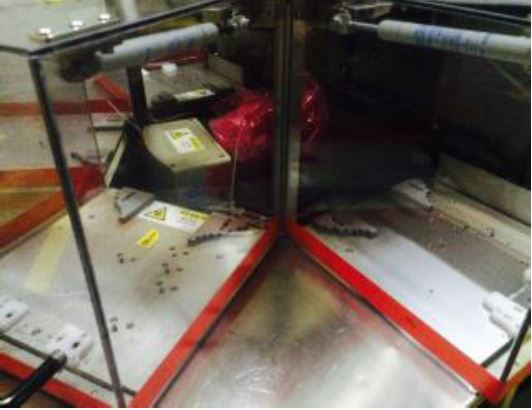

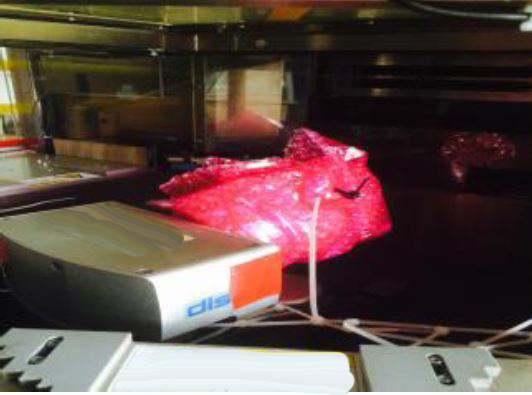

Used DISCO DFG 840HS #9110900 for sale

URL successfully copied!

Tap to zoom

ID: 9110900

Wafer Size: 8"

Vintage: 2000

Back wafer grinder, 8"

Available thickness: Max Ø200mm (Ø4~8"), 1mm

Method of grinding: infeed method grinding

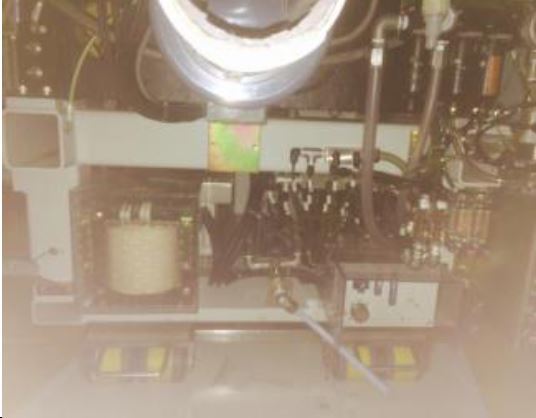

Spindle:

Spindle motor: 4.2kw direct high pressure motor

Infeed speed of spindle: 1000 - 7000 min-1 (1000 - 7000rpm)

Infeed speed order grade: 1 min-1(1rpm)

Stroke: 110mm

Cut & send speed: 0.00001 - 0.080 mm/sec

Power:

Consumption of electrical power: 17kVA (MAX)

Noise: plus range 500ns under 2000V

Earth: JIS Thirth under 100Ω

Air:

Range of changing pressure: 0.03MPa under(about 0.3kgf/cm2)

Current amount: 3001/min above (A.N.R)

Dew point: -15℃under

Remain oil: 0.1 wtppm

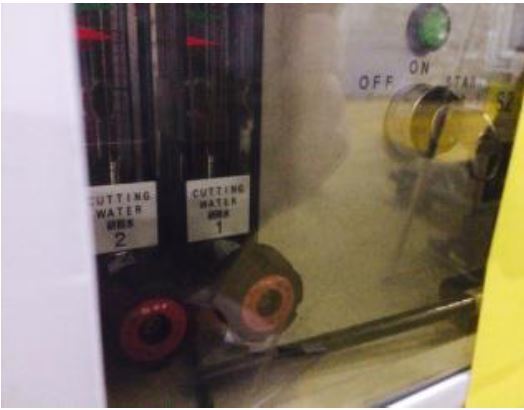

Water:

Use water: distilled water

Pressure: 0.2~0.3 MPa (2~3kgf/cm2)

Flow amount: 151/min above

Temperature: room±2℃

Coolant, Vacuum Pump:

Use water: city water

Pressure: 0.2~0.3MPA

Flow amount: coolant 41/min above

Vacuum pump 51/min above

Coolant temperature: 20~25°C (2°C/1h)

200V AC ±10%, 3 ph, 50/60 Hz

2000 vintage.

