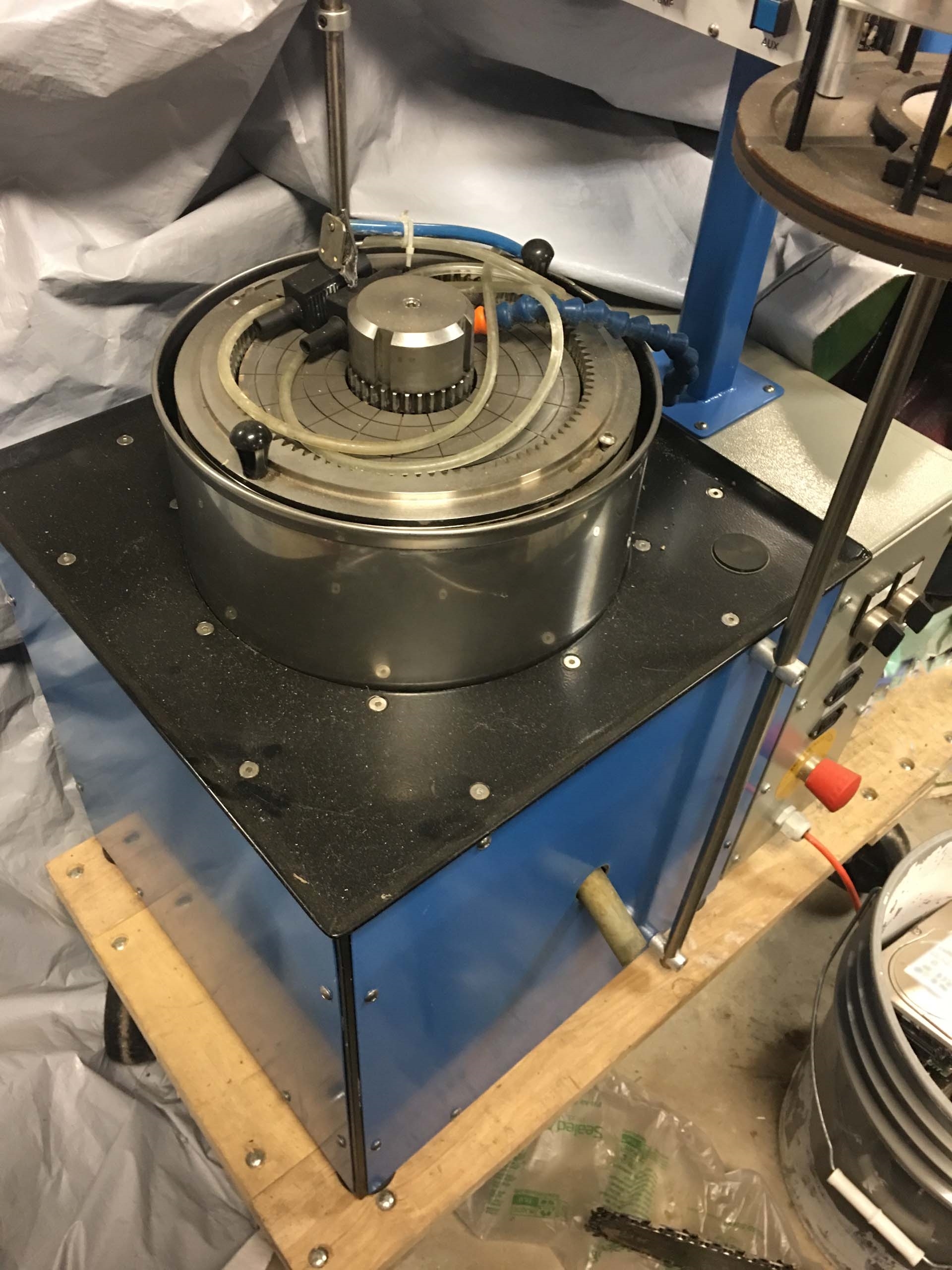

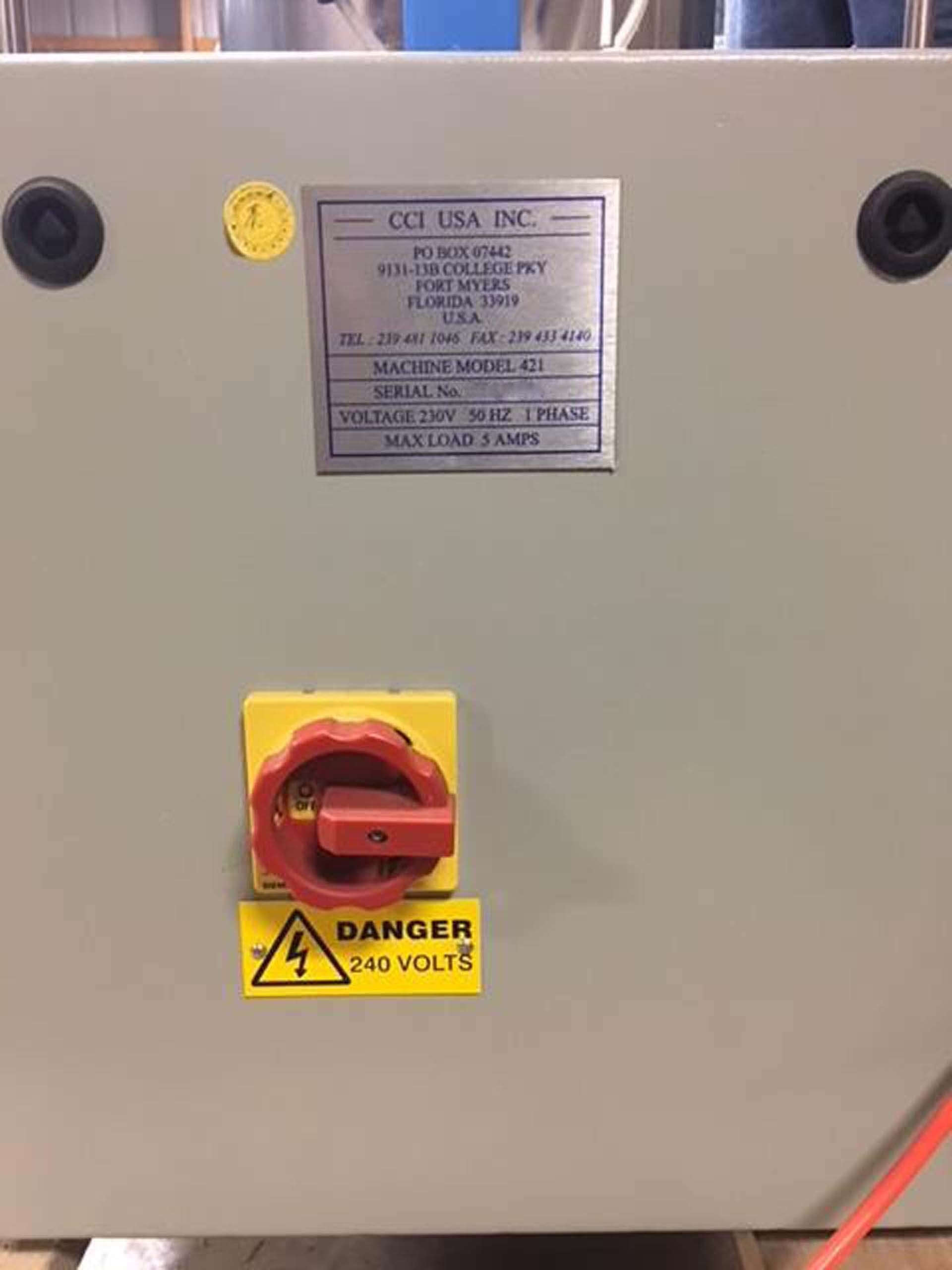

Used CRYSTAL COMPLETE INTERFACE / CCI 421 #9235963 for sale

URL successfully copied!

