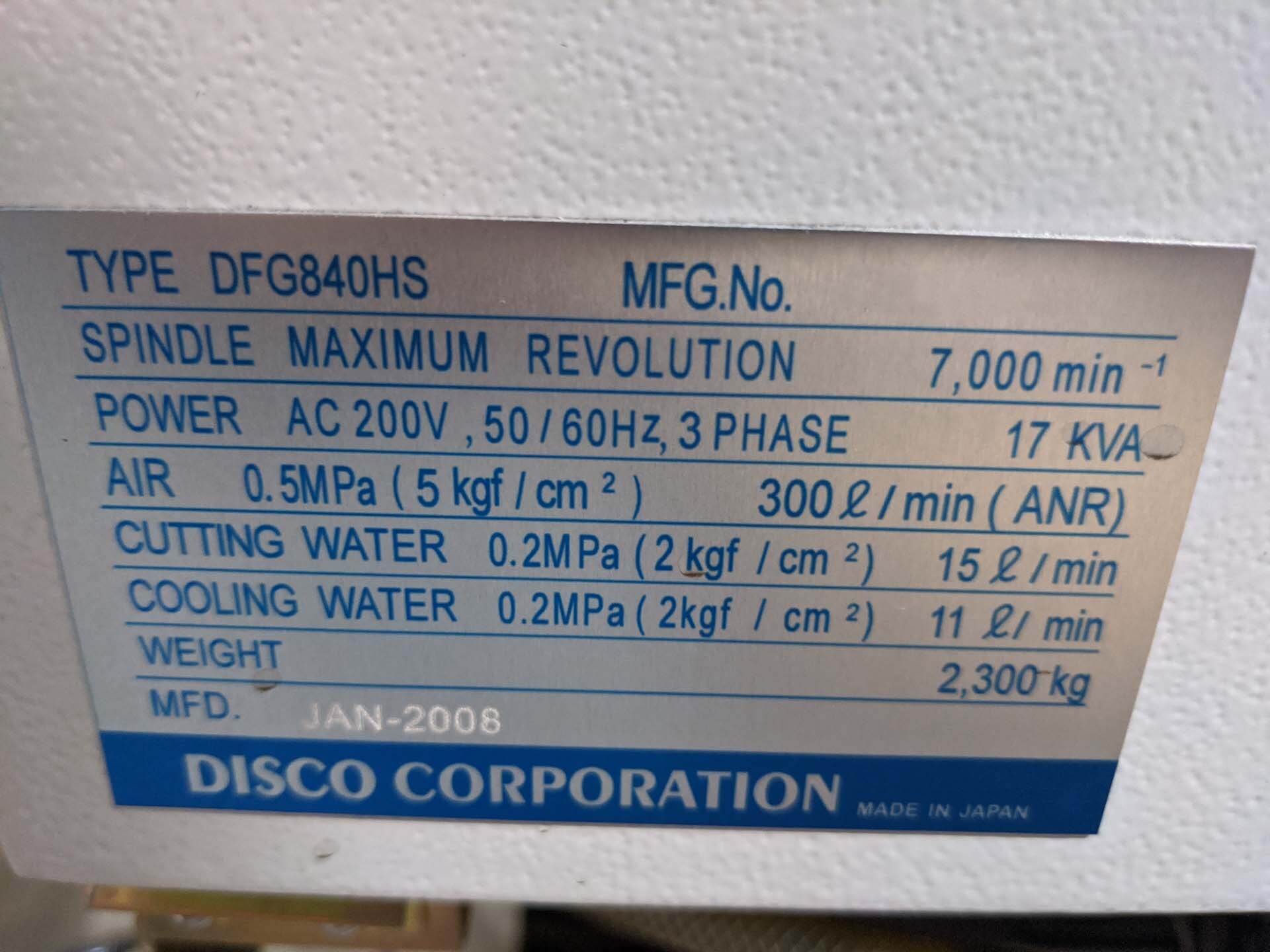

Used DISCO DFG 840HS #9386038 for sale

URL successfully copied!

