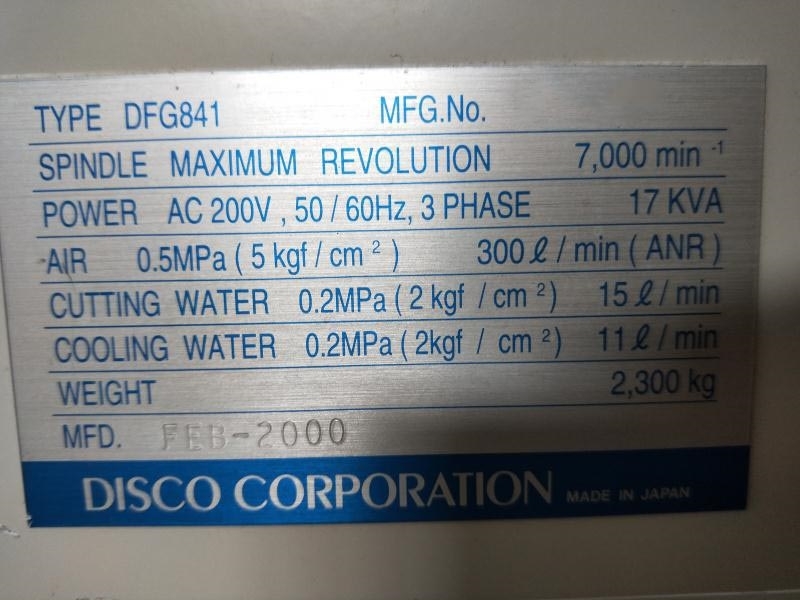

Used DISCO DFG 841 #9226641 for sale

URL successfully copied!

