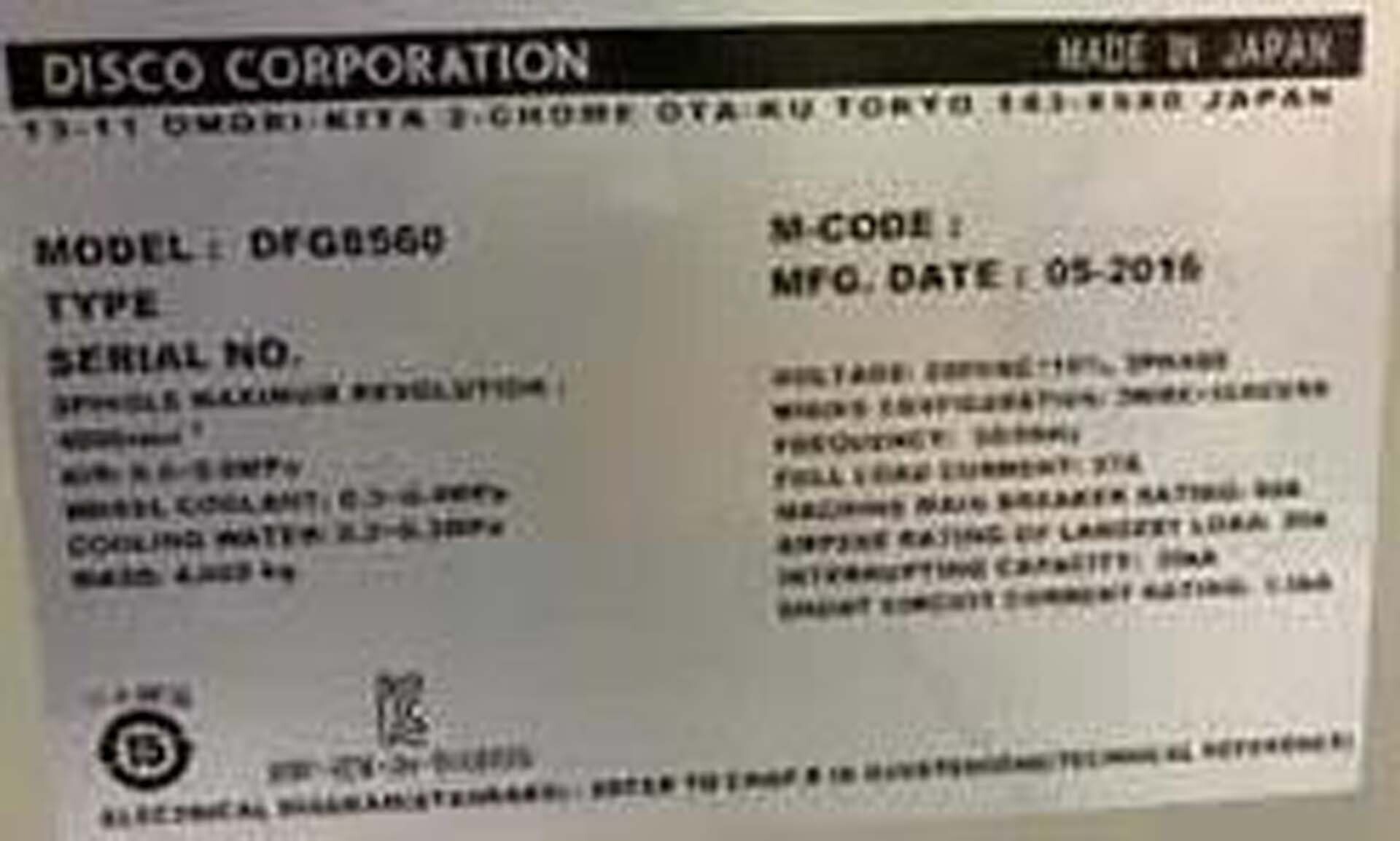

Used DISCO DFG 8560 #9360996 for sale

URL successfully copied!

