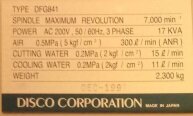

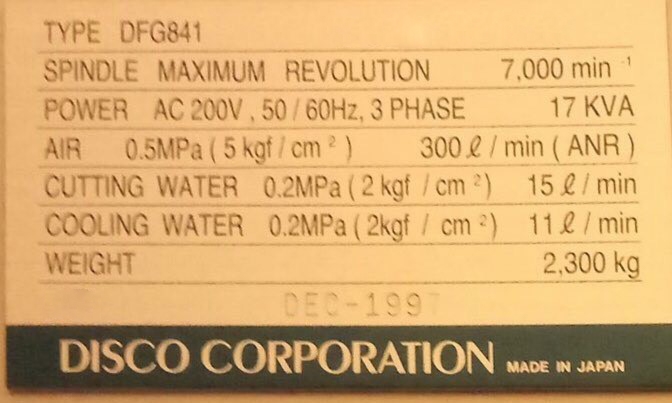

Used DISCO DFG 841 #9155028 for sale

URL successfully copied!

Tap to zoom

ID: 9155028

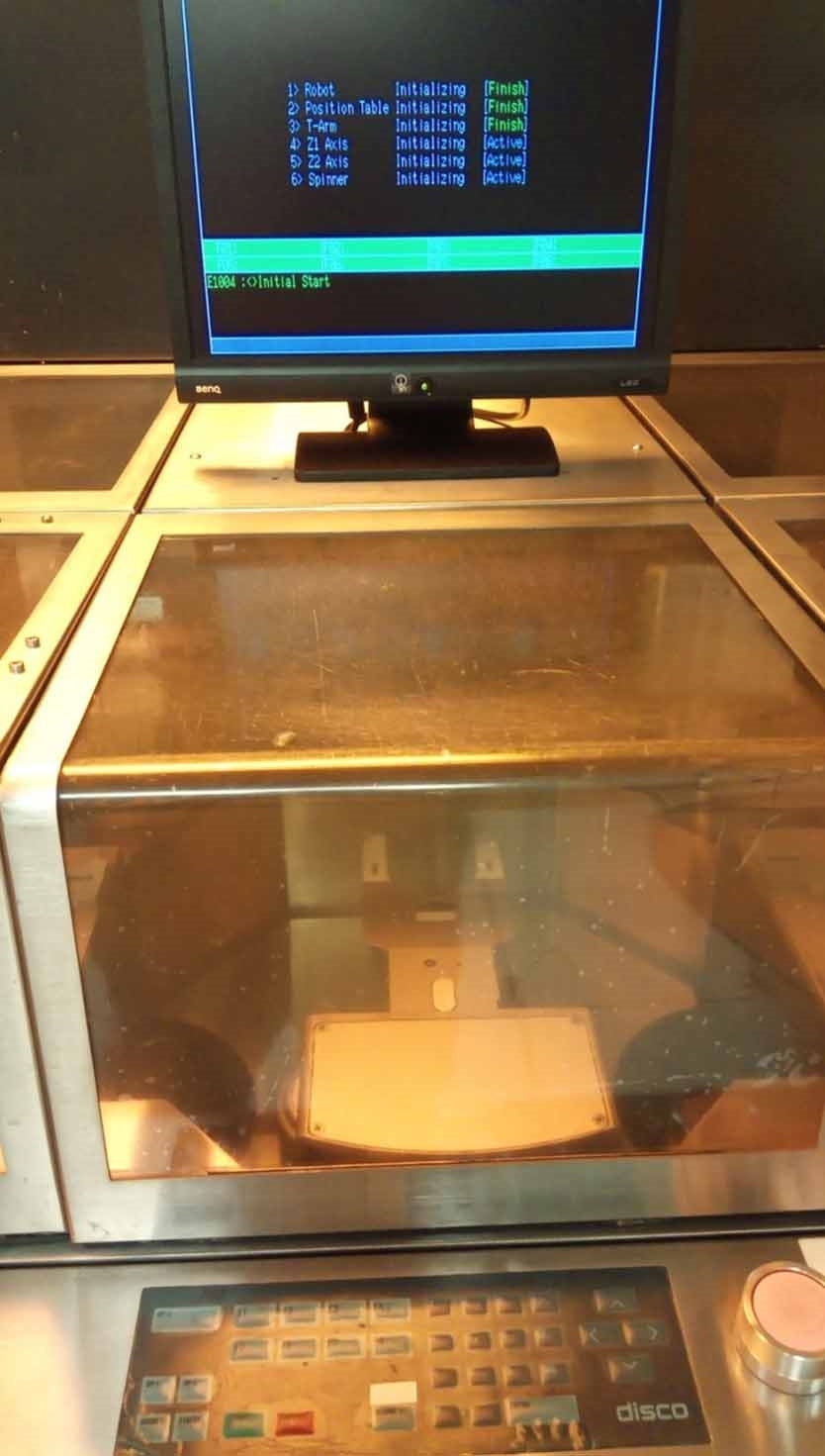

Vintage: 1997

Grinder