Tap to zoom

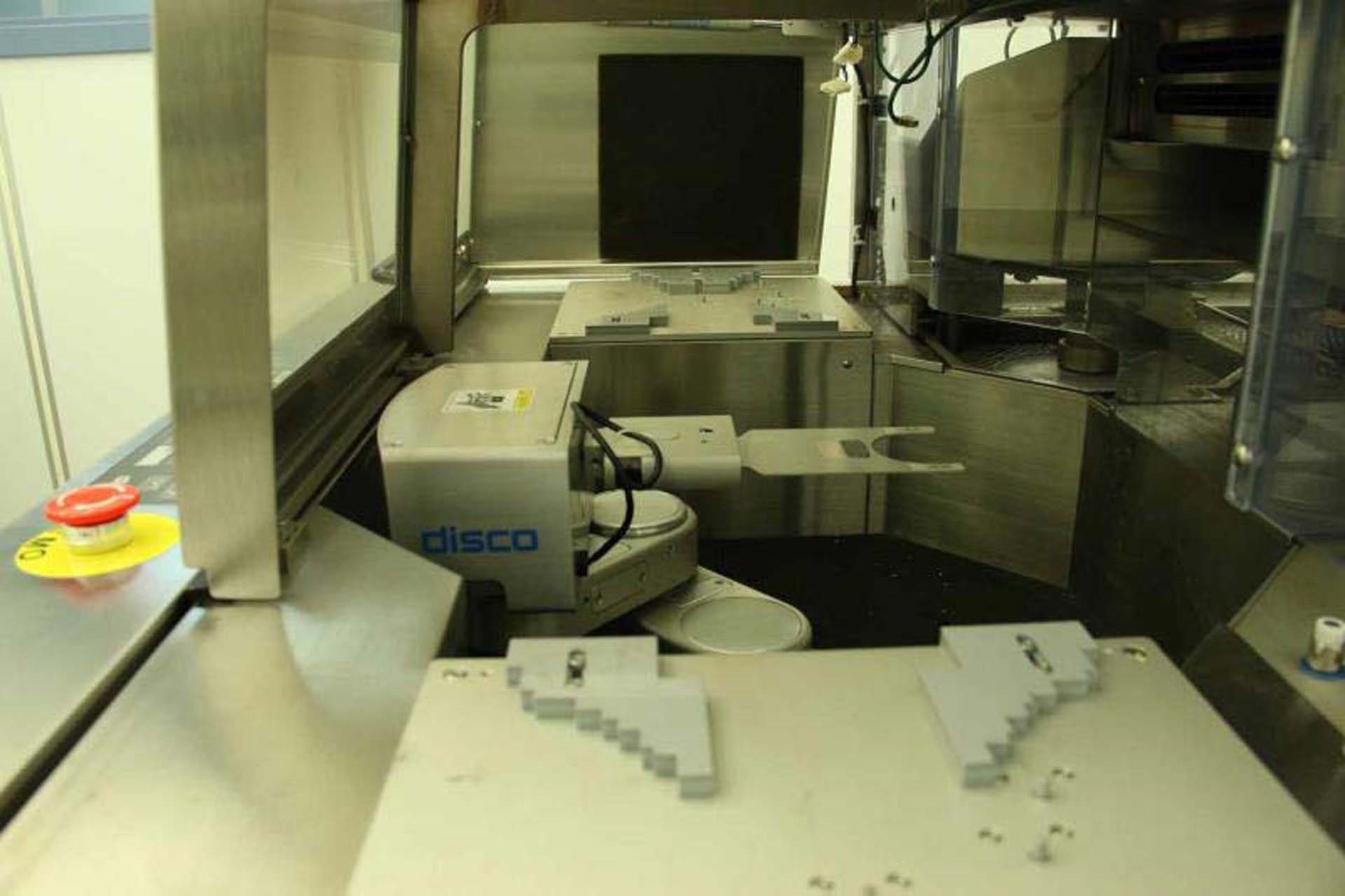

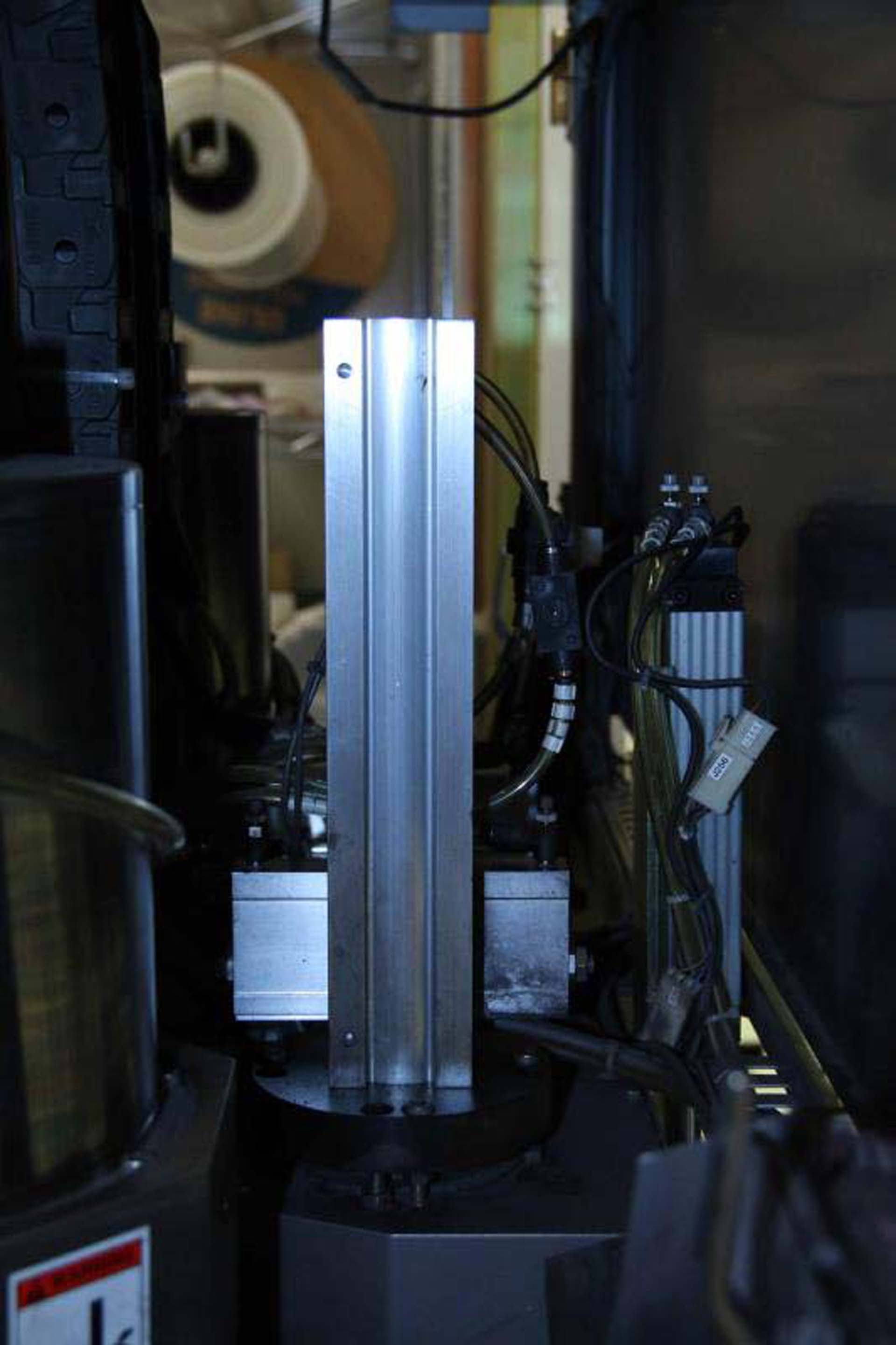

DISCO DFG 841 Wafer Grinding, Lapping & Polishing (GLP) equipment provides high accuracy and throughput for complex and large wafer grinding. It is a full CCD-based driving system capable of automated grinding, lapping, and polishing of lead frame or thin wafer substrates. It features the highest quality ultrafine polishing results with the utmost accuracy and cost effectiveness. The unit is designed with a high speed motor that can effectively grind and finish wafer substrates up to 10 μm in thickness. The rapidly rotating polishing head is comprised of three adjustable platens that allow for an optimal surface finish. The motor is capable of generating speeds up to 1,200 rpm, and can be coupled with an ultra-precise programmable control machine. This tool allows precise control of the rotational speed traversing feed, grinding force, and indexing direction for providing a consistent surface finish for all wafers. In addition to the motor and control asset, DISCO DFG841 GLP model also includes a vacuum suction chuck for mounting the wafers, a cooling & ventilation equipment, an automatic spindle indexing system, and a dust collection unit. It is equipped with a pick-and-place alignment machine and a powerful loading and unloading arm for quick and repeatable loading of wafers into the chuck. The automatic spindle indexing tool is designed to accurately position the wafer onto the three platens for processing. The dust collection asset is important to maintain the cleanliness in the chamber during processing. The results of DFG 841 GLP model are impressive, as it is capable of producing wafer substrates with the highest quality of finish within a repeatable and reliable equipment. Additionally, its fast setup time, high throughput, and cost-efficiency make it an attractive option for both research and industrial applications.

There are no reviews yet