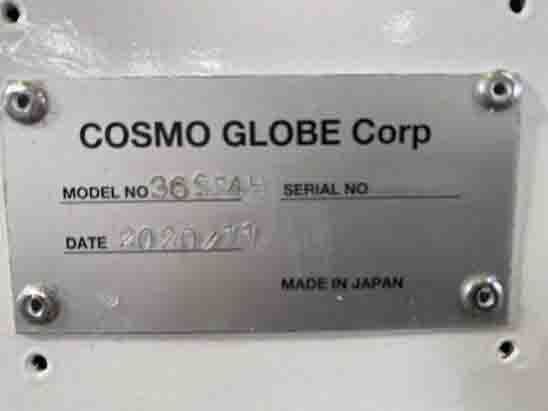

Used COSMO 36SP4H #293606211 for sale

URL successfully copied!

Tap to zoom

ID: 293606211

Vintage: 2020

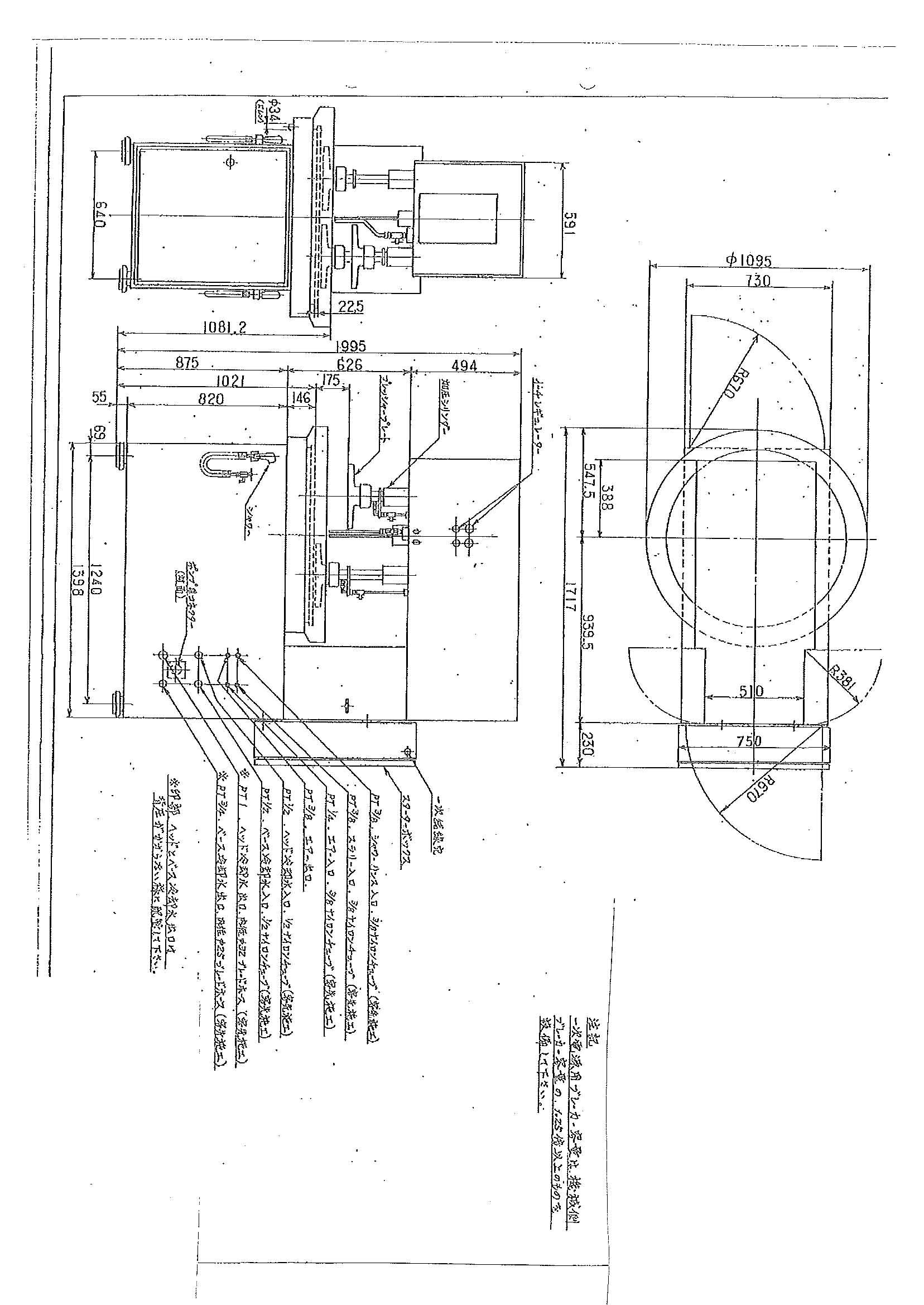

CMP Polishing machine

Surface plate diameter: 914 mm

Pressure plate diameter: 360 mm

Surface plate speed: 30-61 RPM

Ceramic plate dimensions: 360 mm x 15 mm

Water volume: 360 L/h

Cooling water temperature: 20°

(4) Air cylinders

Air pressure: 0.4 MPa

Air consumption: 50NL / 1 cycle

Surface plate drive motor: 11 kW

Pump motor: 100 V, 0.4 kW, Single phase

Operation circuit: 100 V, 50 Hz, Single phase

Power supply: 200 V, 50 Hz, 3-Phase

2020 vintage.

COSMO 36SP4H is an advanced wafer grinding, lapping and polishing equipment designed to provide very high precision, surface quality and flatness of wafers used in the semiconductor industry. This system features a heavy duty robust construction, consisting of a cast iron base, stainless steel and alloy construction that ensure maximum durability and performance. The machine has a working capacity of up to 6" (150 mm) diameter, which can process all types of materials. COSMO grinding platform is equipped with high precision diamond wheel, lapping plate and polishing disk, which reduces the processing times and ensures excellent surface finishing. In addition, the wheelhead is driven by a digital spindle motor for precise control and maximum accuracy. 36SP4H incorporates a "smart cloth" wheel turner technology that ensures a stable wafer relative position between the wheelhead and the grinding/polishing/lapping plates for higher accuracy. The machine also offers a range of pre-set grinding/lapping and polishing programs that can be selected according to the user's needs. COSMO 36SP4H is easy to use with the user-friendly interface and various safety features that ensure safety while using