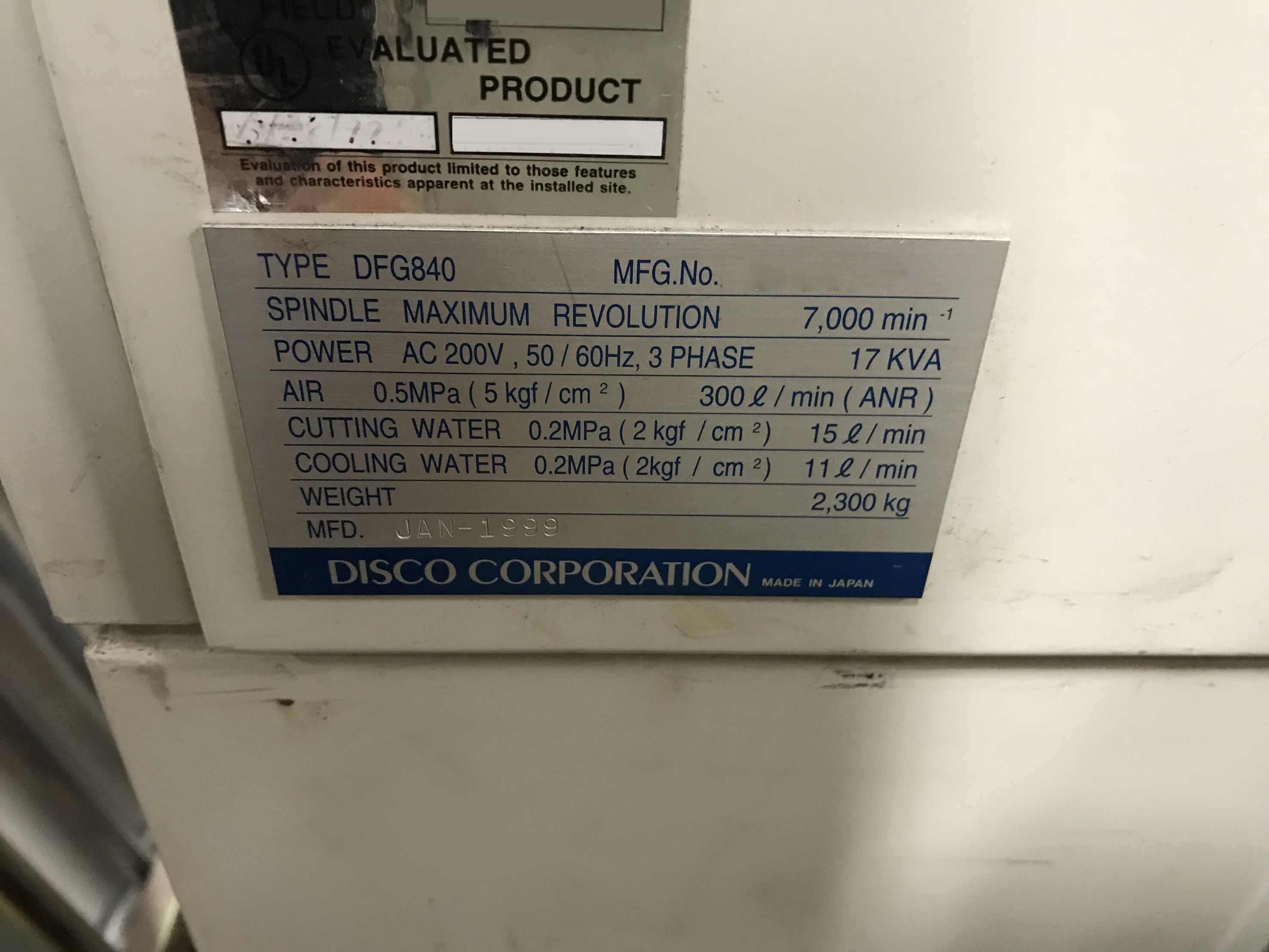

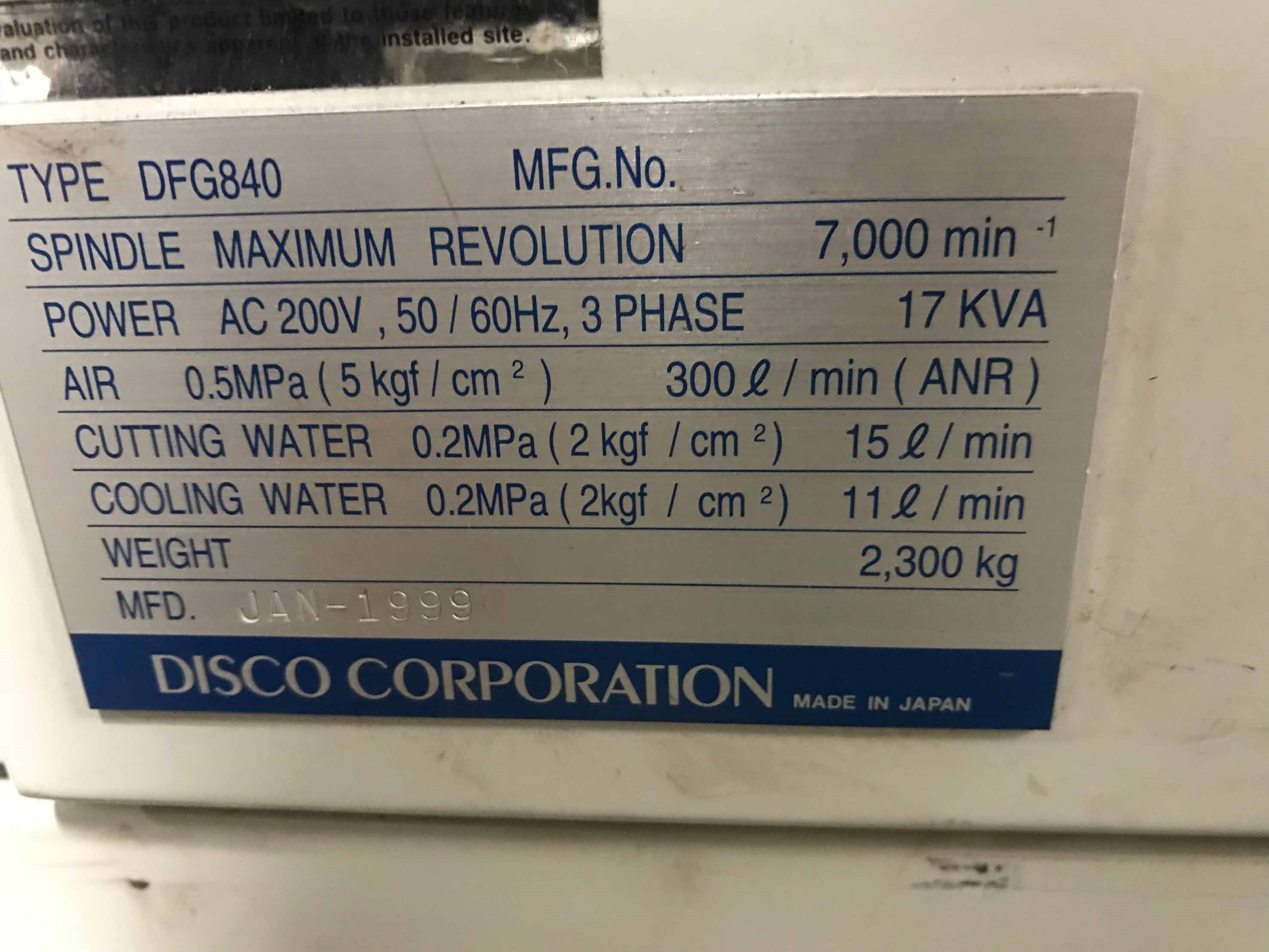

Used DISCO DFG 840HS #9212148 for sale

URL successfully copied!

Tap to zoom

DISCO DFG 840HS is a wafer grinding, lapping and polishing equipment designed to efficiently handle a variety of precision manufacturing needs related to wafers of multiple sizes. The system's design is capable of handling wafers up to 8 inches in diameter. The machine is designed to accept multiple types of grinding saw blades that can be used to shave down the wafer to the desired thickness. It is also able to handle the lapping or polishing process as needed. DISCO DFG 840 HS is equipped with a single turning table for the purpose of grinding and polishing. The turning table is adjustable in terms of speed and pressure, allowing the operator to make the precision adjustments necessary to complete a project. This unit also contains a built-in sensor to detect when the process of grinding or polishing is complete. The machine's design includes two separate motors that ensure a steady rotation of the wafers during the grinding and polishing process. The grinding motor is adjustable in terms of speed and torque to facilitate the process of grinding, while the polishing motor is designed to provide a relentless stable rotation. DFG 840HS is also equipped with two on-board computers that are responsible for controlling the grinding motor and polishing motor. The computers are able to track the wafer's progress and send feedback to the operator in order to monitor its performance. This machine also records data for the purpose of reviewing the manufacturing process and making adjustments for more efficient operations. The platform is accompanied by a full suite of monitoring and control systems to ensure user safety and optimal operation. The tool also includes a asset monitoring program which is used to monitor the model's performance. This program verifies that the grinders and polishers are properly aligned and that the blades are functioning properly. The equipment also includes software that is designed for wafer grinding, lapping, and polishing. This software facilitates the entire process by providing the operator with the tools and information necessary to complete a project efficiently. The software also detects any anomalies that may occur during the manufacturing process and sends an alert in order to take action. DFG 840 HS is an efficient and innovative wafer grinding, lapping and polishing system that facilitates precision manufacturing of wafer-based products. This unit makes it possible to achieve higher levels of precision with greater efficiency and reduces the manufacturing time necessary to complete projects.

There are no reviews yet