Tap to zoom

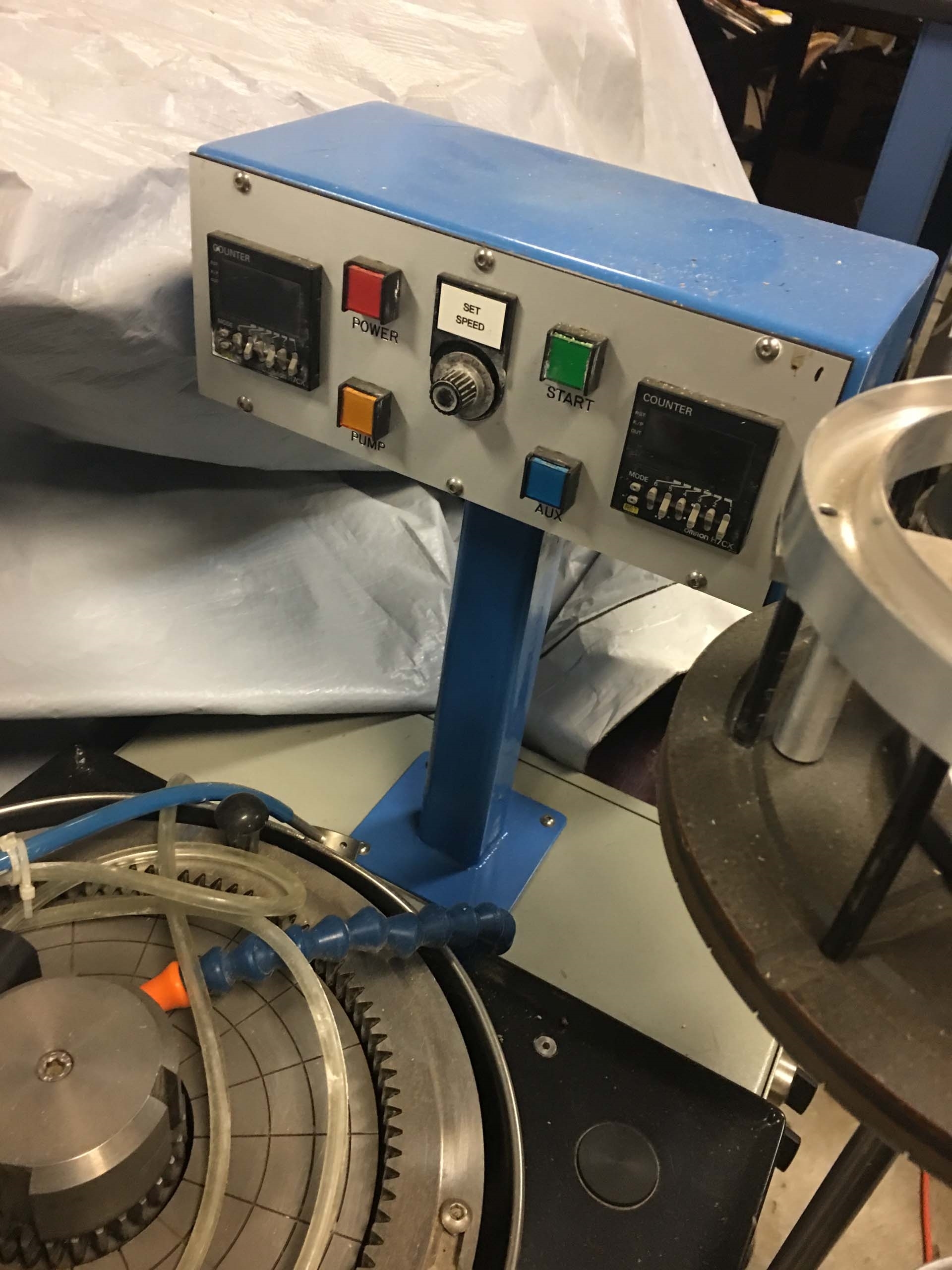

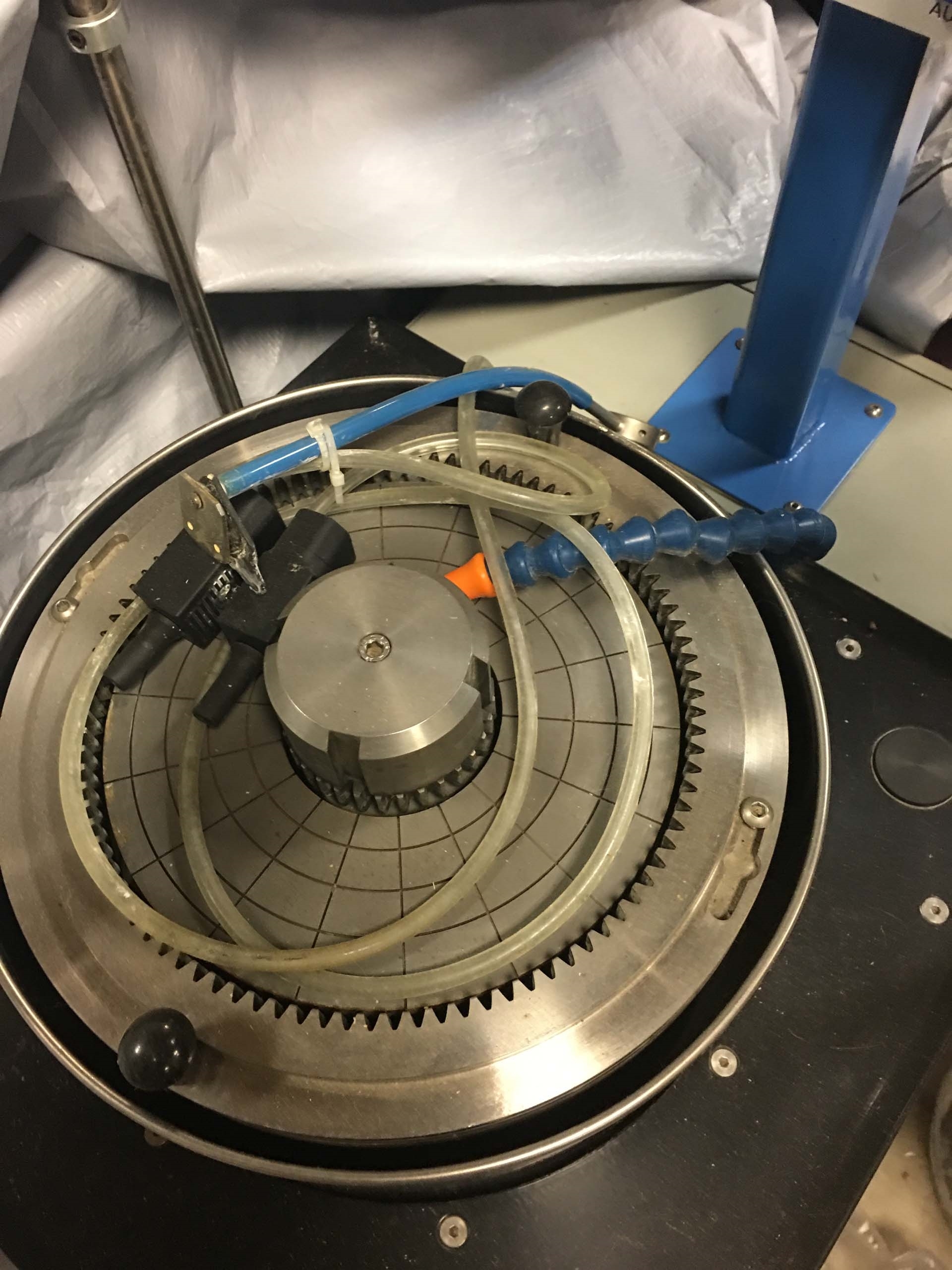

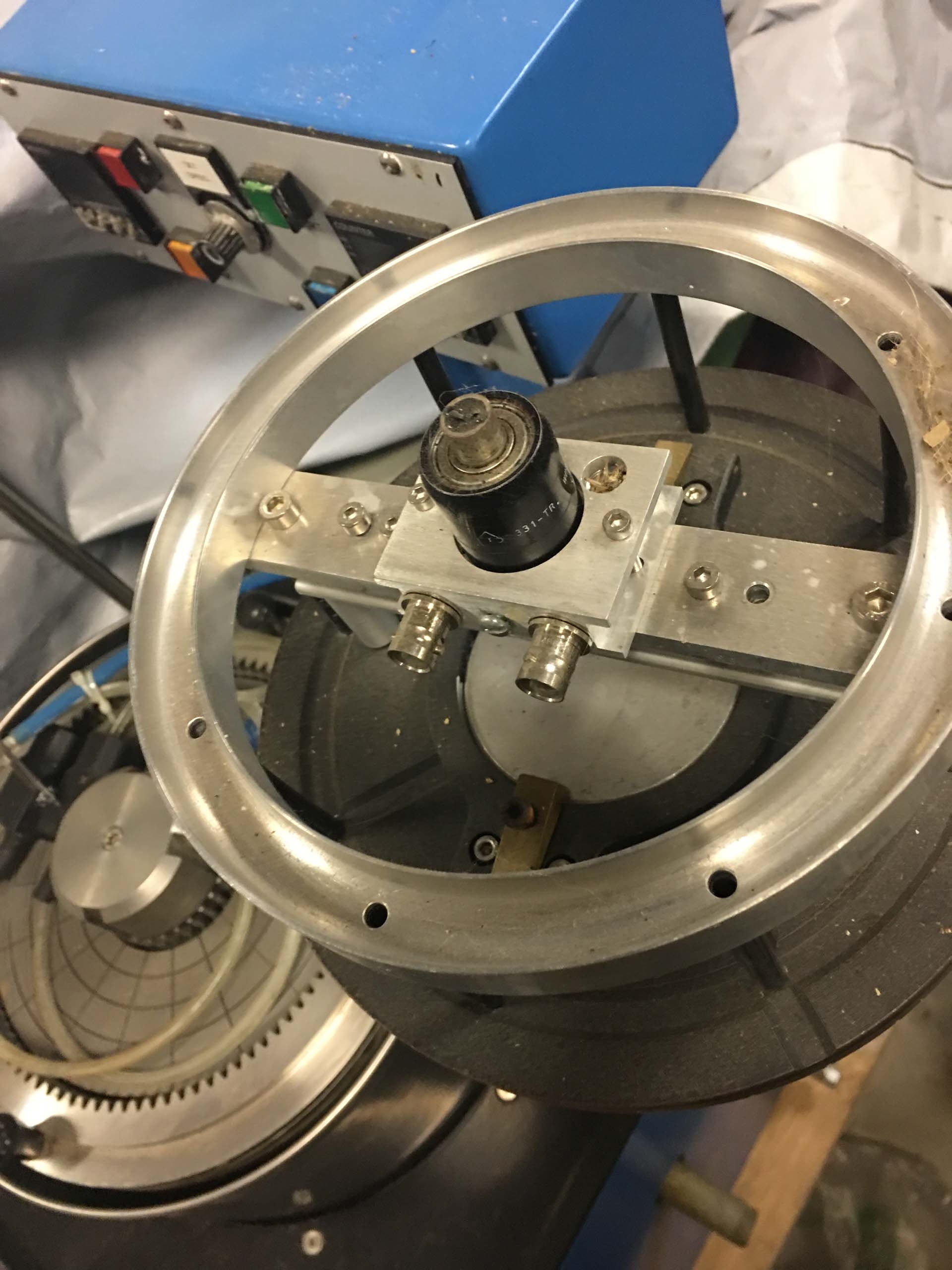

CRYSTAL COMPLETE INTERFACE / CCI 421 is a wafer grinding, lapping, and polishing equipment designed for the production of high-precision, ultra-thin semiconductor wafers. The system offers fast, efficient grinding and lapping to achieve tight tolerances and maximum surface accuracy without the need for extra clamping fixtures. CCI 421 offers a single platform solution for grinding, lapping, and polishing of large, complex and ultra-thin substrates. The unit is equipped with a single grinding, lapping, and polishing platform that allows for the production of wafers with the highest possible surface accuracy and uniformity. It is capable of reaching the tight tolerance requirements needed for today's advanced semiconductor wafer production. The design also offers a high level of automation, enabling the machine to automatically adjust the polishing process based on the substrate profile. This ensures optimal and consistent performance while greatly reducing cycle time and improving efficiency. CRYSTAL COMPLETE INTERFACE 421 has a vacuum table that securely clamps substrates during the grinding and lapping processes. It also has a computer-controlled cold-plasma ion tool that uses ionized air to accurately and consistently grind, lap, and polish substrate surfaces. The grinding and lapping processes are enhanced by the use of the tool's diamond grinding wheels, which provide maximum performance with minimal tool wear. The asset is designed for use in high-volume wafer fabrication environments. It is highly versatile, and can accommodate a wide variety of substrates, including single- and double-sided materials in various shapes, from 0.2mm to 2mm thick. The model is also capable of similar precision and repeatability on any material, including glass and metals. 421 is an ideal solution for the high-precision and high-volume wafer production required in the semiconductor industry. It offers an automated solution for accurate and repeatable grinding, lapping, and polishing of wafers, enabling manufacturers to increase throughput and efficiency while reducing costs.

There are no reviews yet