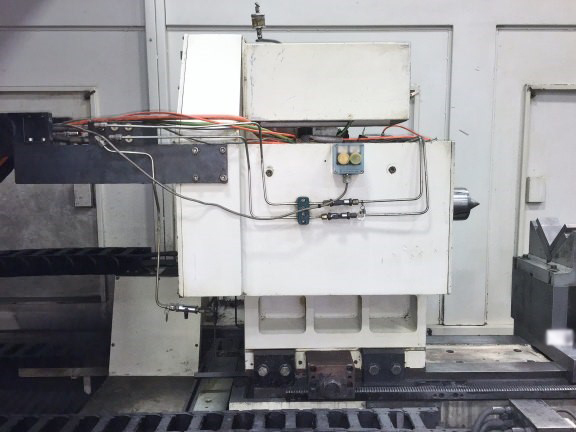

Used DANOBAT HG-91 #9128487 for sale

URL successfully copied!

Tap to zoom

ID: 9128487

Vintage: 2005

Features:

Siemens 810D CNC Control:

Touch Probe System:

(2) Steady Rest:

Balancing & Detecting Package:

Work capacity:

Max Swing Over Table: 41.3"

Distance Between Centers: 157.5"

Centres height: 20.6"

Max Grinding Diameter: 33.4"

X-Axis Stroke: 25.5"

Programmable Speed (X & Z Axis): .0004 -236" IPM

Wheel Size, (Right Side): 29.9" x 3.93"

Wheel Size, (Left Side): 29.9" x 3.14"

Wheel Hub (Both): 12"

Wheel Motor: 29 HP Variable Speed

Wheel Speed: 8856 SFPM

Wheel Head Swivel (+/-): 30 Degrees

Workhead Speed: 12-300 RPM

Work Head Motor Torque: 42 NM

Center Taper: #6 MT

Weight Capacity, Unsupported: 5,513 lbs

Weight Capacity, Supported: 11,025 lbs

Machine Weight: 48,510 lbs

Equipped with:

Siemens 810D CNC Control

Dual Grinding Heads on Same Spindle

Danobat Absolute Measuring Option

Balancing & Detecting Package

Positioning Package

Touch Probe System

(2) Two Point Steady Rest 3.93" -7.87"

Full Splash Enclosure

2005 vintage.

DANOBAT HG-91 Wafer Grinding, Lapping & Polishing equipment is an advanced technology machine tool designed for high precision, wafer grinding, lapping and polishing. This high-end system is perfectly suited for the Advanced Packaging and Semiconductor industries. The HI-PG91 is the most advanced unit in the series, with a maximum wafer size capability of 200 mm. The machine is exceptionally well designed to provide state of the art wafer grinding and shaping. An innovative grinding spindle and precise control tool provides vibration-free operation. The complex linear axes are driven by advanced German class drive motors and driven by precision ball screws. This combination of innovative German drive-train technology and powerful hi-speed servo spindle operations provide accurate and stable operations. A key feature of the HI-PG91 is its intuitive HMI (Human Machine Interface) which has an intuitive interface to provide smooth operation across the entire asset. This model is user configurable, allowing the user to customize configuration parameters and setup. The HI-PG91 includes a comprehensive built-in safety equipment to protect personnel and the valuable machine itself. This includes a safety interlock, laser triangulation system, and multiple emergency stop switches. The HI-PG91 unit utilizes advanced lapping and polishing technologies to achieve a uniform surface finish. The lapping element consists of a Platespeed control machine, which controls the speed and amount of lapping abrasives. This tool ensures the even application of lapping materials and careful monitoring of the grinding force, allowing repeatable processes. The automated lapping and polishing asset is enclosed in a stainless steel cabinet, keeping dust and debris to a minimum and protecting machine components from the elements. The cabinet has an air filtration model to keep the environment clean and promote an optimal wafer grinding and polishing environment. The equipment is highly efficient, providing an output rate of up to 0.6 m2/hr. The system allows for grinding and lapping operations to occur in parallel, providing high throughput rates. The high-performance grinding processes are augmented by an efficient automatic plate-change procedure to increase process repeatability. Overall, HG-91 Wafer Grinding, Lapping & Polishing unit is a robust and high-end machine tool specifically designed for advanced wafer processing. This machine offers high accuracy and repeatability, ensuring that wafers are consistently of the highest quality. The intuitive user interface, powerful German drive-train, built-in safety systems, and lapping and polishing technologies make this an excellent option for the Advanced Packaging and Semiconductor industries.

There are no reviews yet