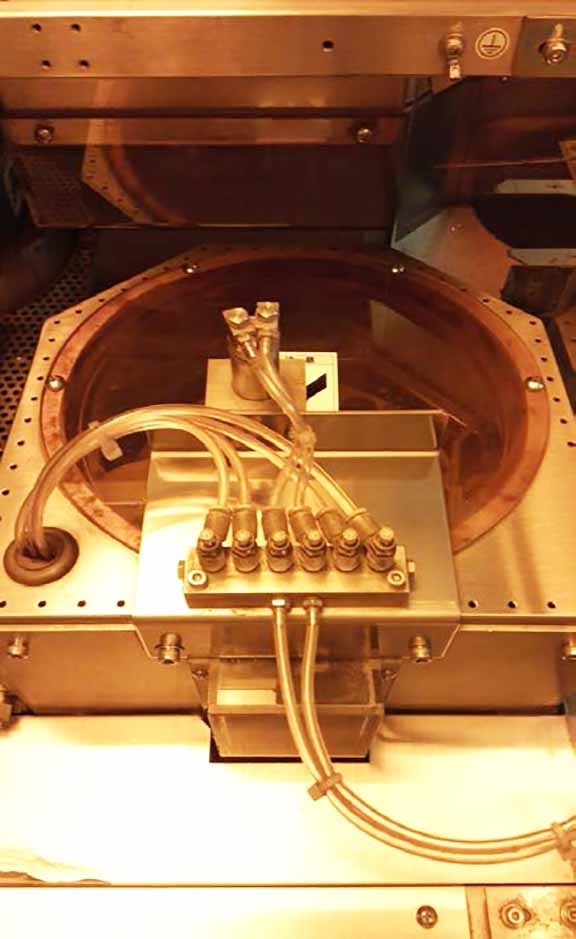

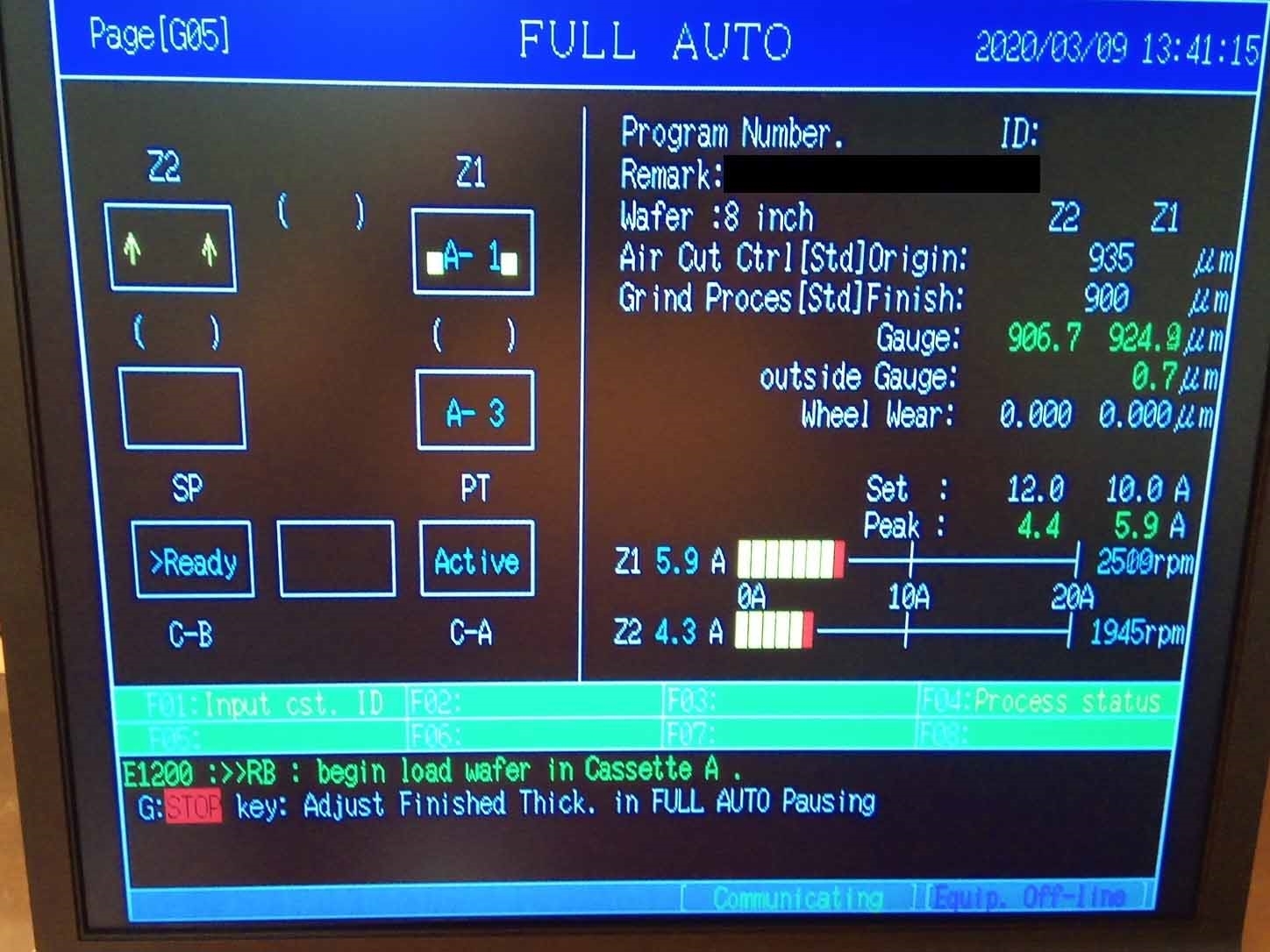

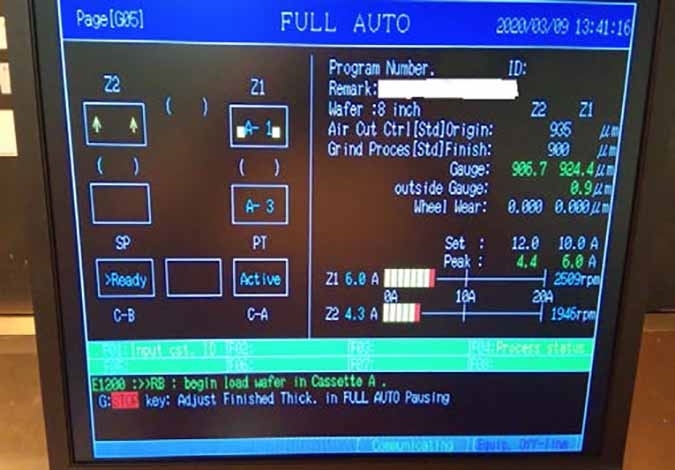

