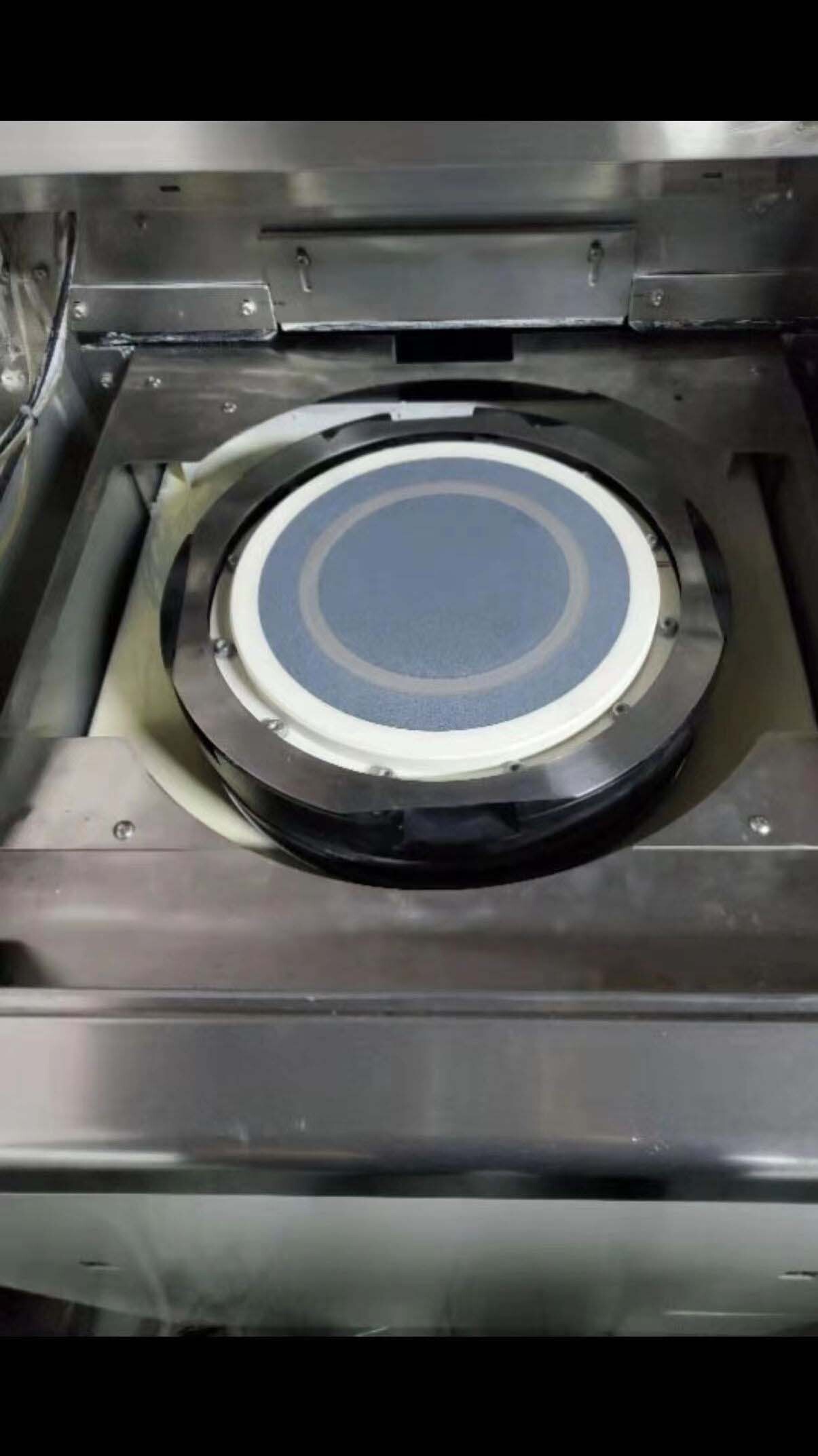

Used DISCO DAG 810 #293636528 for sale

URL successfully copied!

Tap to zoom

ID: 293636528

Vintage: 2012

Grinder

Movement of working disc Y-Direction: 430 mm

Speed of working disc Y-Direction: 0.01- 50 mm/s

Fast feed speed of working disc Y-Direction: 200 mm/s

Feed accuracy of working disc Y-Direction: 0.001 mm

Thickness measuring devices, 6"-8"

Range of measurement: 0-1000 µm

Weight measurement accuracy: 0.1 µm

TAIKO Grinding wheel, 6"-8"

Cleaning disc speed range: 0-2,000 RPM

TAIKO Ring width: 3 ± 0.2 mm

CDA Pressure: 0.8-5.0 MPa

CDA Stream: 150 L/min

CDA Dew point: -15°C

CDA Residual oil: 0.1 wtppm

Spindle cooling water: Deionized pure water

Pressure: 0.2-0.3 MPa

Stream: >2 L/min

Temperature: 20°C-25°C

Grinding cooling water: Deionized pure water

Pressure: 0.2-0.3 MPa

Stream: >20 L/min

Room temperature: ± 2°C

Environment temperature: 20°C - 25°C

Environment humidity: 55 ± 15%

Maximum power consumption: 12 kVA

Maximum leakage current: 15 mA

Power supply: 200 V, 3 Phase, 50/60 Hz.

2012 vintage.

DISCO DAG 810 wafer grinding, lapping & polishing equipment is a fully automated, single-station system designed for the fast and accurate finishing of wafers. It performs wafer grinding, lapping, and polishing operations in a single environment. The unit is equipped with a large-capacity base table that can support up to 160, 160-mm-diameter wafers. The self-contained setup of the machine offers a quick, simple setup and operation with minimal maintenance. The tool is equipped with a range of processing steps, all of which are customizable to best meet the needs of the user. The grinding step of the asset is designed to provide high accuracy and stability by using an ultra-precision spindle and a super-precision feed mechanism. The engineered design of the spindle eliminates vibration and provides high accuracy and repeatability at process speeds up to 10,000 rpm. The lapping portion of the model is designed to offer increased control over the lapping process at both high and low speeds. A motorized stage controls the lapping process and can adjust down to the micron level for accurate, repeatable results. The equipment includes a series of diamond-encrusted lapping plates with a unique meshing mechanism that prevents delamination and contamination. The system is further equipped with a series of polishing steps for a smooth, even finish. The polishing steps utilize a unique spindle mechanism that improves process speeds and uniformity, while simultaneously eliminating vibrations. Combined with multiple polishing heads, the unit produces a highly uniform, highly accurate finish. In addition to the grinding, lapping, and polishing steps, the machine is designed with a comprehensive safety suite. A variety of safety features such as emergency stops, motion sensors, and process management strategies help protect the user and the tool from potential risks. Additionally, each of the processing steps is monitored with a comprehensive asset of sensors that detect temperature, pressure, and other environmental variables for optimal performance and stability. All in all, DISCO DAG810 is an advanced, single-station wafer grinding, lapping & polishing model. Its high-accuracy, programmable design provides repeatable results at process speeds up to 10,000 rpm, while its comprehensive safety suite ensures optimal safety and performance.

There are no reviews yet