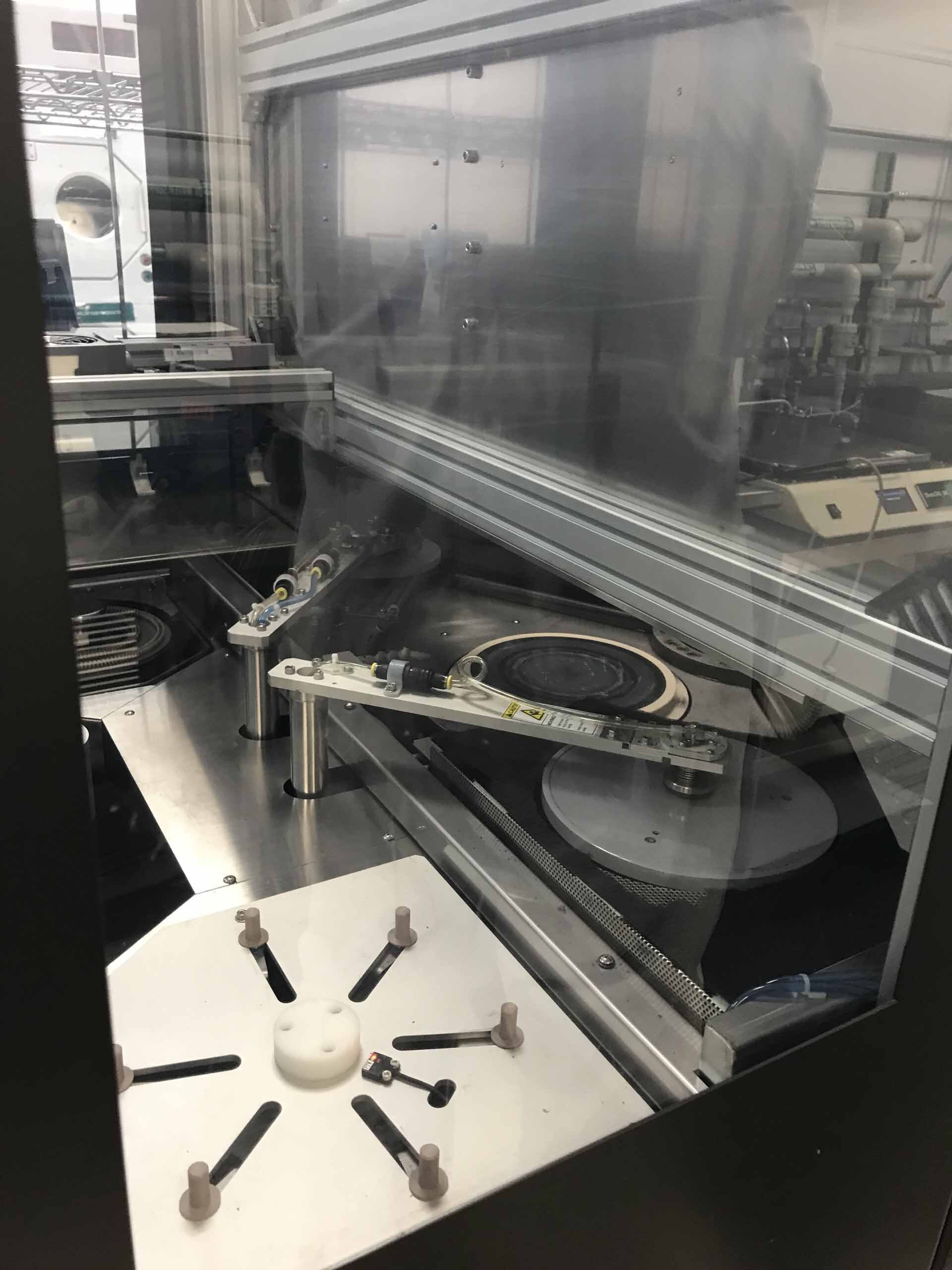

Used DISCO DFG 8540 #9395420 for sale

URL successfully copied!

Tap to zoom

DISCO DFG 8540 wafer grinding, lapping and polishing equipment is a high-precision, automated machine tool used to create smooth, flat surfaces on semiconductor wafers. The system is able to process any material from tungsten to quartz in a wide range of different sizes and shapes. DISCO DFG8540 features an advanced design, allowing it to operate quickly and accurately with minimal setup time. The machine includes a spindle with a high-precision and easy-to-use grinding/polishing head, enabling it to achieve flatness values below 0.5 μm. Additionally, the unit can accommodate a wide range of grinding/polishing pads and process variations, including wafer through-hole hole and plate surface processing. The machine utilizes 5-axes motion control with permanent-magnet direct-drive linear motors, providing high-accuracy step-motion and dynamic response rates. Moreover, the tool accommodates 3D grinding and polishing control, allowing operators to achieve planarization up to 0.05-μm accuracy. DFG 8540 also features an optimized CCD asset designed to provide high-resolution digital feedback for total process control. This model is capable of measuring displacement, displacement of planar height, surface roughness and roundness. The equipment also features a high-speed servo drive for optimization of lapping rate and polishing process. Additionally, DFG8540 is equipped with a vacuum chuck for improved wafer flatness, enabling operators to achieve results in a fraction of the time compared to traditional processes. Overall, DISCO DFG 8540 is an ideal solution for creating near-perfect surfaces on semiconductor wafers. With its 5-axes motion control, high-accuracy step-motion capabilities, and optimized CCD system, the unit offers the utmost precision and accuracy while providing unparalleled speed and efficiency with its high-speed servo drive.

There are no reviews yet