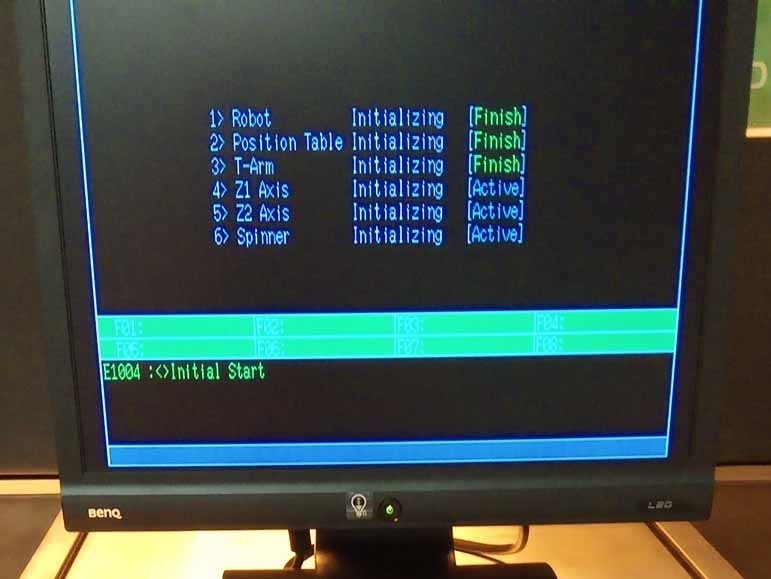

(2) Cassettes running (2) substrates simultaneously

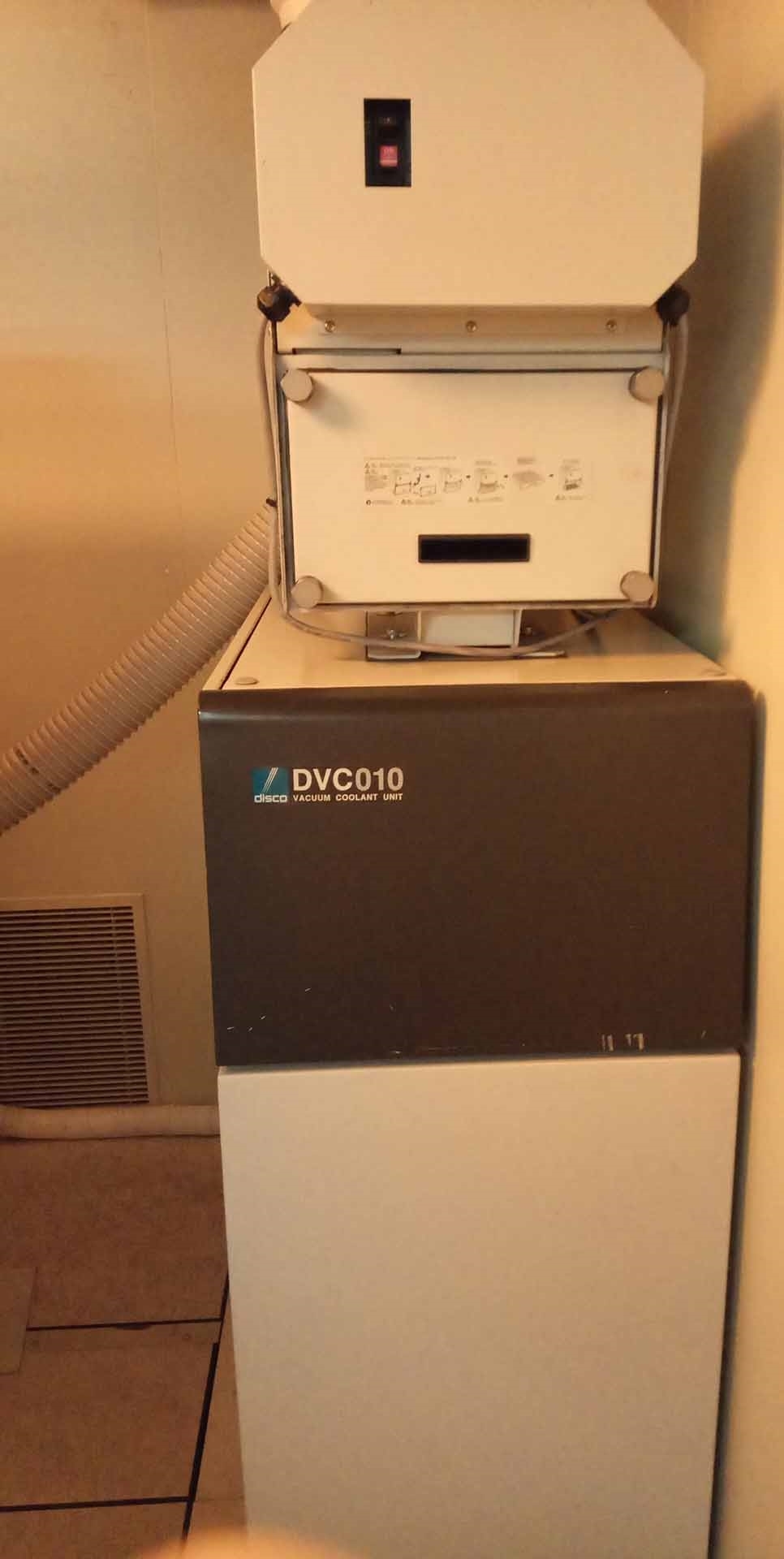

