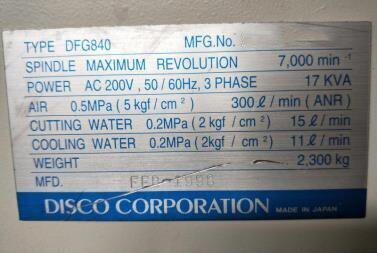

Used DISCO DFG 840 #9355522 for sale

URL successfully copied!

Tap to zoom

DISCO DFG 840 is a wafer grinding, lapping and polishing equipment designed to provide consistent and superior quality finish on any wafer surface. This system is well-suited for grinding, lapping and polishing of ultra-thin wafers and other substrates used in semiconductor and related industries. It's also capable of handling up to 8" (200 mm) diameter production sequences. DISCO DFG840 uses a range of high-precision abrasive technology, ranging from the finest diamond abrasive for ultra high-precision polishing at the beginning of the process chain to more aggressive abrasive for removing large amounts of stock from the wafer. This unit also features totally closed-loop process control for continuous wafer feed and programmable feed speed. DFG-840 is also equipped with a proprietary trim production machine that automatically detects and trims defects on the surface of the wafer. The tool includes a Multi-Sensor Edging Asset (MSES) that can evaluate and automatically trim the edge of the wafer. This model is capable of producing high quality finishes on a wide range of wafer substrates. Its High-Speed Smart Pulser-II feature helps it produce uniform finish and quality across a range of wafer diameters. The equipment can further adjust tooling rotation, feed rate and pulser speed to enhance wafer surface quality for a wide range of wafer substrates. DISCO DFG-840 features a number of advanced features such as real-time monitoring, reporting, and data analysis. It supports Ethernet, RS232 and other computer network interfaces, and comes with an open control software that allows users to customize the system with specific parameters, analysis, and commands. The unit can be integrated with the existing wafer grinders, lappers and polishers, and is designed to optimize the total grinding and polishing process through easy to use communication interface. This wafer polishing machine is designed to automatically and consecutively polish an abrasive sheet, feed sheet to sheet and provide high-quality finish on various types of wafer materials and configurations.

There are no reviews yet