the machine. It has automatic computing technology that calculates the necessary settings depending on the size and type of the wafer automatically. The machine also includes a unique abrasive management unit that dynamically adjusts itself to ensure high quality and uniform surface finish with minimal waste production. The machine can be used for both wet and dry grinding/lapping/polishing processes. It is also equipped with a fully programmable cycle, motion and feed control technology that allows the user to customize the process and settings according to the application. The machine also features real-time monitoring that provides feedback to the user about the part causing any problems during the processing cycle. 36SP4H is designed to perform long-lasting and strong grinding, lapping and polishing operations. Its advanced microprocessor-based control machine uses a sophisticated motor control of both speed and torque. This ensures smooth metal removal, which provides surface finish quality results that cannot be achieved manually. The machine is also special for its superior grinding, lapping and polishing performance. It ensures precise accuracy and reliable repeatability in its operations even when working with high-tolerance wafers. Overall, COSMO 36SP4H is an ideal wafer grinding, lapping, and polishing tool for those who need precise flatness and quality on their workpieces. Its robust construction and sophisticated machinery ensure maximum durability, accuracy and quality performance. Its user-friendly control asset makes it very easy to use, while its unique abrasive management model minimizes waste production. The machine provides superior precision, accuracy and repeatability and is a great choice for those looking for an efficient and reliable wafer grinding, lapping and polishing equipment.

There are no reviews yet