DVC010 Vacuum cooling unit

(2) Spindles

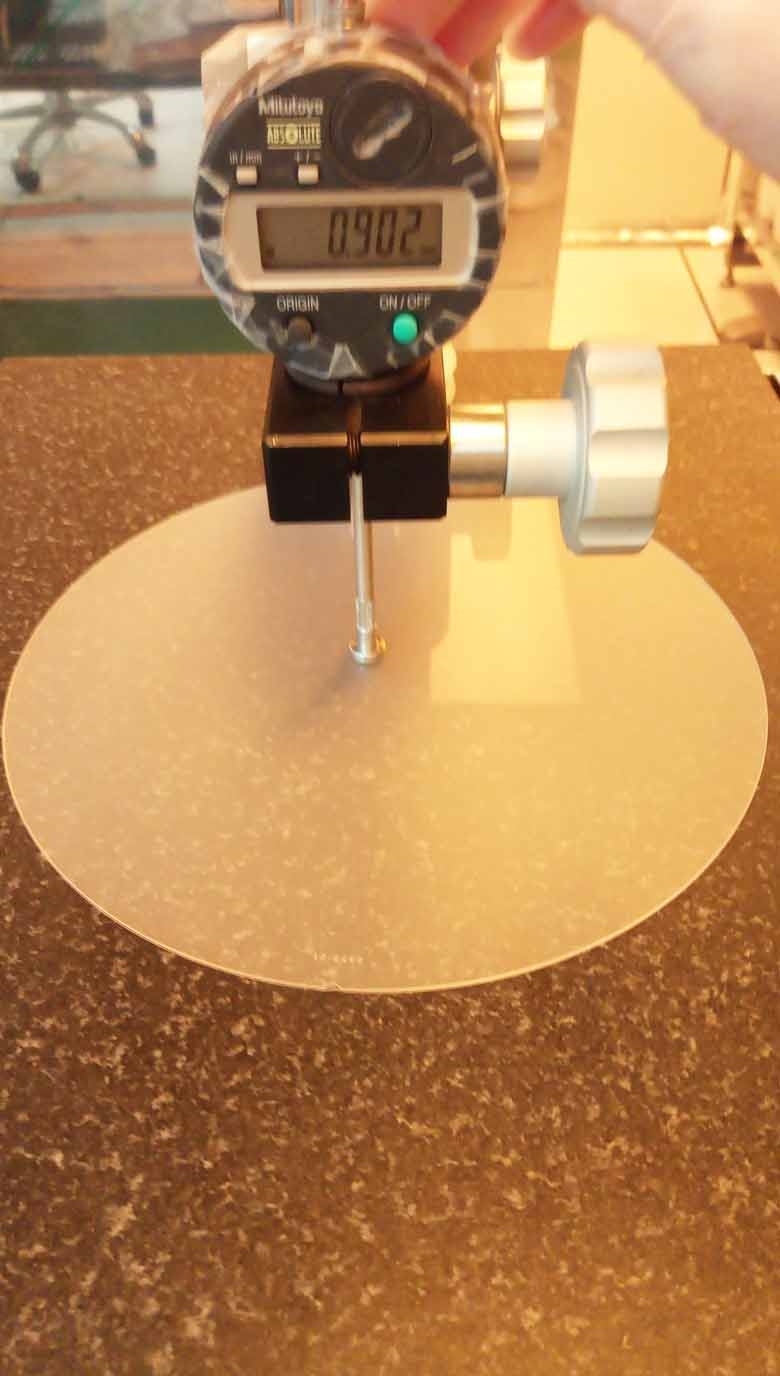

Table type: Porous chuck table