Tap to zoom

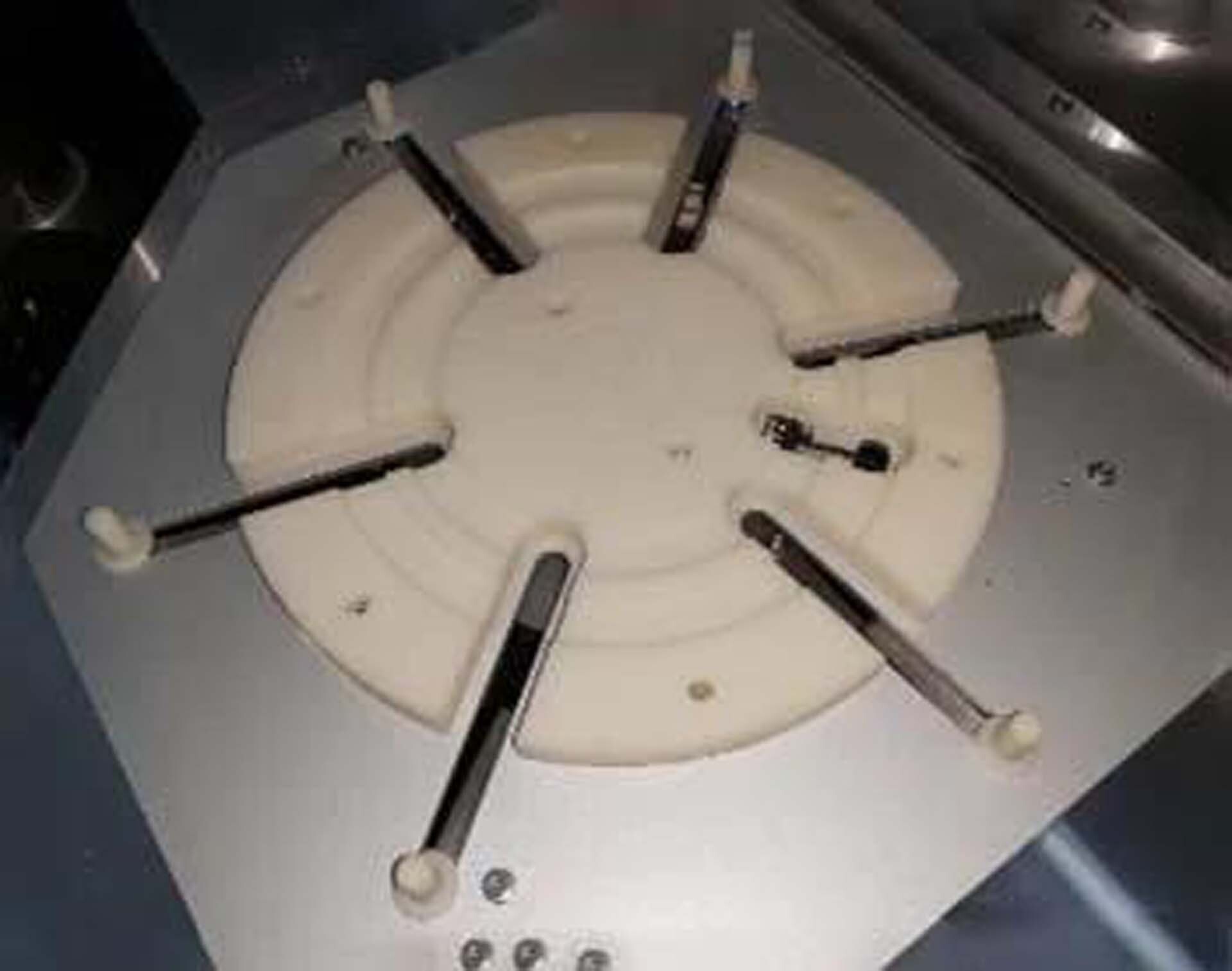

DISCO DFG 8560 is a wafer grinding, lapping and polishing equipment that is designed to enable repeatable, high quality lapping and polishing of wafers in both research and production environments. The machine is capable of processing silicon or gallium arsenide substrates up to 6 inches in diameter. The main features of DISCO DFG8560 include a high-precision spindle drive system, an automated wafer loader, an in-line process control unit, a programmable pressure and rotation speed, and an electronically controlled lapping and polishing force control unit. The spindle drive machine uses a servo motor to provide accurate speed and torque control, while the in-line process control tool enables the user to monitor and record the progress of the lapping and polishing process. The asset is also equipped with a programmable sensor to detect changes in the wafer's surface contour and to adjust the lapping/polishing pressure accordingly. DFG 8560 has been designed to deliver a smooth, consistent finish on wafers. The model is also capable of carrying out a wide range of polishing techniques, such as back-lapping, line polishing, and grinding. The lapping force control unit enables mounted wafers to be loaded and unloaded without having to move them manually. Additionally, the equipment uses a diamond-impregnated diamond grinding belt to ensure that the lapping process is carried out quickly and accurately. DFG8560 is equipped with an operator friendly user interface, allowing for the easy monitoring and adjustment of the lapping/polishing process. The system also has an intuitive data logging software that allows for the collection and analysis of lapping and polishing data. The data logging software can store up to 1000 sets of lapping and polishing conditions, allowing for the easy reproduction and optimization of the lapping and polishing process. DISCO DFG 8560 is the ideal unit for both researchers and manufacturers that need to repeatably lap and polish wafers with precision. The machine is capable of achieving high-quality finishes on substrates with the utmost accuracy and consistency. The user-friendly interface, programmable features, and ability to carry out a range of polishing techniques make the tool an ideal choice for carbon-based wafer manufacturing.

There are no reviews yet