Tap to zoom

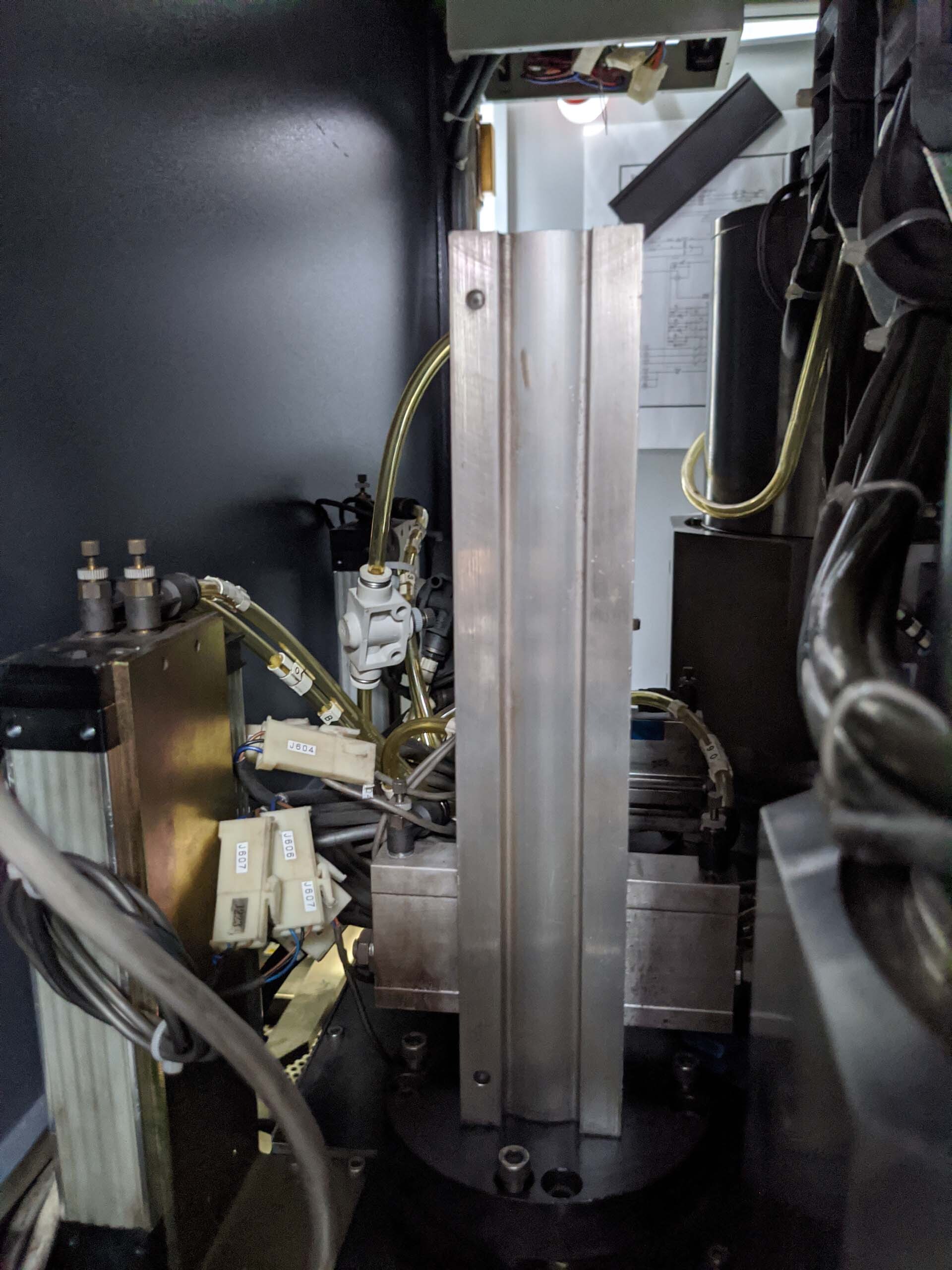

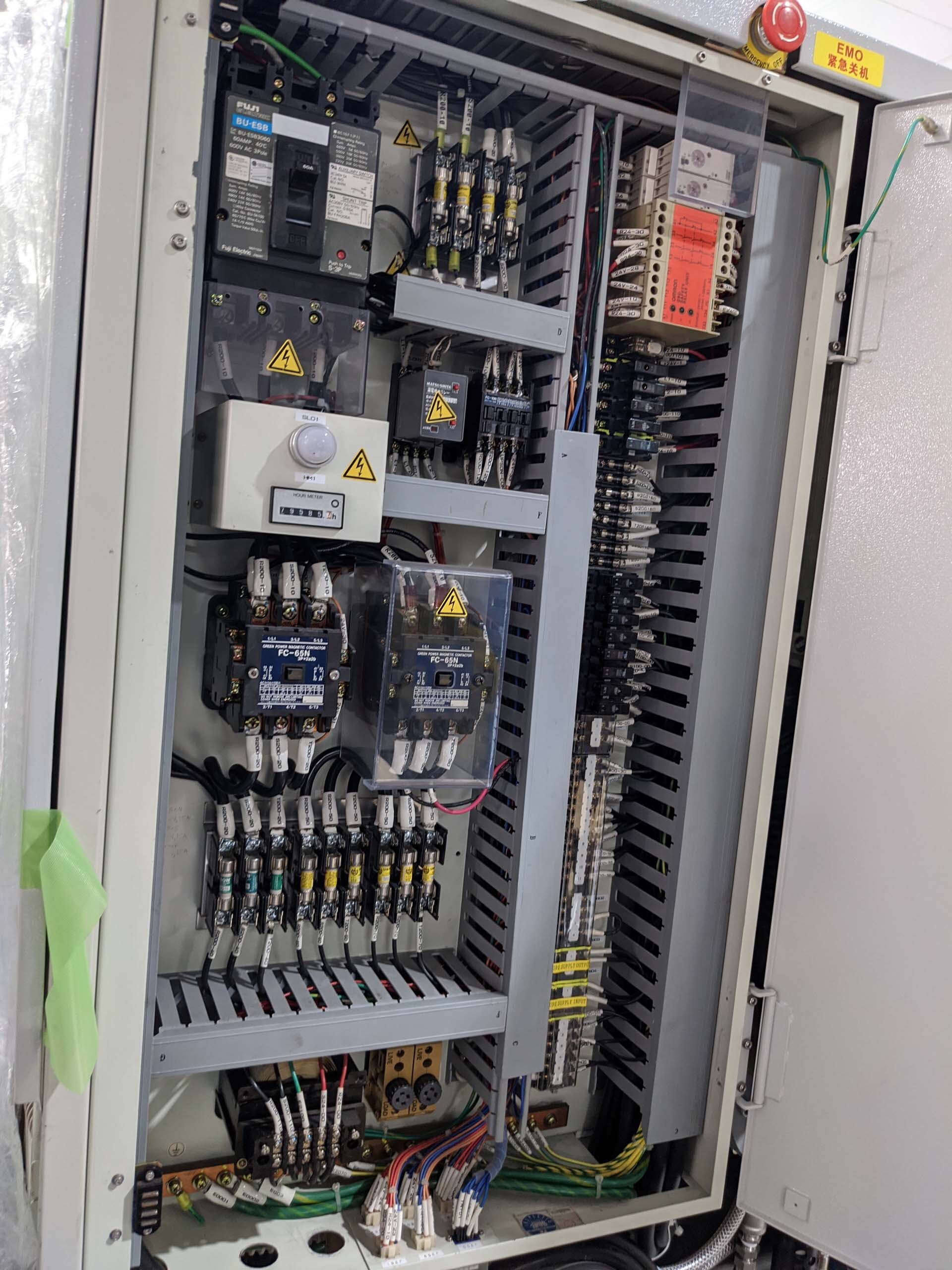

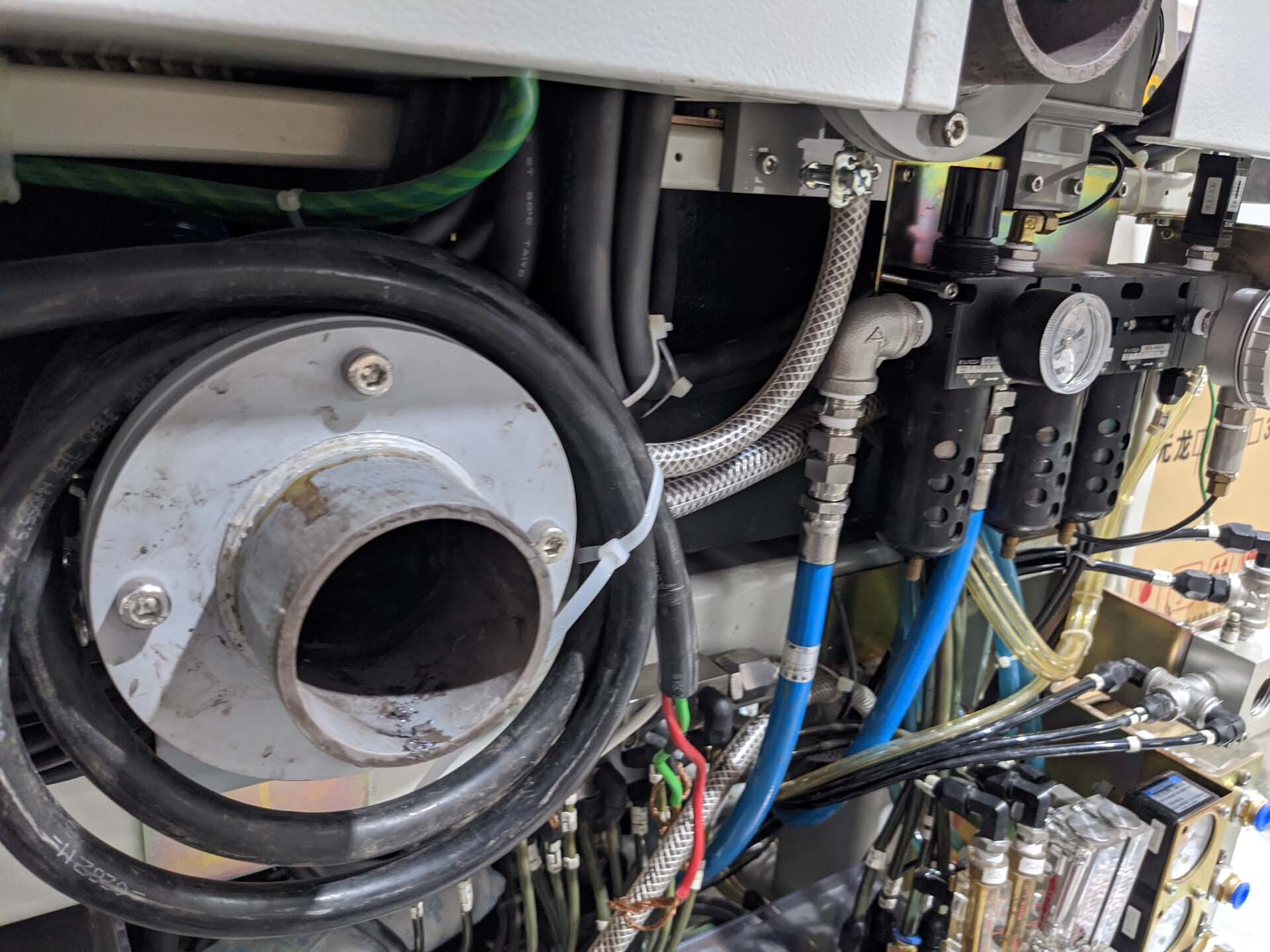

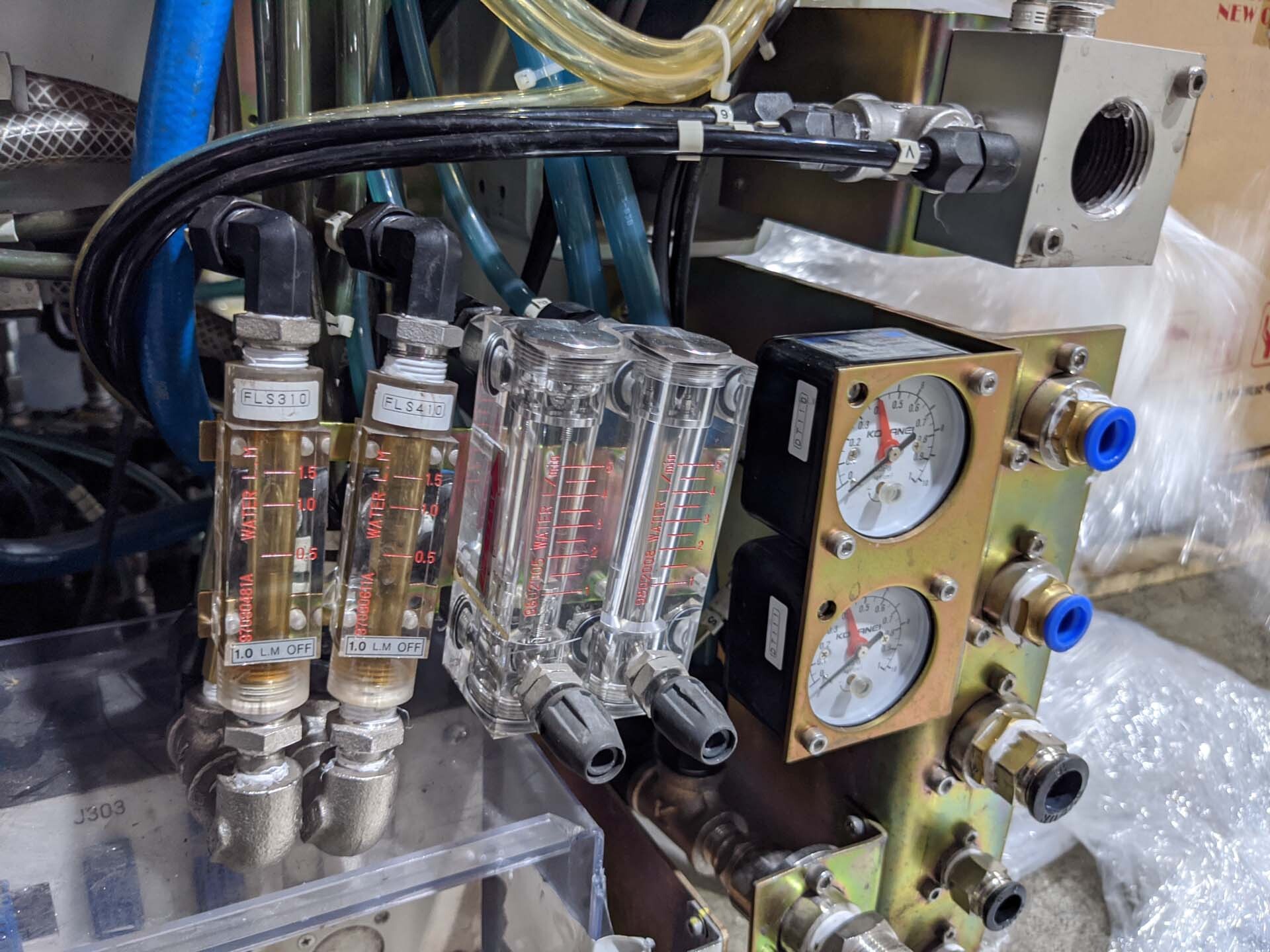

DISCO DFG 840HS is a wafer grinding, lapping, and polishing equipment designed to provide an optimal solution for the demanding needs of advanced semiconductor circuit fabrication. It is a high-speed, multi-function system that can quickly and efficiently process a variety of wafer materials including polysilicon, silicon-on-insulator (SOI) wafers, and ultra-shallow junction (USJ) substrates. The equipment's high-efficiency, spindle