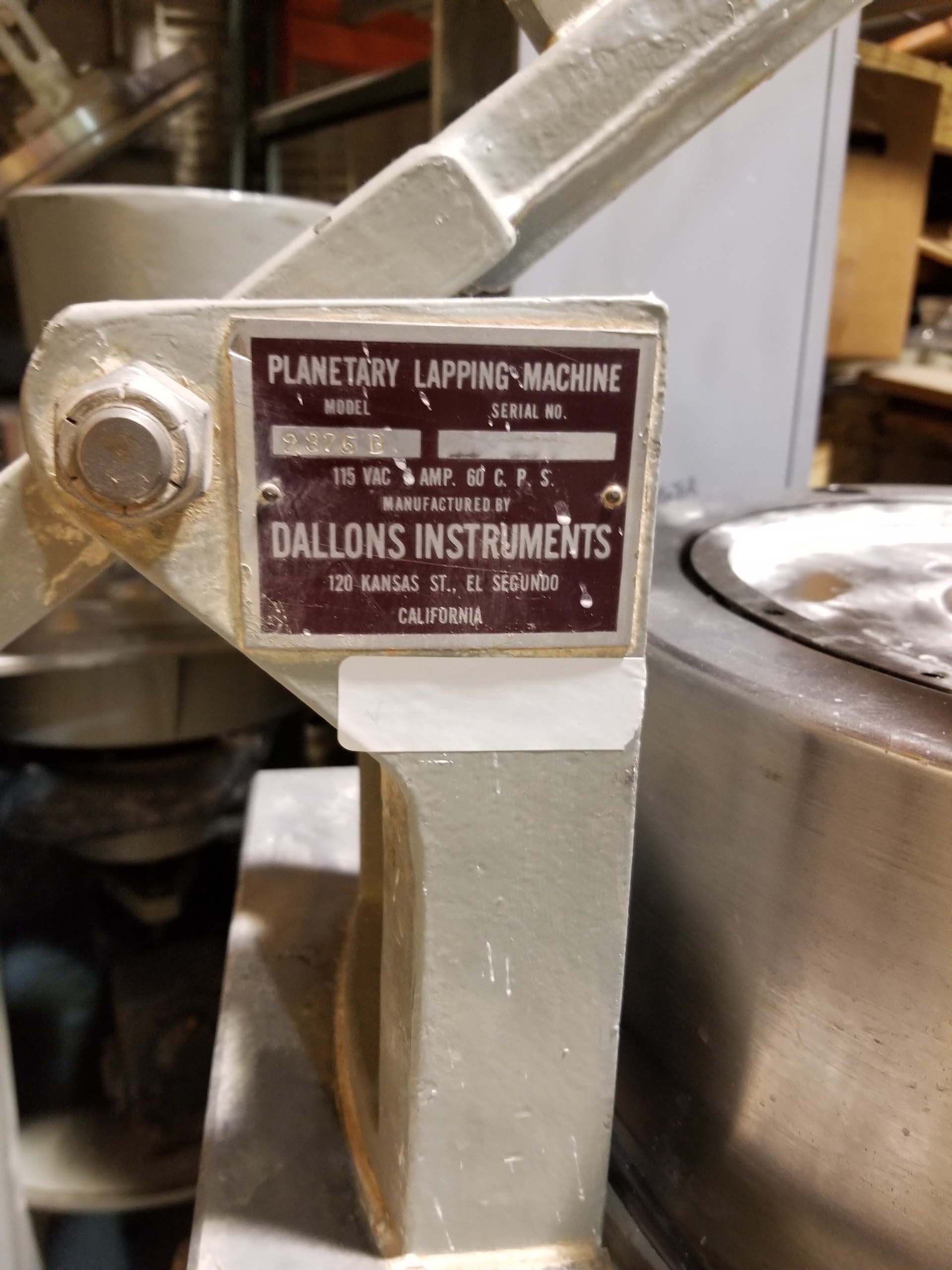

Used DALLONS INSTRUMENTS 8875B #9233102 for sale

URL successfully copied!

Tap to zoom

ID: 9233102

Wafer Size: 12"

Double side lappers / Polishers, 12"

Variable speed: 51 Tooth

Lapping plate: 12" Diameter

Cast iron laps

Carrier: 5" - 51 Tooth

Motor:

DC Gear motor

With controller

Power supply: 110 V, Single phase.

DALLONS INSTRUMENTS 8875B is a semi-automatic, programmable wafer grinding, lapping, and polishing equipment, designed to produce flat, defect-free surfaces on a variety of materials. This machine is designed to be used in wafer fabrication processes requiring high surface precision. It is appropriate for a variety of semiconductor applications, such as die grinding, edge trimming, and wafer lapping and polishing. 8875B operates on a two-axis system, featuring two vertical axes, one horizontal axis, and a torsional axis. These axes move and rotate grinding and polishing media to create a precise finish on the material being worked on. There is also a touch panel with a joystick control that the operator uses to adjust the axes and the pressure between them for an optimal grinding, lapping, and polishing process. The machine is equipped with an automated safety unit, featuring sensors that monitor the position of the grinding and lapping media to ensure that the material's surface is not significantly damaged in the process. The machine also features a remote monitoring machine that allows multiple users to view the machine's performance and the material surface from a remote location. To maximize workflow, DALLONS INSTRUMENTS 8875B includes a highly efficient vessel loading tool. This asset allows operators to load, unload and store vessels quickly and accurately. It eliminates the need to manually load and unload vessels during the process, thus reducing grunt time. Vessels can also be loaded directly into the model to save time and effort. 8875B is a fully automated equipment, meaning it can be run without constant operator supervision. This system can provide optimum grinding/lapping performance with accuracy and repeatability, making it ideal for developing complex structures, such as those needed for advanced semiconductor fabrication processes. The unit can be outfitted with a variety of accessories, such as a multichamber cooling machine, to further enhance its capabilities. The reliable construction of DALLONS INSTRUMENTS 8875B ensures that it can withstand rigorous production requirements. In summary, 8875B is a semi-automatic, programmable wafer grinding, lapping, and polishing tool that is designed for high surface precision and repeatability, making it ideal for complex semiconductor fabrication processes. It features an automated safety asset, remote monitoring, and a highly efficient vessel loading model that allows for quick and accurate vessel changeover and storage. This equipment also includes various accessories depending on the process needs, making it a reliable and efficient solution for modern semiconductor production.

There are no reviews yet