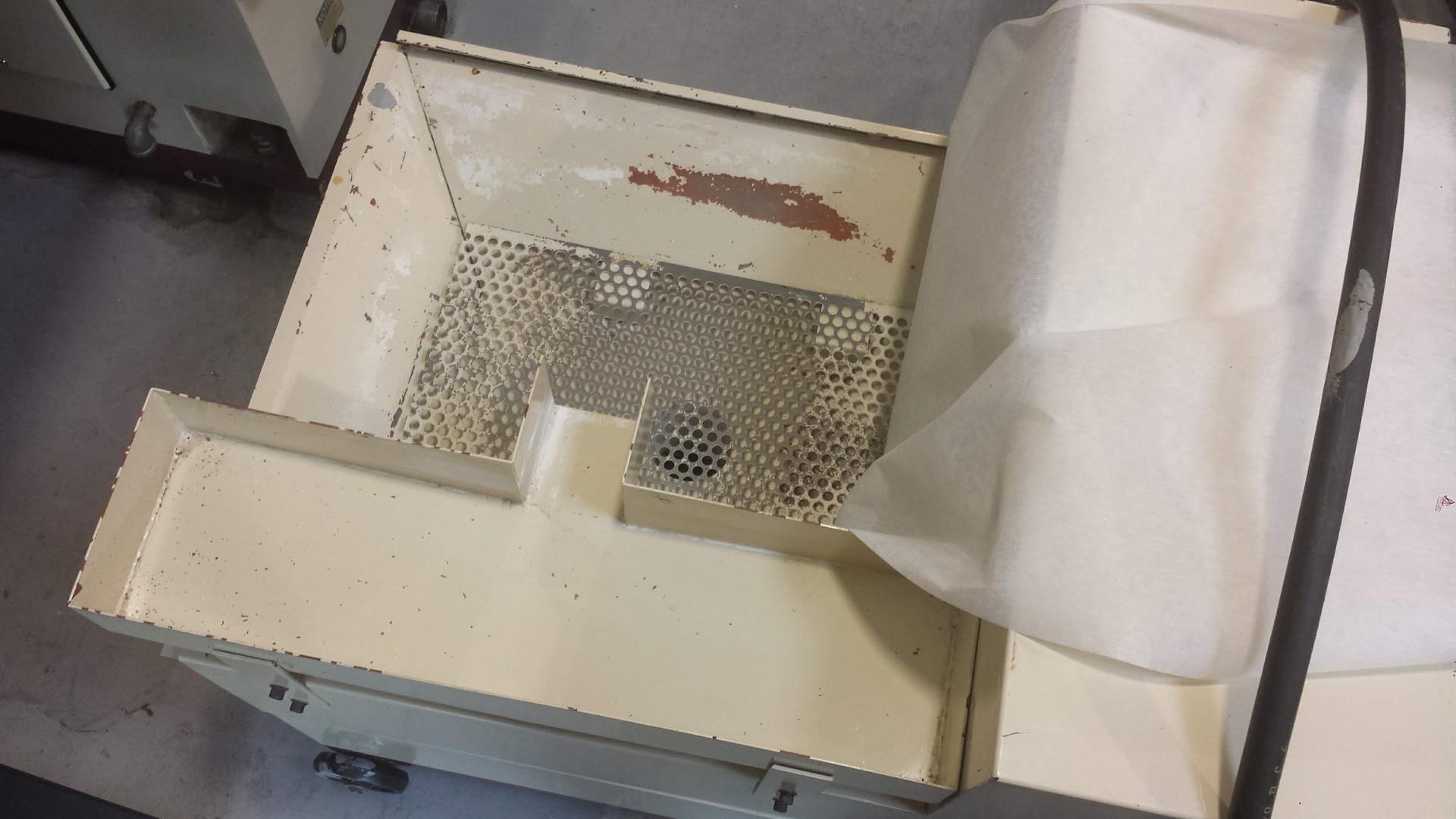

Coolant tank with paper filter

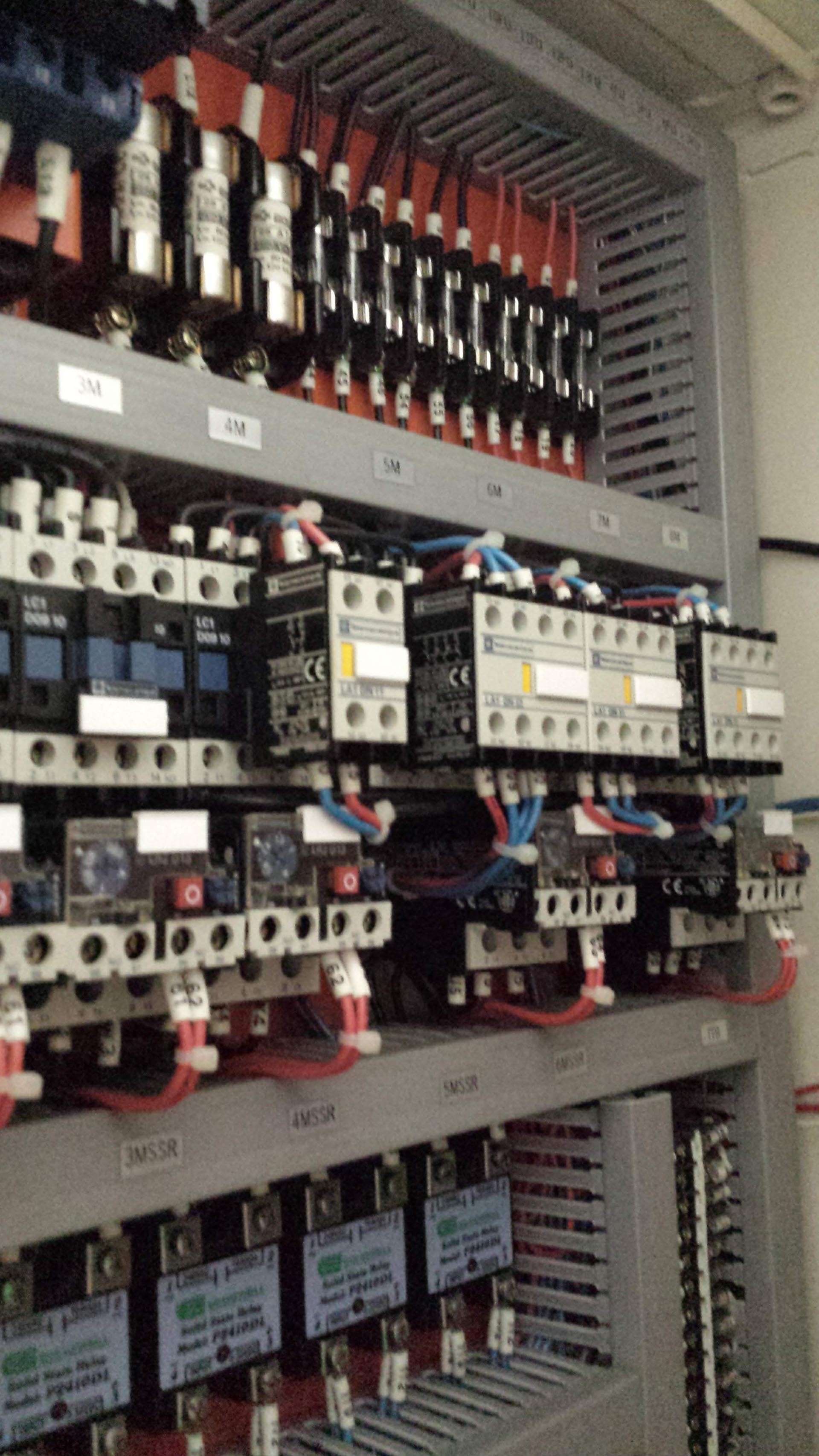

Machine with control arm / Digital read out

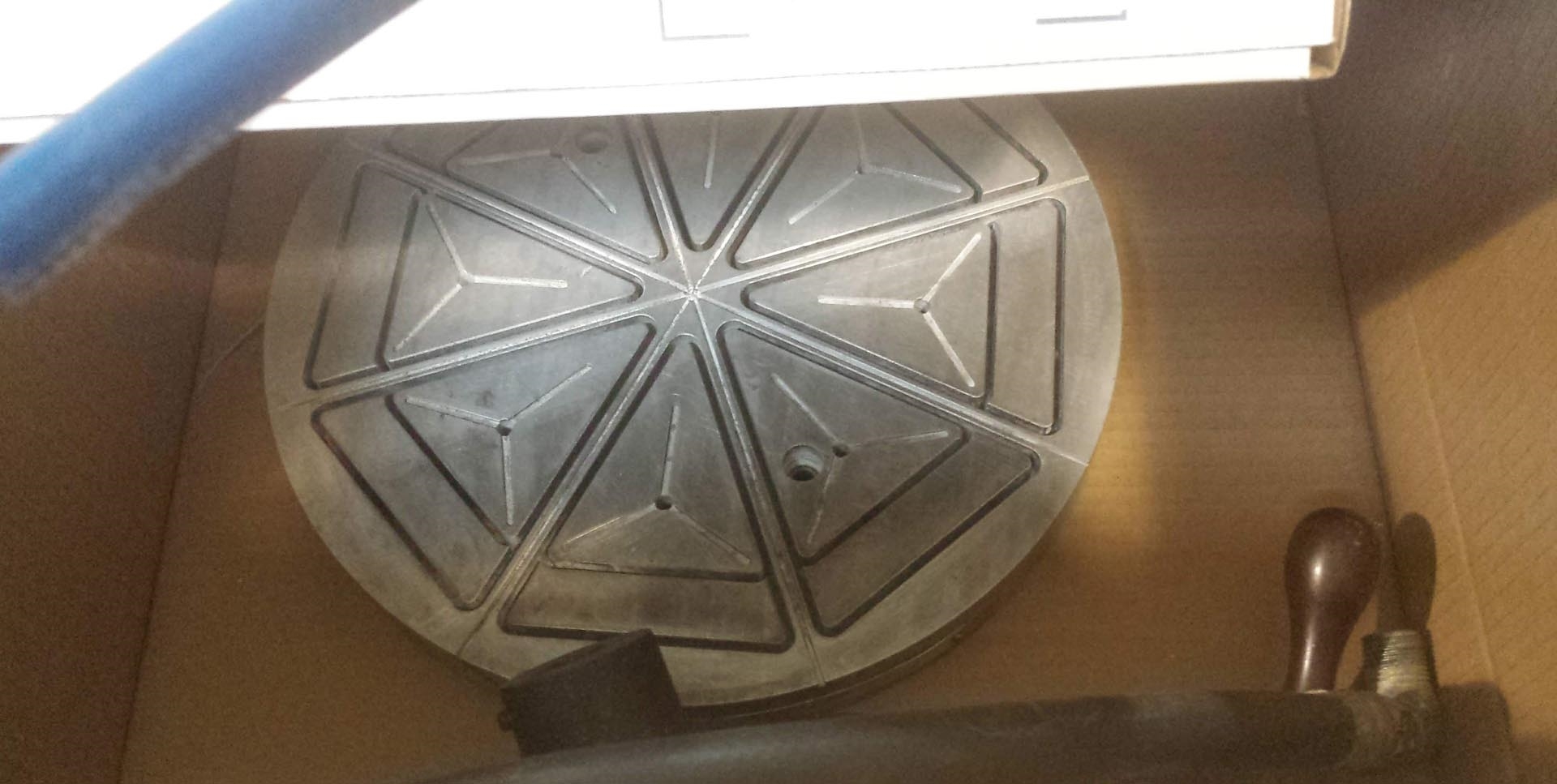

Round vacuum chuck and accessories

Hydraulic unit

Manuals

Spare parts

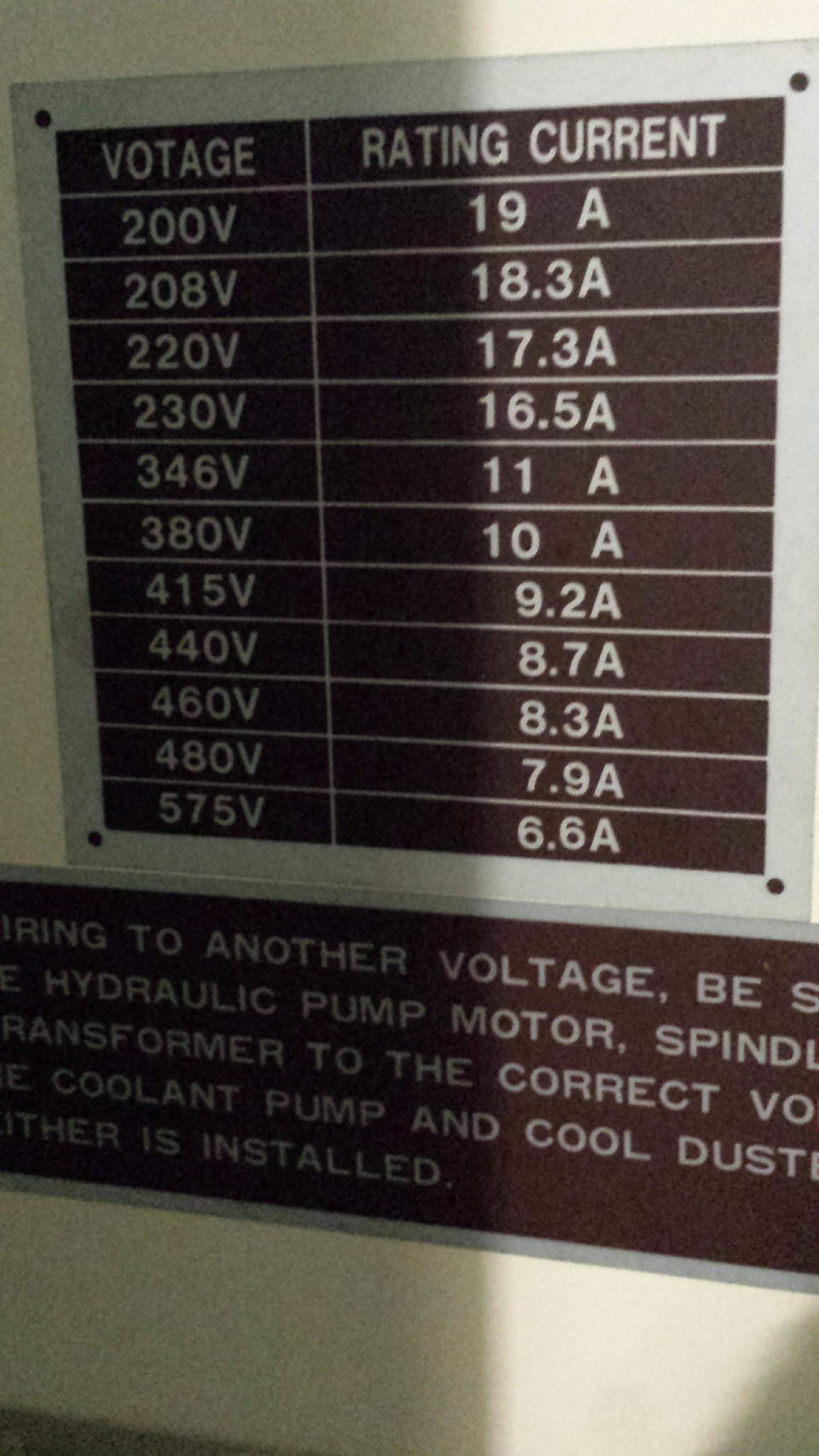

Table speed: 16~82 FPM

Spindle drive speed: 60 Hz / 3, 450 RPM, 50 Hz / 2, 850 RPM

Spindle drive power rating: 2 HP

Hydraulic drive power rating: 1 HP

Cross feed drive power rating: 0.05 HP

Elevating drive power rating: 0.25 HP

Rated power: 5 HP.