design allows for grinding at speeds up to 17,000 RPM, while a secondary spindle can provide rotational stability for rough grinding and higher accuracy finish operations. Additionally, DISCO DFG 840 HS is equipped with a diamond grinding wheel featuring an unique "taper-wall" structure to minimize grinding-induced wafer damage. The optimized work flow of DFG 840HS incorporates discreet processing stages, including pre-processing, grinding, lapping, polishing, and post-processing. The pre-processing stage consists of the application of a low-force grinding media or a custom-built diamond abrasive wheel to achieve a coarse, uniform grinding of the wafer surface. The 420mm diameter grinding wheel utilizes multiple rotational speeds and reduces grinding-induced damage to limit process time. The grinding stage involves the use of specific grinding media to improve the surface profile of the wafer. The lapping process utilizes the wafer's existing surface profile and applies specialized diamond paste to achieve a flattened, highly polished surface. The polishing stage further perfects the wafer surface with extremely fine diamond paste solutions. Finally, the post-processing stage uses the wafer's existing surface profile and further polishes it with specialized diamond pads. For maximum polishing uniformity, an optional post-coating unit can be added to uniformly coat the wafer's surface with polishing slurry. In summary, DFG 840 HS provides an efficient solution for advanced semiconductor circuit fabrication. The machine utilizes high speed grinding and lapping capabilities to achieve a superior wafer finish and reduce process time. Its optimized process flow, coupled with an optional post-coating tool, makes it an ideal solution for the demanding needs of today's semiconductor industry.

There are no reviews yet