Chuck method: Vacuum

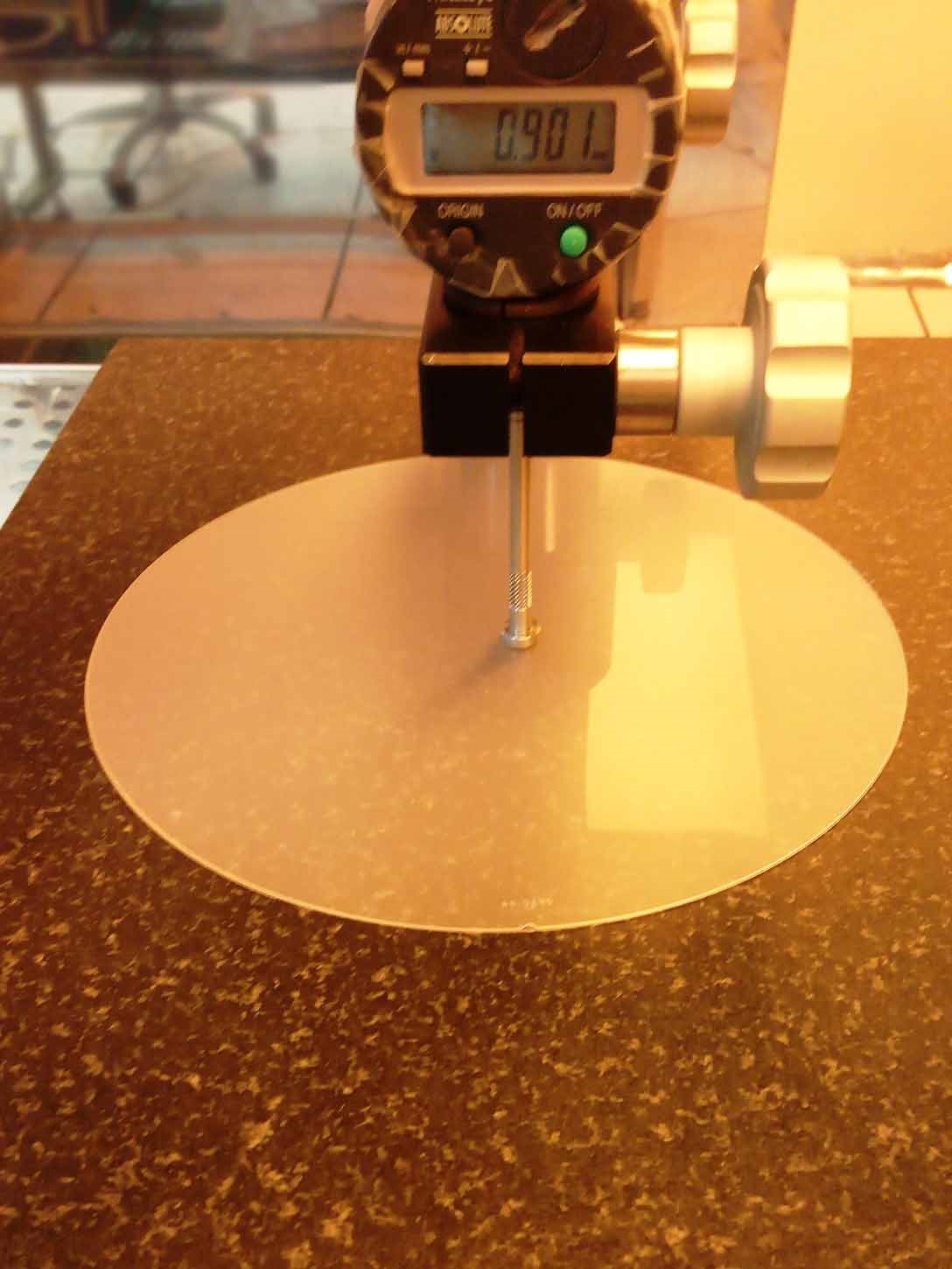

Grinding wheel: Diamond wheel, 8"

1997 vintage.