CHEVALIER FSG-3A818 is a wafer grinding, lapping & polishing equipment designed for the process of precision finishing of different wafer surfaces. This system is well suited for high-precision processing of large area opto-electronic, semiconductor, optics and flat-panel industries. The step motor driven cross-slide unit of FSG-3A818 ensures precise positioning over the full range of travel and a mechanical precision of less than 0.0005mm. The grinding, lapping and polishing unit of the machine provides a maximum grinding area of 16 inches x 8 inches and a polishing area of 16 inches x 8.5 inches. The operation table of the tool is provided with an air floating asset for easy adjustment of the table height, thereby ensuring smooth movement of wafers. CHEVALIER FSG-3A818 is equipped with a powerful and efficient servo model that enables high-precision grinding, lapping and polishing of the wafers under tight control. The equipment uses a single grinding wheel which is designed to decrease wheel loading and enhance the lifespan of the grinding wheel. The grinding wheel automatically detects and compensates for the surface of the wafer, making it easy to control the process. The system is also equipped with a built-in obscuration unit which allows for quick and effective grinding and polishing of the wafers. This machine uses a single set of parameters for every wafer, reducing wastage of time in setting up and changing the parameters. The machine also features a wafer cooling tool which helps to reduce the thermal load on the grinding wheel and ensure consistent temperature across the entire wafer. This asset is also designed with safety features such as emergency stop, power failure detection model and machine control equipment that help to provide the machine with improved safety and reliability. FSG-3A818 is an efficient and reliable system, capable of achieving superior grinding, lapping and polishing of large area wafers.

There are no reviews yet