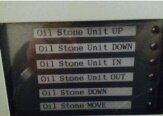

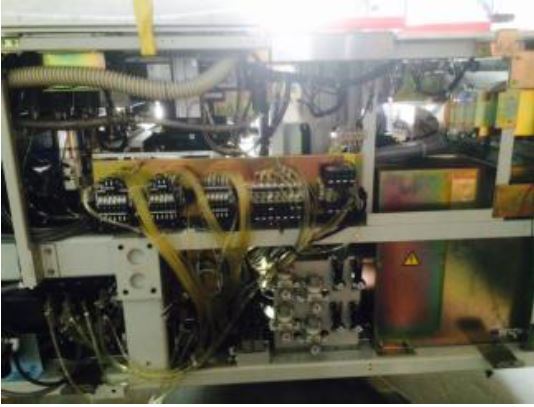

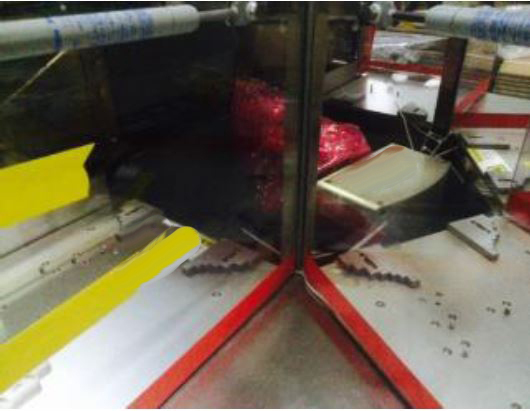

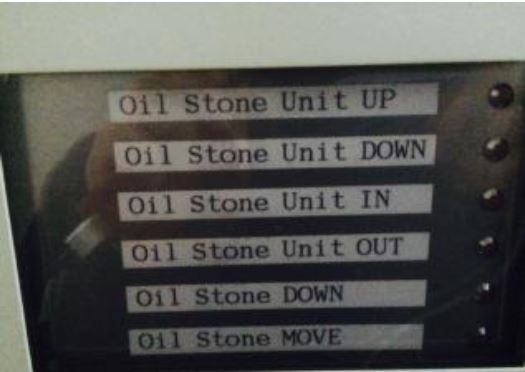

DISCO DFG 840HS Wafer Grinding, Lapping & Polishing Equipment is a high performance machine designed for the specialized processing of compound semiconductor wafers such as Silicon, Gallium Arsenide and Sapphire. DISCO DFG 840 HS offers accurate and repeatable processing to produce consistently high quality surfaces, both flat and non-planar. The system is equipped with state-of-the-art intelligent software for easy operation and automated wafer handling. DFG 840HS has a robust and intelligent controls unit that allows for rapid production setup and set-point adjustment. The machine features 3 process stages including - in-situ shape lapping, in-situ shape flat grinding and polishing. This allows a wide range of complex and layered materials to be processed. The lapping and grinding stages are tailored to the type of wafer material being processed. DFG 840 HS's precision automated wafer handling tool is designed to handle up to 8" diameter wafers. It utilizes an integrated robot for loading and unloading wafers from a cassette onto the processing plate. The wafer is clamped securely to the plate during the polishing stage, the closed-loop control asset ensures accurate and repeatable results for highly efficient processing. The model also includes an integrated sorter for rapid sorting and analysis of wafers post-processing. After sorting the wafers are returned to the cassette and unloaded for further processing. The sorter offers outstanding accuracy and high repeatability to optimize the production cycle. The 840HS features a unique abrasive distribution equipment which contributes to greater precision and accuracy of wafer processing. The abrasives are loaded automatically into the system's reservoir and the precise amount of abrasives is then distributed evenly across the entire wafer. This unit ensures high-quality results every time, regardless of the size or shape of the wafer. The machine utilizes a powerful process-control tool for the ultimate in control. The real-time closed loop control uses advanced algorithms and sensors to monitor the process and make any necessary corrections and adjustments. This allows the asset to quickly adjust to the changing needs for any type of material. DISCO DFG 840HS offers maximum processing efficiency and unparalleled precision in the wafer grinding and polishing process. Automated wafer handling and abrasive distribution ensure a precise and repeatable result, while the active process control model ensures maximum process accuracy. With its wide range of materials compatibility and automated operation, DISCO DFG 840 HS is the ideal solution for high-volume production of compound semiconductor wafers.

There are no reviews yet