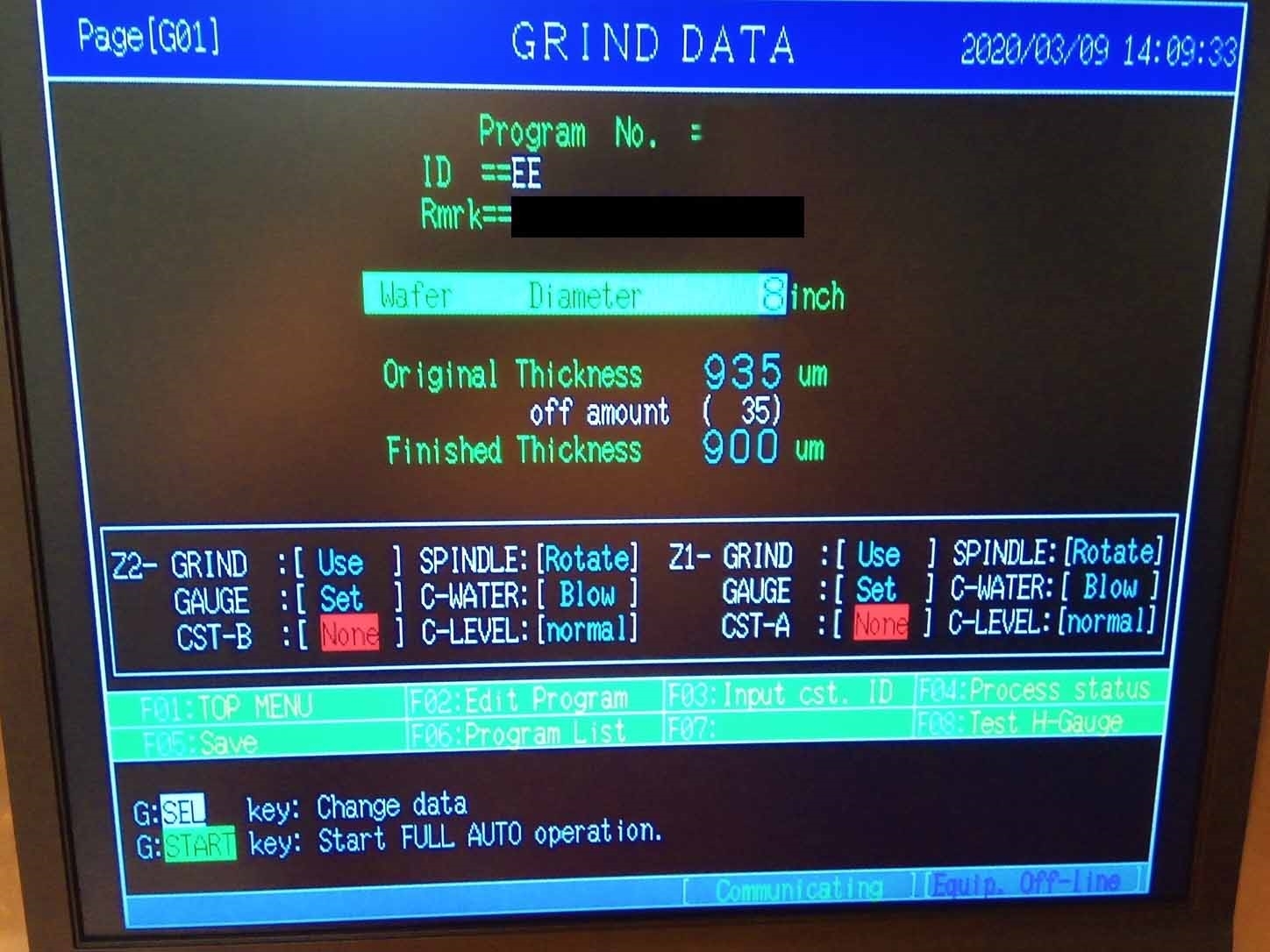

DISCO DFG 841 is a wafer grinding, lapping and polishing system designed for small-scale production. It offers the ability to edge the wafer to specific shapes, grind wafers to micron level accuracy, and polishes them to a mirror finish in a single step. The system features a compact, efficient design capable of satisfying a wide range of applications. DISCO DFG841 includes a grinding stage, polishing stage, and a lapping stage for the finished wafer. The grinding stage utilizes a high-precision turntable and grinding wheel to ensure accurate grinding to a precise shape and finish. A precise angle regulation technology is also employed to guarantee a uniform edge profile. The polishing stage utilizes a specially designed rubber grinding wheel to further refine and polish the wafer surface. The combined process results in a uniform surface roughness and a mirror finish surface even without the use of additional polishing materials. Furthermore, DFG 841 automate polishing parameters to ensure a consistent and reliable outcome. Real-time monitoring of the process can be performed with the use of a microscope, allowing for feedback control of the process. This system incorporates a number of features to support the processing of a wide range of wafer sizes and shapes, such as non-parallel topography, depth control, and process management. All in all, DFG841 offers an efficient, cost-effective way to grind, lap and polish wafers for precise micron accuracy and a mirror finish in one step. The advanced design is capable of producing repeatable results, and has a wide range of application, making it suitable for various production runs.

There are no reviews yet