Used CINCINNATI 2 #134544 for sale

URL successfully copied!

Tap to zoom

ID: 134544

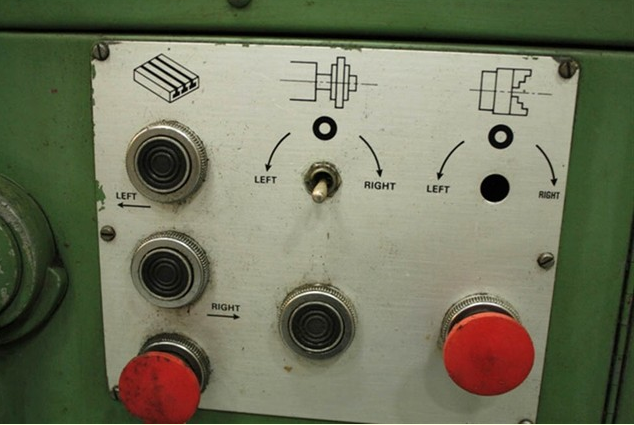

Tool and cutter grinder

Area of table: 36"x5.25"

Swing over table: 10"

Length between workhead and centers: 21.5"

Longitudinal travel: 21"

Cross travel: 8"

Table swivels: 180°

Vertical travel of wheel head: 7.5"

Swival movement of wheel head: 120° (either way)

Motor: 1.5 horse power.

CINCINNATI 2 wafer grinding, lapping & polishing equipment is designed to produce superior-quality polished components, while maintaining accuracy and repeatability. The system is capable of grinding, lapping, and polishing simultaneously, resulting in a high-precision polish finish. The machine utilizes two spindles, each of which can work independently to perform grinding, lapping, and polishing processes. The lapping spindle can be programmed to provide consistent polishing pressure and speed, while the grinding spindle can provide variable speed for the specific process. The grinding, lapping, and polishing processes are all inter-dependent, requiring careful control over each individual process step. 2 allows the user to make micro-adjustments to the machine's settings, ensuring that the desired results are achieved. The unit also comes equipped with an automated feeder station, capable of accurately aligning and delivering workpieces to the grinding, lapping, and polishing spindles. CINCINNATI 2 machine supports multiple wafer sizes, ranging from 8" to 16" in diameter. The tool also features programmable wafer diameter sensors for precise control over material splitting times. Additionally, 2 includes adjustable feed rollers that allow to easily adjust workpiece size and thickness. The asset allows for precise process control, with a wide range of parameters that can be adjusted to fit individual applications. The machine comes with a user-friendly graphical interface and can be connected to a computer for processing data feedback. This helps the user to monitor the model's performance in real time and make any adjustments or modifications as required. In addition to its grinding, lapping, and polishing capabilities, CINCINNATI 2 also supports a wide range of other processing methods. These include multiple wafer cutting, single wafer sanding, and cleaning processes. The cutting process is designed to reduce material waste and reduce polishing times. With its powerful cutting capabilities, 2 is capable of achieving the tightest tolerances with a minimum of material loss. CINCINNATI 2 wafer grinding, lapping, and polishing equipment offers a highly-precise solution for any precision component fabrication needs. This system is designed to be reliable and accurate, with a wide range of adjustable parameters that allows users to work effectively and efficiently. With its diverse range of processing and control options, 2 unit is an ideal solution for a variety of component fabrication needs.

There are no reviews yet